Datakom DKM-430 User manual

DKM-430 User Manual Rev_02 Firmware V-1.8

DKM-430

MULTIPLE NETWORK

ANALYSER

DATAKOM DKM-430 is a precision instrument

allowing the measurement, recording and remote

monitoring of 10 3-phased or 30 single-phased feeders

(or any combination of these two). The number and

flexibility of current inputs allow the unit to be used in a

variety of applications like power distribution network

monitoring, ISO50001 energy efficiency or home and

factory automation.

The unit can be mounted on a DIN rail or backplane. It

can be easily adapted to existing panels.

Current inputs of the unit are designed for 0.1A output

current transformers (CTs). Different 0.1A rated CTs

are available at Datakom for sales.

Each CT can be assigned to any phase voltage and

any virtual analyzer. Inputs can be moved between

analyzers without modifying connections.

Independently adjustable current limits for each phase

provide pre-alarms and help to reduce energy failures.

All measurement values and program parameters may

be displayed on the graphic LCD screen.

The unit logs all fault conditions together with date and

time information. The internal real time clock is capable

of running 10 years without energy.

The astronomical relay function calculates sunrise and

sunset times precisely for daylight based applications.

Any fault or warning signal can be connected to digital

inputs of the unit. Input functions are selected from list.

Any function can be assigned to relay outputs of the

unit. Relays may be remotely operated through the

central monitoring program.

The isolated RS-485 MODBUS RTU data port is

unaffected by ground potential differences and allows

safe transmission of information to monitoring and

automation systems.

The optional internal GPRS modem allows remote

monitoring and control of the distribution panel without

the use of any additional module.

Parameter setting of the unit is made either manually or

through the USB port using the free PC program.

The unit records electrical parameters in its 1MB

internal memory with programmed period. Records are

read through Modbus.

Equivalent to 10 3-phase analyzers

True RMS measurements

0.5% measurement precision

Internal record memory: 1MB

Internal battery backed-up real time clock

Astronomical relay function

Isolated RS-485 serial port

MODBUS-RTU communication

Internal GPRS modem (optional)

2 programmable relay outputs

2 optically isolated programmable inputs

Active-reactive energy counters

USB port for programming

Free programming software

Graphic LCD, 128x64 pixels

Wide supply range:85-305VAC / 88-450VDC

DC supply version available

Wide operating temperature range

VOLTAGE INPUTS:

▪P-N and P-P voltages: V1-V2-V3-U12-U23-U31

▪Harmonics: Voltage inputs, 2-17 harmonics

EACH CT INPUT:

▪Current: In

▪Active/reactive/apparent powers: Pn-Qn-Sn

▪Power factor: COSn

▪Current harmonics 2-17

EACH VIRTUAL ANALYSER:

▪Total active/reactive/apparent power: ∑P-∑Q-∑S

▪Total power factor: ∑cos

▪Active and reactive counters: Pn-Qn

FEATURES

MEASUREMENTS

DESCRIPTION

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 2 -

Any unauthorized use or copying of the contents or any part of this document is prohibited.

This document describes minimum requirements and necessary steps for the successful installation of the

DKM-430 family units.

Follow carefully advices given in the document. These are often good practices for the installation which

reduce future issues.

For all technical queries please contact Datakom at below e-mail address:

If additional information to this manual is required, please contact the manufacturer directly at below e-mail

address: datakom@datakom.com.tr

Please provide following information in order to get answers to any question:

- Device model name (see the back panel of the unit),

- Complete serial number (see the back panel of the unit),

- Firmware version (read from the display screen),

- Measuring-circuit voltage and power supply voltage,

- Precise description of the query.

FILENAME

DESCRIPTION

500-Rainbow Installation

Rainbow Plus D-500 D-700 Installation Guide

500-Rainbow Usage

Rainbow Plus D-500 D-700 Usage Guide

500-Rainbow Scada Installation

Rainbow Scada Installation Guide

500-Rainbow Scada Usage

Rainbow Scada Usage Guide

QUERRIES

RELATED DOCUMENTS

ABOUT THIS DOCUMENT

COPYRIGHT NOTICE

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 3 -

REVISION

DATE

AUTHOR

DESCRIPTION

01

15.06.2015

MH

First edition

02

15.02.2017

ME

Modbus addresses updated

CAUTION: Potential risk of injury or death.

WARNING: Potential risk of malfunction or material damage.

ATTENTION: Useful hints for the understanding of device operation.

The D-500 family units are available in various options and peripheral features. Please use below information

for ordering the correct version:

DKM-430

-M

-T

-00

REVISION HISTORY

TERMINOLOGY

ORDERING CODES

Family Code

With Internal

GSM-GPRS

Modem

With Conformal

Coating

Variant

00: standard unit

01...99: customer

specific products

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 4 -

▪Electrical equipment should be installed only by qualified

specialist. No responsibility is assured by the manufacturer or

any of its subsidiaries for any consequences resulting from the

non-compliance to these instructions.

▪Check the unit for cracks and damages due to transportation. Do

not install damaged equipment.

▪Do not open the unit. There are no serviceable parts inside.

▪Fuses must be connected to the power supply and phase voltage

inputs, in close proximity of the unit.

▪Fuses must be of fast type (FF) with a maximum rating of 6A.

▪Disconnect all power before working on equipment.

▪When the unit is connected to the network do not touch

terminals.

▪Short circuit terminals of unused current transformers.

▪Any electrical parameter applied to the device must be in the

range specified in the user manual. Although the unit is designed

with a wide safety margin, over-range parameters may reduce

lifetime, alter operational precision or even damage the unit.

