STAGO PR 4 Guide

- 1 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

Operating instr ctions and

spare parts list

Paper jogger PR 4

Machine no.: 11694

Date of iss e: 2011

- 2 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

1. Contents

1. General ..................................................................................... 3

2. Technical data ........................................................................... 4

3. Safety instr ctions ..................................................................... 5

4. Start p .................................................................................... 6

5. Maintenance .............................................................................. 7

6. Interr ption repair ..................................................................... 8

7. Circ it diagram .......................................................................... 9

8. Spare parts list .......................................................................... 10

9. Spare parts drawing .................................................................. 12

- 3 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

1. General

The STAGO paper jogger PR 4 is easy to handle for the operating personnel d e to its

rob stness and its simple operating mode. Its tilisation is very appropriate for operating

personnel changing freq ently.

D e to the application of this machine, the paper piles are jogged smoothly for

s bseq ent treatment after printing and copying. Concerning different employments of

the machine it is mandatory to contact the man fact rer.

With the STAGO - PR 4 sizes p to a maxim m paper size of DIN A4 can be jogged

smoothly.

The jogger is available as table model with height adj stable col mn. The table model

can be refitted with a col mn, of co rse.

The machine corresponds to the reg lations of the professional association. It is tested

according to VDE possessing the q ality seal of the professional association "Tested

Safety".

- 4 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

2. Technical data

Voltage 230 V / 50 Hz

or 115 V / 60 Hz

Nominal c rrent with 230 V 0,39 A

115 V 0,78 A

A f se of connection power o tlet 10 A

Noise press re level 70 dB(A)

Maxim m paper size DIN A4

Capacity content 60mm

Table size 230 x 230 mm

Machine size 330 x 240 x 370 mm

Working height with col mn 700 bis 1000 mm

Weight (table model) approx. 10 kg

Weight with col mn approx. 30 kg

- 5 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

3. Safety instructions

•Before connecting the mains pl g it has to be verified, whether the voltage indicated

on the name plate corresponds to the s pply voltage.

•When exec ting maintenance or repair, the mains switch has to be p lled!

•The connection cable of the machine is to be laid in s ch a way that no st mble

position arises.

•The col mn machine has to be to ched on the col mn for transport. The table

machine can either be to ched on the pper part or on the lower part.

•The foot switch and the appropriate cable are to be laid in s ch a way that no st mble

position arises and/or limited to the mini m req ired.

•Attention has to be paid to the height adj stment, if the machines are s pplied with a

col mn. In this case the machine has to be held in s ch a way that it can not fall

downwards when loosening the height adj stment screw! The safety screw has to be

adj sted according to req irement.

•The machine is only allowed to be used for the purpose described in this

instruction.

Adj stment

of jogging

strength

- 6 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

4. Start up

4.1 Place machine on a solid ndergro nd.

4.2 Insert prod ct to jog. Connect machine and switch on principal switch.

4.3 Adj st the vibration intensity by means of star handle. Weak vibrations are

s fficient for easy paper types or few sheets. Strong vibration are to be selected

for heavy papers and large q antities.

- 7 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

5. Maintenance

The STAGO – paper joggers PR 4 are eq ipped with maintenance-free bearings and

therefore, no maintenance is req ired.

- 8 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

. Interruption repair

Interruption Cause and removal

Machine does not jog •Machine not switched on

•Mains pl g not connected

•

F se in feed line defect

Paper is damaged •Red ce jogging strength

Jogging time too long •Increase jogging strength or position table into a

steeper position

- 9 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

7. Circuit diagram

1N4007

MKT 0.01

-

1000

10 M 250 VB

WS

6/30

Mains switch

2

4

1

3

S1

U

Y1

- 10 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

8. Spare parts list

Pos.

Description Pcs.

Part no. Remarks

1 Table plate 1 390 121 300

2 Limit stop 2 390 122 400

5 Fastening plate complete 1 385 0301 301

6 Spring bearing 2 385 114 400

7 Press re spring 2 385 120 900

8 R bber disc 5 385 147 400

9 R bber b ffer 4 385 125 900

10 Damping r bber 1 385 110 400

11 Adj stment screw 1 385 133 400

12 Magnet 1 385 113 900 230 V

1 385 150 900 115 V

13 Additional piece for magnet 1 385 130 900

15 Jogger box complete 1 385 0201 300

16 Screwed down bar 1 385 112 400

17 Fastening disc 1 385 111 400

18 Disc 6 364 170 400

20 Ho sing cap 1 385 108 400

21 Star handle 1 300 062 900

23 Slinding limit stop complete 1 390 0303 900

31 Machine foot 1 385 0101 400

32 Limit stop b ffer 4 385 123 901 Table model

33 GM – b ffer 4 385 148 900 Col mn model

35 Electric ho sing 1 385 0503 900

36 Rocker switch On / Off 1 300 076 900

37 Screwed cable gland 1 300 092 900

38 Plastic hexagonal bolt n t 1 Pg 9

39 Screwed cable gland 1 385 149 900 Pg 7

40 S pply line cable with pl g 1 300 071 900

50 Col mn complete 1 385 0602 400

52 Rectang lar t be 1 378 0602 400

54 Star handle 1 378 0604 900

55 Base col mn complete 1 378 0601 300

56 B ffer conical 4 300 046 900

- 11 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

8. Spare parts list

Pos.

