STAR Water Systems SW1369 User manual

1

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

POOL PUMP

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our customer service

department at 1-800-742-5044, 7:30 a.m. - 5:00 p.m., EST, Monday - Friday.

ATTACH YOUR RECEIPT HERE

IL2306

148014 1HP, 025191 1-1/2HP - SINGLE SPEED

DUAL VOLTAGE (115/230)

SW1369 B

Español p. 17

2 3

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

PACKAGE CONTENTS

SAFETY INFORMATION

DESCRIPTION QUANTITY

APump 1

BAdapters

2” Slip Union 2

CAdapters

1.5” Slip Union 2

DCouplings 2

Basic safety precautions should always be followed, including the following. Failure to follow

instructions can cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for

one of the following signal words and be alert to the potential for personal injury.

Warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

Warns about hazards that will or can cause minor or moderate personal injury and/or

property damage and if ignored presents a potential hazard. It can also make consumers

aware of actions that are unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

READ AND FOLLOW ALL INSTRUCTIONS in this owner’s manual and on the

equipment. Failure to follow instructions can cause severe injury and/or death.

SUCTION ENTRAPMENT HAZARD. Suction inlets and outlets and/or suction outlet

covers which are damaged, broken, cracked, missing, or unsecured can cause severe

injury and/or death due to the following entrapment hazards:

• Hair Entrapment- Hair can become entangled in suction outlet cover.

• Limb Entrapment- A limb inserted into an opening of a suction outlet sump or suction outlet cover that is

damaged, broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of

the limb.

• Body Suction Entrapment- A negative pressure applied to a large portion of the body or limbs can result

in an entrapment.

• Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an

unprotected suction outlet sump or suction outlet cover which is, damaged, broken, cracked, missing, or

unsecured can result in evisceration/ disembowelment.

• Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, nger, toe or knuckle to

be caught in an opening of a suction outlet cover resulting in mechanical entrapment.

To Reduce the risk of Entrapment Hazards:

• When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets

per pump must be installed. Suction outlets in the same plane (i.e. oor or wall), must be installed a

minimum of three feet (3’) [1 meter] apart, as measured from near point to near point.

• Dual suction ttings shall be placed in such locations and distances to avoid “dual blockage” by a user.

• Dual suction ttings shall not be located on seating areas or on the backrest for such seating areas.

• The maximum system ow rate shall not exceed the ow rating as listed on Table 1.

• Never use pool or spa if any suction outlet component is damaged, broken, cracked, missing, or not

securely attached.

• Replace damaged, broken, cracked, missing, or not securely attached suction outlet components

immediately.

• Install two or more suction outlets per pump in accordance with latest ASME, APSP Standards and CPSC

guidelines. Follow all applicable National, State, and Local codes.

• Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa

from the suction outlets can result in an increase potential for suction entrapment as

described above.

Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper

and other material can result in an increased potential for suction entrapment as

described above.

Suction outlet components have a nite life. The cover/grate should be inspected

frequently and replaced at least every ten years or if found to be damaged, broken,

cracked, missing, or not securely attached.

Components such as the ltration system, pumps and heater must be positioned so as to

prevent their being used as means of access to the pool by young children.

Never operate or test the circulation system at more than 50 PSI.

Never change the lter control valve position while the pump is running.

To reduce risk of injury, do not permit children to use or climb on this product. Closely

supervise children at all times.

Hazardous Pressure. Pool and spa water circulation systems operate under hazardous

pressure during start up, normal operation, and after pump shut o. Stand clear of

circulation system equipment during pump start up. Failure to follow safety and operation instructions could

result in violent separation of the pump housing and cover, and/or lter housing and clamp due to pressure in

the system, which could cause property damage, severe personal injury, or death. Before servicing pool and

spa water circulation system, all system and pump controls must be in o position and lter manual air relief

valve must be in open position. Before starting system pump, all system valves must be set in a position to

allow system water to return back to the pool. Do not change lter control valve position while system pump is

running. Before starting system pump, fully open lter manual air relief valve. Do not close lter manual air

relief valve until a steady stream of water (not air or air and water) is discharged.

Separation Hazard. Failure to follow safety and operation instructions could result in

violent separation of pump and/or lter components. Strainer cover must be properly

secured to pump housing with strainer cover lock ring. Before servicing pool and spa circulation system, lter

manual air relief valve must be in open position. Do not operate pool and spa circulation system if a system

component is not assembled properly, damaged, or missing. Do not operate pool and spa circulation system

unless lter manual air relief valve body is in locked position in lter upper body.

IL2306

IL2322

IL2320

A

B

IL2319

CD

4 5

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable

local codes, regulations, and the National Electric Code (NEC). Hazardous voltage can

shock, burn, and cause death or serious property damage. To reduce the risk of electric shock, do NOT use an

extension cord to connect unit to electric supply. Provide a properly located electrical receptacle. Before

working on any electrical equipment, turn o power supply to the equipment.

To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit

to prevent contact from lawn mowers, hedge trimmers and other equipment.

Ground all electrical equipment before connecting to electrical power supply. Failure to

ground all electrical equipment can cause serious or fatal electrical shock hazard.

Do NOT ground to a gas supply line.

To avoid dangerous or fatal electrical shock, turn OFF power to all electrical equipment

before working on electrical connections.

Failure to bond all electrical equipment to pool structure will increase risk for electrocution

and could result in injury or death. To reduce the risk of electric shock, see installation

instructions and consult a professional electrician on how to bond all electrical equipment. Also, contact a

licensed electrician for information on local electrical codes for bonding requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external

bonding lug to reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) [No. 6 AWG (13.3 mm2) for Canada]

solid copper bonding wire to the pressure wire connector provided on the electrical equipment and to all metal

parts of swimming pool, spa, or hot tub, and metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of

inside walls of swimming pool, spa, or hot tub.

Reference NEC codes for all wiring standards including, but not limited to, grounding,

bonding and other general wiring procedures.

