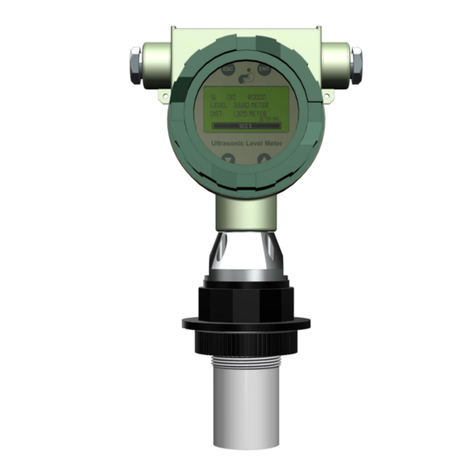

Star Meter CYW03 User manual

Installation instructions

CYW03 piezoresistive osmometer

Warning!

The osmometer must be installed by professional technical

personnel who have read and understood this operating

manual.

Warning!

It is prohibited to measure media that are incompatible

with the material in contact with the osmometer.

danger

This product is non explosion-proof and is strictly

prohibited from use in explosion-proof areas, as it may

cause serious personal injury and significant material

damage.

!

!

!

Installation precautions

ID

!No modifications or changes can be made on the device.

!Please handle it gently and not throw it casually.

Please do not use brute force when installing this

pressure gauge.

!This product belongs to weak current equipment and must

be laid separately from strong current cables during

wiring. It should comply with the relevant national wiring

standards (GB/T50312-2016) for wiring.

Ensure that the power supply voltage meets the power

supply requirements of the osmometer.

Prevent direct damage to sensors by chemical

reagents, oil, dust, etc. Do not use in extreme

temperature environments.

The pressure formula for the sensor facing the liquid

surface is: Ρ=ρ In the gh+Po equation:

P: The pressure exerted on the liquid surface of the

sensor (hereinafter collectively referred to as pressure

for ease of understanding)

ρ: The density of the measured liquid (defaults to 1g/cm

during debugging) ³)

g: Gravity acceleration (default during debugging is

9.8m/s ²)

Po: Atmospheric pressure above the liquid level

h: The depth of liquid input by the sensor

When the sensor is inserted into a certain depth of the

measured liquid, the pressure of the measured medium is

introduced into the positive pressure chamber of the

sensor. The atmospheric pressure Po on the liquid surface

is connected to the negative pressure chamber of the

sensor through a cable air duct to counteract the Po on

the front of the sensor, so that the pressure measured by

the sensor is: ρ Obviously, by measuring the pressure P,

the depth of the liquid level can be determined.

