STALEX C0632D User manual

EC- DECLARATION OF CONFORMITY

We, DKSH Hong Kong Limited, 23/F Tower A, Southmark, 11 Yip Hing Street, Wong Chuk Hang,

Hong Kong,

declare under our sole responsibility, that the machinery

Factory Product name: C0632Dx750

Function: Metal working and finishing machine

Model: ST – 1330T

Type: Metal Working Lathe

Article number: 77.930.93034.12

Year of production: 2011

is in conformity with all the relevant provisions of Directives:

2006/42/ EC (Machinery directive),

2006/95/ EC (Low voltage directive),

2004/108/ EC (EMC),

2002/95/ EC (RoHS directive),

2002/96/ EC (WEEE directive)

and tested in accordance with below standards:

EN 349:2008-9

EN 11202:2010

EN 12100-1:2004

EN 12100-2:2004

EN 12840:2001

EN 13850:2008

EN 13857:2008

EN 23125:2010

EN 55014-1:2006

EN 55014-2:1997+A1

EN 61000-3-2:2006

EN 61000-3-3:1995+A1+A2

EN 60204-1/A1:2009

Hong Kong, 31.03.2011 Managing Director

Authorized to compile the technical file

DKSH Hong Kong Limited

23/F Tower A, Southmark, 11 Yip Hing Street,

Wong Chuk Hang, Hong Kong

www.dksh.com

OPERATION MANUAL

& PARTS LIST

MODEL: C0632D/C0636D

Operation Manual

1

CONTENTS

Preface………………………………………………………………………………………2

1.Safty Rules for Lathes……………………………………………………………………3

2.Mchine Specification….…… ………………………………………..……………………6

3.Constructional Indication………………………………………………………………7

4.Unpacking and Installation………………………………………………………………8

4.1 Unpacking………………………………………………………………..……………8

4.2 Cleaning…………………………………………………………………..……………8

4.3 Installation………………………………………………………………..……………8

5.Lubrication………………………………………………………………………………10

5.1 Headstock……………………………………………………………………………10

5.2 Gearbox………………………………………………………………………………10

5.3 Apron…………………………………………………………………………………10

5.4 Change gears………………………………………………………………………10

5.5 Others parts…………………………….…………………………………………10

6.Test Running…………………………………………………………………………11

6.1 Operation symbols………………………………………………………..…………11

6.2 Spindle speed control……………………………………………………..…………12

7.Thread and Feed Selection……………………………………………………………13

7.1 Thread and feed selection…………………………………………………………13

7.2 Feed and thread tables……………………………………………………………14

7.3 Thread cutting operation……………………………………………………………17

8.Electric Circuit Control………………………………………………………………19

9.Chucks and Chuck Mounting…………………………………………………………21

10.Maintenance and Servicing…………………………………………………………22

10.1 Lathe alignment……………………………………………………………………22

10.2 Saddle strip…………………………………………………………………………22

10.3 Cross slide…………………………………………………………………………22

10.4 Compound rest……………………………………………………………………23

10.5 Cross slide nut……………………………………………………………………23

10.6 Tail stock bed clamp………………………………………………………………23

11.Bed Assembly………………………………………………………………………24

12.Headstock Assembly………………………………………………………………29

13.Gearbox Control……………………………………………………………………36

14.Change Gear…………………………….………………………………………41

15.Apron…………………………………………………………………………………43

16.Cross Slide & Compound……………………………………………………………46

17.Tailstock Assembly……………………………………………………………………50

18.Steady & Follow Rest…………………………………………………………………53

19.Coolant System…………………………………………………………………………55

Operation Manual

2

Preface

For an efficient and appropriate way of utilization, also for extending the

machine’s life, all the operators are requested to carefully read the instruction of this

Manual before start to operate.