Risk of Electric Shock. Connect only to a branch circuit protected by a ground-fault

circuit-interrupter (GFCI). Contact a qualied electrician if you cannot verify that the circuit

is protected by a GFCI.

Risk of Electric Shock. The electrical equipment must be connected only to a supply

circuit that is protected by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be

provided by the installer and should be tested on a routine basis. To test the GFCI, push the test button. The

GFCI should interrupt power. Push reset button. Power should be restored. If the GFCI fails to operate in this

manner, the GFCI is defective. If the GFCI interrupts power to the electrical equipment without the test button

being pushed, a ground current is owing, indicating the possibility of an electrical shock. Do not use this

electrical equipment. Disconnect the electrical equipment and have the problem corrected by a qualied

service representative before using.

This pump is intended for use with permanently-installed pools and may be used with hot

tubs and spas if so marked. Do not use with storable pools. A permanently-installed pool

is constructed in or on the ground or in a building such that it cannot be readily disassembled for storage. A

storable pool is constructed so that it is capable of being readily disassembled for storage and reassembled to

its original integrity.

MATERIALS NEEDED:

PVC Glue Tape Measure

Hack Saw Phillips Screwdriver

Flathead Screwdriver PTFE Pipe Thread Sealant Tape

Tongue and Groove Pliers Pipe Wrench

Round File or Sand Paper 2 in. Threaded Connections

(2 in. Slip Union & 1 1/2 in. Slip Union Included)

Shut O Valve On/O Timer

INTRODUCTION

This manual contains information for the proper installation and operation of the pool pump. The instructions in

this manual MUST be followed precisely. Failure to install according to dened instructions will void warranty.

PRODUCT BENEFITS

• See-through strainer cover lets you see when the basket needs cleaning.

• Heavy-duty, high performance motor for quieter, cooler operation.

• Service-ease design gives simple access to all internal parts.

• Handle for easy carrying and moving.

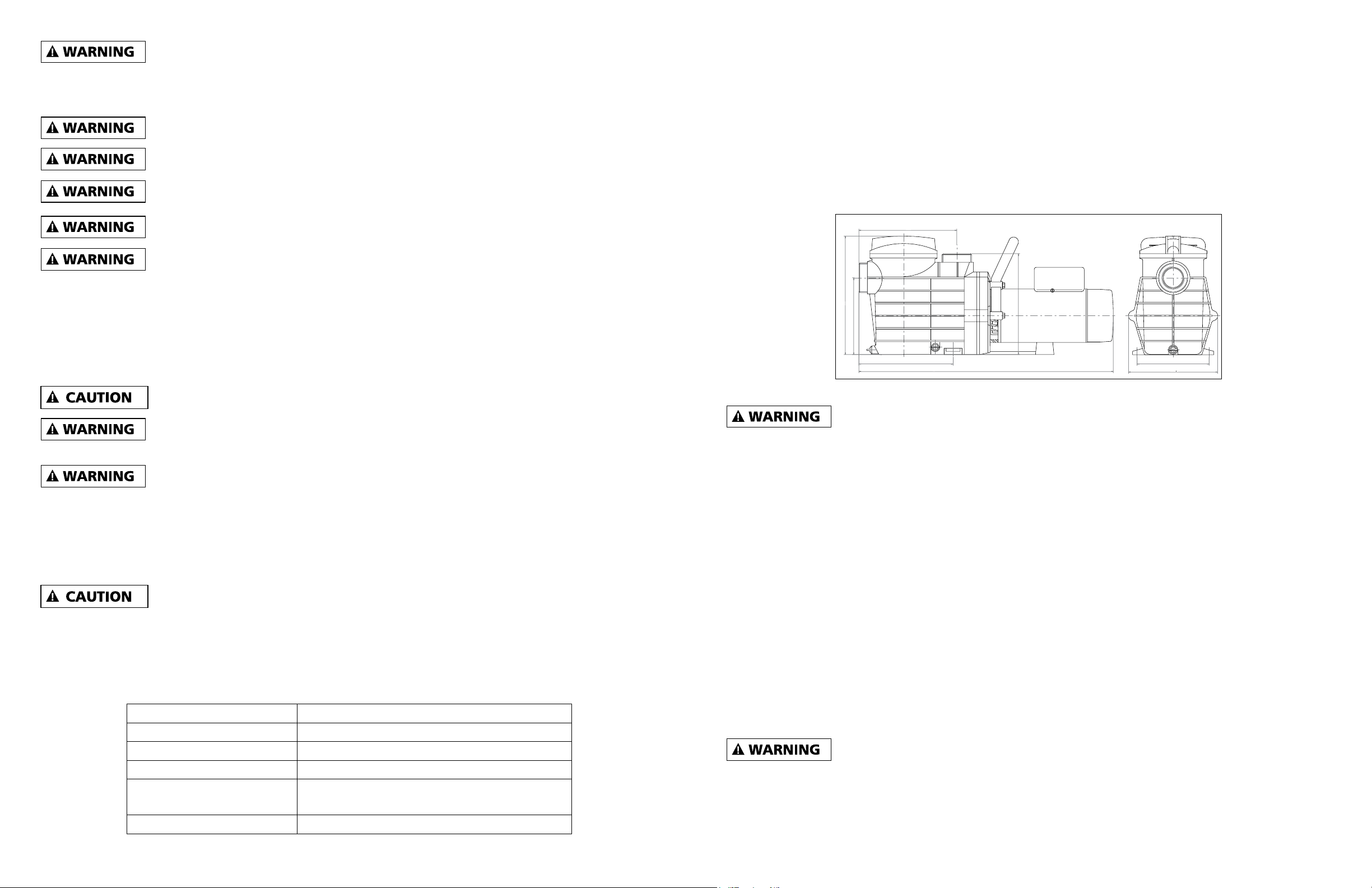

PRODUCT SPECIFICATIONS

10 in

10.4 in

8.1 in

12.6 in

10.7 in

7.6 in

9.5 in

Model 148014 16.6 in., Model 025191 25.6 in

This product should be installed and serviced only by a qualied professional.