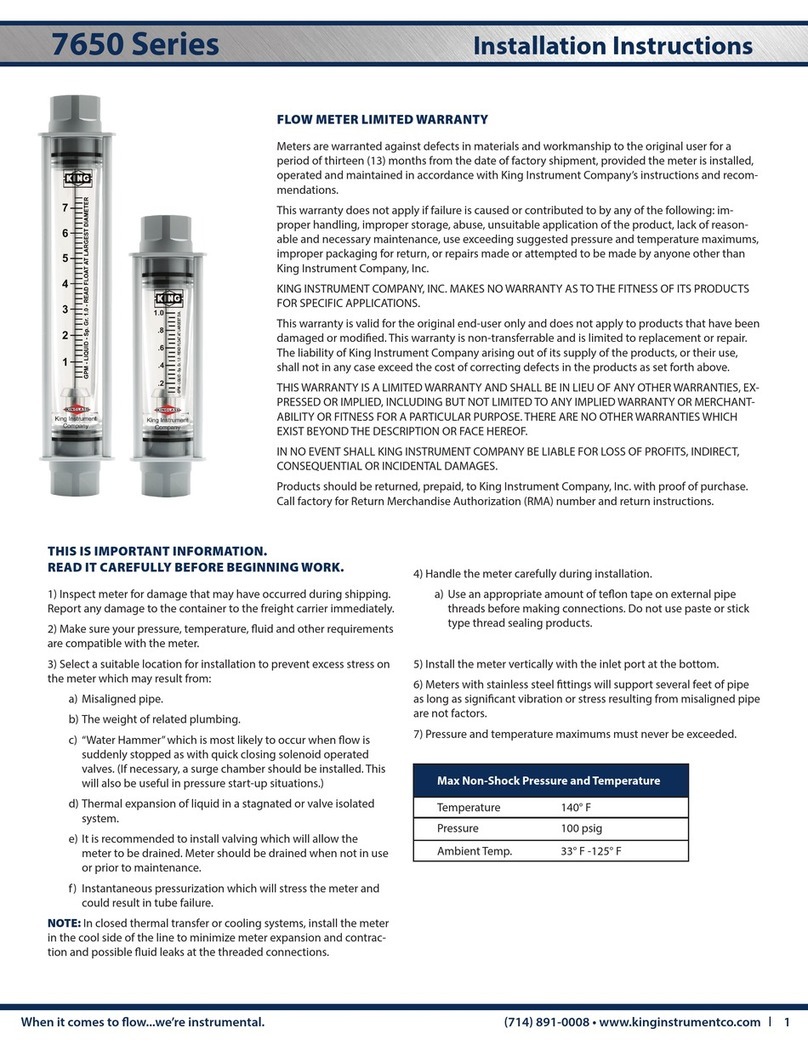

(1) According to the design, drill holes at the installation site of

the instrument, with a required aperture of 90-110mm, and drill holes

to 30cm below the instrument installation elevation.

(2) Clean the borehole and conduct a water injection (sensitivity) test

inside the borehole. When the permeability characteristics of the

borehole meet the requirements, start installing the instrument.

(3) When installing the instrument, first use clean medium to fine sand

at the bottom of the borehole and backfill it to 15 centimeters below

the end of the osmometer. Then, the osmometer can be placed. It is best

to package the osmometer in a sand bag and keep it clean. Soak the sand

with water and place it in position (marked on the cable). When the

instrument is in this position, clean medium to fine sand should be

placed around the osmometer. The sand can be placed 15 centimeters

above the osmometer, forming a "collection area".

(4) Once the "collection area" mentioned above is reached, the holes

need to be sealed. There are two methods available: one is to backfill

an alternating layer of about 25 centimeters with bentonite and an

appropriate amount of sand, and then backfill with ordinary soil (as

shown in Figure A), or backfill with a mixture of impermeable bentonite

and cement slurry (as shown in Figure B). If multiple osmometers are

installed in a single hole, bentonite and sand should be backfilled to

the lower part of the upper osmometer, and alternating at intervals of

the distance between each two osmometers.

