Stanley Electric STW1147ASE-TR User manual

Looking for a discount?

Check out our current promotions!

This coversheet was created by Verical, a division of Arrow Electronics, Inc. (“Verical”). The attached document was created by the part supplier,

not Verical, and is provided strictly 'as is.' Verical, its subsidiaries, affiliates, employees, and agents make no representations or warranties

regarding the attached document and disclaim any liability for the consequences of relying on the information therein. All referenced brands,

product names, service names, and trademarks are the property of their respective owners.

00000005981LF-000

EOS Power

Buy Now

We have 45,000 LP502030-PCM-NTC-LD-A02554 - EEMB - Lithium Battery Rectangular 3.7V 250mAh Rechargeable in

stock now. Starting at $0.034. This EEMB part is fully warrantied and traceable.

1-855-837-4225

Give us a call

International: 1-555-555-5555 1-415-281-3866

1-415-281-3866

Arrow Electronics,

Verical Division

P.O. Box 740970

Los Angeles, CA 90074-0970

Arrow Electronics, Inc

9201 East Dry Creek Road

Centennial, CO 80112

STW1147ASE-TR

STANLEY ELECTRIC

Buy Now

STW1147ASE-TR

Page : 1

2013/2/12

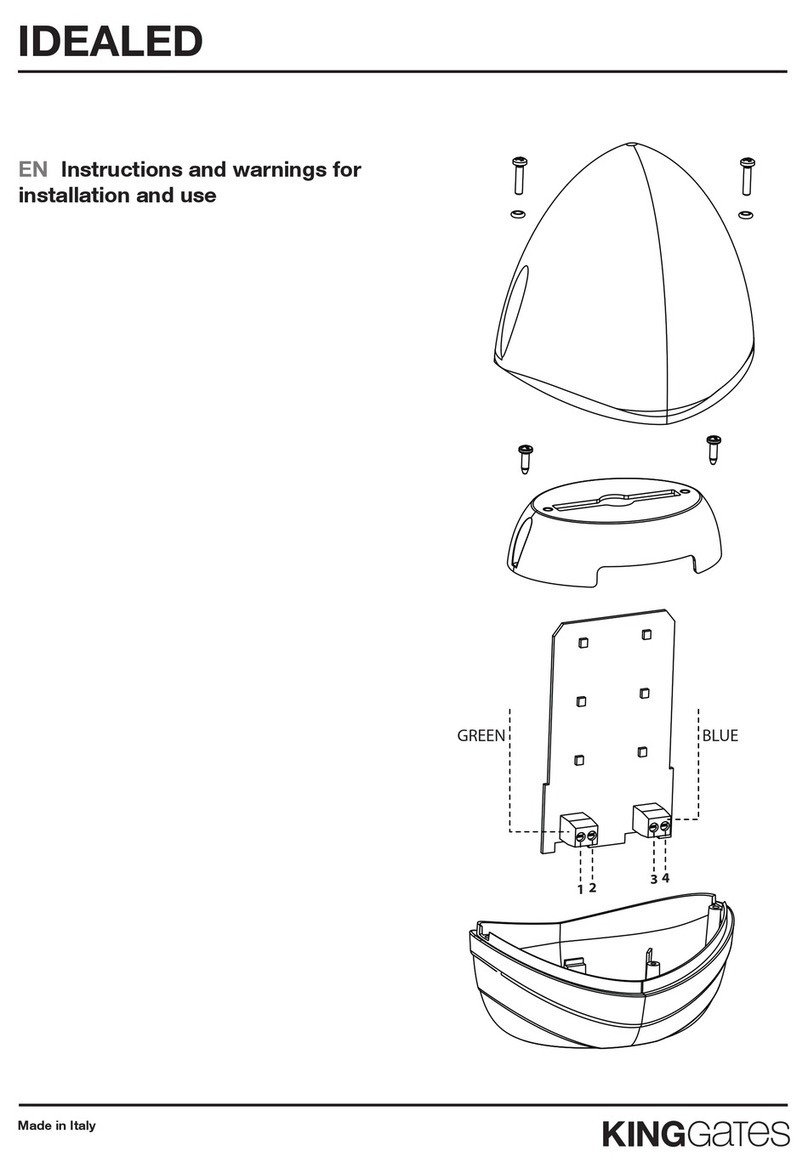

Outer Dimension 2.4 x 1.85 x 0.6mm ( L x W x H )

Diffused pale yellow color lens

Standard Product Reference Sheet

Features

Recommended Applications

Package

Product features ・Thinner package, White color emitting LED

・Lead–free soldering compatible

・RoHS compliant

・Amusement equipment, Home appliances, OA/FA equipment, Other general lighting use, etc.

STW1147ASE-TR

Page : 2

Unit :mm

Weight :5.2mg

Tolerance :±0.1mm

SYMBOL PART NAME REMARKS QTY.

①LED Die InGaN 1

②Protection

Diode Si 1

③Lamp Housing Glass fabric 1

④Terminal Au Plating 2

⑤Encapsulant Silicone Resin 1

2013/2/12

Outline Dimensions

Recommended Pad

Unit:mm

STW1147ASE-TR

Page : 3

【Absolute Maximum Ratings 】

Note2

℃

ITEM SYMBOL MAXIMUM RATINGS UNIT

mW

ESD

Storage Temperature T

stg

-40 ~+85

Note1

Forward Current

V

T

sld

ΔI

F

0.625 mA/℃

I

F

25 mA

ΔI

FRM

2.5 mA/℃

100

Repetitive Peak Forward Current

"1ms,1/20duty"

(

Ta=25℃

)

Diffused Pale Yellow

InGaN

White

【Product Overview 】

Resin Color( Emitting Area)

Power Dissipation P

d

I

FRM

Derate Linearly from "60℃"

Die Material

Emitting Color

Please refer to the attached sheets

,

Solderin

g

Conditions.