PUMP LOCATION

Locate pump as close to pool as practical and run suction lines as direct as possible to reduce friction loss.

Suction line diameter must equal or be larger than the discharge line diameter. Suction lines should have

continuous slope upward from lowest point in line. Joints must be tight (but not over-tightened).

Though the pump is designed for outdoor use, it is strongly advised to protect the electrical components from

the weather. Select a well-drained area, one that will not ood when it rains. Do NOT install pump in a damp

or non-ventilated location. Keep motor clean. Pump motors require free circulation of air for cooling.

PUMP MOUNTING

Install pump on a rm, level base or pad to meet all local and national codes. Fasten pump to base or pad with

screws or bolts to further reduce vibration and stress on pipe or hose joints. The base MUST be solid, level,

rigid, and vibration free.

PUMP MOUNT MUST:

• Allow pump inlet height to be as close to water level as possible.

• Allow use of short, direct suction pipe (to reduce friction losses).

• Allow for gate valves in suction and discharge piping.

• Be protected from excess moisture and ooding.

• Allow adequate access for servicing pump and piping.

• Incorporate a straight portion of pipe prior to pump inlet no less than (5) pipe diameters in length.

Hazardous Pressure. Pumps, lters, and other equipment/components of a swimming

pool ltration system operate under pressure. Incorrectly installed and/or improperly

tested ltration equipment and/or components may fail resulting in injury and/or property damage.

67

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

MAXIMUM RECOMMENDED SYSTEM FLOW RATE BY PIPE SIZE - TABLE 1

PIPE SIZE FLOW RATE WATER

VELOCITY PIPE SIZE FLOW RATE WATER

VELOCITY

Inches MM GPM Liter/

Min Ft/sec Meters/

sec Inches MM GPM Liter/

Min Ft/sec Meters/

sec

1-1/2 50 50.76 192 62.44 2.5” 75 119.40 452 8 2.44

2” 63 83.65 317 8 2.44 3” 90 184.32 698 8 2.44

NOTE – No system should allow any higher than 8-ft/sec (2.44 meters/sec) water velocity. It is recommended

that a minimum length of piping, equivalent to 10 pipe diameters, be used between the pump suction inlet and

any plumbing ttings.

PERFORMANCE

1. Find Your Pool Size

Use the formulas below to nd the capacity of your pool.

• Rectangular Pools: Length (ft.) x Width (ft.) x Average Depth (ft.) x 7.5 = Total pool capacity in gallons

• Circular Pools: Diameter (ft.) x Diameter (ft.) x Average Depth (ft.) x 5.9 = Total pool capacity in gallons

• Oval Pools: Length (ft.) x Width (ft.) x Average Depth (ft.) x 6.7 = Total pool capacity in gallons

Example for Rectangular Pool: 40 ft. L x 20 ft. W x 6 ft. average depth x 7.5 = 36,000 gallon capacity pool

2. Calculate Flow Rate, Gallons Per Minute (GPM) and Turnover

Pools should typically turn water over once every 8 hours. Use this ow rate formula along with your pool

capacity from step 1 to nd the Gallons Per Minute (GPM) you need for your system:

Pool Volume in Gallons ÷ Turnover Rate in Minutes = Flow Rate

Example: If you have a 30,000-gallon pool and you want the water to turn over once every eight hours:

30,000 ÷ 480 (60 minutes x 8 hours) = 62.5 GPM

Your 30,000-gallon pool needs 62.5 gallons per minute to circulate the water once every eight hours.

3. Calculate Maximum Flow Rate

This number helps you match the pump with your pool lter. Your pool lter has a maximum ow rate, which

is measured in GPM. The GPM rating of the pump should be less than the GPM rating of the pool lter. If the

pump is rated higher than the lter, the lter is undersized and will not work properly.

The size of your pool pipes determines the maximum ow rate for your system.

Count the number of intake lines for your pool and reference the pipe sizes below:

• For each 1.5-inch intake line, the maximum ow rate is 42 GPM.

• For each 2-inch intake line, the maximum ow rate is 73 GPM.

Example: Two 1.5-inch intake lines = 84. The maximum ow rate is 84 GPM.

4. Calculate Resistance

Every piece of equipment in the pump system creates resistance to water ow. Pipe length and size, type of

lter, heaters and pool cleaners all add to this resistance.

The easiest way to nd resistance is to use a pressure meter and these formulas:

• Check the pressure of water owing into the lter tank and multiply that number by 2.31.

• Check the vacuum reading on the pump suction line and multiply that by 1.13.

• Add the two numbers together to nd is the resistance, or total dynamic head.

Example: If the water owing into the lter tank is 15 PSI, and the vacuum reading on the pump suction line

is 6 PSI:

Water ow into lter tank: 15 PSI x 2.31 = 34.65

Vacuum reading on pump suction line: 6 PSI x 1.13 = 6.78

Total = 41.43 ft. of resistance or TDH

Use the chart below to determine expected gallons per minute for your installation.

PLUMBING

Use Teon tape to seal threaded connections on molded plastic components. All plastic ttings must be new

or thoroughly cleaned before use. NOTE - Do NOT use Plumber’s Pipe Dope as it may cause cracking

of the plastic components. When applying Teon tape to plastic threads, wrap the entire threaded portion

of the male tting with one to two layers of tape. Wind the tape clockwise as you face the open end of the

tting, beginning at the end of the tting. The pump suction and outlet ports have molded-in thread stops. Do

NOT attempt to force hose connector tting past this stop. It is only necessary to tighten ttings enough

to prevent leakage. Tighten tting by hand and then use a tool to engage tting an additional 1-1/2 turns. Use

care when using Teon tape as friction is reduced considerably; do NOT over-tighten tting or you may

cause damage. If leaks occur, remove connector, clean o old Teon tape, re-wrap with one to two additional

layers of Teon tape, and re-install connector.