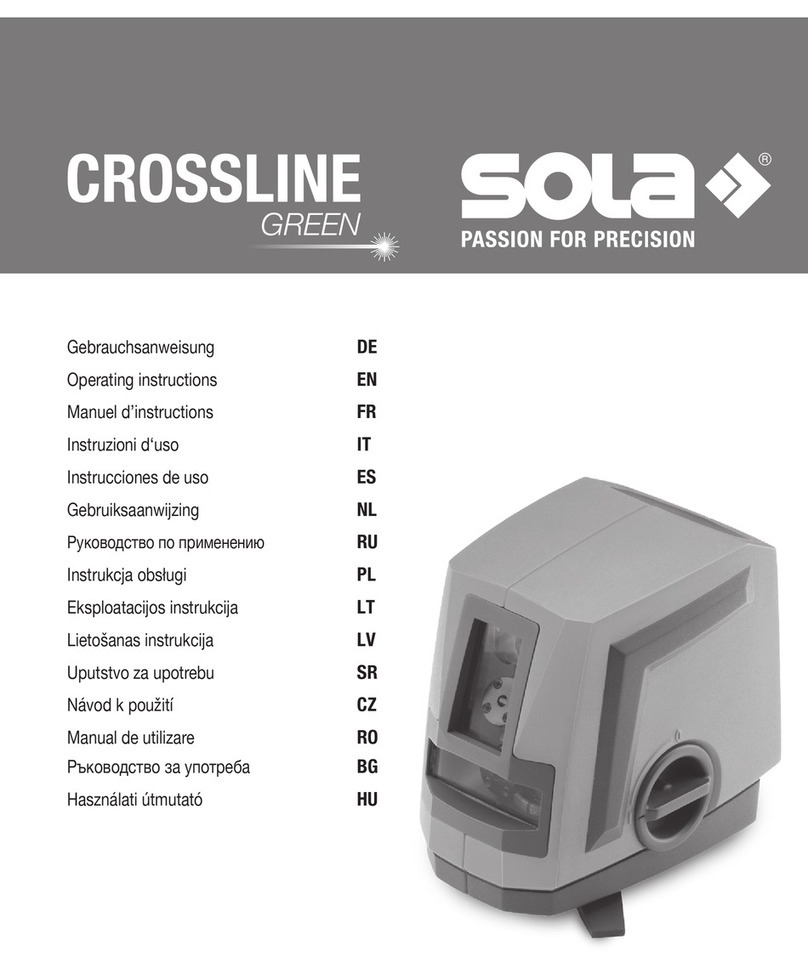

(1) Pour 15cm thick cement mortar into the bottom of the

borehole, and then place a pressure measuring pipe. The

pressure measuring tube adopts Φ 50mm PVC pipe; The

permeable section is 2m long, and the opening rate of the

water inlet area is 20%. The outer part is wrapped with

non-woven geotextile to prevent sediment from entering the

pipe, and the wrapping is firm and not loose;

(2) The inverted filter section is backfilled with inverted

filter material (medium fine sand) until it reaches 2m

above the inverted filter section, and then the upper part

is fully filled with cement mortar;

(3) Lower the instrument to the installation elevation.

(4) Cover and lock the orifice for protection

Various types of osmometers can be installed with a

single or multiple pipes, whether in a borehole with or

without a casing. If monitoring microporous pressure in a

special area, special attention should be paid to the

sealing of the borehole.

During installation, materials that quickly sink over

time should not be used. Our company uses polyethylene

cables, which are relatively wear-resistant and scratch

resistant. However, caution should also be exercised when

designing and using filling tools to avoid damaging the

cables of the osmometer.

Precautions for use

追求品质/贴心服务/终身维护

24小时服务热线:400-600-4496 执行标准JB∕T 12598-2016 www.star-sensor.com

第1/2页

版号23.02.27

本文档中列出的规格数据仅代表本文档出版时产品的工程状态,我们保留修改产品规格和材料的权利。

星仪传感器

Star MeterR

Warning!

Equipment installation must be carried out without power

supply.

If the osmometer is installed in a harsh environment

and may encounter dangerous damage such as lightning

strikes or overvoltage, we recommend that users provide

lightning protection and overvoltage protection between the

distribution box or power supply and the osmometer.

In addition to serving as power supply and signal

transmission, the gas conducting cable also plays a key role

in atmospheric compensation. During installation, avoid

locking the cable too tightly or bending the cable too

sharply to prevent the gas conducting pipe from being

blocked or broken.

The osmometer and wires should be kept away from places

with high voltage and severe electromagnetic interference,

and should be kept away from high-power interference

equipment as much as possible to avoid inaccurate

measurement, such as frequency converters, motors, etc.

Confirm whether the power supply voltage is correct,

and whether the positive and negative wiring of the power

supply corresponds to the positive and negative wiring of

the product; Avoid installing in easily bumped locations to

avoid damaging the product.

When installing an extension cable on site, please

ensure that the wiring section remains dry and ventilated.

It is strictly prohibited to soak or prevent moisture or

dirt from blocking the atmospheric connection pipe in the

center of the cable, otherwise it may cause damage to the

osmometer or inaccurate measurement.

Please avoid scratching the cable of the osmometer by

knives or other sharp metal objects, which may cause water

damage to the osmometer.

Users should not disassemble the film themselves or touch

it during use to avoid product damage.

!