▪Do not try to clean the device with solvent or the like. Only clean

with a dump cloth.

▪Verify correct terminal connections before applying power.

▪Only for panel base mounting.

SAFETY NOTICE

Failure to follow below instructions

will result in death or serious injury

Current measurement is made with CTs provided together

with the module.

Do not apply direct connection, do not use 1A/5A current

transformers.

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 5 -

1. INSTALLATION INSTRUCTIONS

2. MOUNTING

2.1 DIMENSIONS

2.3 ELECTRICAL INSTALLATION

3. TERMINAL DESCRIPTIONS

3.1. BATTERY VOLTAGE INPUT

3.2. AC VOLTAGE INPUTS

3.3. AC CURRENT INPUTS

3.4. DIGITAL INPUTS

3.5. RELAY OUTPUTS

3.6. RS-485 PORT

3.7. USB DEVICE PORT

3.8. GSM MODEM (OPTIONAL)

4. CONNECTION DIAGRAM

5. TECHNICAL SPECIFICATIONS

6. DESCRIPTION OF CONTROLS

6.1. FRONT PANEL FUNCTIONALITY

6.2. PUSHBUTTON FUNCTIONS

6.3. LED FUNCTIONS

6.4. SCREEN SCROLLING

7. WAVEFORM DISPLAY & HARMONIC ANALYSIS

8. ASTRONOMIC RELAY FUNCTIONALITY

9. PROTECTIONS AND ALARMS

10. PROGRAMMING

10.1. ENTERING THE PROGRAMMING MODE

10.2. NAVIGATING BETWEEN MENUS

10.3. MODIFYING PARAMETER VALUE

10.4. PROGRAMMING MODE EXIT

TABLE OF CONTENTS

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 6 -

11. PROGRAM PARAMETER LIST

11.1. CONTROLLER CONFIGURATION GROUP

11.2. ELECTRICAL PARAMETERS GROUP

11.3. CHANNEL CONFIGURATION

11.4. GSM MODEM PARAMETERS

11.5. DIGITAL INPUT PARAMETERS

11.6. DIGITAL OUTPUT PARAMETERS

11.7. USER INPUT SCREENS

11.8. DEMAND AND COUNTERS

11.9. USER SCREENS

11.10. DEVICE CALIBRATION

11.11. ADJUST DATE AND TIME

11.12. CHANGE PASSWORD

11.13. RETURN TO FACTORY SETTINGS

11.14. LOCATION SETUP

12. INTERNAL RECORD MEMORY

13. CENTRAL MONITORING OF UNITS

14. E-MAIL SENDING

15. SMS COMMANDS

16. MODBUS COMMUNICATIONS

16.1. PARAMETERS REQUIRED FOR RS-485 MODBUS OPERATION

16.2. DATA FORMATS

16.3. EXCHANGE BUFFER

16.4. DATE-TIME AND LOCATION ARRAY

16.5. COUNTERS ARRAY

16.6. COMMANDS ARRAY

16.7. MEASUREMENTS ARRAY

16.8. ANALYZER BLOCKS

16.9. DIGITAL INPUTS AND OUTPUTS

16.10. HARMONIC ANALYSIS

16.11. OSCILLOGRAPHIC RECORDS

16.12. DEVICE INFORMATION

16.13. ALARM INFORMATION

17. DECLARATION OF CONFORMITY

18. MAINTENANCE

19. DISPOSAL OF THE UNIT

20. ROHS COMPLIANCE

21. TROUBLESHOOTING GUIDE

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 7 -

Before installation:

▪Read the user manual carefully, determine the correct connection diagram.

▪Install to the panel base or DIN rail. In order to install to panel base, pull mounting tabs at corners.

▪Make electrical connections with plugs removed from sockets, then place plugs to their sockets.

▪Be sure that adequate cooling is provided.

▪Be sure that the temperature of the environment will not exceed the maximum operating temperature in any

case.

▪Be sure that the unit is not subject to water spill.

Below conditions may damage the device:

▪Incorrect connections.

▪Incorrect power supply voltage.

▪Voltage at measuring terminals beyond specified range.

▪Voltage applied to digital inputs over specified range.

▪Current at measuring terminals beyond specified range.

▪Overload or short circuit at relay outputs

▪Connecting or removing data terminals when the unit is powered-up.

▪High voltage applied to communication ports.

▪Ground potential differences at non-isolated communication ports.

▪Excessive vibration, direct installation on vibrating parts.

Below conditions may cause abnormal operation:

▪Power supply voltage below minimum acceptable level.

▪Power supply frequency out of specified limits

▪Phase order of voltage inputs not correct.

▪Current transformers not matching related phases.

▪Current transformer polarity incorrect.

▪Missing grounding.

Current measurement is made with CTs provided together

with the module.

Do not apply direct connection, do not use 1A/5A current

transformers.

1. INSTALLATION INSTRUCTIONS

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 8 -

Dimensions: 158x90x60mm (6.22”x3.55”x2.36”)

Installation: Panel base or DIN rail

Weight: 350g (0.77 lb)

Although the unit is protected against electromagnetic disturbance, excessive disturbance

can affect the operation, measurement precision and data communication quality.

▪ALWAYS remove plug connectors when inserting wires with a screwdriver.

▪Fuses must be connected to the power supply and phase voltage inputs, in close

proximity of the unit.

▪Fuses must be of fast type (FF) with a maximum rating of 6A.

▪Use cables of appropriate temperature range.

▪Use adequate cable section, at least 0.75mm2 (AWG18).

▪Follow national rules for electrical installation.

