3

Standard Pump Operating Instructions and Parts Manual (OIPM-IND-HV-BCS-0713)

Models: 7610, 7611, 7620, 7621, 7614, 7615, 7624, 7625, 7630,

7631, 7640, 7641, 7634, 7635, 7644 & 7645

1. Introduction

1.1. Unpacking

Please verify that the product is complete

and without any damage. This package

should contain the following parts:

1. Pump Motor

2. Pump Tube Assembly

3. Flow Chamber Assembly

4. Chamber Assembly/Batch Controller

5. Operating Instructions

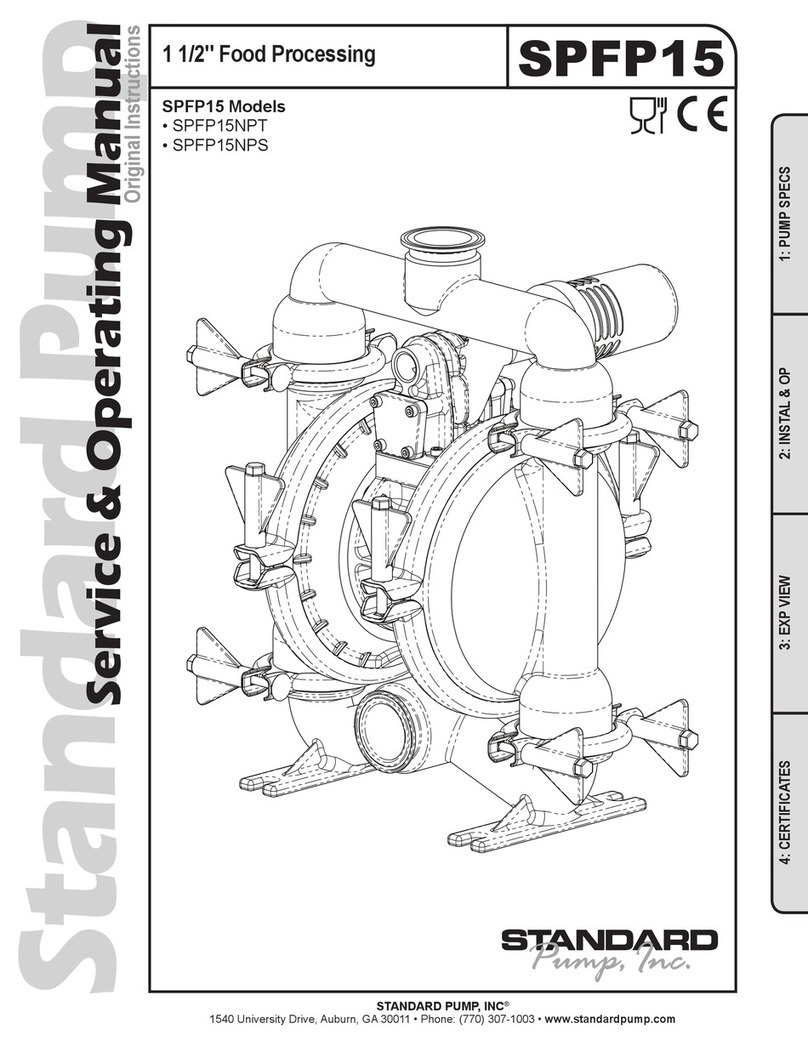

1.2. Assembly

1. Remove the pump and motor from

packaging.

2. Inspect all contents for damage.

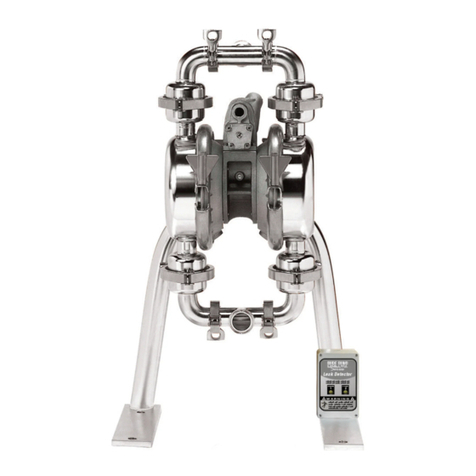

3. Couple the motor to the pump tube by

using the stainless steel connection nut

or bolt pneumatic motor to the pump

using the hardware provided by the

manufacturer (see Figure 1).

4. Attach the flow chamber assembly to

pump tube assembly by threading the

Oval Gear Flow Chamber clockwise onto

discharge of pump tube assembly (use

teflon tape on the discharge threads to

ensure a proper seal).

5. Connect communication cable from batch

controller to mating plug located on the

motor. (see Figure 1).

1.3. Start-Up & Safety

Precautions

Do not use this batch

control system to

transfer flammable or combustible

liquids or in an environment where

flammable or combustible fumes are

present. The batch control module emits

an output signal; therefore, the system is

not intrinsically safe. Failure to comply

may result in serious injury or death.

Before operating this

equipment, the

operator should thoroughly read and

understand all instructions and safety

warning labels including the

manufacturer’s instructions on the

material being pumped.

General Safety Information

1. The operator should wear suitable

protective clothing including: face mask,

safety shield or goggles, gloves, apron,

and safety shoes.

2. Check a chemical resistance chart to

be sure the chemical being pumped is

compatible with pump construction.

3. All federal, state and local safety codes

should be followed.

4. Make sure nameplate information

corresponds to voltage supplied.

Pre-Start-Up

1. All connections must be properly in

place and securely tightened. Stainless

steel hose clamps are required on hose

and must be properly tightened. Pump

hand wheel must be snug, otherwise

pump coupling damage can occur.

2. Confirm yellow meter communication

cable is securely fastened to connection

port located on the side of motor handle.

3. First use pump on water to become

familiar with the assembly and check

motor operation, flow rate, security of all

hose connections, operation of speed

control knob, liquid velocity and pump

drainage.

4. Before starting motor, check to be sure

hose is securely fastened in receiving

vessel so hose cannot splash chemicals,

causing injury.

5. Before connecting motor to power

supply, be sure motor switch is OFF

(“O” position) and speed control is

turned down.

6. Never submerge pump below the

discharge.

7. Never leave unit unattended during

operation.

8. Do not use speed control knob as ON/

OFF switch.*

9. If liquid appears below discharge

assembly, check security of hose clamps

and wing nut. If leakage fails to stop,

cease operation. Neutralize pump and

refer to specific parts list and operating

instructions to repair. If unable to repair,

contact factory.

10. When finished using pump, drain pump

and hose thoroughly and operate on 1-2

gallons of clear water or neutral solution

for 15-30 seconds to completely flush

and rinse pump and hose assembly.

11. Never store the pump and hose

assembly in the container. Always rinse

thoroughly and hang on a wall bracket.

*The speed control

switch should not be

used as the main ON/OFF switch. Using

the speed control switch in this manner

causes excessive wear to the

potentiometer and may result in

premature failure. The use of the speed

control switch does not cut power to the

motor and inadvertent activation could

result in injury.

Communication

Cord

Figure 1