℃

I

FRM

100

T

opr

Reverse Voltage V

R

70

ESD testin

g

method : EIA

J

4701

/

300

(

304

)

Human Bod

y

Model

(

HBM

)

1.5

k

Ω

,

100

p

F

260 ℃

mA

Operating Temperature

Soldering Temperature

"Reflow Soldering"

Electrostatic Discharge Threshold "HBM" 1,000 V

-40 ~+100

Note 1

Note 2

I

F

Derate Linearly from "60℃"

2013/2/12

Specifications

STW1147ASE-TR

Page : 4

※Tolerance : I

V

±10%

Note5 Viewing Angle at 50% Iv, Δθx ; Housing long side axis, Δθy ; Housing short side axis

Δθy

1,000

I

F

= 20mA -

Forward Voltage

I

V

Φ

V

-

Δθx

UNIT

-

-

【Electro and Optical Characteristics 】

-

2.8

0.32 -

Note4I

F

= 20mA

Above table of Luminous Intensity (I

V

) values and

Chromaticity Coordinates values are the setup value of the selection machine.

VV

F

3.6

(

Ta=25℃

)

I

F

= 20mA

2,000

0.31

3,300

-

I

F

= 20mA

I

F

= 20mA

lm

-

120

-

ITEM SYMBOL CONDITIONS

mcd

MIN. TYP. MAX.

3.2

y

Chromaticity coordinate

Luminous Intensity

Luminous Flux 6.0-

x

Note3,4 Please refer to the following sorting charts.

Chromaticit

y

coordinate:x

,y

coordinate accordin

g

to CIE1931

Note3

Note5

Half Intensity Angle I

F

= 20mA deg.

120

【Sorting For Luminous Intensity 】

LEDs shall be sorted out into the following ranks of Luminous Intensity.

1,000

MIN.

DA

MAX.

Rank Condition

I

V

(mcd)

DC 2,200 3,300

DB I

F

=20mA

Ta=25℃

1,500

1,500 2,200

2013/2/12

Specifications

Notes

・All luminous intensity ranks are not selectable because selectable ranks depend on chromaticity.

・Intensity Tolerance Each Rank : ±10%

・Above the table of Luminous Intensity (IV) values is the setup value of the selection machine.

STW1147ASE-TR

Page : 5

【Sorting chart For Chromaticity coordinates】

Chromaticity coordinates shall be sorted out into the following chart and each rank parts shall be packed separately

when shipping.

2013/2/12

Specifications

Above table of Chromaticity Coordinates values are the setup value of the selection machine.

Toleranse : Each Rank ±0.02

(I

F

=20mA, Ta=25℃)

Rank

0.311 0.294 0.339

0.307

0.311

0.330

0.330

y

0.296

y

0.276

Left Down Left Up

0.351

Right Up Right Down

0.385 0.356

0.315

0.360

0.287

0.315

0.280

x

1

x

0.264

xy

0.294

0.339

0.318

0.360 0.361

0.296

2D

2F

2C

2E

0.276

0.307

0.283

0.287

0.304

30.330 0.318 0.330

※

0.248

0.295

0.307

y

0.267

0.305

0.295

0.330

0.315

x

0.330

0.283 0.305

0.304 0.330

0.307

0.330

0.315

STW1147ASE-TR

0

50

100

-100 -50 0 50 100

-30

-60

-90

60

30

0

90

Spatial Distribution

Conditions: Ta = 25℃, IF=10mA

Relative Intensity: (%)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

380 430 480 530 580 630 680 730 780

Page : 6

2013/2/12

Wavelength vs. Relative Intensity

Conditions: Ta = 25℃, IF=20mA

Wavelength: (nm)