Description Pcs.

Part no. Remarks

100 Kn rled screw 1 M6x12

101 Cylinder screw with slot 1 DIN 84-AM4x10 Zinc coated

102 Cylinder screw with slot 2 DIN 84-AM4x16 Zinc coated

104 Disc 4 DIN 125-B6,4

105 Disc 9 DIN 125-B8,4

106 Disc 2 DIN 125-A4,3

111 Cyl.head screw Hexagon socket 1 DIN 912-M5x10

112 Cyl.head screw Hexagon socket 2 DIN 912-M5x16

113 Cyl.head screw Hexagon socket 6 DIN 912-M6x16

115 Cyl.head screw Hexagon socket 3 DIN 912-M8x20

117 Set screw internal hexagonal bolt 4 DIN 913-M8x25

121 Hexagonal bolt n t 9 DIN 934-M8 Zinc coated

122 Co ntersink screw 4 DIN 963-AM8x12 Zinc coated

123 Rec.co nters nk flat head screw 4 DIN 965-AM5x50 Zinc coated

125 Serrated washer 5 DIN 6798-A4,3

126 Cyl.head screw Hexagon socket 4 DIN 7984-M5x25

127 Cyl.head screw Hexagon socket 4 DIN 7984-M8x12

128 Cyl.head screw Hexagon socket 4 DIN 7984-M8x16

129 Lense head screw 4 M6x10

130 Schnorr retaining washer 6 S5

131 Schnorr retaining washer 10 S6

132 Schnorr retaining washer 8 S8

Schnorr retaining washer 16 S8

- 12 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

10. Spare parts drawing

- 13 -

STAGO GmbH ▪ Max-Eyth-Straße 21 ▪ D-73095 Albersha sen ▪ Tel: +49/7161/37380 ▪ Fax: +49/7161/34278 ▪

info@stagogmbh.de ▪ www.stagogmbh.de

EC-Declaration of Conformity

We hereby certify that the following described machine in its conception, constr ction and form p t

by s into circ lation is in accordance with all the relevant essential health and safety req irements

of the EC machinery directive 2006/42/EEC as amended and the

national laws and reg lations adopting this directive.

This declaration is no longer valid if the machine is modified witho t o t o r consent

STAGO GmbH

Maschinenba - Papierverarbeit ngsmaschinen

Bahnhofstraße 44

D-72639 Ne ffen

•Prod ct STAGO – Paper Jogger

•Type PR 4

•Serial n mber 121781

•Year of constr ction 2012

The agreement with f rther valid g idelines/reg lations following for the prod ct is

explained:

•Co ncil Directive 2004/108/EC (December 15, 2004) on Electromagnetic Compatibility

•Low Voltage Directive (LVD) 2006/95/EC)

Applied one harmonized standards in partic lar:

•DIN EN ISO 12100 Safety of machinery - General principles for design - Risk assessment

and risk red ction

•DIN EN 60204-1 Safety of machinery - Electrical eq ipment of machine

•DIN EN ISO 13849 Safety of machinery - Safety-related parts of control systems

•EN 1010-1 Safety of machinery — Safety req irements for the design and constr ction of

printing and paper converting machines — Part 1: Common req irements

A thorized person for the technical doc mentation:

Gerd Gemander, STAGO GmbH, Maschinenba – Papierverarbeit ngsmaschinen, Bahnhofstraße 44,

D-72639 Ne ffen

Stago GmbH

Albersha sen, 2013-01-14

.………………………………………. …………………………………………….

