Dikai DK-D03S User manual

DK-D03S V2.3版本

OPERATIONAL MANUAL

- 2- D03S THERMAL TRANSFER OVERPRINTER

NOTICE

Thank you for choosing DIKAI to provide printing solutions.

DIKAI is a top manufacturer of coding machines & coding consumables in China, established in 1995,

products include:

Thermal Transfer Overprinter

Ink Roll Coder

Hot Stamp Coder

Case & Carton Coder

Thermal Transfer Ribbon

Hot Ink Roll

Hot Stamping Foil

Brass/Steel/Rubber Types

If you have questions or comments, or any information wanted, please visit our website at

www.dikaiproducts.net

Before using this printer, please read and fully comply with these instructions.

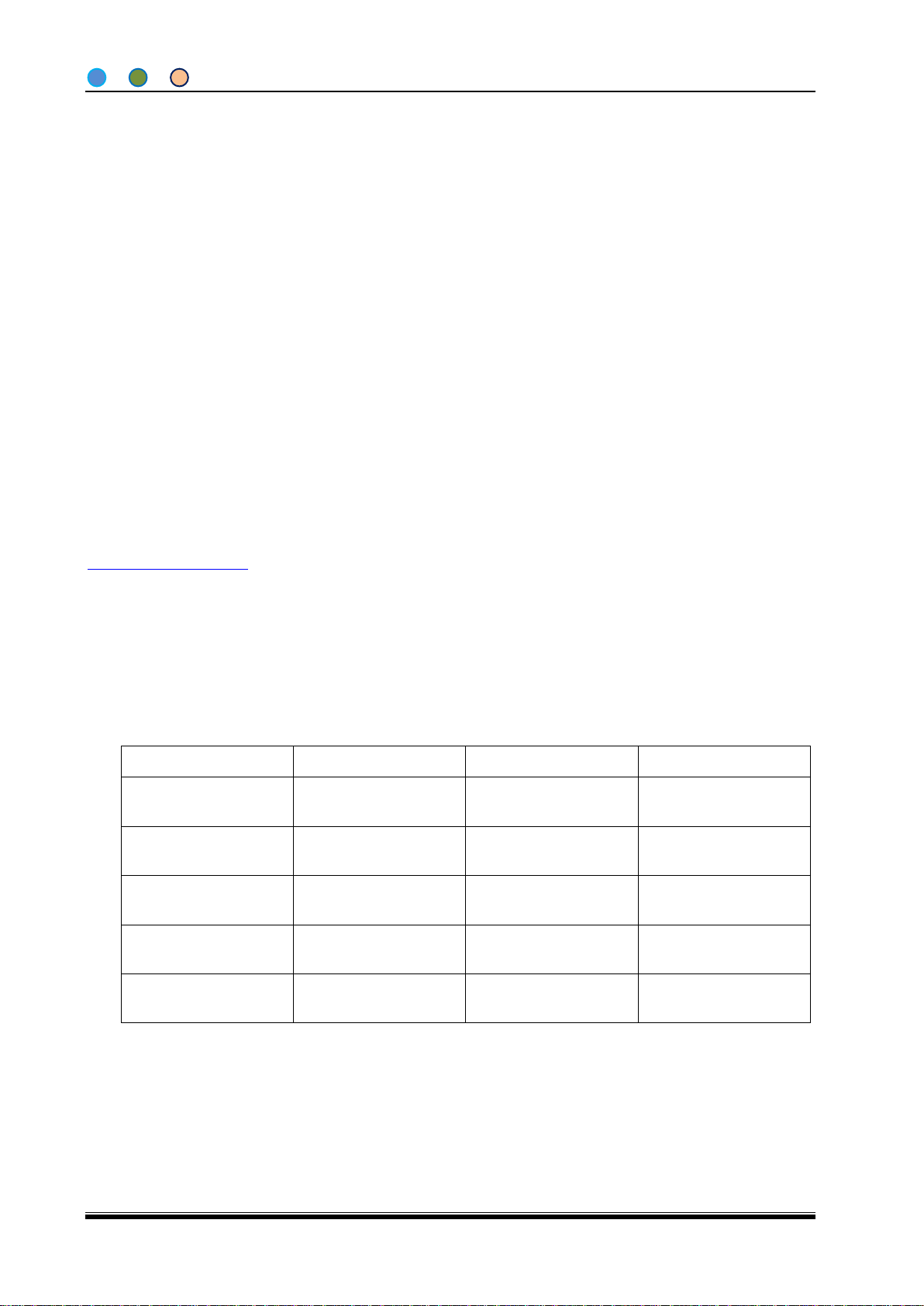

Version Clarification

Part NO. Y03S05014EN

Update Date

Manual Version

Revision Department

Description

2017/08/08

V1.1

Technology

Department

Stop

2017/12/29

V2.0

Technology

Department

Stop

2018/06/29

V2.1

Technology

Department

Stop

2019/3/26

V2.2

Technology

Department

Stop

2019/9/20

V2.3

Technology

Department

Officially Published

Version

OPERATIONAL MANUAL

D03S THERMAL TRANSFER OVERPRINTER - 3 -

CONTENTS

1. GENERAL & SAFETY INFORMATION .................................................................................................- 4 -