Relative Intensity

Technical Data

x Direction

y Direction

STW1147ASE-TR

0.1

1.0

10.0

-40-200 20406080100

0.0

0.5

1.0

1.5

2.0

0 5 10 15 20 25 30

2.4

2.6

2.8

3.0

3.2

3.4

3.6

3.8

4.0

-40-200 20406080100

1

10

100

2.0 2.5 3.0 3.5 4.0

Page : 7

2013/2/12

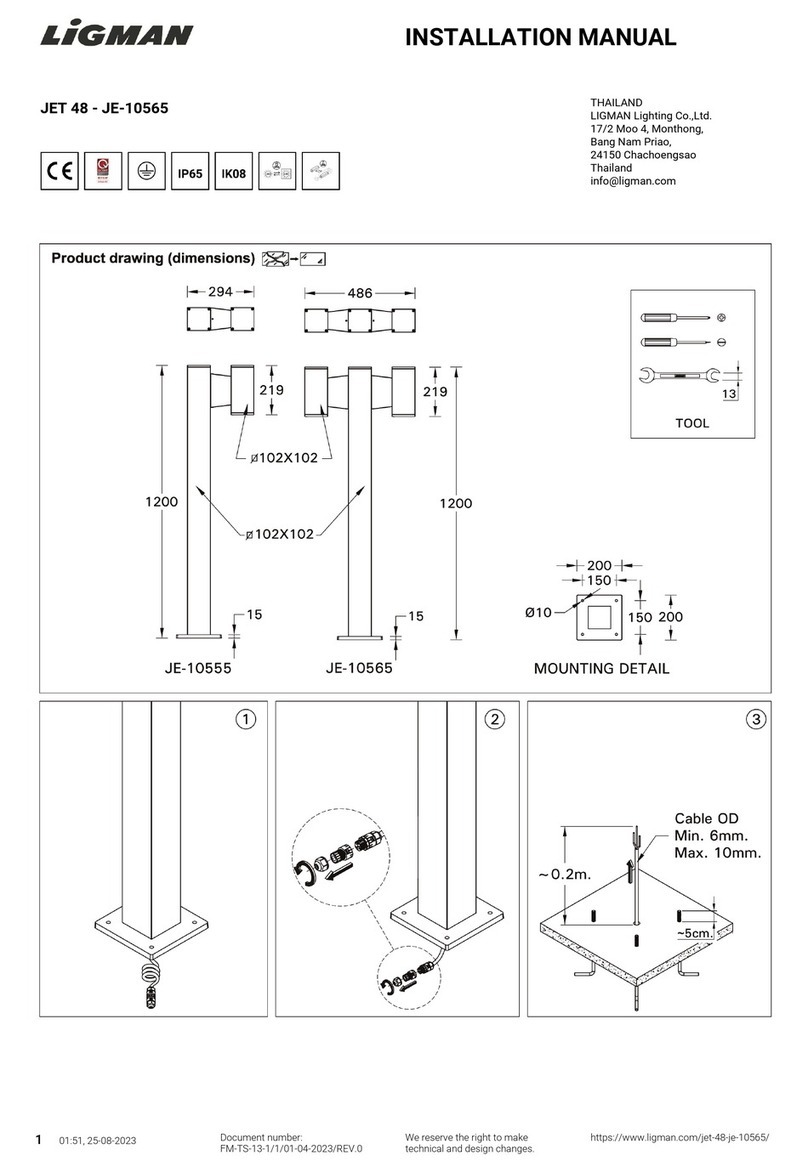

Forward Voltage vs. Forward Current

Condition : Ta = 25℃

Forward Voltage : VF (V)

Forward Current : IF (mA)

Forward Current vs. Relative Intensity

Condition : Ta = 25℃

Forward Current: IF (mA)

Relative Intensity

Ambient Temperature vs. Relative Intensity

Condition : IF= 20mA

Ambient Temp. : Ta (℃)

Technical Data

Relative Intensity

Ambient Temperature vs. Forward Voltage

Condition : IF= 20mA

Ambient Temp. : Ta (℃)

Forward Voltage: VF(V)

STW1147ASE-TR

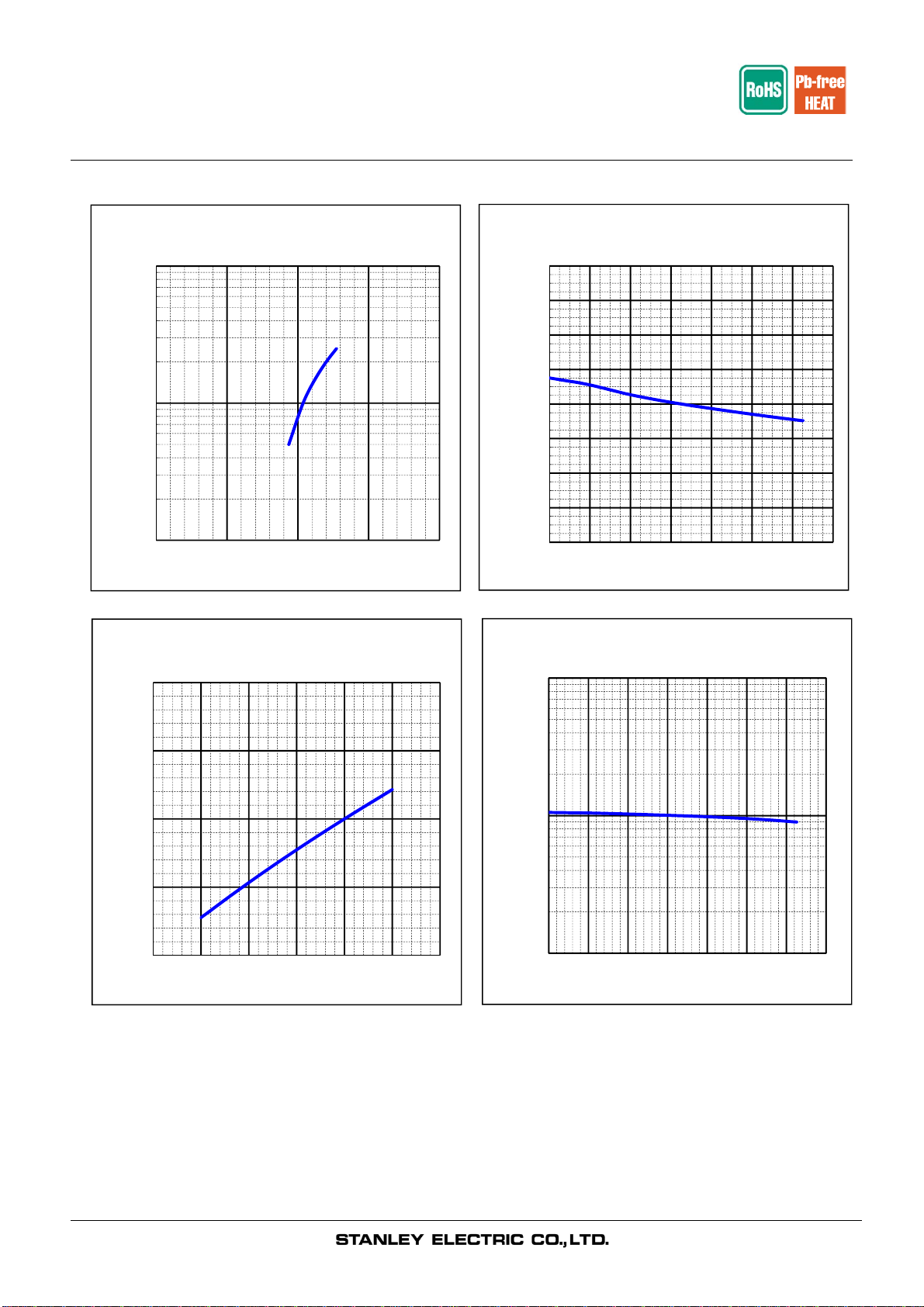

0

20

40

60

80

100

120

-40 10 60 110

MAX Forward Current : IFMAX (mA)