▪Current transformers must have 0.1A output.

2.1. DIMENSIONS

Current measurement is made with CTs provided together with

the module.

Do not apply direct connection, do not use 1A/5A current

transformers.

Do not install the unit close to high electromagnetic

noise emitting devices like contactors, high current

busbars, switchmode power supplies and the like.

2.2. ELECTRICAL INSTALLATION

2. MOUNTING

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 9 -

Supply voltage:

AC SUPPLY VERSIONS: 85-305VAC, 45-65Hz, 88-450VDC

DC SUPPLY VERSIONS: 19-150VDC

Reverse voltage:

Non polarized inputs, works in both polarizations.

Maximum input power:

6W

Typical operating current:

250mA @ 12VDC. (all options passive, digital outputs open)

125mA @ 24VDC. (all options passive, digital outputs open)

Maximum operating

current:

30mA @ 230VAC. (all features active, digital outputs open)

60mA @ 110VDC. (all features active, digital outputs open)

Measurement method:

True RMS

Sampling rate:

2048 Hz

Harmonic analysis:

up to 17th harmonic

Input voltage range:

5 to 300 VAC (phase-neutral)

Measurement range:

0 to 330VAC ph-N (0 to 570VAC ph-ph)

Input impedance:

4.5M-ohms

Display resolution:

0.1VDC

Accuracy:

0.5% + 1 digit @ 230VAC ph-N (±2VAC ph-N)

0.5% + 1 digit @ 400VAC ph-ph (±3VAC ph-ph)

Frequency range:

45 to 65 Hz

Frequency display

resolution:

0.01 Hz

Frequency accuracy:

0.2% + 1 digit (±0.1 Hz @ 50Hz)

3.1. BATTERY VOLTAGE INPUT

3. TERMINAL DESCRIPTIONS

3.2. AC VOLTAGE INPUTS

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 10 -

Measurement method:

True RMS

Sampling rate:

2048 Hz

Harmonic analysis:

up to 17th harmonic

CT secondary rating:

100mA

Measurement range:

5/0.1 to 5000/0.1A minimum

Input impedance:

1 ohm

Burden:

10 mW

Maximum continuous

current:

500mA

Measurement range:

0.5 to 120mAA

Display resolution:

0.1A

Accuracy:

0.5% + 1 digit @ 100mA

SELECTING THE CT ACCURACY CLASS:

The CT accuracy class should be selected in accordance with the required measurement precision. The

accuracy class of the Datakom controller is 0.5%. Thus 0.5% class CTs are advised for the best result.

3.3. AC CURRENT INPUTS

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 11 -

CONNECTING CTs:

Be sure of connecting each CT to the related phase input with the correct polarity. Mixing CTs between

phases will cause faulty power and pf readings.

Many combinations of incorrect CTs connections are possible, so check both order of CTs and their polarity.

Reactive power measurement is affected by incorrect CTs connection in similar way as active power

measurement.

CORRECT CT CONNECTIONS

Let’s suppose that the network is loaded with 100 kW on each phase. The load Power Factor (PF) is 1.

Measured values are as follows:

kW

kVAr

kVA

pf

Phase L1

100.0

0.0

100

1.00

Phase L2

100.0

0.0

100

1.00

Phase L3

100.0

0.0

100

1.00

Total

300.0

0.0

300

1.00

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 12 -

EFFECT OF POLARITY REVERSAL

The network is still loaded with 100 kW On each phase. The load Power Factor (PF) is 1.

PF in phase L2 will show -1,00 due to reverse CT polarity. The result is that total network power displayed by

the controller is 100 kW.

Measured values are as follows:

kW

kVAr

kVA

pf

Phase L1

100.0

0.0

100

1.00

Phase L2

-100.0

0.0

100

-1.00

Phase L3

100.0

0.0

100

1.00

Total

100.0

0.0

300

0.33

EFFECT OF PHASE SWAPPING

The network is still loaded with 100 kW on each phase. The load Power Factor (PF) is 1.

PF in phases L2 and L3 will show -0,50 due to phase shift between voltages and currents which is caused by

CT swapping. The result is that total network power displayed by controller is 0 kW.

Measured values are as follows:

kW

kVAr

kVA

pf

Phase L1

100.0

0.0

100

1.00

Phase L2

-50.0

86.6

100

-0.50

Phase L3

-50.0

-86.6

100

-0.50

Total

0.0

0.0

300

0.0

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 13 -

Number of inputs:

2 inputs, all configurable

Input type:

Opto-isolated digital input

Function selection:

from list

Contact type:

Normally open or normally closed (programmable)

Minimum pulse duration:

250ms

Active level:

85-305VAC

Isolation:

1000VAC, 1 minute

Noise filtering:

yes

Structure:

Relay output, normally open contact. One terminal is internally

connected to the common terminal for both relays.

Max switching current:

5A @250VAC

Max switching voltage:

250VAC

Max switching power:

1250VA

Structure:

RS-485, isolated.

Connection:

3 wires (A-B-GND). Half duplex.

Baud rate:

2400-115200 bauds, selectable

Data type:

8 bit data, no parity, 1 bit stop

Termination:

External 120 ohms required

Common mode voltage:

-0.5 VDC to +7VDC, internally clamped by transient suppressors.

Max distance:

1200m @ 9600 bauds (with 120 ohms balanced cable)

200m @ 115200 bauds (with 120 ohms balanced cable)

Isolation:

1000VAC, 1 minute

The RS-485 port features MODBUS-RTU protocol. Multiple modules (up to 128) can be paralleled on the

same RS-485 bus for data transfer to automation or building management systems.