FITTINGS

Fittings restrict ow. For better eciency, use the fewest possible ttings (but at least two suction outlets).

Avoid ttings that could cause an air trap. Pool and spa ttings MUST conform to the International Association

of Plumbing and Mechanical Ocials (IAPMO) standards. Use a non-entrapping suction tting in pool (multiple

drains) or double suction (skimmer and main drain).

SPECIFICATIONS

MODEL HP PERFORMANCE IN GALLONS PER MINUTE

20’ TDH 30’ TDH 40’ TDH 50’ TDH 60’ TDH 70’ TDH

148014 1 90 80 64 43 16 -

025191 1-1/2 110 100 90 79 62 47

8 9

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

Fuse Box

5

Fuse Box

Fill Level

6

Return Line

Filter Outlet

Return Line

Goes to Pool Jets

IL2562

4

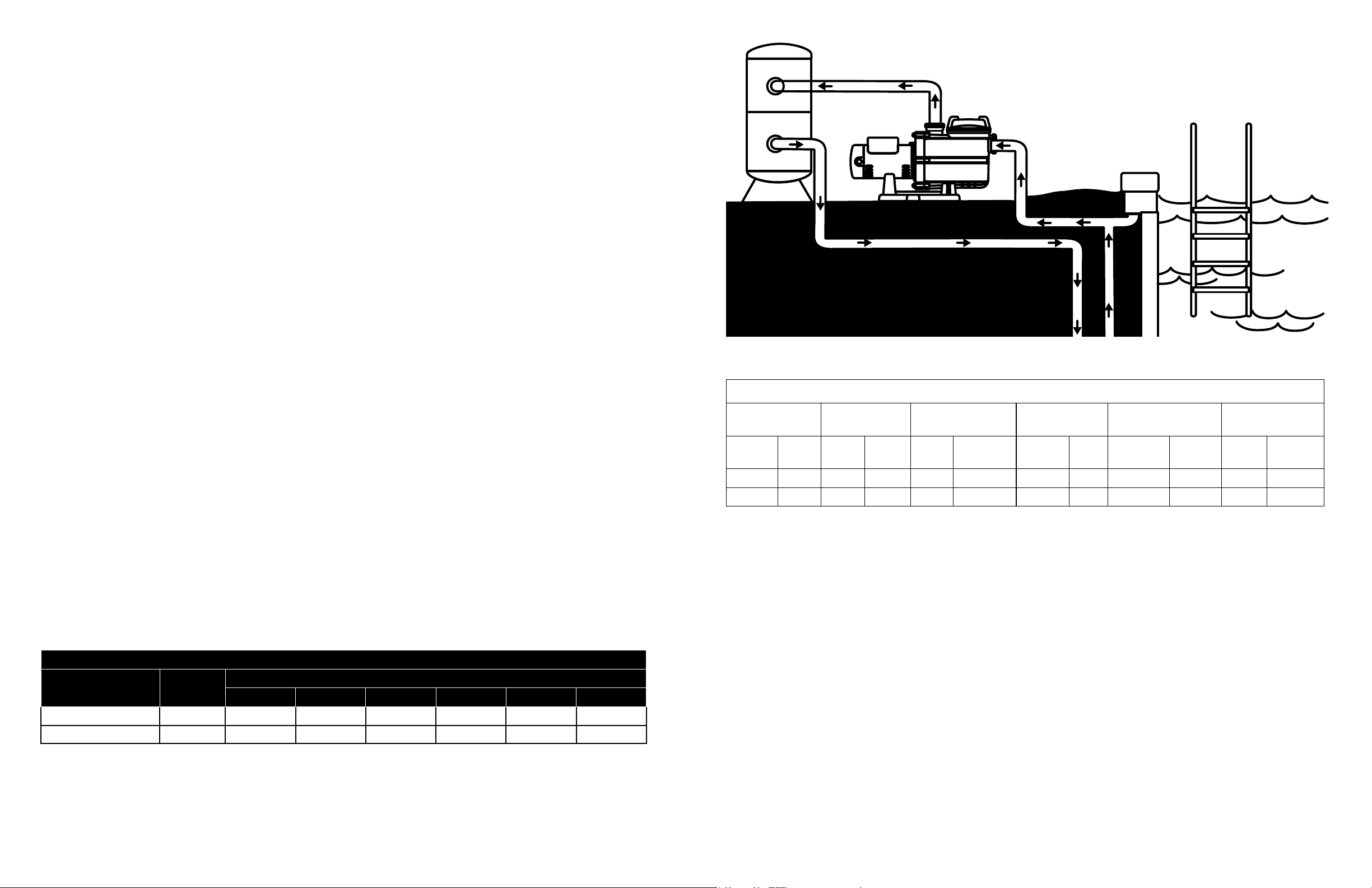

4. Connect return line from lter to swimming pool

return inlet.

6. Fill pump and trap with water, replace trap lid

and check system for leaks. If no leaks, proceed

with pump startup.

NOTE: DO NOT START PUMP if any leaks are

present in the system.

After startup check again for leaks again at

each connection.

5. Make sure power is o and attach wiring.

Always disconnect

pump from electricity

before performing any work on the motor.

Refer to instructions for wiring connections.

INSTALLATION:INSTALLATION:

IL2562

Pump inlet

1

IL2562

Shut Off

Valve

Pump

Inlet Pipe

Pool

Skimmer

Pipe Union

2

Shut Off

Valve

Pump Discharge Line

Filter Inlet

Pipe Union

IL2562

3

NOTE: Before installing the pump check your

voltage requirements. The pump is preset to

230V. If your power source is 115V see page 10

and follow instructions to change wiring according

to the diagrams.

1. Install pump on a rm, level base or pad with

screws or bolts. The base MUST be solid, level,

rigid, vibration free and protected from both

weather and pool splash. Make sure pump inlet

height is as close to the water level as possible.