Ambient Temp. : Ta(℃)

Duty=5%

Duty=10%

Duty=20%

Duty=50%

1

10

100

110100

Duty Ratio vs. Max. Forward Current

Condition: Ta = 25℃

Duty Ratio: (%)

0

20

40

60

80

100

120

-40-200 20406080

0

10

20

30

40

50

60

-40-200 20406080

Forward Current : IF MAX (mA)

Ambient Temp. : Ta(℃)

DC

Ambient Temperature vs. Maximum Forward Current

Repetition Frequency : f ≧50Hz

Page : 8

2013/2/12

Ambient Temperature vs.

Maximum Forward Current

Technical Data

Forward Current : IFRM MAX. (mA)

Power Dissipation Pd (mW)

Ambient Temperature vs. Power Dissipation

Ambient Temp. : Ta(℃)

STW1147ASE-TR

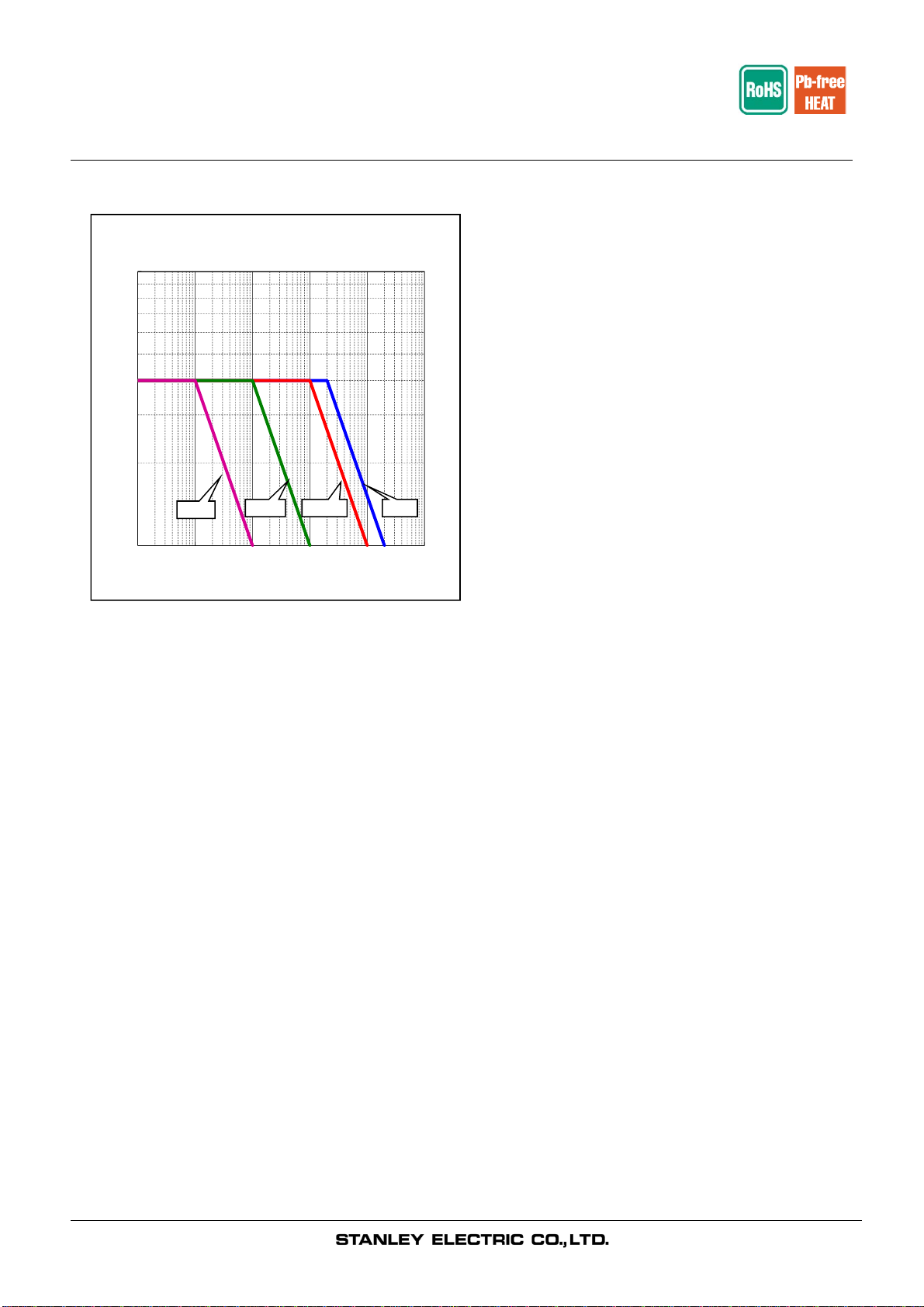

1

10

1.0 10.0 100.0 1,000.0 10,000.0 100,000.0

50Hz100Hz1kHz

10kHz

2

Page : 9

2013/2/12

Technical Data

IFpeak MAX./ IFDC MAX.