Most of the operators think, according to their own experience, they can handle

the machine appropriately and hopeful to neglect what so important items in this

booklet. Anyhow, we may say, as per previous experiencing, that many of the

breakdowns are resulted from ignoring the instructions of the Manual. Although you

have our one-year’s warranty for the damage caused by the defect of the machine,

either in material or functional, we will not take any responsibility for any damages

arise out of improper operation.

In the mean time, besides specification, operator should also thoroughly and

deeply acknowledge the character, function and maintenance of this machine before

starting.

Generally, in addition to the description stated in coming chapter, you are

requested to notice the following points:

1. Never install the machine in the place where the sun shines directly or where

the radiation of heat can reach for avoiding from affecting the accuracy of the

machine.

2. Use only the recommended lubrication oil.

3. Clean the machine every time when finish working, or a cover will be a plus to

prevent the dust.

4. Try to get rid of chips or dusts especially in the grooves of the machine. Keep it

as clean as possible or it may be scratched.

5. Whenever the grooves of the machine damaged by falling in extra articles,

don’t ever try to move Apron. It needs to be repaired to resume its work.

Hope this Operation Manual can be of great assistance and provide you more

convenience when operating. The content of this Manual is the best solution derived

from our long terms of manufacturing and operating experience. We wish to service

you always with a policy of upgrading quality and a conviction in pursuit of perfection.

Operation Manual

3

1. Safety Rules for Lathes

Safety is a combination of operator common sense and alertness at all times

when lathe is being used. Study these safety rules and general safety rules before

operating and retain for future use.

(1) Do not grip a component with grease or oil on it.

Grip all components firmly.

Do not attempt to hold components that are too awkward or too difficult to hold.

Do not hold components that are too heavy for the machine.

Know how to hold components properly when lifting.

(2) Be sure to clean oil or grease from hand tools, levers and handles.

Be sure there is enough texture on the surface of the hand tool or lever handle

for proper safe hand contact.

(3) Grip hand tools and lever handles firmly.

Always choose the proper hand tool and appropriate grip position on the lever

handle.

Do not use hand tools or lever handles in an awkward position.

Do not apply excessive force.

(4) Always use the recommended gripping position to grasp hand tools and lever

handles.

(5) Do not allow turning or hand tools to be caught in the chuck or other holding

device.

(6) Do not use broken, chipped or defective tools.

(7) Be sure work piece cannot move in chuck or other holding device.

(8) Beware of irregular shaped work pieces.

(9) Beware of large burrs on work pieces.

(10) Always select the correct tool for the job.

(11) Do not run the machine unattended.

(12) Do not use tools without handles.

(13) Always support the work piece as necessary using chucks, steadies and

centers.

(14) Correctly locate tool in socket heads and screw slots.

(15) Beware of obstructions that prevent complete tightening of screws-ensure

screw is tight.

Operation Manual

4

(16) Do not rush work.

(17) Never substitute the wrong size tools if the correct sized tool is not available

or cannot be located in the shop.

(18) Do not move guards while lathe is under power.

(19) Do not place hand or body in path of moving objects.

Beware of moving lathe parts that can fall.

Beware of where you are moving your hand or body in relationship to the lathe.

Beware of holding a tool or other parts inserted in or attached at the chuck or

work piece.

Beware of hands or other parts of the body that may in position to be hit by a

chuck or work piece.

(20) Beware of accidentally moving levers or turning the power on.

(21) Know the function of each and every control.

(22) Never place hand on chuck or workpiece to stop rotation of the spindle.

(23) Make sure power has been turned off when lathe id unused for sometime.

(24) Allow chuck to stop before operating it.

(25) Always check chuck area for chuck keys and loose items.

(26) Never start spindle with chuck key in the chuck.

(27) Do not allow distractions to interfere with lathe operations.

Do not operate lather whilst talking.

(28) Beware of lathe dangers when attending to other aspects of lathe operation.

E.g. whilst operating tailstock.

(29) Beware of loose clothing near the rotating parts of the lathe.

(30) Beware of loose hair near the rotating parts of the lathe.

(31) Beware of performing another operating while in close proximity to rotating

parts on the lathe.