2. Attach discharge line from pump to lter inlet

using a pipe union and attach shut-o valve.

Use a short and direct suction pipe. Be sure to

incorporate a straight portion of pipe that is at

least 5 times longer than the diameter of the

pump inlet pipe.

3. Use a pipe union to attach discharge line from

pump to lter inlet and attach shut-o valve.

Suction line pipe must the same diameter or

larger than the discharge line.

10 11

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

VOLTAGE

Voltage at motor MUST NOT be more than 10% above or below motor name plate rated voltage, or motor may

overheat, causing overload tripping and reduced component life. If voltage is less than 90% or more than 110%

of rated voltage when motor is running at full load, consult power company.

GROUNDING AND BONDING

• Install, ground, bond, and wire motor in accordance with local or national electrical code requirements.

• Permanently ground motor. Use green ground terminal provided under motor canopy or access place; use

size and type wire required by code. Connect motor ground terminal to electrical service ground.

• Bond motor to pool structure. Bonding will connect all metal parts within and around the pool with a

continuous wire. Bonding reduces the risk of a current passing between bonded metal objects, which could

potentially cause electrical shock if grounded or shorted. Reference NEC codes for all wiring standards

including, but not limited to, grounding, bonding and general wiring procedures.

• Use a solid copper conductor, per code. Run wire from external bonding lug to reinforcing rod or mesh.

Connect per code solid copper bonding wire to the pressure wire connector provided on the motor housing

and to all metal parts of swimming pool, spa, or hot tub, and to all electrical equipment, metal piping

(except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

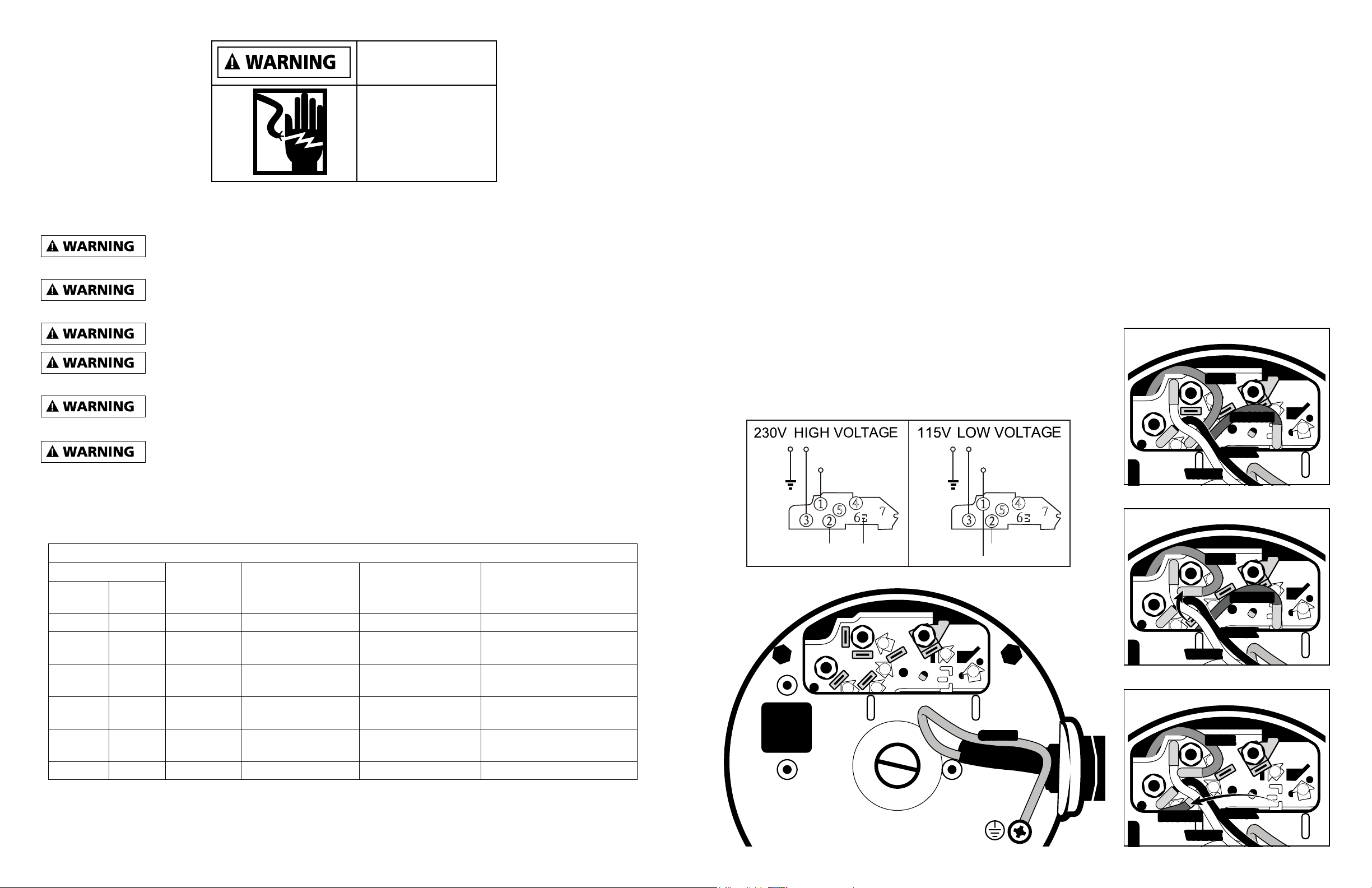

CHANGING THE VOLTAGE

• Pump is preset to 230V. If your power source is 115V, open the

back of the motor housing. Use pliers to switch plugs following the

steps to the right in order to match the 115V diagram below.

• While set for 230V the brown wire may still have current. It must

stay grounded in position 6 to avoid touching other contacts.