Pulse Width vs. Maximum Tolerable Peak Current

Condition : Ta=25℃

Pulse Width : tw (μs)

STW/JS□/JU□11□7AS(E)-TR

Page : 10

Soldering condition

1. Heat stress during soldering will influence the reliability of LEDs, however that effect will vary on

heating method. Also, if components of varying shape are soldered together, it is recommended to set

the soldering pad temperature according to the component most vulnerable to heat (e.g., surface

mount LED).

2. LED parts including the resin are not stable immediately after soldering ( when they are not at room

temperature), any mechanical stress may cause damage to the product. Please avoid such stress after

soldering, especially stacking of the boards which may cause the boards to warp and any other types

of friction with hard materials.

3. Recommended temperature profile for the Reflow soldering is listed as the temperature of the resin

surface. Temperature distribution varies on heating method, PCB material, other components in the

assembly, and mounting density.

Please do not repeat the heating process in Reflow process more than twice.

Note 1 Recommended temperature profile for the reflow soldering is listed as the temperature of the resin

surface. This should be the maximum temperature for soldering. Lowering the heating temperature and

decreasing heating time is very effective in achieving higher reliability.

Note 2 The reflow soldering process should be done up to twice(2 times Max). When second process is

performed, interval between first and second process should be as short as possible to prevent absorption

of moisture to resin of LED. The second soldering process should not be done until LEDs have returned to

room temperature (by nature-cooling) after first soldering process.

【Soldering Precaution】

(acc.to EIAJ-4701/300)

【Recommended Reflow Soldering Condition】

40sec MAX.

150℃~180℃

+1.5~+5℃/s

260℃MAX.

-1.5~-5℃/s

90~120secMAX.

(

Pre-heating

)

(Soldering

)

230℃MAX.

Peak Temperature

2013/2/12 Page : 10

STW/JS□/JU□11□7AS(E)-TR

Page : 11

Soldering condition

4. If soldering manually, Stanley recommends using a soldering iron equipped with temperature control.

During the actual soldering process, make sure that the soldering iron never touches the LED itself, and

avoid the LED's electrode heating temperature reaching above the heating temperature of the solder

pad. All repairs must be performed only once in the same spot, and please avoid reusing components.

5. In soldering process, immediately after iron tip is cleaned, please make sure that the soldering iron

reaches the appropriate temperature before using. Also, please avoid applying any types of pressure to

the soldered components before the solder has been cooled and hardened, as it may deteriorate solder

performance and solder quality.

6. When using adhesive material for tentative fixatives, thermosetting resin or Ultraviolet radiation (UV)

setting resin with heat shall be recommended.

《The curing condition, Temperature:150℃Max./Time:120sec.Max.》

7. Flow soldering (dip soldering) is not recommended for this product.

8. lsopropyl alcohol is recommended for cleaning. Some chemicals, including Freon substitute detergent

could corrode the lens or the casing surface, which cause discoloration, cloud, crack and so on. Please

review the reference chart below for cleaning. If water is used to clean (including the final cleaning

process), please use pure water (not tap water), and completely dry the component before using.

【Recommended Manual Soldering Condition】

Temperature of Iron Tip 350℃MAX.

Soldering Duration, Time 3sec.Max.,1 time

Chemical Adaptability

Isopropyl Alcohol ○

Trichloroethylene ×

Chlorothene ×

Acetone ×

Thinner ×

2013/2/12 Page : 11

STW/JS□/JU□11□7AS(E)-TR

Page : 12

Handling Precaution

This kind of LED lamp is highly sensitive to surge voltage generated by the On/Off status change and

discharges of static electricity through frictions with synthetic materials, which may cause severe damage to

the die or undermine its reliability. Damaged products may experience conditions such as extremely high

reverse voltage, or a decrease of forward rise voltage, deteriorating its optical characteristic.

Stanley products are designed to withstand up to 1,000V under the EIAJ ED-4701/300 Test ♯304 (HBM),

and are packed with anti-static components. However, the following precautions and measures are vital in

ensuring product quality during shipment.

EIAJ ED-4701/300(304/HBM)Electrification model: C=100pF, R2=1.5KΩ

①Do not place electrified non-conductive materials near the LED product.

Avoid LED products from coming into contact with metallic materials.( Should the metallic material be

electrified , the sudden surge voltage will most likely damage the product.)

②Avoid a working process which may cause the LED product to rub against other materials.

③Install ground wires for any equipment, where they can be installed, with measures to avoid static

electricity surges.

④Prepare a ESD protective area by placing a Conductive Mattress (1MΩMAX.) and Ionizer to remove

any static electricity.

⑤Operators should wear a protective wrist-strap.

⑥Operators should wear conductive work-clothes and shoes.

⑦To handle the products directly, Stanley recommends the use of ceramic, and not metallic, tweezers.

2. Working Environment

①A dry environment is more likely to cause static electricity. Although a dry environment is ideal for

storage state of LED products, Stanley recommends an environment with approximately 50%

humidity after the soldering process.

②Recommended static electricity level in the working environment is 150V, which is the same value as

Integrated Circuits (which are sensitive to static electricity).

【For Electric Static Discharge ( ESD) 】

1. Electrification/Static Electricity protection

Stanley recommends the following precautions in order to avoid product (die) damage from static

electricity , when an operator and other materials electrified by friction coming in contact with the product.

