6 ► SRA User Manual

SAFETY

This Stanley machine has been designed and constructed

in conformance with current standards and directives. This

machine can constitute a danger to persons and property if:

• It is not used for the intended purpose

• It is not operated by trained personnel

• It is incorrectly modied or converted

• The safety requirements are not observed

For this reason, all persons concerned with operation,

maintenance and repair of the machine must read and follow

the safety requirements. This may have to be conrmed with

respect to the user company by signature.

The following also apply:

• The pertinent regulations for the prevention of accidents

• Generally recognised safety rules and road trafc regulations

• Country-specic requirements

Intended use

This machine is only intended for:

• The compaction of all types of surfaces

• Repairs to all types of surfaces

• Stabilisation of pavements and roads

• Working in trenches

• Underlling and compaction of verges

Improper use

The machine can constitute a hazard if used improperly by un-

trained persons or not for the intended purpose.

For example:

• Working in horizontal direction

• Pile driving

• Compaction of verges

Who is allowed to operate the machine?

Only trained, instructed and authorised persons over the age of

18 may operate the machine. The responsibilities must be clearly

dened and observed prior to operation of the machine.

In variance from this, minors can be employed, as long as it is

necessary to their training objective and their protection is as-

sured by a supervisor.

Persons who are under the inuence of alcohol, medicines or

drugs must not operate, maintain or repair the machine.

Maintenance and repairs, in particular of hydraulic systems and

electronic components require special knowledge and must be

carried out only by trained specialists (mechanics specialising in

construction and agricultural machinery).

Conversions and changes to the machine

Unauthorised changes to the machine are not permitted for safety

reasons.

Original parts and accessories have been specially designed for

the machine. It should be noted that parts and special equipment

not supplied by Stanley are not approved by Stanley . The instal-

lation and/or the use of such products can also affect the active

and/or passive safety.

The manufacturer disclaims all liability for any damage caused by

using non-original parts or special equipment.

Safety information contained in the operating and maintenance

instructions

The following terms and symbols are used in this operating

manual that draw attention to important information:

Refers to special information and/or orders and

prohibitions directed towards preventing damage

Refers to orders and prohibitions designed to

prevent injury or extensive damage.

Refers to special information on how to use the machine

most efciently.

Loading the machine

Always shut off the motor when loading and transporting. Secure

the machine to prevent it tilting or slipping.

A risk to life exists if persons walk or stand under suspended

loads. It should be noted that the machine may swing when sus-

pended. Secure the machine on transport vehicles to prevent it

rolling, slipping or tilting.

Starting the machine

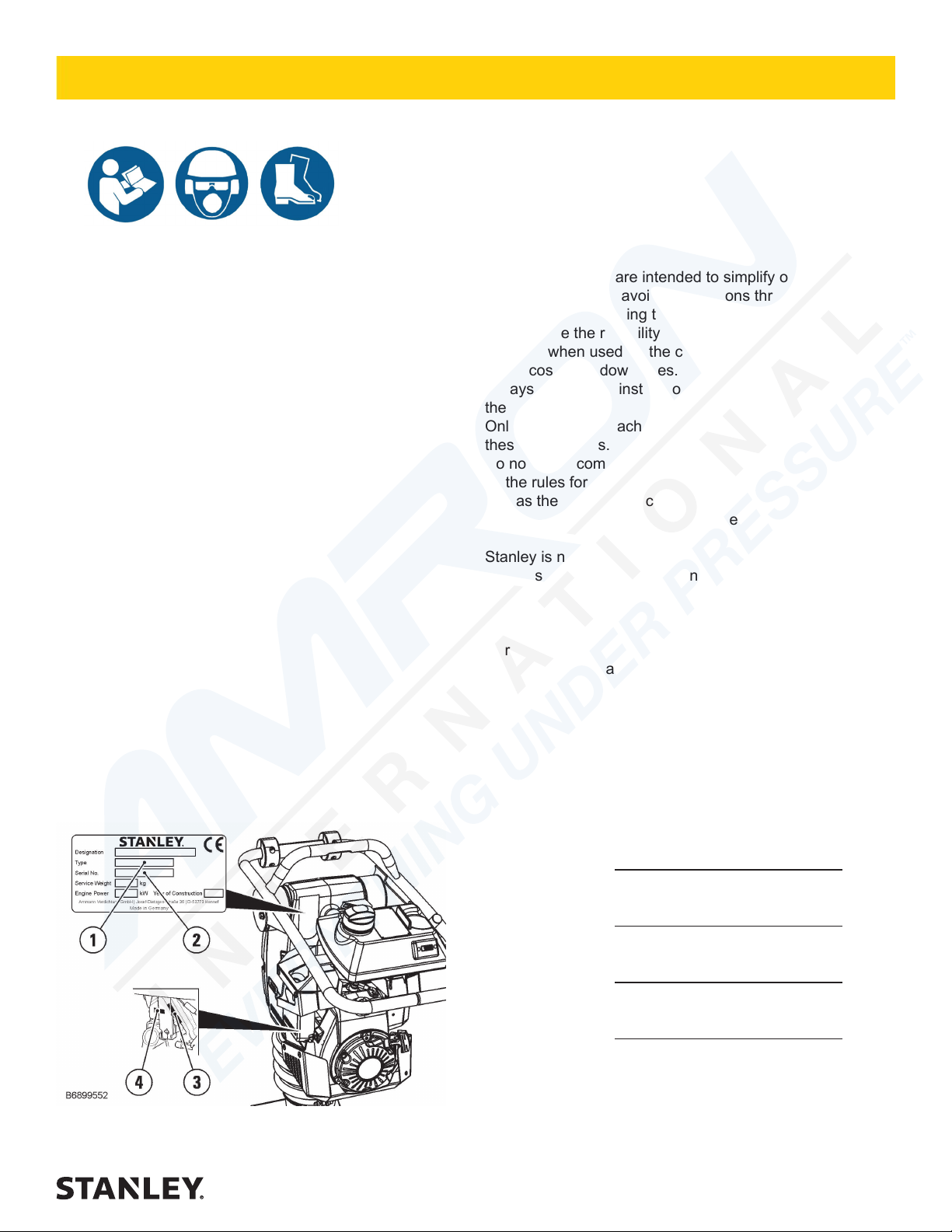

Before starting the machine

Familiarise yourself with the operating and control elements and

mode of operation of the machine and the working area.

Use personal protective equipment (protective helmet, safety

shoes, etc.) Use hearing protection.

Before starting the machine, check whether:

• The machine has any noticeable defects

• All protective devices are securely in place

• The control elements function

• The machine is free from oily and ignitable material

• All handles are free from grease, oils, fuels, dirt, snow and ice.

Only use machines that have been regularly maintained.

Starting in enclosed spaces, tunnels, mines or deep ditches

Engine exhaust gas are highly dangerous!

For this reason, when operating the machine in enclosed spaces,

tunnels, mines or deep ditches, it is important to ensure that there

is sufcient air to breath (see UVV «Construction work», BGV

C22, paragraphs 40 and 41).

Operation

Guide the machine so that hands do not come against xed ob-

jects; risk of injury.

Guide the machine so that the operator cannot be crushed be-

tween the machine and hard objects.

Listen for any abnormal noise and smoke. Locate the cause and

have the damaged repaired.

Do not hold the throttle below «MAX», as this can damage the

centrifugal clutch.

Never release the machine with the engine running. Keep feet

away from the tamping base plate.

Parking the machine

If possible, park the machine on a level, rm surface.

Before leaving the machine:

Secure the machine to prevent it tilting.

Attention

Danger

Important