1

32

5

4

67

GREENGREEN

1

32

5

4

67

BROWNBROWN

BLACK

BLACK

BLUE

BLUE

WHITE

WHITE

1

32

5

4

67

BLACKBLACK

BLUE

BLUE

BROWN

BROWN

WHITE

WHITE

1

32

5

4

67

BLACKBLACK

WHITE

WHITE

BROWN

BROWN

BLUE

BLUE

4

57

4

57

Blue

White

Black

Green

(LINE)

(LINE)

BrownBlue

White

Black

Green

(LINE)

(LINE)

Brown

Single Speed

STEP 1

STEP 2

STEP 3

Default 230V wire positions.

Move blue wire from slot 2 to slot 1

Move brown wire from position 6 to slot 2

Hazardous voltage. Can

shock, burn, or cause

death.

BEFORE WORKING

ON PUMP OR

MOTOR:

Unplug pump motor.

ELECTRICAL

All wiring must be done by a licensed electrician and must conform to all local and

national codes and regulations.

Ground and bond motor before connecting to electrical power supply. Failure to ground

and bond pump motor can cause serious or fatal electrical shock hazard.

Do NOT ground to a gas supply line.

To avoid dangerous or fatal electrical shock, turn OFF power to motor before working on

electrical connections.

Ground Fault Circuit Interrupter (GFCI) tripping indicates electrical problem. If GFCI trips

and won’t reset, consult electrician to inspect and repair electrical system.

Fire Hazard. Match supply voltage to motor nameplate voltage.

Ensure that the electrical supply available agrees with the motor’s voltage, phase, and cycle, and that the wire

size is adequate for the HP (kW) rating and distance from the power source. NOTE - All electrical wiring

MUST be performed by a licensed electrician, and MUST conform to local codes and NEC regulations.

Use copper conductors only.

ELECTRICAL GUIDE - 60 CYCLE - SINGLE PHASE

MOTOR

VOLTS

CIRCUIT

BREAKER

RATINGS-AMPS

BRANCH

FUSETRON

RATINGS-AMPS

RECOMMENDED

WIRE SIZE 0-50’

KW HP

.37 1/2 115 15 15 No. 14

.55 3/4 115

230

15

10

15

6.25 No. 14

.75 1 115

230

20

10

20

9

No. 12

No. 14

1.1 1 1/2 115

230

30

15

30

15

No. 10

No. 14

1.55 2 115

230

30

15

30

12

No. 10

No. 14

1.88 2 1/2 230 20 20 No. 12

12 13

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

MAINTENANCE

• Clean strainer basket regularly. Do NOT strike basket to clean. Inspect strainer cover gasket regularly and

replace as necessary.

• Pump has self-lubricating motor bearings and shaft seals. No lubrication is necessary.

• Keep motor clean. Ensure air vents are free from obstruction to avoid damage. Do NOT use water to hose

o motor.

• Occasionally, shaft seals must be replaced, due to wear or damage.

Separation Hazard. Do not purge the system with compressed air. Purging the system

with compressed air can cause components to explode, with risk of severe injury or death

to anyone nearby. Use only a low pressure (below 5 PSI), high volume blower when air purging the pump,

lter, or piping.

Allowing the pump to freeze will void the warranty.

Use ONLY propylene glycol as antifreeze in your pool/spa system. Propylene glycol is

non-toxic and will not damage plastic system components. Other anti-freezes are highly

toxic and may damage plastic components in the system.

Drain all water from pump and piping when expecting freezing temperatures or when storing pump for a long

time (see instructions below).

Keep motor dry and covered during storage. To avoid condensation/corrosion problems, do NOT cover or wrap

pump with plastic lm or bags.

STORING PUMP FOR WINTERIZATION

To avoid dangerous or fatal electrical shock hazard, turn OFF power to

motor before draining pump. Failure to disconnect power may result in

serious personal injury or death.

1. Drain water level below all inlets to the pool.

2. Remove drain plugs from bottom of strainer body, and remove strainer cover from

strainer housing.

3. Disconnect pump from mounting pad, wiring system (after power has been turned OFF),

and piping system.

4. Once the water is emptied from the pump, re-install the strainer cover and drain plugs. Store pump in a dry

area.

WIRING

A licensed electrician must do all wiring.

Pump MUST be permanently connected to circuit. If other lights or appliances are also on the same circuit, be

sure to add their amp loads before calculating wire and circuit breaker sizes. Use the load circuit breaker as

the Master On-O switch.

Install a Ground Fault Circuit Interrupter (GFCI) in circuit; it will sense a short-circuit to ground and disconnect

power before it becomes dangerous to pool users. For size of GFCI required and test procedures for GFCI,

see manufacturer’s instructions. Pump MUST be permanently connected to GFCI. In case of a power outage,

check GFCI for tripping, which will prevent normal pump operation. Reset if necessary.

All suction and discharge valves MUST be OPEN, as well as lter air relief valve (if

available) on lter, when starting the circulating pump system. Failure to do so could result

in severe personal injury.

STARTING/PRIMING THE PUMP:

Pumps with single speed motors are self priming to 10 ft. and pumps with 2 speed motors are self priming to

10 ft. on high speed only. Fill strainer housing with water to suction pipe level. If water leakage occurs from

anywhere on the pump or lter, DO NOT start the pump. If no leakage occurs, stand at least 10 feet from pump

and/or lter and proceed with starting the pump.

Return to lter to close lter manual air relief valve when a steady stream of water (not air

or air and water) is discharged from valve. Failure to do so could result in severe personal

injury.

NEVER OPERATE THE PUMP WITHOUT WATER. Water acts as a coolant and

lubricant for the mechanical shaft seal. NEVER run pump dry. Running pump dry may

damage seals, causing leakage, ooding, and voids warranty. Fill strainer housing with water before starting

motor.

Do NOT add chemicals to pool/spa system directly in front of pump suction. Adding

undiluted chemicals may damage pump and voids warranty.