2013/2/12 Page : 12

STW/JS□/JU□11□7AS(E)-TR

Page : 13

Handling Precaution

【Other Precautions 】

1. Stanley LED Lamps have semiconductor characteristics and are designed to ensure high reliability.

However, the performance may vary depending on usage conditions

2. Absolute Maximum Ratings are set to prevent LED lamps from failing due to excess stress( temperature,

current, voltage, etc.). Usage conditions must not exceed the ratings for a moment, nor do reach one

item of absolute maximum ratings simultaneously.

3. In order to ensure high reliability from LED Lamps, variable factors that arise in actual usage conditions

should be taken into account for designing. ( Derating of TYP., MAX Forward Voltage, etc.)

4. Please insert Protective Resistors into the circuit in order to stabilize LED operation and to prevent the

device from igniting due to excess current.

5. Please avoid the stick of foreign material because molding resin in the products have adhesiveness. Also

please don't touch lens portion.

6. Please check the actual performance in the assembly because the Specification Sheets are described for

LED device only.

7. Please refrain from looking directly at the light source of LED at high output, as it may harm your vision.

8. The products are designed to operate without failure in recommended usage conditions. However,

please take the necessary precautions to prevent fire, injury, and other damages should any malfunction

or failure arise.

9. The products are manufactured to be used for ordinary electronic equipment. Please contact our sales

staff beforehand when exceptional quality and reliability are required, and the failure or malfunction of

the products might directly jeopardize life or health ( such as for airplanes, aerospace, transport

equipment, medical applications, nuclear reactor control systems and so on).

10. When there is a process of supersonic wave welding etc. after mounting the product, there is a

possibility of affecting on the reliability of junction part in package (junction part of die bonding and wire

bonding). Please make sure there is no problem before using.

11. The formal specification sheets shall be valid only by exchange of documents signed by both parties.

2013/2/12 Page : 13

STW/JS□/JU□11□7AS(E)-TR

Page : 14

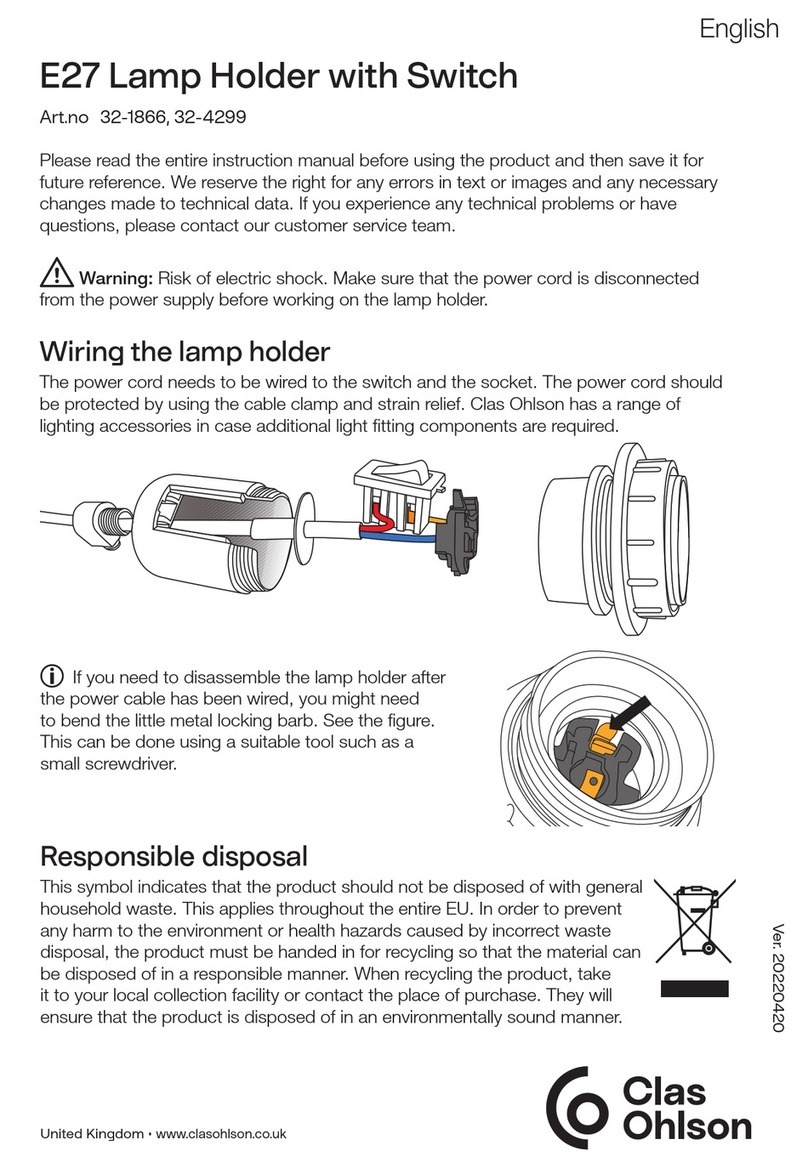

1. Picking up point with nozzle: Lamp housing of the product ( area)

(Shown below)

<Recommendation>

The picking up point should be within lamp housing portion, because the silicone resin used for the lens

is soft. (If the nozzle makes contact with the lens, the products might be destroyed)

Handling Precaution

【Handling Precautions for Product Mounting 】

Please adjust the load, the pick up point, the nozzle diameter, etc. before mounting because

the over load can cause the breakage of the lamp housing.

2013/2/12 Page : 14

STW/JS□/JU□11□7AS(E)-TR

Page : 15

Packaging Specifications

This product is baked (moisture removal) before packaging, and is shipped in moisture-proof packaging (as

shown below) to minimize moisture absorption during transportation and storage. However, with regard to

storing the products, Stanley recommends the use of dry-box under the following conditions is recommended.

Moisture-proof bag as the packaging is made of anti-static material but packaging box is not.