The RS-485 port provides also a good solution for distant PC connection where RainbowPlus program will

enable programming, control and monitoring.

3.5. RELAY OUTPUTS

3.6. RS-485 PORT

3.4. DIGITAL INPUTS

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 14 -

Description:

USB 2.0, not isolated, HID mode

Data rate:

Full Speed 1.5/12 Mbits/s, auto detecting

Connector:

USB-B (printer connector)

Cable length:

Max 6m

Functionality:

Modbus, FAT32 for firmware upgrade (boot loader mode only)

The USB-Device port is designed to connect the module to a PC. Using the RainbowPlus software,

programming, control of the genset and monitoring of measured parameters are achieved.

The RainbowPlus software can be downloaded from www.datakom.com.tr website.

The connector on the module is of USB-B type. Thus A to B type USB cable should be used. This is the

same cable used for USB printers.

For more details about programming, control and monitoring please refer to RainbowPlus user manual.

If USB connector provides also power supply to the

unit. During computer connection additional supply

is not required.

3.7. USB PORT

USB

Connector

USB A to B

Cable

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 15 -

The optional internal GSM modem offers the advantage of being internally powered and is fully compatible

with the unit. It does not require any special setup.

The 1800/1900 MHz magnetic antenna together with its 2 meter cable is supplied with the internal modem

option. The antenna is intended to be placed outside of the genset panel for the best signal reception.

The module requires a GPRS enabled SIM card for full functionality. Voice-only type SIM cards will usually

not function properly.

Please refer to GSM Modem Configuration Guide for more details.

Description:

Quad-band GSM/GPRS 850/900/1800/1900MHz module.

GPRS multi-slot class 12/10

GPRS mobile station class B

Compliant to GSM phase 2/2+.

–Class 4 (2 W @850/ 900 MHz)

–Class 1 (1 W @ 1800/1900MHz)

Functionality:

Web Client, SMTP, Modbus TCP/IP (client), SMS, e-mail

Operating temp range:

-40°C to +85 °C

Data speed:

max. 85.6 kbps (download), 85.6 kbps (upload)

SIM card type:

external SIM 3V/1.8V, GPRS enabled

Antenna:

Quad band, magnetic, with 2m cable

Module certificates:

CE, FCC, ROHS, GCF, REACH

3.8. GSM MODEM (OPTIONAL)

SIM Card slot

SIM Card extraction tab

Antenna connector

Communication

indicator

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 16 -

4. CONNECTION DIAGRAM

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 17 -

Supply Input:

85 - 305VAC, 50/60Hz,

88 - 450VDC

Optional 19-150VDC

Measurement Inputs:

Voltage: 7 - 300 V AC (P-N)

14 - 520 V AC (P-P)

Current: 0.001 –0.12 A AC

Frequency: 45 - 65 Hz

Accuracy:

Voltage: 0.5% + 1 digit

Current: 0.5% + 1 digit

Frequency: 0.5% + 1 digit

Power (kW,kVAr): 1.0% + 2 digit

Cos: 0.5% + 1 digit

Measurement Range:

CT range: 5A to 6500A

VT range: 1.0/1 to 5000.0/1

kW range: 1.0 kW to 5000 MW

Power Consumption: < 6 VA

Loading:

Voltage Input: < 0.02VA per phase

Current Input: < 0.02VA per phase

Relay Outputs: 5A @ 250V AC

Digital Inputs:

Active level: 85 –305VAC

Min pulse: 250ms.

Isolation: 1000V AC, 1 minute

Serial Port:

Signal type: RS-485

Protocol: Modbus RTU

Data Rate: 2400-115200b adjustable

İsolation: 1000V AC, 1 minute

Operating Temp. Range: -20°C to +70 °C (-4°F to 158°F)

Max Relative Humidity: 95%, non-condensing

Case Material: Flame retardant, ROHS compliant, high temp. ABS/PC (UL94-V0)

Installation: DIN rail or backpanel

Dimensions: 158x90x60mm (WxHxD)

Weight: 350 gr

AB Directives:

2006/95/EC (LVD)

2004/108/EC (EMC)

Reference Standards:

EN 61010 (safety)

EN 61326 (EMC)

5. TECHNICAL SPECIFICATIONS

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 18 -

BUTTON

FUNCTION

Selects previous display screen in the same display group.

Selects previous display group.

Selects next display group.

Selects next display screen in the same display group.

When held pressed for 5 seconds, enters PROGRAMMING mode.

6.2. PUSHBUTTON FUNCTIONS

6.1. FRONT PANEL FUNCTIONALITY

6. DESCRIPTION OF CONTROLS

Energy and

communication

indicators

Graphic LCD

screen

Next screen in

the same group.

Previous

display group

Next display

group

Previous

screen in the

same group.

Fault condition

indicators

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 19 -

POWER: Turns on as long as energy is supplied to the unit.

COMM: Flashes when the RS-485 Modbus communication is active.

ALARM: Turns on in case of high level alarm (trip condition).

UYARI: Turns on in case of warning.

The unit performs a detailed set of AC measurements. Displaying these parameters are organized under

PARAMETER GROUPS and subgroups.

Switching between parameter groups are made with and buttons.

Each depression of the button switches the screen to the next parameter group. After the last group, the

first group is displayed again.

Each depression of the button switches the screen to the previous parameter group. After the first

group, the last group is displayed again.

Switching within the same group is performed with and buttons.

Each depression of the button switches the screen to the next display in the same group. After the last

display, the first display comes again.

Each depression of the button switches the screen to the previous display in the same group. After the

first display, the last display comes again.

