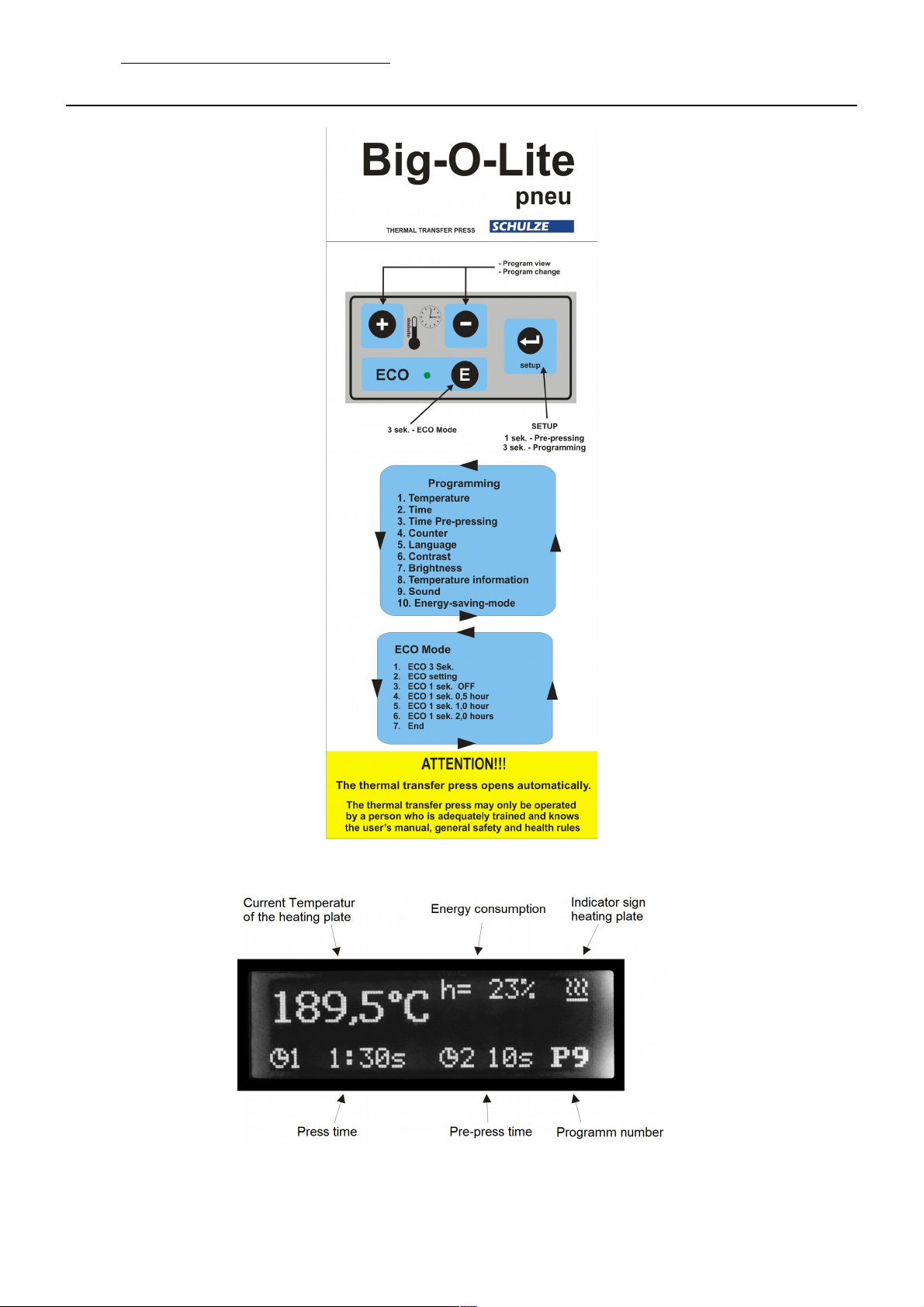

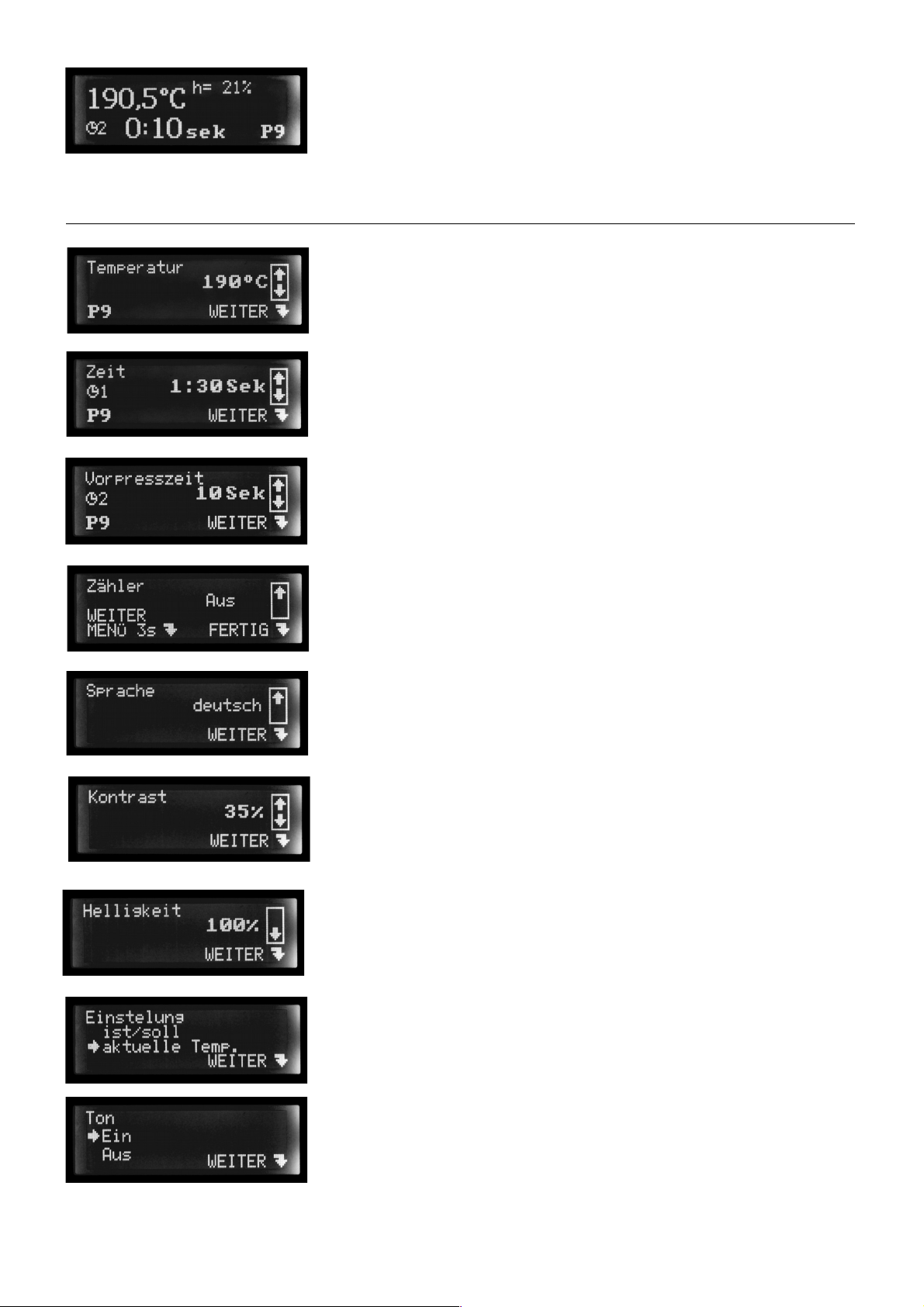

3.4 „ECO“ mode

With the ECO mode you will save power. If the ECO mode 1, 2 or 3 is active, the electronic devices will control the progress of work of

the press. If you should have forgotten to turn-off the press, never mind, the ECO mode will deactivate it. In phase 1 of the ECO mode,

while the press is momentarily not in use, the temperature will decrease 50°C (a 3 second long acoustic signal will sound). In phase 2, if

the press is furthermore not in use, the heating elements will e deactivated to save power (5 sec. acoustic signal).

3.5 Prepressing

Prepressing will activated with Button Setup. With an adjusted prepress time, e.g. 2 s, the press will close for 2 seconds. After that the

adjusted pressing time will automatically e activated.

3.6 Application range and sample adjustments of t e eat press

This press is used to put transfers and transfer films on textiles. To get good achievements, get in contact with the producer of the textiles.

Here are some settings:

Film Flex 150°C – 160°C Time 15 Seconds

Film Flex S 155°C – 160°C Time 15 Seconds

Film A-Flex 155°C – 160°C Time 15 Seconds

Film Flock 160°C – 180°C Time 15 Seconds

Su limation Film 190°C – 205°C Time 50 Seconds

