-5-www.igmtools.com

• Keep children away. All visitors should be kept

at a safe distance from the work area.

• Make your workshop kid proof with padlocks,

master switches, or by removing starter keys.

• Don‘t force tool. It will do the job better and

safer at the rate for which it was designed.

• Use right tool. Don‘t force tool or attachment

to do a job for which it was not designed.

• Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and

overheating.

• Wear proper apparel do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewellery which may get caught in moving

parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair.

• Always use safety glasses. Also use a face

or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant

lenses, they are not safety glasses.

• Secure work. Use clamps or a vice to hold the

work when practical. It‘s safer than using your

hand and it frees both hands to operate the tool.

• Don‘t overreach. Keep proper footing and

balance at all times.

• Maintain tools with care. Keep tools sharp

and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

• Disconnect tools before servicing and when

changing accessories, such as blades, bits,

cutters, and the like.

• Reduce the risk of unintentional starting. Make

sure power switch is in the o position before

plugging the machine in.

• Use recommended accessories. Consult the

owner‘s manual for recommended accessories.

The use of improper accessories may cause

risk of injury to persons.

• Never stand on tool serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

• Check damaged parts. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that

it will operate properly and perform its intended

function - check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

aect its operation. A guard or other part that

is damaged should be properly repaired or

replaced.

• Direction of feed. Feed work into a blade or

cutter against the direction of rotation of the

blade or cutter only.

• Never leave tool running unattended. Turn

power o. Don‘t leave tool until it comes to a

complete stop.

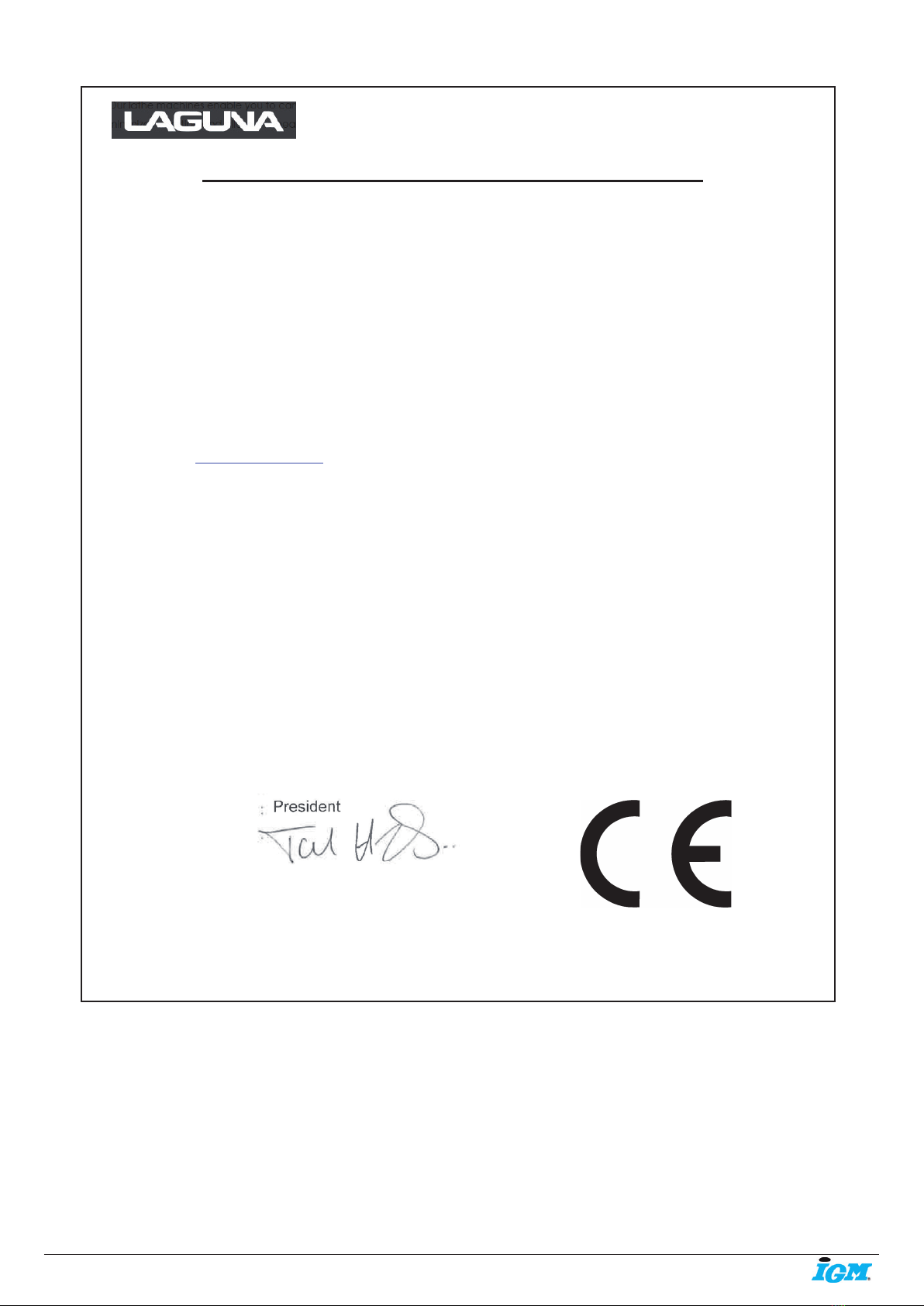

Location of warning signs

Pic. 14

Locking the lathe

It is strongly recommended that the lathe is

never be left unattended in the unlocked

condition.