The list of parameter groups are below:

Channel Measurement Screens: Voltage, current, kW, kVA, kVAr, pf and reactive ratio of each input

channel.

Channel Counter Screens: Instantaneous current, demand current, demand power, active and reactive

energy counters of each input channel.

Main busbar voltages and frequency: Phase-neutral, phase-phase and average voltages of the main

busbar in different screens.

GSM Modem Parameters: Signal level, counters, connection status, IP addresses, etc...

Status Group: Various information as date-time, firmware version, identity, configuration, etc...

User Screens: Screens in this group are configured by the user.

Oscilloscope Screen: In this group, waveforms of currents and voltages may be visualized as an

oscilloscope. All phase-neutral and phase-phase voltages and each current input are avalable. Thanks to

this feature, waveform distorsions and harmonic components are displayed in graphichal form.

Harmonic Analysis Result Tables: In this group, THDs of currents and voltages are displayed with 0.1%

precision. All phase-neutral and phase-phase voltages and each current input are avalable.

6.3. LED FUNCTIONS

6.4. SCREEN SCROLLING

DKM-430 User Manual Rev_02 Firmware V-1.8

K92D01-EN - 20 -

The unit features waveform display together with a precision harmonic analyzer for both voltages and

currents. Both phase to neutral and phase to phase voltages are available for analysis, thus 36 channels in

total are possible.

Available channels are:

Main busbar volts: V1, V2, V3, U12, U23, U31

Currents: I1, I2, I3,….,I29,I30

Scopemeter Display

The waveform display memory is of 100 samples length and 13 bit resolution, with a sampling rate of 2048

s/s. Thus one cycle of a a 50Hz signal is represented with 41 points. The vertical scale is automatically

adjusted in order to avoid clipping of the signal.

The waveform is displayed on the device screen, and with more resolution on PC screen through the

RainbowPlus program.

The display memory is also available in the Modbus register area for third party applications. For more

details please check chapter “MODBUS Communications”.

The waveform display is updated twice a second. All channels may be scrolled using buttons.

