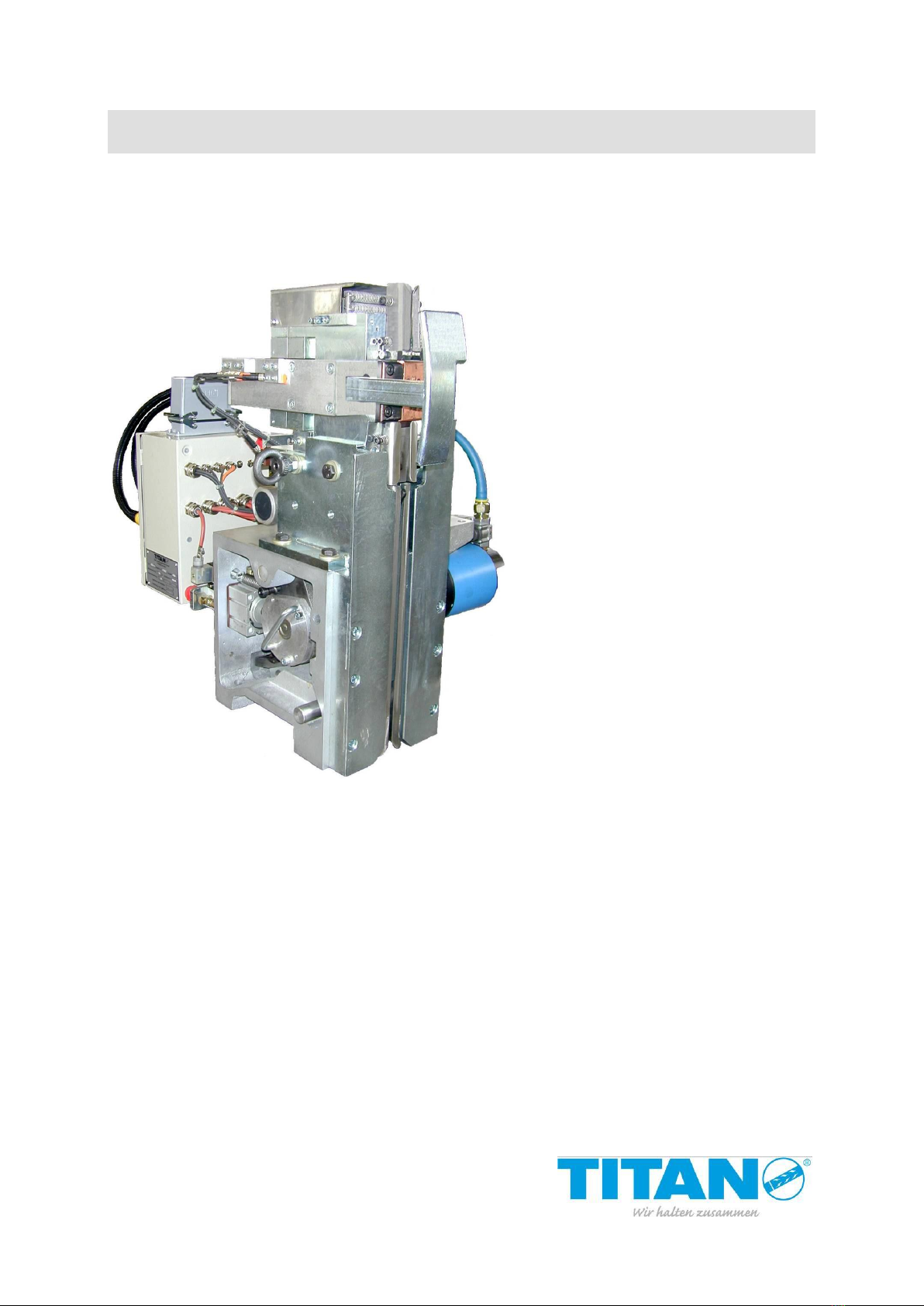

VS-32-L 2

Table of contents

Page

1. Manufacturer details....................................................................................................................3

2. General..........................................................................................................................................4

3. Safety regulation ..........................................................................................................................7

4. Life phases of the unit .................................................................................................................9

5. Technical data ........................................................................................................................... 11

5.1. Technical data of the welding unit..................................................................................... 12

5.2. Finding the time required for a strapping operation.......................................................... 13

5.3. Smallest support with different packing items................................................................... 14

5.4. Measurements and assembly dimensions VS-32-L ......................................................... 15

5.5. Pneumatic plan equipment (head control system)............................................................ 16

5.6. Functional time diagram.................................................................................................... 17

5.7. Arrangement and designations......................................................................................... 18

6. Designations.............................................................................................................................. 19

6.1. Switches and motors......................................................................................................... 19

6.2. Switches............................................................................................................................ 21

6.3. Positions of the switches, valves, pressure controllers and motors ................................. 22

7. Functional description.............................................................................................................. 23

7.1. Process description........................................................................................................... 23

7.1.1. Insertion of strap..................................................................................................... 23

7.1.2. Feed of strap, medium speed................................................................................. 23

7.1.3. Strap feed, precise movement................................................................................ 24

7.1.4. Closing strap gripper 1............................................................................................ 24

7.1.5. Transport back of strap........................................................................................... 24

7.1.6. Tensioning the strap ............................................................................................... 24

7.1.7. Closing strap gripper 2............................................................................................ 25

7.1.8. Welding................................................................................................................... 25

7.1.9. Swivelling the welding station open........................................................................ 25

7.1.10.Swivelling the welding station back ........................................................................ 25

7.2. Positions on the cam gear ................................................................................................ 26

7.3. Description of the welding operation................................................................................. 27

8. Adjustments............................................................................................................................... 28

8.1. Setting switches B1 to B8 ................................................................................................. 28

8.2. Setting the zero position ................................................................................................... 30

8.3. Setting the clamping and opening positions ..................................................................... 30

8.4. Setting the air pressure..................................................................................................... 31

8.5. Setting the quantity of gas ................................................................................................ 33

8.6. Setting the distance between electrodes.......................................................................... 34

8.7. Setting the torch................................................................................................................ 35

8.8. Setting the welding parameters ........................................................................................ 36

9. Maintenance............................................................................................................................... 37

9.1. General ............................................................................................................................. 37

9.2. Maintenance intervals....................................................................................................... 38

9.3. Check seal ........................................................................................................................ 38

9.4. Lubricating points.............................................................................................................. 39

9.5. Maintenance of the transport unit ..................................................................................... 40

9.6. Maintenance of the clamp guide....................................................................................... 42

9.7. Maintenance of the cutter ................................................................................................. 44

9.8. Dismounting the torch, replacement of electrode ............................................................. 45

9.9. Dismounting and mounting the clamp............................................................................... 46

9.10. Dismounting and mounting the torch holder..................................................................... 47

10. Fault detection - remedy........................................................................................................... 48

11. Declaration of incorporation.................................................................................................... 50