(32) Always attend to filing and deburring operations.

Always pay attention to file or deburring tools close to the chuck , files and

deburring tools may catch on chuck.

(33) Be sure lathe is in neutral position when placing gauges on components

gripped in the chuck.

(34) Be sure motor is not running when using gauges on the machine.

(35) Always wear protection before operating the lathe.

Operation Manual

5

Always wear the correct protection for even a short time when operating the

lathe.

Never remove protection for even a short time when operating the lathe.

Wear protection devices correctly.

Know the correct way to wear protective devices.

(36) Beware of material flying from the lathes.

(37) Keep protective guards at the point of operation.

Know how to set or attach protective guards properly.

Never use the wrong protective guard.

(38) (a) When the chuck and workpiece are in motion never reach over, under or

around a workpiece to make an adjustment.

(b) Never reach over, under or around a workpiece to retrieve anything.

(c) Beware of there you leave your tools during set up.

(d) Never reach over, under or around workpiece to move hand tool/lathe to

another position.

(e) Never reach over, under or around the workpiece to tighten a lathe part.

(f) Never reach over, under or around workpiece to remove swarf.

(39) Know the proper procedure for applying loads.

Never apply force form an awkward position.

(40) Never mount a workpiece too large for the lathe.

(41) Never mount a workpiece too large for the operator to handle.

(42) Use the equipment necessary for handling workpiece.

(43) Never apply undue force on the accessory or control lever.

(44) Secure all workpiece.

(45) Secure all jaws, nuts, bolts and locks.

(46) Always use the excessive force in polishing, filling and deburring.

(47) Never take cuts beyond lathe’s capability.

(48) Never use excessive force in polishing, filling and deburring.

(49) Always use the proper hand tool to remover swarf. Never hurry to remove

swarf bewares of swarf wrapped around the chuck or workpiece.

(50) Never change gears by moving them with your hands.

(51) Beware of tools/lathe parts falling on controls.

Operation Manual

6

2. Machine Specification

Bench lathe are especially suitable for machining, tool tooms and repairing working

shops to machine shafts, spindle, sleeves, and disc work piece of middle or small

types. They can also be used to cut imperial, diametric and module thread, and with

compact construction and reasonable composition, they can cut very well. They are

easy and reliable to operate, convenient to repair high in efficiency, and low noise.

Technical specification

Swing over bed……………………………………….…………………330/358mm

Swing over support…………………………….…..……………………198/223mm

Swing over gap…………………………………….………….…………476/502mm

Center height………………………………………………….………166/179mm

Distance between centers……………………….……..………750mm or 1000mm

Bed width………………………….………………….…………………………187mm

Bed height………………………………………………………………………290mm

Motor output…………………………………….………………………………1.5kw

Voltage…………………………………….…………………………220V or 380V

Spindle bore…………………………………….……………………………….38mm

Cam lock system……………………………………………………….………D1-4

Spindle speed…………………………………………………………70-2000r.p.m

Spindle taper……...…………………………………………………………MT No.5

Cross slide travel………………………………………………………………170mm

Compound slide travel………………………………………………………..95mm

Leadscrew diameter…………………………………………………………..22mm

Feed rod diameter……………………………………………………………..19mm

Cutting tool (Max. section)…………………………….…………..16mm×16mm

Imperial thread………………………………………………………4-112T.P.I(42)

Metric thread……………………………………………………0.1-7mm(44)

Module thread………………………………………………………...0.1-1.75MP(34)

Diametral thread………………………………………………………..16-112DP(25)

Longitudinal feed(Metric)…………………………………...…0.046-3.249mm/rev

Longitudinal feed(Imperial)………………………..………0.00168"-0.1175"/rev

Cross-feed(Metric)…………………...……………..……..0.010-0.7033mm/rev

Cross-feed(Imperial)………………....…………....…..…0.00046"-0.03231"/rev

Tailstock quill diameter & taper………………………………………….32mm/No.3

Weights (750mm or 1000mm)…………………520/620kg or 550/655kg(NW/GW)