7. WAVEFORM DISPLAY & HARMONIC ANALYSIS

Table of contents

Other Datakom Measuring Instrument manuals

Datakom

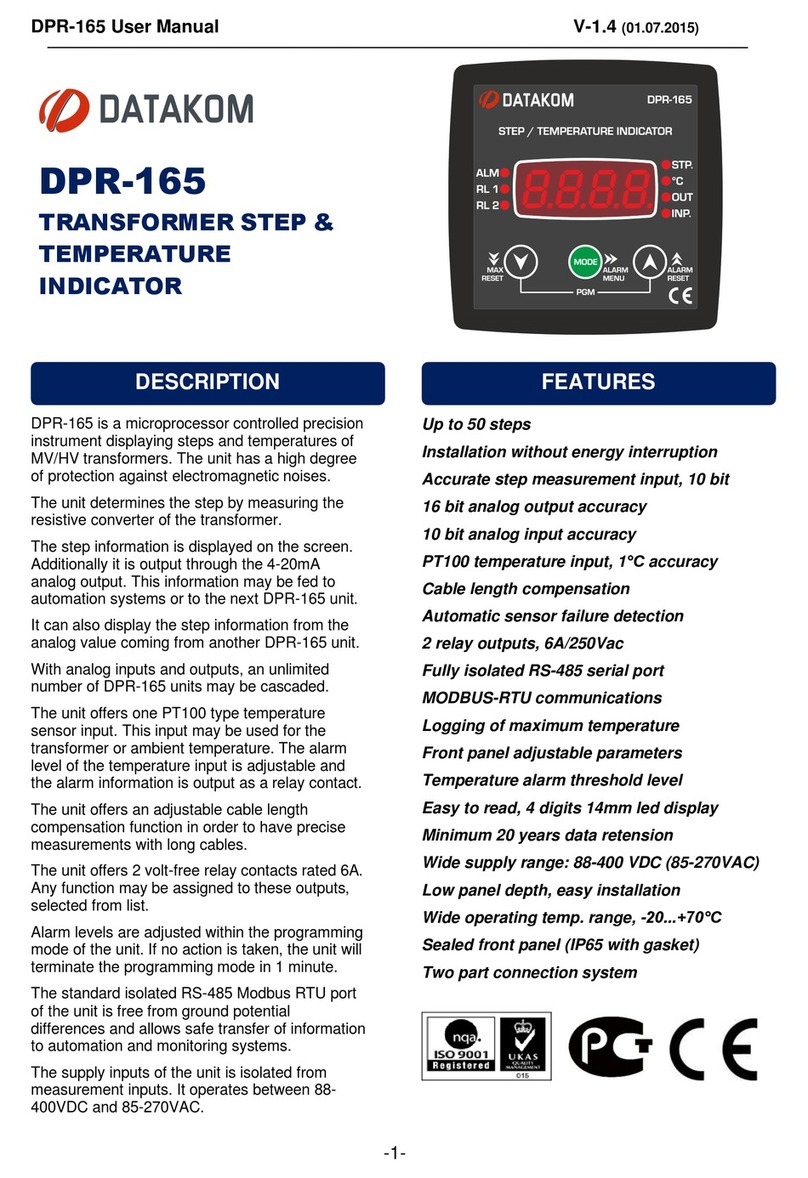

Datakom DPR-165 User manual

Datakom

Datakom DPR-350 Series User manual

Datakom

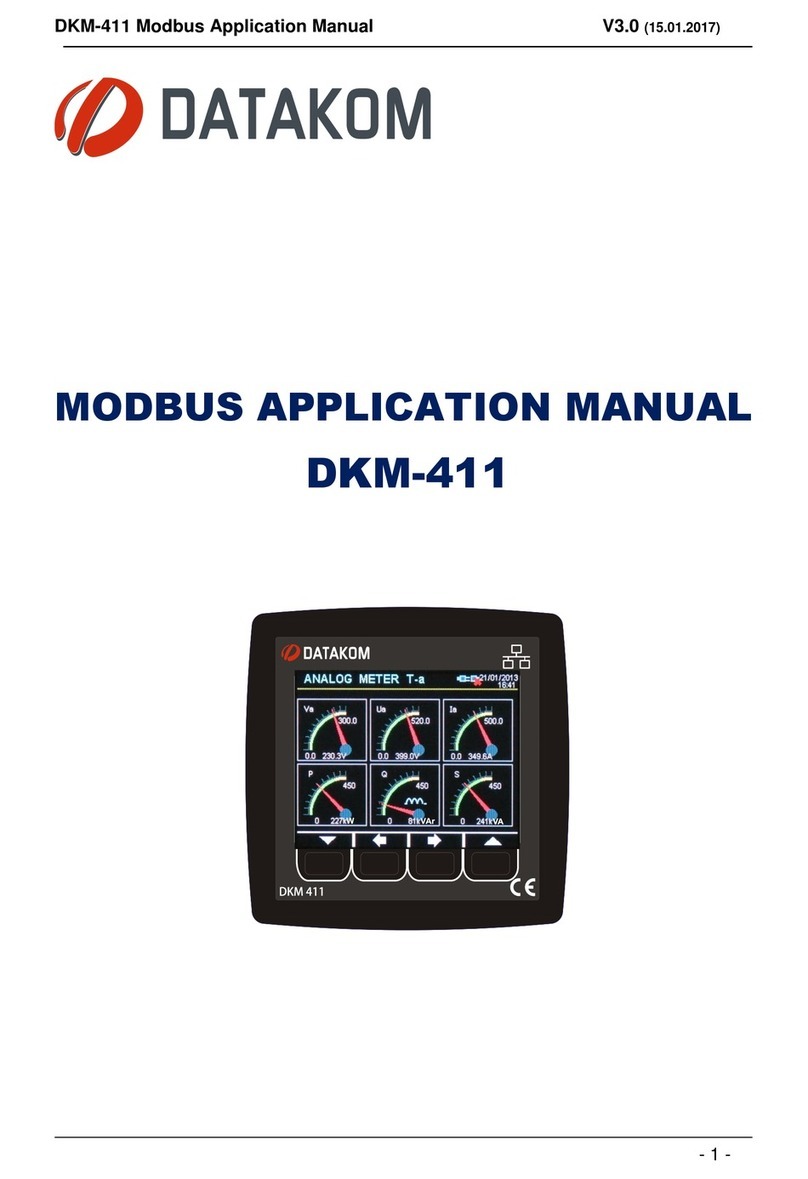

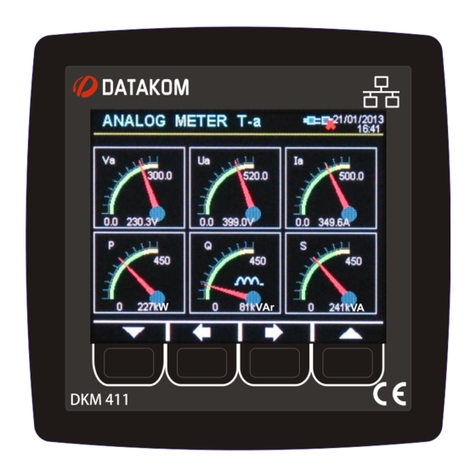

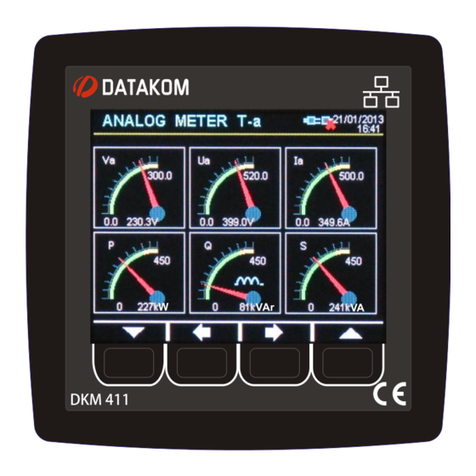

Datakom DKM-411 User manual

Datakom

Datakom DV-0101 User manual

Datakom