Before removing strainer cover:

1. STOP PUMP before proceeding.

2. CLOSE VALVES in suction and outlet pipes.

3. RELEASE ALL PRESSURE from pump and piping system using lter manual air relief valve. See lter

owner’s manual for more details.

4. If water source is higher than the pump, pump will prime itself when suction and outlet valves are opened.

If water source is lower than the pump, unscrew and remove strainer cover; ll strainer housing with water.

5. Clean and lubricate strainer cover O-ring with silicone lubricant each time it is removed. Inspect O-ring and

re-install on strainer cover.

6. Replace strainer cover on strainer housing; turn strainer cover clockwise to tighten cover.

Before re-starting pump, see “Starting/Priming the Pump” instructions.

Wait ve (5) seconds before re-starting pump. Failure to do so may cause reverse

rotation of motor and consequent serious pump damage.

Turn on power and wait for pump to prime, which may take up to ve (5) minutes. Priming time will depend on

vertical length of suction lift and horizontal length of suction pipe. If pump does NOT prime within ve minutes,

stop motor and determine cause. Be sure all suction and discharge valves are open when pump is running.

See Troubleshooting Guide.

14 15

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

PROBLEM CHECK FOR: SOLUTION

A. Motor Will NOT

Start

Improper or loose wiring connections;

open switches or relays; tripped circuit

breakers, GFCI’s, or blown fuses.

Check all connections, circuit breakers,

and fuses. Reset tripped breakers or

replace blown fuses

Check rotation of motor shaft Remove any obstructions.

Properly working timer. Bypass timer if necessary.

B. Motor Shuts OFF

Low voltage at motor or power drop

(frequently caused by undersized wiring

or extension cord use.)

Contact qualied professional to check

that the wiring gauge is heavy enough.

**NOTE: Your motor is equipped with an “automatic thermal overload protector.” The motor will automatically

shut o if power supply drops before heat damage can build up causing windings to burn out. The “thermal

overload protector” will allow the motor to automatically restart once the motor has cooled. It will continue to

cut On/O until the problem is corrected. Be sure to correct cause of overheating.

C. Motor Hums, But

Does NOT Start

Impeller jammed with debris. Have a qualied repair professional open

the pump and remove the debris.

D. Pump Won’t Prime

Empty pump/strainer housing. Make sure pump/strainer housing is lled

with water and cover O-Ring is clean.

Ensure O-Ring is properly seated in the

cover O-Ring groove. Ensure O-Ring

is lubricated and that strainer cover is

locked rmly in position.

Loose connections on suction side. Tighten pipe/union connections.

Leaking O-Ring or packing glands on

valves. Strainer basket or skimmer

loaded with debris.

Remove strainer housing cover or

skimmer cover, clean basket, and rell

strainer housing with water. Tighten

cover.

Suction side clogged. Contact a qualied repair professional.

Block o to determine if pump will develop a vacuum. You should have 5”-6” of vacuum at the strainer cover

(Only your pool dealer can conrm this with a vacuum gauge). You may be able to check by removing

the skimmer basket and holding your hand over the bottom port with skimmer full and pump running. If no

suction is felt, check for line blockage.

a. If pump develops a vacuum, check for blocked suction line or dirty strainer basket. An air leak in the

suction piping may be the cause.

b. If pump does not develop a vacuum and pump has sucient “priming water”:

i. Re-check strainer housing cover and all threaded connections for suction leaks. Check if all

system hose clamps are tight.

ii. Check voltage to ensure that the motor is rotating at full RPM’s.

iii. Open housing cover and check for clogging or obstruction in suction. Check impeller for debris.

iv. Remove and replace shaft seal only if it is leaking.

PROBLEM CHECK FOR: SOLUTION

E. Low Flow

Clogged or restricted strainer or suction line.

Contact a qualied repair professional.

Undersized pool piping. Correct piping size.

Plugged or restricted discharge line of lter,

valve partially closed (high gauge reading).

Sand lters - backwash as per

manufacturer’s instructions; D.E. lters -

backwash as per manufacturer’s instructions;

Cartridge lters - Clean or replace cartridge.

Air leak in suction (bubbles issuing from

return ttings).

Re-tighten using Teon tape.

Plugged, restricted, or damaged impeller. Replace, including new seal assembly.

F. Noisy Pump

1. Air leak in suction piping, cavitations

caused by restricted or undersized

suction line or leak at any joint, low

water level in pool, and unrestricted

discharge return lines.

1. Correct suction condition or throttle return

lines, if practical. Holding hand over tting

will sometimes prove this point or putting

in a smaller eyeball tting.

2. Vibration due to improper mounting, etc.

2. Replace mounting.

3. Foreign matter in pump housing. Loose

stones/debris hitting impeller could be

cause.

3. Clean the pump housing.

4. Motor bearings noisy from normal wear,

rust, overheating, or concentration of

chemicals causing seal damage which

will allow chlorinated water to seep into

bearings wiping out the grease causing

bearing to whine.