Packing Size(750mm or 1000mm)………………168×76×153 or 193×76×153cm

Operation Manual

7

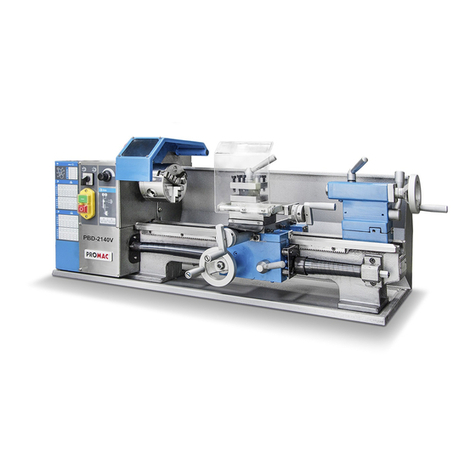

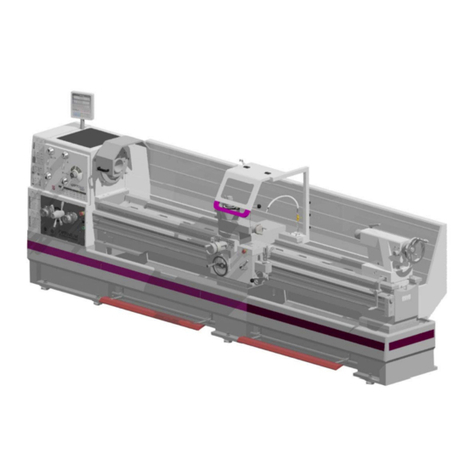

3. Constructional Indication

1. Headstock

2. Speed selector for H or L

3. Eclectic control box

4. Speed selector lever

5. Spindle

6. Splash guard

7. Lead screw

8. Feed rod

9. Longitudinal traverse hand wheel

10. Carrage

11. Tool post

12. Cross traverse handle

13. Feed axis selector

14. Compound rest

15. Compound rest traverse handle

16. Thread cutting engagement lever

17. Spindle control lever

18. Quill clamp lever

19. Tailstock clamp lever

20. Tailstock

21. Tailstock Set-Over screw

22. Quill traverse hand wheel

23. Support body

24. Chip tray

25. Right mounting feet

26. Foot-Brake

27. Front plate

28. Cabinet stand

29. Left mounting feet

30. Gear box

31. Selector handle for “1~8” position

32. Selector handle for “RST” position

33. Selector handle for “ABC” position

34. Selector handle for “WXY” position

35. Gear box cover

36. Feed direction selector

Operation Manual

8

4. Unpacking and Installation

4.1. Unpacking

Unload the machine with a tackle, using clamping plates and eyebolts. Keep the

machine in balance by moving the tailstock and the bed slide to the right. Avoid using

sling chains as they could damage to feed rod and leadscrew. Lift the lathe carefully and

place it softly into the floor or workbench.

4.2. Cleaning

Before taking the machine into operation, using kerosene (paraffin) or white spirit to

remove the anti-corrosive coating or grease from all slideways and gear train. Don’t use

lacquer thinner or other caustic solvents. Oil all bright machine surfaces immediately after

cleaning. Use heavy oil or grease on the change gears.

4.3. Installation

Place the lathe on a solid foundation. A concrete floor is the best base for the

machine. (If necessary, use an under frame operational). Make sure there is sufficient

area around the lathe for easy work and maintenance. Use a precision level on the

bedways to make further adjustment for level condition, then tighten the foundation bolts

evenly and finally recheck for level condition.

Operation Manual

9

Distance between

centers (A) B C D E

750mm 1618 1050 1538 1808

1000mm 1868 1300 1788 2058

Operation Manual

10

5. Lubrication

Before putting the lathe into operation, make the following lubrication check.