1.1 GENERAL ...........................................................................................................................................- 4 -

1.2 INTRODUCTION.................................................................................................................................- 4 -

1.3 LABEL ................................................................................................................................................- 5 -

1.4 PARAMETER ......................................................................................................................................- 7 -

2. SAFETY ..............................................................................................................................................- 8 -

2.1 OPERATION GUIDELINES ...................................................................................................................- 8 -

2.2 APPLICATION AND ABUSING.............................................................................................................- 9 -

3. INSTALLATION.................................................................................................................................- 10 -

3.1 COMPONENTS.................................................................................................................................- 10 -

3.2 INSTALLATION REQUIREMENTS ......................................................................................................- 11 -

3.3 STANDARD BRACKETS .....................................................................................................................- 11 -

3.4 INSTALLATION OF THE MOUNTING BRACKET .................................................................................- 13 -

3.5 INSTALLING THE CONTROLLER........................................................................................................- 15 -

3.6 CONTROLLER CONNECTION POINTS...............................................................................................- 15 -

3.7 PRINTER CONNECTORS ...................................................................................................................- 17 -

3.8 PRINT SIGNAL..................................................................................................................................- 20 -

3.9 I/O CABLE CONNECTION .................................................................................................................- 20 -

3.10 INSTALLATION DIMENSION .........................................................................................................- 23 -

4. OPERATION.....................................................................................................................................- 26 -

4.1 START THE PRINTER ........................................................................................................................- 26 -

4.2 HOME PAGE ....................................................................................................................................- 27 -

4.3 SCREEN ICONS.................................................................................................................................- 29 -

4.4 START/ STOP THE PRINTER..............................................................................................................- 41 -

4.5 FILE MANAGEMENT ........................................................................................................................- 42 -

4.6 PARAMETER SETTING......................................................................................................................- 46 -

4.7 UPGRADING THE CONTROLLER BOX ...............................................................................................- 63 -

4.8 REMOVING THE CASSETTE..............................................................................................................- 65 -

4.9 LOADING OR REPLACING THE RIBBON ...........................................................................................- 65 -

4.10 TEST THE CURRENT PRINT JOB....................................................................................................- 69 -

5. MAINTENANCE................................................................................................................................- 70 -

5.1 CLEANING AND CARE.......................................................................................................................- 70 -

5.2 MAINTENANCE SCHEME.................................................................................................................- 71 -

5.3 REPLACING THE PRINTHEAD............................................................................................................- 74 -

5.4 REPLACING THE REEL ROLLER..........................................................................................................- 75 -

6. TROUBLE SHOOTING .......................................................................................................................- 76 -

7. SCHEMATICS AND PARTS ILLUSTRATIONS ......................................................................................- 78 -

7.1 CONTROLLER BOX ............................................................................................................................- 78 -

7.2 CASSETTE ASSEMBLY........................................................................................................................- 79 -

7.3 PRINTER UNIT .................................................................................................................................- 82 -

7.4 OTHER SPARES .................................................................................................................................- 87 -

7.5 RECOMMENDED SPARES .................................................................................................................- 88 -

8. CONSUMABLES INTRODUCTION.....................................................................................................- 89 -

OPERATIONAL MANUAL

- 4- D03S THERMAL TRANSFER OVERPRINTER

1. GENERAL & SAFETY INFORMATION

1.1 GENERAL

This Manual aims to explain how to safely install, operate and maintain D03S Thermal Transfer

Overprinter.

1. Reproduction of any or part of this manual in any form whatsoever without the expressed written

permission of DIKAI is forbidden. The contents of this manual are subject to revision without notice.

2. The use of non genuine DIKAI consumables and spare parts may adversely affect the performance of the

product and could invalidate the warranty.

3. All efforts have been made to ensure the accuracy of the contents of this manual. However, should any

errors be detected, DIKAI would greatly appreciate being notified.

4. DIKAI make no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties and fitness for purpose. DIKAI shall not be liable for any errors contained in this material or for

incidental or consequential damages in connection with the furnishing, performance, or use of this material.

5. Thank you for choosing DIKAI to provide printing solutions. If questions arise, please contact the local

business center or distributor to assist with your purchase.

1.2 INTRODUCTION

D03S is our new version smart coding machine developed on the basis of D03 which also adopts advanced

thermal transfer technology, providing more flexible printing solutions for package and marking industries. As

the latest contact printing technology, we keep on improving our products by continuous research & develop

and technical innovation. Meanwhile, DK aims at extending TTO technology in every possible field.

