Star FS1R User manual

1

FAST

STEAMER

MODEL

FS1R, FS1D, FS1RT, FS1DT

FS2R, FS2D, FS2RT, FS2DT

FSFR, FSFD, FSFRT, FSFDT

Installation and

Operation

Instructions

2M-Z10887 Rev. E 10/24/2011

FSFRT

FS2DT

2

2M-Z10887 Owners Manual Fast Steamers

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail [email protected]

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail [email protected]

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

3

2M-Z10887 Owners Manual Fast Steamers

SPECIFICATIONS

A

C

B

A

C

B

FRONT LOADING TOP LOADING

IL1361

ELECTRICAL SPECIFICATIONS

Front Loading

Model No. Voltage Wattage Amps Nema Plug

Certication

UL CUL

FSF 208V 3,300 15.9 6-20P X X

FSF 240V 3,600 15 6-20P X X

Top Loading

Model No. Voltage Wattage Amps Nema Plug

Certication

UL CUL

FS1/FS2 120V 1,800 15 5-15P X -

FS1/FS2 120VC 1,800 15 5-20P X X

FAST STEAMERS SPECIFICATIONS

FRONT LOADING

Model No. “A” Width

Inches/CM

“B” Height

Inches/CM

“C” Depth

Inches/CM

Approx. Shp

Weight

Capacity (inches)

W_x_D_x_H

Direct Connect (D)

Water Reservoir (R)

FSFR

23in. /

58.4cm 9.5in / 24.1c, 21.5in /

54.4cm

48lbs /

21.8kg 13.75” x 13.75” x 3”

R

FSFD D

FSFRT R

FSFDT D

TOP LOADING

Model No. “A” Width

Inches/CM

“B” Height

Inches/CM

“C” Depth

Inches/CM

Approx. Shp

Weight Pan Size Direct Connect(D)

Water Reservoir (R)

FS1R

18.8in /

47.8cm

10.5in /

26.7cm

17.2in /

43.7cm

48lbs /

21.8kg 1/2

R

FS1D D

FS1RT R

FS1DT D

FS2R

22.4in /

56.9cm

58lbs /

26.4kg 2/3

R

FS2D D

FS2RT R

FS2DT D

4

2M-Z10887 Owners Manual Fast Steamers

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

Before using your new equipment read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand the

units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This

unit has been tested and carefully packaged to insure delivery of your unit in perfect condition. If

equipment is received in damaged condition, either apparent or concealed, a claim must be made

with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials for inspection. The carrier will make

an inspection and will supply necessary claim forms.

These models are equipped for the voltage and wattage indicated on the nameplate. These units

are designed to operate on alternating current (A.C.), two wire single phase service only and are

equipped with an approved lead in cord set with a three prong grounding type plug.

DO NOT CONNECT TO DIRECT CURRENT (D.C.).

UNPACKING

Carefully remove the steamer from the shipping and packing & protective material. Remove all

removable parts and clean with hot water and mild detergent. Wipe the unit using damp cloth. Never

hose down the unit with water, this steamer has

Unit should also contain:

• Operations manual & Authorized Service Agent Listing Packet

• Inlet Hose Assembly (non-reservoir units only)

• Spatula tray (front loading units only)

Purchasers Responsibility

• To see that the electric & water services for the unit are installed on site in accordance with

the manufacturer's specications and municipal codes.

• A water pressure regulator must be used, failure to operate this unit without a regulator will

result in situations that will damage the unit.

CAUTION

WARNING

5

2M-Z10887 Owners Manual Fast Steamers

INSTALLATION

ELECTRICAL CONNECTION

For your protection, we recommend that a qualied electrician install this appliance.

The electrician should be familiar with electrical installations and your local electrical requirements.

Proper connections and power supply are essential for efcient performance. The supply circuit should

be properly fused as required by local electrical code.

Before making any electrical connection be sure to read data plate which is located on the rear

of the unit.

Electrical Grounding Instructions

This unit is equipped with a 3-prong (grounded) plug for your protection against shock hazard and must

be plugged directly into a properly grounded 3-prong receptacle.

DO NOT CUT OR REMOVE THIS PLUG OR GROUNDED PRONG FROM THE

PLUG.

CONNECT/PLUG UNIT INTO DEDICATED A.C. LINE ONLY SPECIFIED ON THE

DATA PLATE OF THE UNIT.

PRESET TIME

If adjustments are required, please refer to the time programming section in this manual.

°F/°C CONVERSION

To change the temperature display from °F to °C or from °C to °F, hold the TEMP button while the

unit is turned off. While holding the TEMP button, turn the unit on. The display will be the changed

temperature mode. To change back, repeat the procedure.

WARNING

CAUTION

6

2M-Z10887 Owners Manual Fast Steamers

INSTALLATION continued

WATER CONNECTION

These units come equipped with either a direct connect, rear mounted quick disconnect uid control

valve, or a 12 cup water tank with tank drain and supply pump. It is vital that all water supply lines be

thoroughly ushed with clean water before being connected to the steamer.

