®Viton is a registered trademark of DuPont Dow Elastomers.

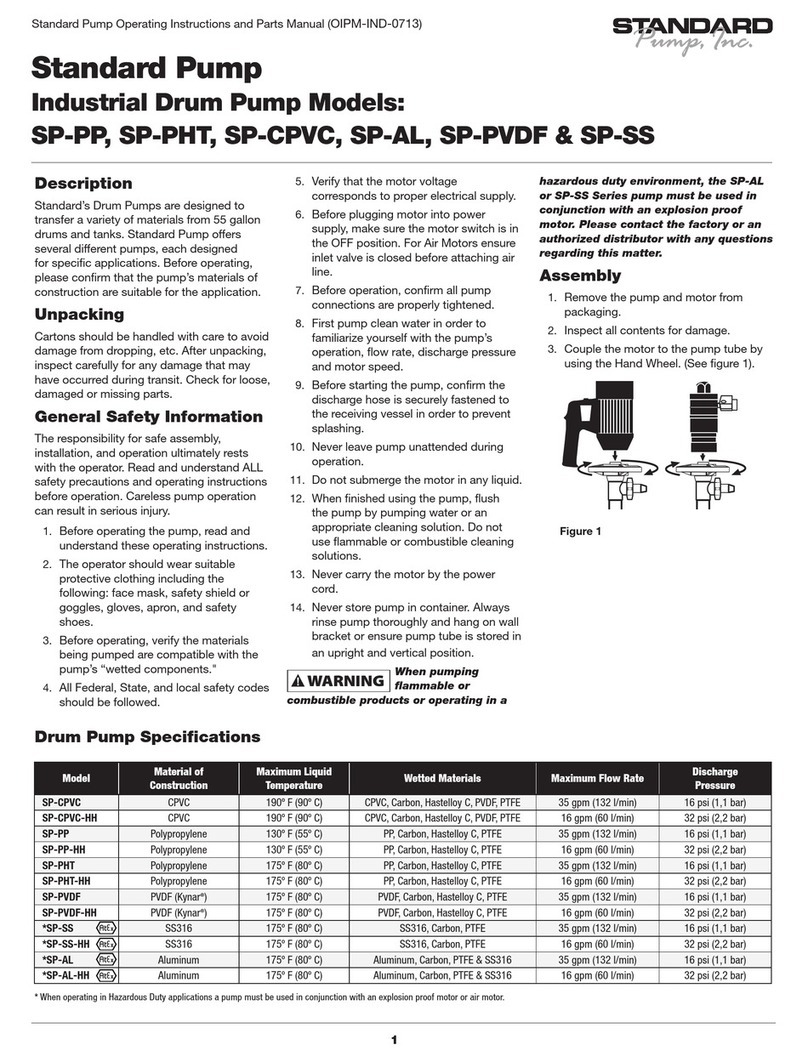

Model HP Voltage Phase Meter Wetted Components Immersion

Length Hose Length Nozzle

Material

9400 1 110V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9401 1 220V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9402 1 110V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9403 1 220V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9714 1 110V 1 No SS316L, PTFE, Carbon, PVC, Viton 39" (1000 mm) 6 ft. (1,83 meters) SS316

9715 1 220V 1 No SS316L, PTFE, Carbon, PVC, Viton 39" (1000 mm) 6 ft. (1,83 meters) SS316

9716 1 110V 1 No SS316L, PTFE, Carbon, PVC, Viton 47" (1200 mm) 6 ft. (1,83 meters) SS316

9717 1 220V 1 No SS316L, PTFE, Carbon, PVC, Viton 47" (1200 mm) 6 ft. (1,83 meters) SS316

9420 1 110V 1 No PVDF, Carbon, Hastelloy C, XLPE, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) PVDF

9421 1 220V 1 No PVDF, Carbon, Hastelloy C, XLPE, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) PVDF

9422 1 110V 1 No PVDF, Carbon, Hastelloy C, XLPE, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9423 1 220V 1 No PVDF, Carbon, Hastelloy C, XLPE, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9430 1 110V 1 No CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9431 1 220V 1 No CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9432 1 110V 1 No CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9433 1 220V 1 No CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9500 1 110V 1 YesPolypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9501 1 220V 1 YesPolypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9502 1 110V 1 YesPolypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9503 1 220V 1 YesPolypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9510 1 110V 1 YesPVDF, Carbon, Hastelloy C, XLPE, Viton®, Ceramic,