We successfully applied for patents for D03S’s unique creative structure and operating principle: compact

size, easy operating & daily maintenance, fast printing speed, etc. Adopting 300 dpi print head brings more

artistic print results.

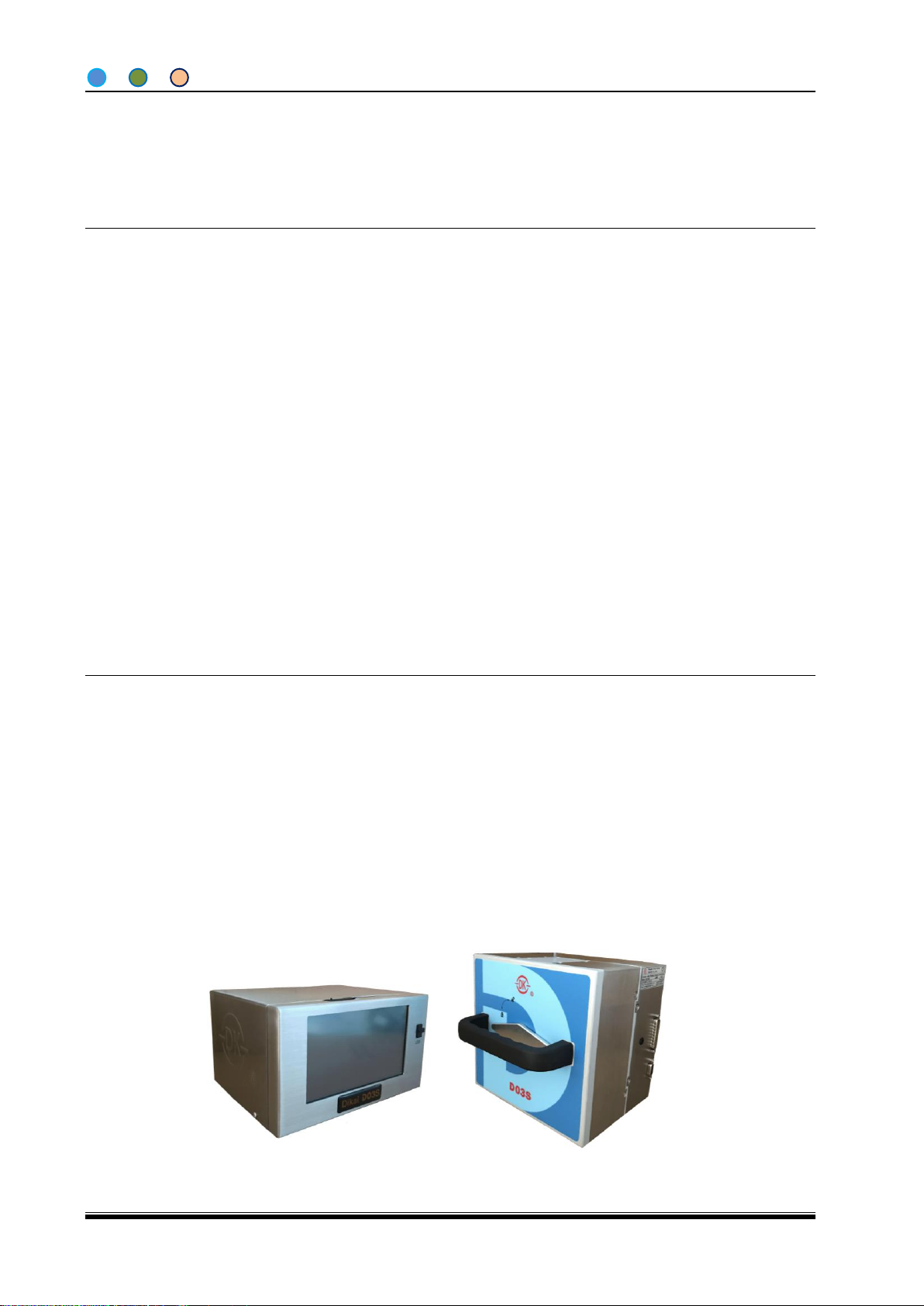

Diagraph 1. Machine Overview

OPERATIONAL MANUAL

D03S THERMAL TRANSFER OVERPRINTER - 5 -

D03S is available in two printer types, flexible for on-site installation:

D03S Model:

D03S Right Hand(D03S RH)

D03S Left Hand(D03S LH)

D03S can print lot number, date and time, variable data, etc directly onto kinds of packing film, variable data

can be modified on controller.

1.3 LABEL

1. High Voltage

This label is located on the back panel of Controller Box.

This label warns the operator that the printer should be well ground connected.

If it’s hiden after installation, please stick another WARNING label in conspicuous place.

Electrical problems should be solved by well-trained engineer.

2. GROUND CONNECTION

This label warns that machine should be ground connected.

Table of contents