Installation in drilling holes

Piezometric tube buried installation

cement mortar

osmometer

cement mortar

Instrument cable

drill

φ 50mm PVC pipe

Wrapped without textile

Conduit inlet section

Medium fine sand

Inversion section

Cover and lock for protection

Osmotometer cablegroundReading instrumentBentoniteOrdinary soilBentoniteMedium fine sandosmometerCatchment areaMedium fine sand

Osmotometer cablegroundReading instrumentBentoniteCement mixed slurryMedium fine sandosmometerCatchment areaInstall

(1) When the soil filling of the dam body exceeds the instrument

elevation by 0.5m, the filling shall be stopped. Measure and set out

the position of the instrument, manually excavate the length with the

instrument point as the center × wide × 1m deep × 0.8m × A pit of

0.5m.

(2) When burying instruments, lay a layer of 10cm medium fine sand at

the bottom of the pit and water it to saturate it. Then, place the

prepared instrument in a sand bag on a sand cushion, wrap the

instrument cable around it and lead it out. Then, lay a layer of

10-15cm medium fine sand on the instrument, water it to saturate the

sand, and then backfill it with small gravel and manually compact it

layer by layer.

(3) When manual compaction causes the buried depth of the instrument to

exceed 1.2m, mechanical compaction is allowed. So the upper layer of

manual backfilling at each instrument burial position should be ensured

to be 1.2m, and manual compaction should be arranged according to the

thickness of the dam filling layer to ensure the safety of the

instruments. See the figure below.

Burial and installation during the filling process

Manual compactionMechanical rolling surfaceExcavation after rollingPervious stoneosmometersandOutgoing cablediagram A diagram B

Summary

Safety guidance

These installation instructions contain important information on how to

use the transmitter correctly. The transmitter installer shall

carefully read the installation instructions before operating the

transmitter. In case of further understanding or special problems,

which are not described in detail in this operation manual, please

contact our company to obtain necessary information.

Please pay attention to the warning signs on the instructions!

Operators must strictly follow the safety instructions in the

installation instructions. In addition, occupational safety rules,

accident prevention guidelines, national installation standards and

engineering specifications must be observed.

Please keep this instruction properly and store it in a convenient

place near the transmitter.

The copyright of these installation instructions is protected. The

installation instructions of this version are written according to the

functions that can be realized by the corresponding product during

printing, and describe the product functions and operation steps as

detailed and complete as possible. If you find mistakes, you are

welcome to criticize and correct them. The company is not responsible

for the possible wrong description and possible consequences.

– reserve the right to modify the technical parameters –

Icon description

Danger! – A dangerous situation that could result in death or

serious injury.

Warning! – A potentially hazardous situation that could result in

death or serious injury.

Be careful! – A potentially hazardous situation that may result

in minor injury.

Reminder! – A potentially hazardous situation that may cause

personal injury.

Tips! – Tips and information to ensure trouble free operation of

the equipment.

User

Warning! These installation instructions are for technicians.

Limitation of liability

If the transmitter is damaged due to non-compliance with the operation

and installation instructions, improper use, self modification and

destruction, the company will not be liable for compensation and will

not provide warranty service.

!

!

!

!

!

a) After unpacking, check whether the documents and accessor ies are

complete according to the packing list.

Packing documents: one copy of operation manual.

One product certificate.

A warranty card.

b) When receiving the product, please check whether the package

is intact, and check whether the transmitter model and specification

are consistent with the product you choose.

c) Observe whether the transmitter is damaged due to

transportation for proper treatment.

d) The user is expected to keep the "warranty card" properly

and do not lose it, otherwise it cannot be returned to the factory

for free maintenance!

Unpack

model

range

output

power supply

Accuracy

protect

Product number

Product certification

Wiring

definition

Liquid level osmometer

星仪

model:

:

:

:

Tel:400-600-4496

Accuracy:

protect:

Warning!

a) Before use, users must check whether the osmometer

is installed correctly and whether there is obvious

damage.

Warning!

b) This osmometer is only suitable for working

conditions that meet technical requirements!

Wiring diagram

追求品质/贴心服务/终身维护

24小时服务热线:400-600-4496 执行标准JB∕T 12598-2016 www.star-sensor.com

第2/2页

版号23.02.27

本文档中列出的规格数据仅代表本文档出版时产品的工程状态,我们保留修改产品规格和材料的权利。

EMC Declaration

Applicable Directive: Electromagnetic Compatibility Equipment

Directive 2014/35/EU.