All information is supplied without lia ility, please run your own testing efore production.

3.7 Pressure settings

With this press you can change the pressure setting.

After every change of the pressure settings, close the heat press to check the new settings.

Damages, w ic arise from to muc pressure, are excluded from t e guarantee.

To adjust the pressure do the following:

1. Take the pressure reading. (p oto 1).

2. To alter the pressure pull the kno to you. (p oto 2).

•Rotating the kno to the right will increase the pressure (p oto 2).

•Rotating the kno to the left will decrease the pressure (p oto 2).

3. To retain the setting push the kno to the press again.

4. Test t e pressure (p oto 3).

The pressure reading you may take at the top on the right.

1,0 ar - ca. 415 kg

2,0 ar - ca. 830 kg

3.0 ar - ca. 1245 kg

4.0 ar - ca. 1660 kg

5,0 ar - ca. 2075 kg

6.0 ar - ca. 2490 kg

It is recommended to keep the pressure accordingly

Plate 8 x 16 cm ~ 0,3 ar (max. 0,6 ar)

Plate 20 x 20 cm ~ 0,3 ar (max. 0,6 ar)

Plate 38 x 45 cm ~ 2 ar (max. 4,0 ar)

Plate 40 x 50 cm ~ 2,5 ar (max. 4,5 ar)

If you alter the pressure to a setting higher than 6 ar, a safety valve will e activated. In this case you have to reduce the pressure.

Version 16.01 10 / 18