1.1 General information EN

For safety reasons it is important to read all of the

enclosed information (Installation guide, service

manual, spare parts, operating instructions) before

mounting this equipment. In addition, the legislation in

force at the time of purchase must always be consid-

ered in connection with installation and mounting of

this equipment, no matter the contents of this manual.

If there are matters of dispute please contact your

dealer.

This equipment is produced and tested by specially

qualied personnel according to approved instructions

to ensure our high level of product quality. After the

product is nished and tested it is manually inspected

with the ultimate test carried out just before the prod-

uct is released for shipping. To obtain our high level

of quality and long life we use stainless steel parts.

These parts, in deance of our manual inspections

may still have some sharp edges, which can present

a cut hazard. Therefore, it is advised always to use

protective gloves and show caution when installing the

equipment.

1.2 Preparation

Note: The pipeline must be rinsed through before

the system is connected. See service manual

1.3 Placing/application

• Do not use the machine outdoors.

• The Booster must be placed in frost-free rooms

only.

• Free space around the Booster: min 1000 mm.

1.4 Water supply

BFE3

Water amount 100 l/min.

Pressure 0,2 - 0,8 MPa (2 - 8 bar)

Max. temperature 70oC

The supply line must be sized so that it can supply the

minimum indicated pressure and water volume when

connected to this equipment. When dimensioning the

water supply. It is recommended to increase the avail-

able volume with 15-20% compared to the minimum

requirements listed in the table.

Note: Recommended water hardness 14-18 dH°.

The equipment will operate with water hardness ex-

ciding this level however, descaling of pump system,

injectors and like must be expected depending on use

pattern and water quality.

1.5 Electric connection

Connection guide is mounted on the cable:

Always check direction of rotation.

Service switch:

A separate service switch must always be mounted

before the unit.

Note! Installation always according to the country’s

legislation.

BFE3

Voltage: 380 - 415V

Frequency: 50 Hz

Motor effect: 5,5 kW

Nom. Voltage: 12,2 A

Fuse: 16 A

L1, L2, L3, PE 1,5 mm²

1.6 Piping

The pipe system should be made of stainless steel

pipes. The pipe joints should be made in a way that

makes separation possible in case of eg. repairs,

moving or similar.

All threads according to ISO 228

The dimensions stated are all indicative.

Always carry out calculations of the piping installation

based on pressure charts for piping and ttings

Pipe connections BFE3

Recommended pipe dimen-

sions 5/4"

Pipe dimensions unit 5/4"

Note: 5/4” – 2” closing valve should be mounted on

the water supply immediately before the Booster and

dirt lter if any.

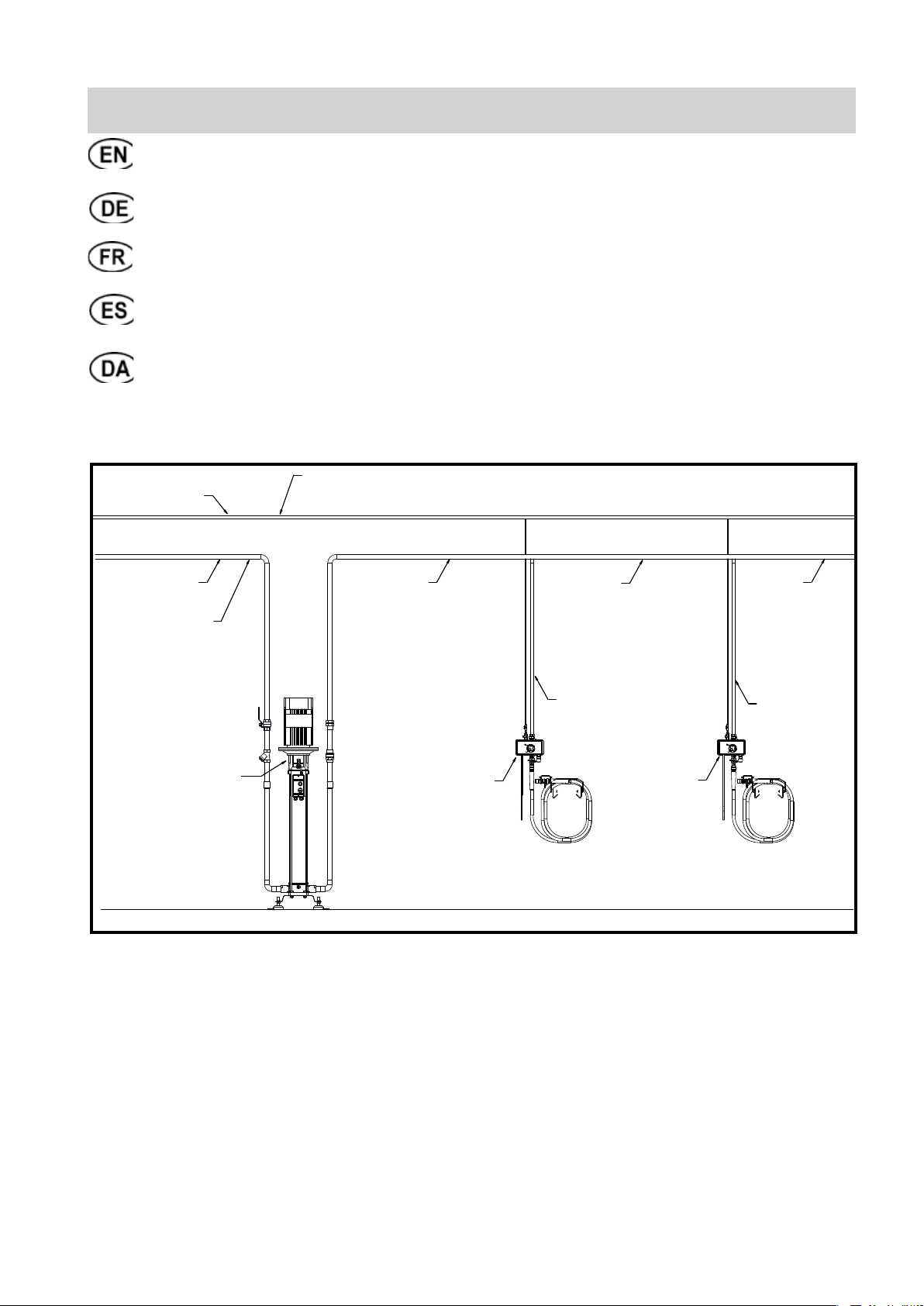

1.7 Assembly

Dimensions see g.1.

Mount the Booster to the oor with the enclosed con-

crete anchors.

3