The package should not be opened until immediately prior to its use, and please keep the time frame between

package opening and soldering which is 【maximum 3days(72h)】.

If the device needs to be soldered twice, both soldering operations must be completed within the 3days(72h).

If any components should remain unused, please reseal the package and store them under the conditions

described in the 【Recommended Storage Condition 】above.

This product must be required to perform baking process (moisture removal) for at 48h( MIN.).∼72h(MAX.) at

60±5 degrees Celsius if following conditions apply.

1.In the case of silica gel (blue) which indicates the moisture level within the package, changes or loses its

blue color.

2. In the case of time passes for 3days(72h) after the package is opened once.

Baking process should be performed after LED having been taken out of the package.

Baking may be performed in the tape-reel form , however if it is performed with the reel stacked over one

another, it may cause deformation of the reels and taping materials and later obstruct mounting. Please handle

only once it has returned to room temperature. Provided that, baking process shall be 2 times MAX.

【Time elapsed after Package Opening】

2013/2/12 Page : 15

In the case of the package unopened , 6 months under 【Recommended Storage Condition 】.

Please avoid rapid transition from low temp. condition to high temp. condition

and storage in corroding and dusty environment.

【Recommended Storage Condition / Products Warranty Period 】

Temperature +5~30℃

Humidity Under 70%

STW/JS□/JU□11□7AS(E)-TR

Page : 16

Packaging Specification

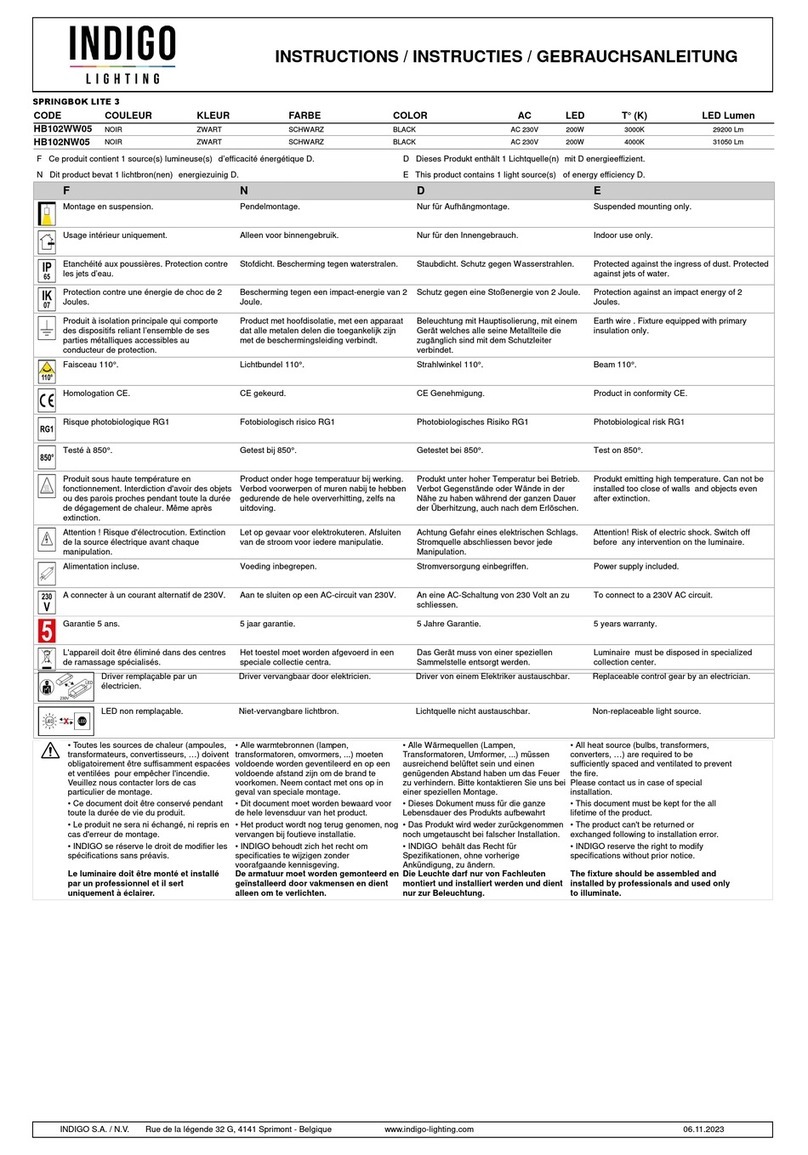

【Moisture-proof Packaging Specification】

Fastener for re-storage

after opening bag

Customer's opening position

Product Label

(Desiccant with indicator for

moisture level is enclosed.)

A

SYM. PART NAME MATELRIAL REMARKS

①Moisture-proof bag

with Aluminum layer PET+Al+PE with ESD

protection

①

2013/2/12 Page : 16

Heat Sealing position (after product being put in)

Yes No

Yes No

Yes No

Baking LED under recommended condition

Product Mounting

Unused-product remained

Return to moisture-proof package and seal Finished

Reopen the moisture-proof package

Flow chart:Package Opening to Mounting

Stored under recommended condition

Moisture-proof package first time opening

Allowable leaving time exceeded (*)

Discoloration of silica gel

Allowable leaving time means the

maximum allowable leaving time after

opening package, which depends on

each LED type.

The allowable leaving time should be

calculated form the first opening of

package to the time when soldering

process is finished.

When judging if the allowable leaving

time has exceeded or not, please subtract

the soldering time. The allowable leaving

time after reopening should be calculated

form the first opening of package, or from

the time when baking process is finished.