Datakom DKM-260 User manual

Datakom

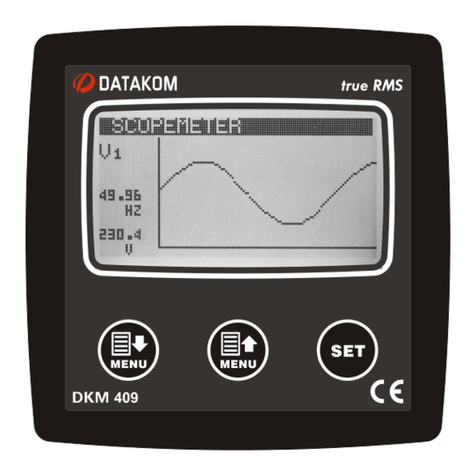

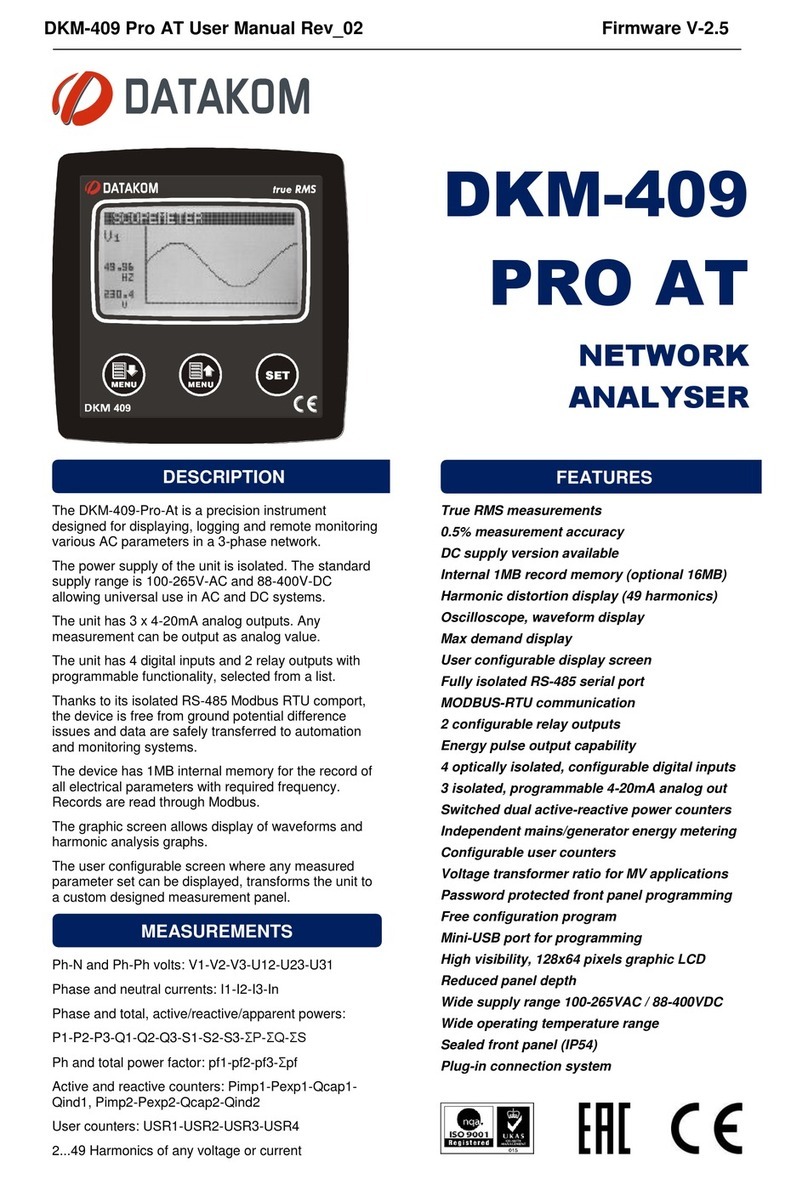

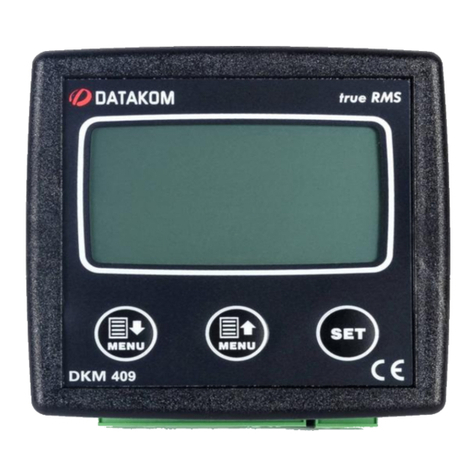

Datakom DKM-409 PRO AT User manual

Datakom

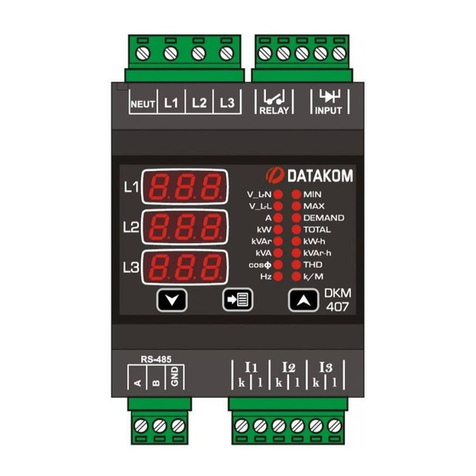

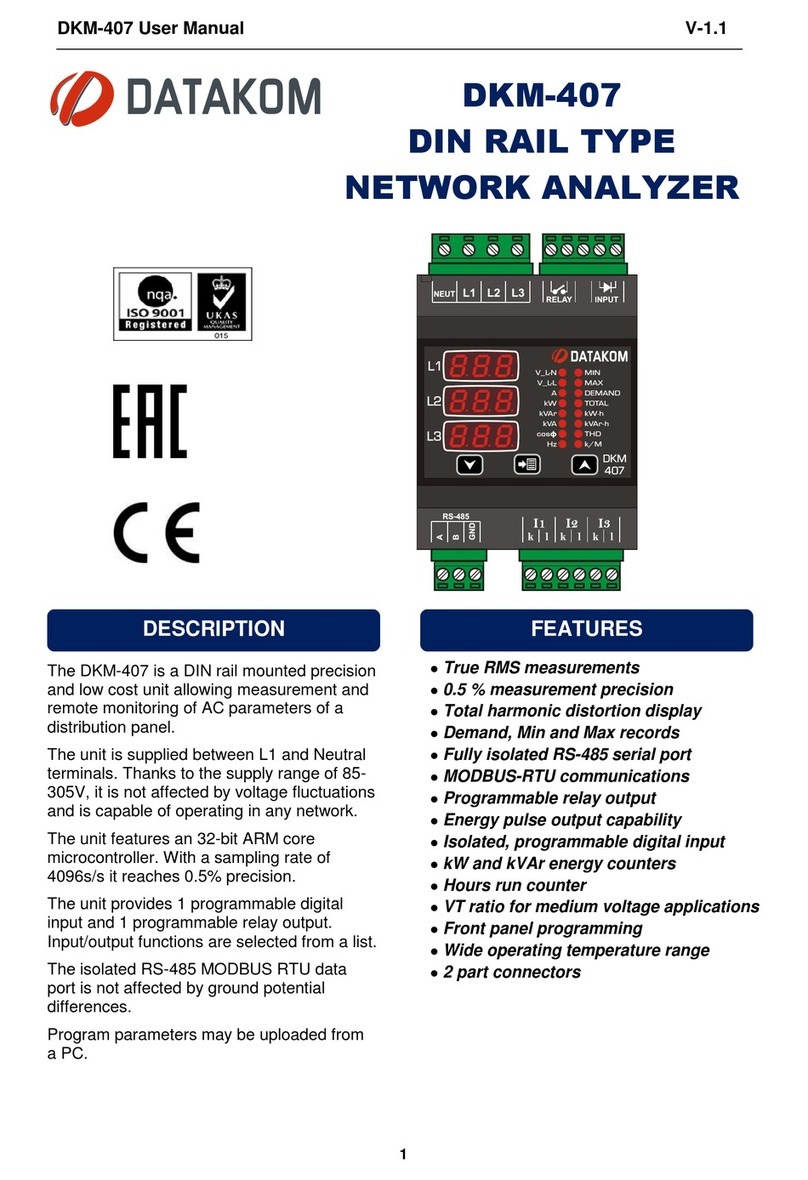

Datakom DKM-407 User manual

Datakom

Datakom DKM-411 User manual

Datakom

Datakom DKM-409 User manual

Datakom

Datakom DKM-405 User manual