To lock the machine it is recommended that a

cover (not supplied) is made to lock the control

panel. We have supplied two concepts for

locking the panel (see below). The cover can

be made from wood or plastic.

First, push down the emergency stop. Then

lock the cover together by putting padlocks [not

included] on the two handles on the control

panel. To safeguard your machine from

unauthorized operation and accidental starting

by young children, the use of padlocks is

strongly recommended.

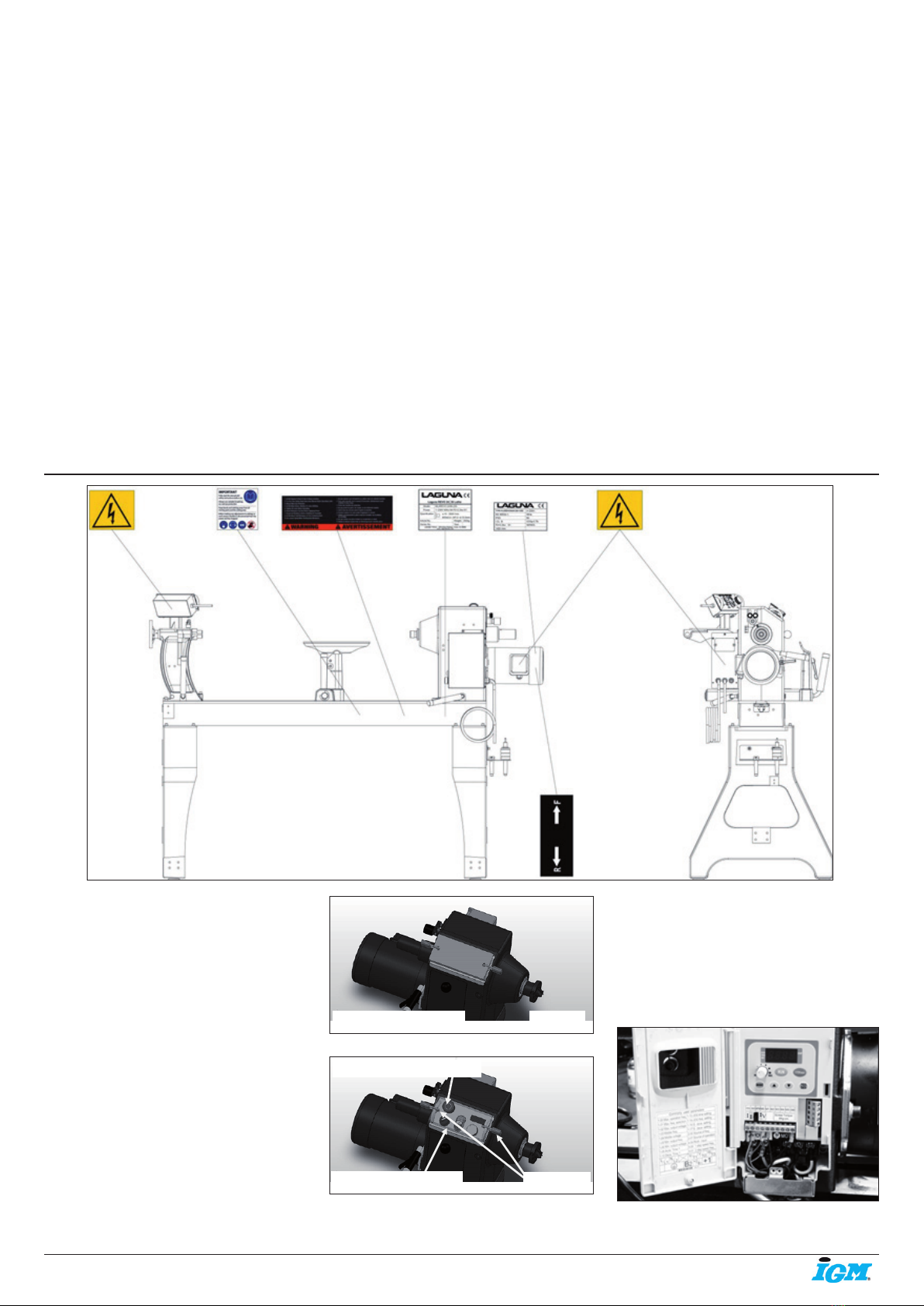

Pic. 15

Pic. 16

4.2 Electrical connections

Make sure that the power supply meets

the machine‘s requirements (230V). We

recommend using a 16 A breaker, tripping

characteristic C (16/1/C). Note.: Perform

adjustments with the help of a qualied

electrician.

VFD with cover open

Pic. 17

Wooden safety cover Padlocks

Padlocks

Emergency stop switch

Plastic safety cover