【Flow Chart-package Opening to Mounting】

STW/JS□/JU□11□7AS(E)-TR

Page : 17

【Packing box 】

(RoHS・ELV Compliant)

The above measure is all the reference value.

The box is selected out of the above table by shipping quantity.

Packaging Specifications

B

Type A

Material / box :Cardboard C5BF

Type B,C

Material / box :Cardboard K5AF

Partition :Cardboard K5AF

Box Type Outline dimension

L ×W ×H (mm) Capacity of the box

Type A 280 ×265 ×45 3 reels

Type B 310 ×235 ×265 15 reels

Type C 440 ×310 ×265 30 reels

2013/2/12 Page : 17

STW/JS□/JU□11□7AS(E)-TR

Page : 18

【Label Specification】

( acc.to JIS-X0503(Code-39)

Product label

A. Parts number

B. Bar-code for parts number

C. Parts code (In-house identification code for each parts number)

D. Packed parts quantity

E. Bar-Code for packed parts quantity

F. Lot number & Rank

(refer to Lot Number Notational System for details )

G. Bar-Code for Lot number & Rank

Opto device label

A. Customer Name

B. Parts Type

C. Parts Code

D. Parts Number

E. Packed Parts Quantity

F. Carton Number

G. Shipping Date

H. Bar-Code for In-house identification Number

<Remark> Bar-code font : acc.to Code-39(JIX0503)

Packaging Specifications

B

A

2013/2/12 Page : 18

STW/JS□/JU□11□7AS(E)-TR

Page : 19

Taping and Reel Specifications

(acc.to JIS-C0806-03)

【Appearance】

Note

"-TR" means cathode side of LEDs should be placed on the sprocket-hole side.

Items Specifications Remarks

Leader area

Cover-tape Cover-tape shall be longer

than 320mm without carrier-tape

The end of cover-tape shall be

held with adhesive tape.

Carrier-tape Empty pocket shall be more than

25 pieces.

Please refer to the above figure

for Taping & reel orientation .

Trailer area Empty pocket shall be more than

40 pieces.

The end of taping shall be

inserted into a slit of the hub.

2013/2/12 Page : 19

Table of contents

Other Stanley Electric Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Kino Flo

Kino Flo Image L80 LED Operation manual

Clevertronics

Clevertronics L10 Supalite LFLLED Series ASSEMBLY, INSTALLATION & MAINTENANCE INSTRUCTIONS

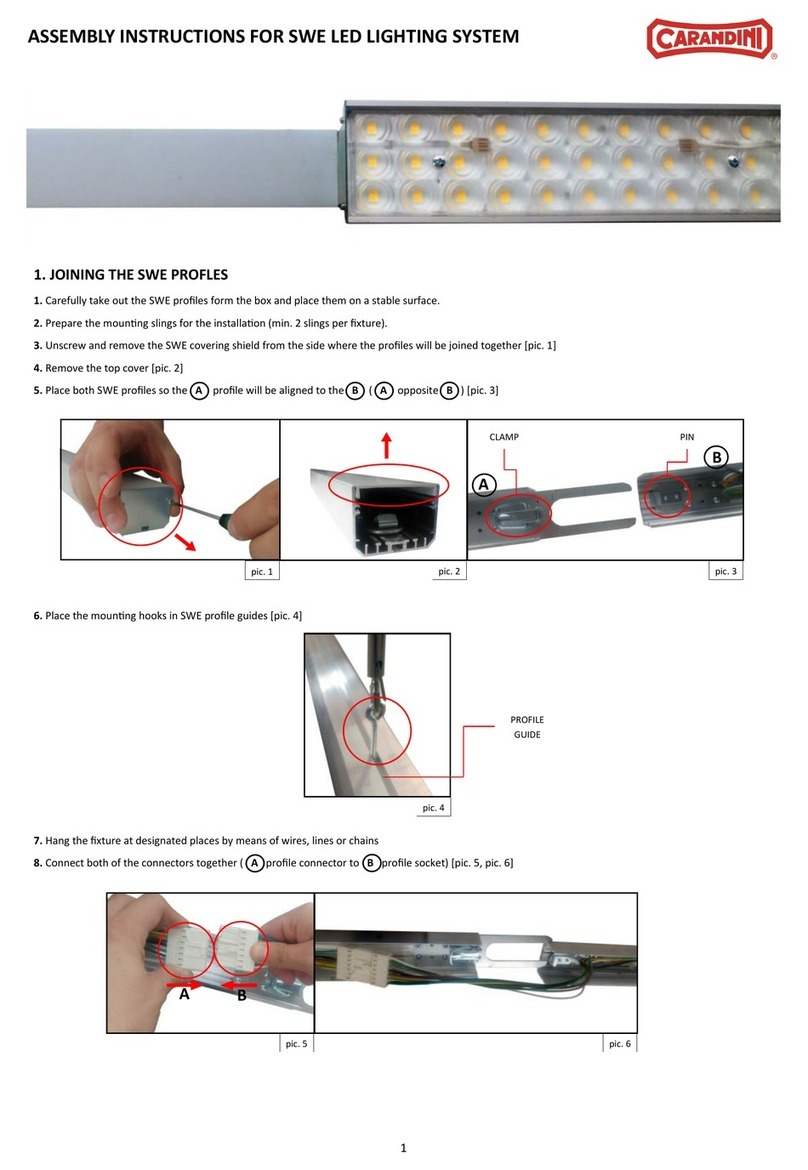

CARANDINI

CARANDINI SWE Assembly instructions

Photoflex

Photoflex LS2205 Assembling

Sunoptics

Sunoptics SVT2 installation guide

Vision & Control

Vision & Control LDLF60x240-W5K7/UDC Instructions for use