Popular Measuring Instrument manuals by other brands

Amprobe

Amprobe UDM45 user manual

Bms Bulut Makina

Bms Bulut Makina BULUMOUNT-3 Operational manual

Pilot Communications

Pilot Communications EGO700 Installation & operation manual

Vaisala

Vaisala M212551EN-B quick guide

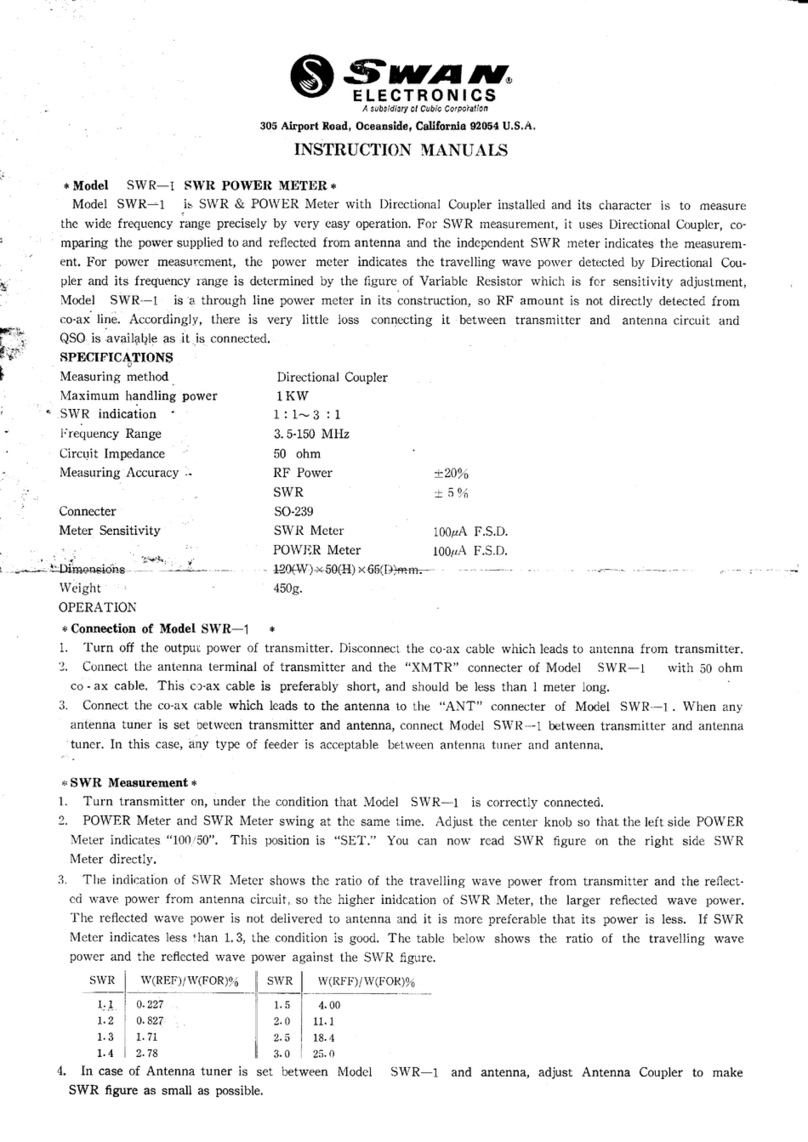

Swan Electronics

Swan Electronics SWR-1 Instruction manuals

BEKA

BEKA BA418CF-F Installation & maintenance instructions