5.1. Headstock

The bearing of the headstock turns in an oil bath. Ensure that the oil level reaches

three quarters of the oil gauge glass.

For exchanging the oil, remove the end cover and the change gears with swing frame.

Drain off the oil by removing the drain plug on the bottom of the headstock. To fill, take off

the headstock cover.

Check the oil level regularly. The first oil change should be made after 3 month, then

change it once a year.

5.2. Gearbox

Remove the end cover to expose the filling plug. Through it the Shell is filled to the oil

level in the oil gauge glass regularly. The first oil change should be made after three

months, then change it once a year.

5.3. Apron

The oil bath is filled with Shell through the filling plug on the right side of the apron.

Check the oil level in the oil gauge glass on the front regular. The first oil change should

be made after three months, then change it once a year.

For exchanging the oil, drain away oil by taking off the drain plug on the bottom of the

apron.

5.4. Change gears

Lubricate the change gears with thick machine oil or grease once a month.

5.5. Other parts

There are other lubricating points on the input shaft bracket of the gearbox, the

handwheel on the apron, the longitudinal and cross slide, the thread dial indicator, the

tailstock and the bracket, use the grease gun to put a few drops of oil from time to time.

Lubricate the apron worm and worm gear, half nut and leadscrew twice a month. Apply a

light oil film to the bed way and all other bright parts like the tailstock quill, feed rod etc.

once a day.

Operation Manual

11

6. Test Running

6.1. Operation symbols

Red Green Power

Green: on

Red: off

Red Green Coolant

Green: on

Red: off

Half nut opened

Half nut closed

Metric thread

Imperial thread

Module thread

Diametral thread

Right-hand thread and longitudinal

feed toward the headstock side

Left-hand thread and longitudinal feed

reverse the headstock side

Oil inlet (hole)

Longitudinal feed

engaged (upward).

Both Longitudinal feed

disengaged (central).

Cross feed engaged

(downward)

Don’t change speed

while is running

Electrical control

(Danger)

JOG

Pilot Lamp

STOP

Operation Manual

12

6.2. Spindle speed control

(A). Identification before operation

Ensure that lubrication has been carried out as described before.

When the main spindle is rotating. The gearbox and feed axis of the bedsides are put

into operation. The forward/reverse switch should be on neutral. The feed axis selector

and feed/thread selector handle are in disengaged position. Under these circumstances,

both the longitudinal traverse handwheel and cross traverse handle can be operated by

hand.

(B). Main spindle rotation

The main spindle rotation is selected by forward/reverse switch.

(C). Main spindle speed

The speed of the main spindle is selecting by (high/low) speed selector (2) and 4

steps speed selector (4). For both high and low speed, there are 4 different positions. For

correct speed, please refer to the speed chart. When selector (2) is on “high”, we can get

the four speeds, according to the graph.

Never change the speed before the motor has stopped completely!

Adjusting the speed can be assisted by turn the main spindle by hand.

(D). Running-in

Running in should be done at lowest possible spindle speed. Let the machine to run

at lowest speed for about twenty minutes, and then check for irregularities. If everything

seems in order, gradually increase the speed.

(E). Operation

Use only high peripheral speed type chucks.

The maximum spindle speed for chuck plate of 255mm diameter should not be more

than 1255r.p.m. When thread cutting or auto feeding are not in use, the feed/thread

selector should be in neutral position, so as to ensure disengagement of the leadscrew

and the feed rod. To avoid unnecessary wear, the thread dial indicator should be out of

mesh with the leadscrew.

Operation Manual

13

7. Thread and Feed Selection

7.1. Thread and feed selection

All feed and threads are given on the feed thread tables, fitted on the front and inside

of the gear box cover (35), by setting the four feed selector handles (31),(32),(33),(34).

(A). Hand feed operation

The movement of carriage is made by the longitudinal traverse handwheel (9), cross

sliding by the cross traverse handle(12), and compound rest by the compound rest

traverse handle (15), the carriage is anchored by turning the carriage lock screw in

clockwise direction.

