MHP3 User Manual 5

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual

and on the stickers and tags attached to the machine.

These safety precautions are given for your safety. Re-

view them carefully before operating the machine and

before performing general maintenance or routine ser-

vice.

Supervising personnel should develop additional pre-

cautions relating to the specic work area and local

safety regulations. If so, place the added precautions in

the space provided in this manual.

If you have not read this manual or the engine manu-

al, you are not ready to operate the MHP3. Read and

understand this manual and any stickers and tags

attached to the machine before operation. Failure to

do so can result in equipment damage, personal in-

jury, or death.

• Operate the machine in a work area WITHOUT BY-

STANDERS. The operator must be familiar with all

prohibited work areas such as excessive slopes and

dangerous terrain conditions.

• DO NOT operate the machine ACROSS excessive

slopes or unstable terrain where “tip over” is a hazard.

• DO NOT operate the machine in conned areas

where there may be a risk of crushing the operator

between the machine and another object.

• DO NOT OPERATE THE TRACHORSE IN EN-

CLOSED SPACES. Inhalation of engine exhaust

can be fatal.

• DO NOT WEAR LOOSE CLOTHING that can get

entangled in the working parts of the machine or hy-

draulic tools.

• DO NOT add fuel to the machine while it is running

or still hot.

• DO NOT operate the machine if a fuel odor is pres-

ent.

• DO NOT operate the machine within 3.3 ft./1 m of

buildings, obstructions, or ammable objects.

• Allow the engine to cool before storing the machine

in an enclosure.

• DO NOT RIDE ON, OR ALLOW ANYONE ELSE TO

RIDE ON, THE MACHINE AT ANY TIME.

• Establish a training program for all operators to en-

sure safe operation.

• DO NOT operate the machine unless thoroughly

trained or under the supervision of an instructor.

• Always wear safety equipment such as goggles,

ear, head protection, respiratory and safety shoes

at all times when operating the TracHorse and hy-

draulic tools.

• DO NOT inspect or clean the machine while the en-

gine is running. Accidental engagement of the ma-

chine can cause serious injury or death.

• Wear a homologated respirator when cutting or

breaking masonry, concrete, asbestos and other

materials that produce dust.

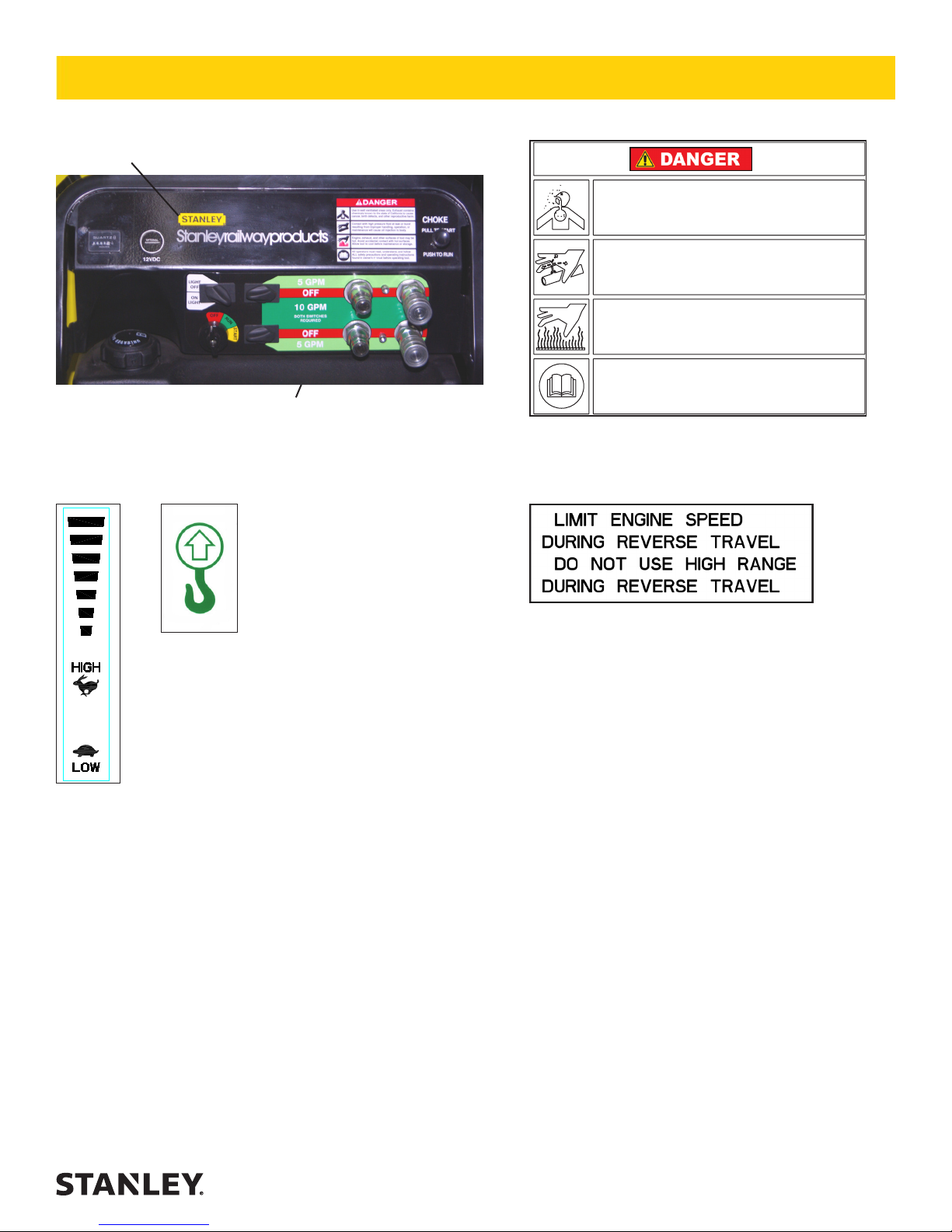

• The hydraulic circuit control switch must be in the

“OFF”position when coupling or uncoupling hydrau-

lic tools. Wipe all couplers clean before connecting.

Use only lint-free cloths. Failure to do so may result

in damage to the quick couplers and cause over-

heating of the hydraulic system.

• Before operating hydraulic tools, read and under-

stand the operation manual furnished with the tool.

• DO NOT operate a damaged, or improperly adjust-

ed, machine. DO NOT operate with guards removed.

• DO NOT weld or cut with an acetylene torch any

surface or component of the equipment. Consult

with the Stanley factory before performing any weld-

ing or acetylene cutting of the equipment.

• Prevent possible personal injury or equipment dam-

age by having all repair, maintenance and service

performed only by authorized and properly trained

personnel.

• DO NOT exceed the rated limits of the equipment

or use the equipment for applications beyond its de-

sign capacity.

• Always keep critical markings, such as labels and

warning stickers legible.

• Always replace parts with replacement parts recom-

mended by Stanley Hydraulic Tools.

• Keep all body parts away from working parts of the

TracHorse.

• Be aware of surrounding hazards. Noise created by

the TracHorse and the tools it operates may mask

early indications of approaching hazards.

• Only use the TracHorse in well-ventilated areas. DO

NOT operate in explosive atmospheres, in closed

environments or near ammable substances.

SAFETY PRECAUTIONS