Page SPS5.1 Manual10

4.0 Error Displays

Thermocouple burn-out is indicated by this display. This indicates that the

thermocouple has become open circuit. The

controller detects this condition while firing and

when in READY mode. The controller will lock up

in this condition with the heater power off. The only

way to reset the controller from this condition is to

turn off the power, clear the fault and then turn the power to the instrument back on.

To clear the fault the thermocouple and associated wiring should be tested for open

circuits. If the thermocouple is open circuit it will need to be replaced.

Heater failure or thermocouple short circuit is indicated by this display. The

instrument detects this condition only in RUN mode

when heating power has been applied continuously

for 15 minutes but the temperature has increased by

less than 2ºC. This indicates either that the wiring to

the thermocouple is short circuited or (more likely)

that one or more of the heater elements has failed and the heater is incapable of

reaching the required temperature. The only way to reset the controller from this

condition is to turn off the power, clear the fault and then turn the power to the

instrument back on.

The controller performs continuous checks of its circuitry and embedded software to

check for potential error conditions. If such an error is detected the control relay is

switched off and an error message is displayed for

one minute. After this period the controller resets

itself and restarts as if a power failure had occurred.

If the potential error has cleared the instrument will

proceed as normal. If the error condition persists the

instrument will repeat the error display cycle.

In the event of an error contact the supplier quoting the error number.

THERMOCOUPLE

OPEN CIRCUIT!

THERMOCOUPLE

SHORT CIRCUIT!

ERROR 7!

SPS5.1 Manual Page 3

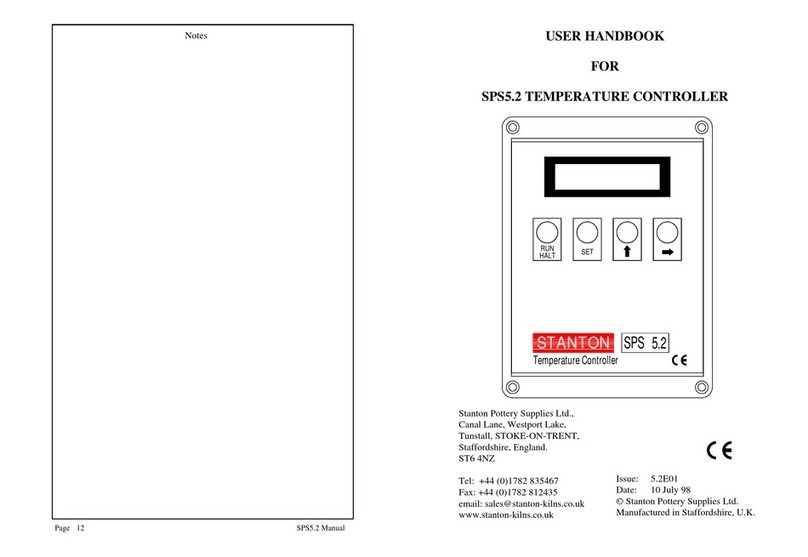

1.0 Features

• Simple to use

• Large clear illuminated alphabetic display

• 2 Temperature break points (0-1310°C)

• Ramp rate control (20-240°C/hour)

• Start delay (0-99hr 59min)

• User settings stored in non-volatile memory

• Intelligent power fail recovery

• Thermocouple failure detection

• Heater element failure detection

• R, K, N & S type thermocouple selection

2.0 Operating Instructions

2.1 Power On

When power is applied to the controller the display will illuminate & show the model number, version

number & the thermocouple type in use. READY will normally1be displayed. The heating power is off and

the controller is ready to accept keyboard commands.

1If the display does not show READY then the instrument is in RUN mode because the previous firing

sequence was interrupted by a power failure - the controller is now trying to complete this interrupted

firing sequence. To return to READY mode, if required, press the RUN/HALT key.

2.2 Instrument Capabilities

General

A typical firing sequence is illustrated below:-

Temperature ºC

ramp 1 rate

variable

ambient Delay

Time

t1

Ramp 1

soak temperature

energy=100%

Ramp 2 Cooling

Soak

time