(B). Replacement of change gears

Take off the gear box cover(35)firstly, and then loosen clamping shaft and the

clamping screw of the swing frame to exchange the transmission shaft gear with another

gear, it is necessary for suitable back lash to intermediate the gears in both cases.

Change gear’s assemble style have 3 kind: F, G, H. F, G assemble style be used for

feed and metric thread, imperial thread cutting. H assemble style be used for MP thread,

DP thread cutting. F assemble style be used on machine for leave factory.

For any special threads not covered by the thread table, our engineering department

is available to specify the most convenient change gearing required.

(C). Automatic feed operation and change

When the feed axis selector (13) on the apron is pulled out and operated upward, we

can obtain a longitudinal feed and cross feed can be obtained by pushing the selector in

and operating it downward. (Make sure the thread cutting engagement lever (16) at

disengaged position before operating the feed axis selector.)

Feed direction can be changed by turning feed direction selector . It have 24 kinds of

feed speeds each in longitudinal and cross feed can be obtained by means of the feed

selector handles.

Operation Manual

14

7.2. Feed and thread tables

(A) .Feed table

(a) Longitudinal and cross feed table for Imperial lathe

(b) Longitudinal and cross feed table for Metric lathe

Operation Manual

15

(B). Thread tables

(a) Thread tables for Imperial leadscrew

Operation Manual

16

(b) Thread tables for Metric leadscrew

Operation Manual

17

7.3. Thread cutting operation

In order to obtain the desired thread, all correct change gears must be installed in

strict accordance with the chart, failure to do so will give incorrect threads.

Rotate the leadscrew by operating the feed/thread selector to any position and be

sure the feed selector handle is engaged. Operate downward the thread cutting

engagement lever (16), and it will be engaged with the leadscrew to obtain the

longitudinal travel of carriage, namely, the thread cutting feed. Make sure the feed axis

selector is disengaged (at neutral position) before operating the thread cutting

engagement lever (16) since there is an interlock mechanism between the auto feeding

and thread cutting engagement.

Direction of thread cutting can be chosen by turning the feed directing selector (36) at

the headstock. There are 42 Nos. of thread pitches each in Imperial, 44 Nos. of Metric

pitches,34 Nos. of module thread , 5 Nos. of diametral thread those which can be

obtained by turning the feed selector handles .

(A).Thread dial indicator

The thread dial indicator is installed on the right hand side of the apron; the indicator

is used for thread cutting to engage with the leadscrew.

For minimum wear the thread dial indicator should be disengaged by swing the pinion

out of mesh with the

leadscrew when not in

use.

Imperial threads on

Imperial leadscrew

machines or Metric

threads on Metric

leadscrew machine.

For these threads it

is recommended that

the thread dial indicator

be used this allows the

half nut of leadscrew to

be engaged at the end

of each thread cutting pass, provided that they are re-engaged in accordance with the

indicator table mounted on the left hand side of the apron.

Operation Manual

18

(1) Imperial leadscrew machines (Imperial threads only)

The table shows:

T.P.I: threads per inch to be cut.

Scale: the dial numbers at which the half nut of leadscrew may be engaged.

(2) Metric leadscrew machines (Metric thread only)

The table shows:

IN column 1: millimeter pitches to be cut.

28T, 30T, 32T: The number of teeth in “pitch-off gear” arranged to mesh with the

leadscrew (this being selected from the stack, stored on the bottom of the dial spindle)

Dial graduation:

The dial numbers at

which the half nut

may be engaged

under No. of teeth of

pick-off gear.

(3) Imperial threads on Metric leadscrew machines or Metric threads on Imperial lead

screw machines

For these threads the half nut is kept engaged throughout the cutting of any one

thread. This involves reversing the whole drive by means of the spindle control lever (17)

at each end of the thread cutting pass whilst at the same time relieving or increasing the

cut as required. (Threads ‘A’ may also be by this method)

This manual suits for next models

1

Table of contents