The CE marking indicates that the product meets the

requirements of applicable EU standards.

Users must ensure that the entire device meets all usage

standards.

first start-up

!

!

If the fault phenomenon does not fall within the above scope,

please contact our company's after-sales service,400-600-4496

Common fault analysis and troubleshooting

The product has been tested by our factory's technical personnel

during the warranty period as a quality issue, and our company will

bear all repair costs;

!

Disassembly and after-sales service

Warning!

Please make sure to clean up any residual media,

especially substances harmful to personal health, such as

corrosive, toxic, carcinogenic, or radioactive substances,

before returning them;

Please keep the warranty card and certificate of

conformity, and return them with the product during

maintenance;

If the osmometer malfunctions, please contact our company's

after-sales service to confirm the problem and send the

osmometer back to our company. Please include the following

information when repairing:

Description of the on-site environment;

Fault phenomenon;

Shipping address and contact information.

Alignment

During the service life of the osmometer, zero and full

range drift may occur.

If the above phenomenon occurs after long-term use, it is

recommended to send the osmometer back to our company for

calibration to ensure high accuracy.

Transportation and Storage

Maintenance and cleaning

The osmometer should be packed in a sturdy cardboard box

(large instruments require wooden boxes), and it is not

allowed to move freely inside the box. It should be

handled with care and rough handling is not allowed. The

storage location should meet the following conditions:

a) Rainproof and moisture-proof.

b) Not subject to mechanical vibration or impact.

c) The temperature range is -30~70 ℃.

d) The relative humidity shall not exceed 90% (non condensing).

e) The environment does not contain corrosive gases.

This osmometer does not require customer maintenance.

Maintenance can only be carried out by the manufacturer.

maintenance

星仪传感器

Star MeterR

Current output wiring diagram (two wire system)

Osmometer

Blue line (V -)

Red line (V+)

collecting device

Power supply (VDC)

Pressure input

U

+-

A

RS485 (Digital Signal) Output Wiring Diagram (Four wire System)

Osmometer Red line (V+)

Blue line (V -)

Yellow line (A)

White line (B)

PC

U

+-

Pressure input

collecting device

Power supply (VDC)

Represents a shielded wire, and all marked grounding

points must be effectively grounded.

If an extension cable needs to be installed, please

ensure that the wiring section remains dry and ventilated.

Fault phenomenon

·The osmometer has

no output signal

·Output irregular jump

at constant liquid level

·When the osmometer does

not sense the liquid level,

the corresponding output

value is incorrect

·The output of the

osmometer does not match

the measured liquid level

·Incorrect power supply

voltage

·Excessive external load

·Is it within the power

supply range

·Adjusting external loads

·The osmometer is not

operating in its

required environment

·Move the osmometer to the specified

environment for operation or take

measures to ensure that the

environment meets the requirements

·Strong on-site radio

frequency interference

·Unused shielded cable

·Using shielded cables

and grounding the

shielding layer

·The osmometer is

not powered

·Wiring error

·Correctly supply power

to the osmometer according

to the wiring diagram

cause analysis Troubleshooting

星仪传感器制造有限公司

Star sensor manufacturing Co., Ltd

Tel:400-600-4496

www.star sensor.com

厂址:燕郊经济开发区 天山国际创业基地 20号

Star MeterR

更多资料请扫码

前往官网获取

Extension cable installation

-Installation method of waterproof and breathable junction box

It can effectively prevent moisture or water from entering

the product cavity through the air duct or shielding layer

The situation that caused damage to the osmometer.

Note: The waterproof junction box needs to be purchased

separately.

Using this wiring method can avoid vertical rainwater

intrusion, but it is important to note that the terminal

is ventilated and dry, and the air duct needs to extend

downwards to be connected to the external atmosphere.

-N-shaped wiring installation method

If the on-site wiring distance is too long and an extension

cable needs to be installed, it is recommended to use the

following two methods for extension.

Waterproof and breathable

junction box

osmometer

Extension cable

Air conducting cable

Trachea

Connection points

Extension cable

osmometer

Air conducting cable