Halar, PTFE 39" (1000 mm) 6 ft. (1,83 meters) PVDF

9511 1 220V 1 Yes PVDF, Carbon, Hastelloy C, XLPE, Viton®, Ceramic,

Halar, , PTFE 39" (1000 mm) 6 ft. (1,83 meters) PVDF

9512 1 110V 1 Yes 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9513 1 220V 1 YesPVDF, Carbon, Hastelloy C, XLPE, Viton®, Ceramic,

Halar, PTFE 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9760 1 110V 1 No Aluminum, Carbon, PTFE, SS316, Buna, PVC 39" (1000 mm) 6 ft. (1,83 meters) Aluminum

9761 1 220V 1 No 39" (1000 mm) 6 ft. (1,83 meters) Aluminum

9762 1 110V 1 No 47" (1200 mm) 6 ft. (1,83 meters) Aluminum

9763 1 220V 1 No 47" (1200 mm) 6 ft. (1,83 meters) Aluminum

99201 110V 1 No 39" (1000 mm) 6 ft. (1,83 meters) SS316

99211 220V 1 No 39" (1000 mm) 6 ft. (1,83 meters) SS316

99221 110V 1 No 47" (1200 mm) 6 ft. (1,83 meters) SS316

99231 220V 1 No 47" (1200 mm) 6 ft. (1,83 meters) SS316

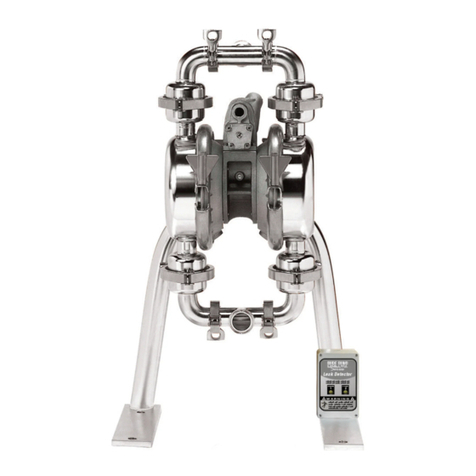

Air Motor Pump Packages

Model HP Meter Immersion Length Hose Length Nozzle Material

9904 0.5

Air Consumption

No

Wetted Components

SS316L, PTFE, Carbon, Viton, UHMWPE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9905 0.75 28 CFM (13.2 L/sec) @ 90 psi (6,2 bar) No 39" (1000 mm) 6 ft. (1,83 meters) SS316

9906 0.5 No 47" (1200 mm)6 ft. (1,83 meters) SS316

9907 0.7528 CFM (13.2 L/sec @ 90 psi (6,2 bar) No 47" (1200 mm)6 ft. (1,83 meters) SS316

9764 0.7528 CFM (13.2 L/sec @ 90 psi (6,2 bar) No 39" (1000 mm)6 ft. (1,83 meters) Aluminum

9765 0.7528 CFM (13.2 L/sec @ 90 psi (6,2 bar) No 47" (1200 mm)6 ft. (1,83 meters) Aluminum

Pump Package Specications

Electric Motor Pump Packages

27 CFM (13 L/sec) @ 80 psi (5,51 bar)

27 CFM (13 L/sec) @ 80 psi (5,51 bar)

8

SS316L, PTFE, Carbon, Viton, UHMWPE

SS316L, PTFE, Carbon, Viton, UHMWPE

SS316L, PTFE, Carbon, Viton, UHMWPE

Aluminum, Carbon, PTFE, SS316, Buna, PVC

Aluminum, Carbon, PTFE, SS316, Buna, PVC

Aluminum, Carbon, PTFE, SS316, Buna, PVC

SS316L, PTFE, Carbon, Viton, UHMWPE

SS316L, PTFE, Carbon, Viton, UHMWPE

SS316L, PTFE, Carbon, Viton, UHMWPE

SS316L, PTFE, Carbon, Viton, UHMWPE

PVDF, Carbon, Hastelloy C, XLPE, Viton®, Ceramic,

Halar, PTFE

Aluminum, Carbon, PTFE, SS316,

Buna, PVC

Aluminum, Carbon, PTFE, SS316,

Buna, PVC

Standard Pump Operating Instructions and Parts Manual (OIPM-IND-1019)