4. All seal leaks should be replaced at once.

TROUBLESHOOTING TROUBLESHOOTING

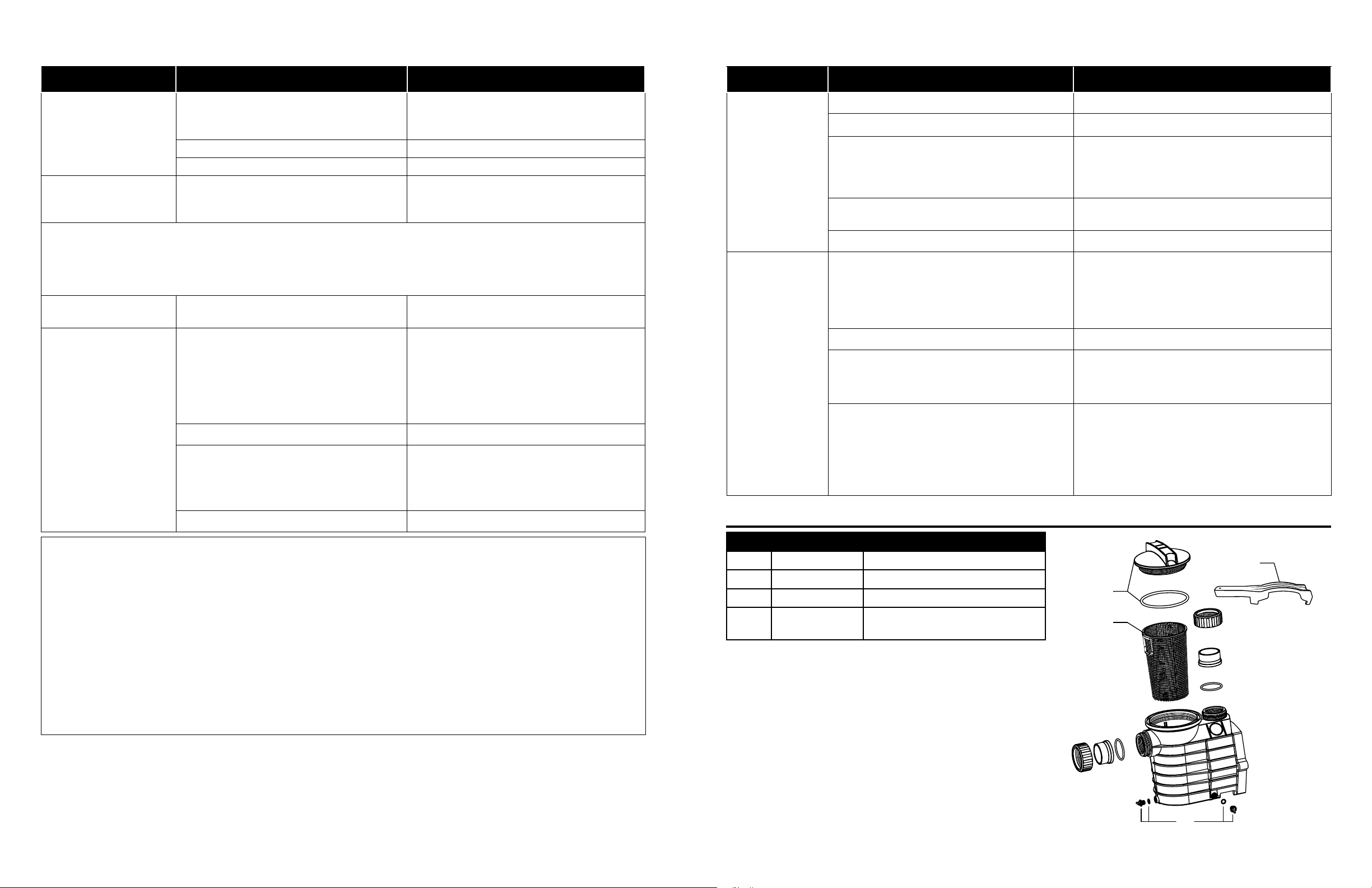

REPAIR PARTS

ITEM P/N DESCRIPTION

A025467 Cover with O-Ring

B025466 Filter/Strainer Basket

C025465 Drainage Plug with O-ring

D025468 Spanner - Tool for Opening the

Transparent Cover

A

B

C

D

IL2594

16

Copyright © 2020. All rights reserved • 95 North Oak Street • Kendallville, IN 46755

WARRANTY

This product is warranted for one year from the date of purchase. Subject to the conditions hereinafter

set forth, the manufacturer will repair or replace to the original consumer, any portion of the product

which proves defective due to defective materials or workmanship. This warranty does not cover

replacement parts for failure due to normal wear and tear. To obtain warranty service, contact the

dealer from whom the product was purchased. The manufacturer retains the sole right and option to

determine whether to repair or replace defective equipment, parts or components. Damage due to

conditions beyond the control of the manufacturer is not covered by this warranty.

THIS WARRANTY WILL NOT APPLY:

(a) To defects or malfunctions resulting from failure to properly install, operate or maintain the unit in

accordance with printed instructions provided;

(b) to failures resulting from abuse, accident or negligence or use of inappropriate chemicals or

additives in the water;

(c) to normal maintenance services and the parts used in connection with such service;

(d) to units which are not installed in accordance with normal applicable local codes, ordinances and

good trade practices; and

(e) if the unit is used for purposes other than for what it was designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired or replaced under this warranty

must be returned to the manufacturer at Kendallville, Indiana or such other place as the manufacturer

may designate, freight prepaid.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES, AND MAY

NOT BE EXTENDED OR MODIFIED BY ANYONE. ANY IMPLIED WARRANTIES SHALL BE LIMITED TO

THE PERIOD OF THE LIMITED WARRANTY AND THEREAFTER ALL SUCH IMPLIED WARRANTIES ARE

DISCLAIMED AND EXCLUDED. THE MANUFACTURER SHALL NOT, UNDER ANY CIRCUMSTANCES, BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES, SUCH AS, BUT NOT LIMITED TO

DAMAGE TO, OR LOSS OF, OTHER PROPERTY OR EQUIPMENT, LOSS OF PROFITS, INCONVENIENCE,

OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY TYPE OR NATURE. THE LIABILITY

OF THE MANUFACTURER SHALL NOT EXCEED THE PRICE OF THE PRODUCT UPON WHICH SUCH

LIABILITY IS BASED.

This warranty gives you specic legal rights, and you may have other rights which vary from state to

state. Some states do not allow limitations on duration of implied warranties or exclusion of incidental

or consequential damages, so the above limitations may not apply to you.

In those instances where damages are incurred as a result of an alleged pump failure, the

Homeowner must retain possession of the pump for investigation purposes.

This manual suits for next models

1

Table of contents

Other STAR Water Systems Swimming Pool Pump manuals