Patrick G gel, Managing Director Gerd Gemander, Prod ction Manager

Table of contents

Popular Industrial Equipment manuals by other brands

Plockmatic

Plockmatic SF 4000 Installation instruction

Vestil

Vestil VST-4-Y Use and maintenance instructions

Schulze

Schulze Big-O-Lite pneu plus instruction manual

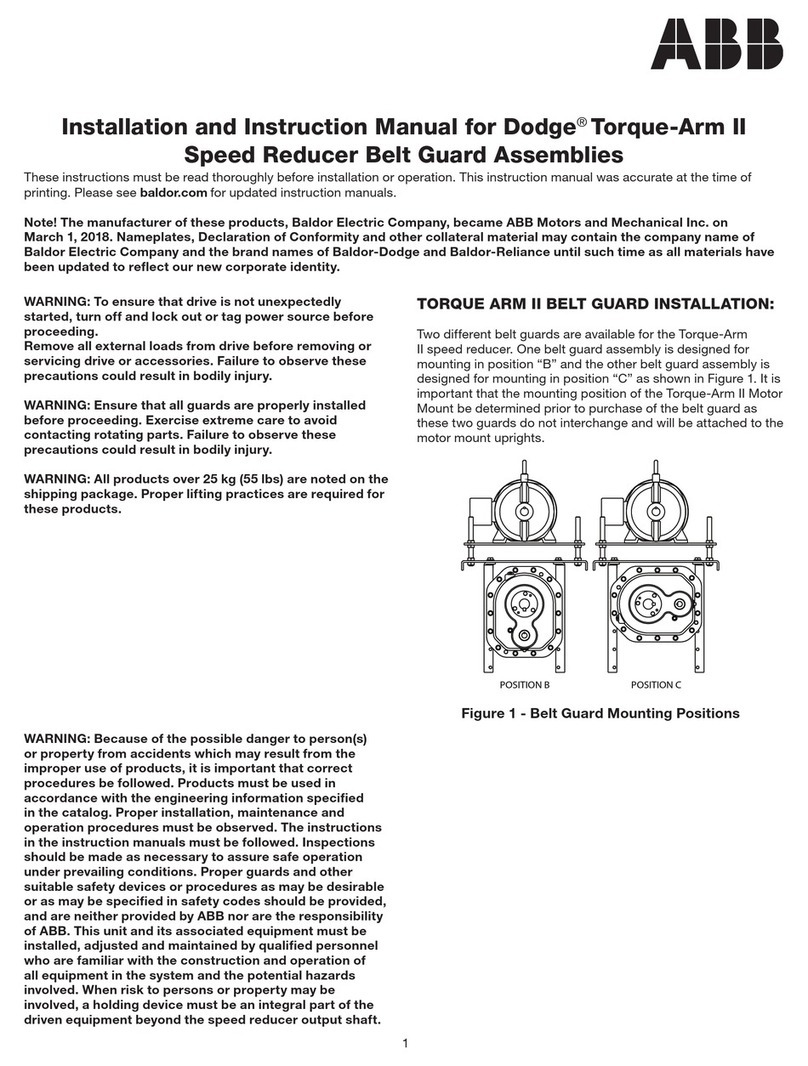

ABB

ABB Power2 340-H44 Operation manual

Rittal

Rittal 3363 Series Assembly and operating instructions

Arrowquip

Arrowquip Q-POWER 106 SERIES product manual

Dikai

Dikai DK-D03S Operation manual

Titan

Titan VS-32-L Operating and maintenance instructions

Forza

Forza 1310THA user manual

ABB

ABB Dodge Torque-Arm II Installation and instruction manual

Siemens

Siemens Simatic S7-1500/ET 200MP Compact operating instructions

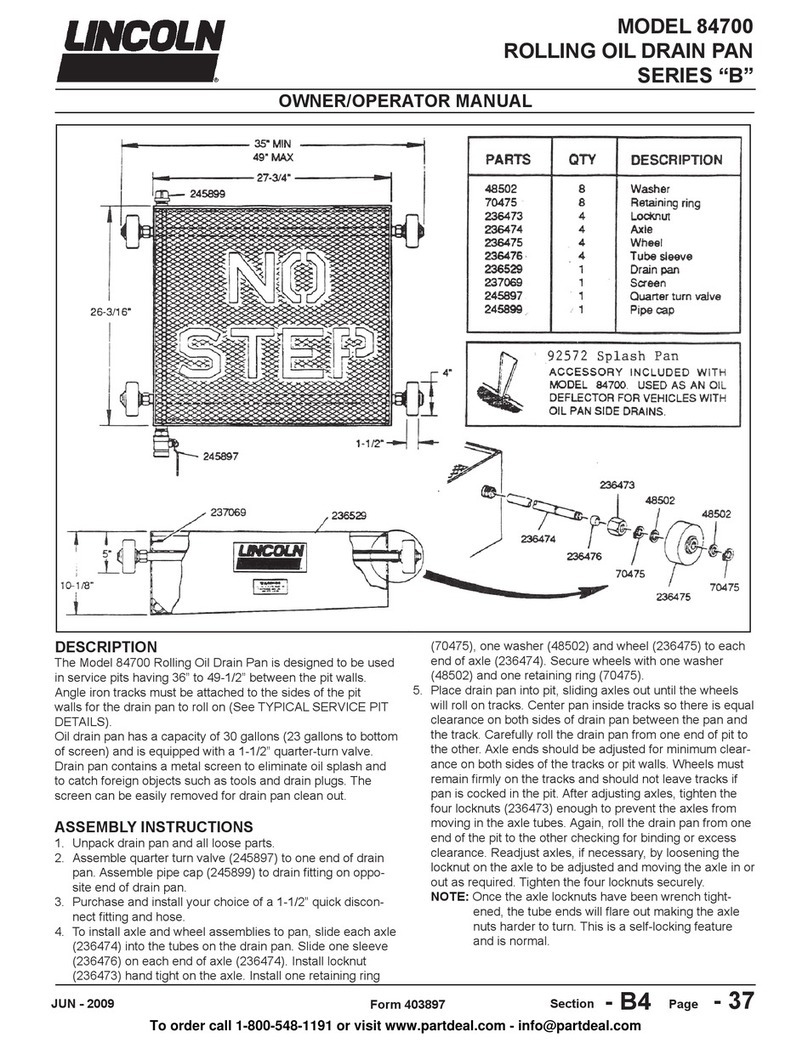

Lincoln

Lincoln 84700 Owner's/operator's manual