The Star Fast-Steamer has a water injection system, to ensure your new equipment works at its

premium, we recommend that a water softener is used in areas where hard water is present. Contact

your local water equipment system provider to assist you in determining your specic water quality, or

contact Star Technical support for assistance, 314-678-6303.

Direct Connect Water Supply Installation

1. Make certain the water valve that

will be suppling the unit is turned

off.

2. Connect the 1/4" I.D. exible

tubing to the outlet side of the water

source and secure with clamps

provided.

3. Holding the end opposite end

over a bucket, turn the water valve on until there is a good consistent supply of water

(this removes any air from the system and ushes it of any particles that may be present).

4. Turn off the water valve.

5. Push the check valve tting into the water inlet located on the rear of the unit.

Make certain the connection is securely attached by lightly tugging on it.

6. Turn on water valve, Turn the knob on the regulator until the guage reads 26 psi.

Check for leaks.

Reservoir Water Units

1. With unit in nal position, open reservoir lid.

2. Check and make sure the reservoir is free of debris

and material that may interfere with its operation.

3. The unit comes with a washer strainer which ts

over the water inlet (see illustration), verify this is

correctly in position. Periodically check strainer and

clean and replace as often as necessary.

4. Pour tap water into reservoir until the water level is

1/4" from the top.

5. Closed lid.

6. Check water level during daily operation and ll as needed.

Filter

Regulator

To Steamer

Guage

Water

Source

26 psi

IL1532

Lid

Strainer

Water Inlet

IL1537

7

2M-Z10887 Owners Manual Fast Steamers

OPERATING PROCEDURE

Connect your unit to a wall outlet which will supply the unit with the proper voltage specied on the

data plate. If you have a reservoir unit, verify the water level, add if water is low.

KEEP HANDS AND FACE AWAY FROM THE UNIT WHEN OPENING OR

REMOVING THE SPATULA FROM THE UNIT. STEAM ESCAPING IS VERY HOT.

MANUAL CONTROL

• Turn unit on

Wait 20 - 30 minutes for the unit to reach its operating temperature before using.

Note: The Temperature Set Point is factory xed at 400°F (204°C) and is not adjustable.

• Place product in cooking chamber and hit the Steam Shot button to steam the product.

Steam Shot: Pressing the Green Steam Shot Green Button will release water in to the steam

generator and will instantly produce steam. Water will only stop when the button is released.

Flooding of the steam generator may occur if the Steam Shot button, or the SST is set to high. When

this occurs wait for the unit to work through the water before applying more water to the steam

generator.

ELECTRONIC CONTROL

• Turn unit on

Current Temperature will Flash on LED, PRESS the

TEMP button to see current temperature

TCT will FLASH until TSP (Temperature Set Point) is reached,

Alarm will sound 3-times when TSP is reached.

Note: The Temperature Set Point is factory xed at 400°F (204°C) and is not adjustable.

• Place product in cooking chamber and choose one of the 4 pre-determined programmed

settings, or hit the Steam Shot steam button to steam the product.

• When program timing is completed, an alarm will sound.

Steam Shot: Pressing the Green Steam Shot Button will release water in to the steam generator

and will instantly produce steam. Water will only stop when the button is released. Flooding of the

steam generator may occur if the Steam Shot button, or the SST is set to high. When this occurs wait

for the unit to vaporize all of the water before applying more water to the steam generator.

TIMER & STEAMER CONTROLLER OPERATION SPECIFICATIONS

Startup:

1. The preset time will ash until the operating temperature is reached.

2. When the control reaches preset temperature, time display, "Heat On" indicator and program

indicator will stop ashing and the alarm will beep three times.

Temperature:

1. To view the actual steam generator temperature, press and hold "Temp Button."

PROGRAMMING DEFINITIONS

TCT Total Cook Time

SIT Shot Interval Time

SST Steam Shot Time

TSP Temp Set Point

CAUTION

8

2M-Z10887 Owners Manual Fast Steamers

OPERATION continued

To Program Time:

The program buttons factory pre-set are listed below.

If changes are required follow these simple steps.

Note, any changes to these settings are stored in

the units memory until changed. Returning to the

factory pre-sets is not available automatically.

1. Press and hold "TEMP"

(actual temperature displays).

2. While holding "TEMP," press and hold any

program button for one second, to begin

programming

3. TCT (Total Cook Time) will display, adjust

time with the "3 or 4" buttons.

• Press the #1 button to move to between minutes and seconds.

• Press the #1 button to move to SIT.

4. SIT (Shot Interval Time) will display, adjust time with the "3 or 4" buttons.

• Press the #1 button to move to between minutes and seconds.

• Press the #1 button to move to SST.

5. SST (Steam Shot Time) will display, adjust time with the "3 or 4" buttons.

• Press the #1 button to move to seconds.

6. Press the "TEMP" button to save time settings and to exit programming mode for this

program. Your program will not be saved if this step is not done within 10 seconds.

7. Repeat process to program for additional programming

Hi-Limit Reset

A hi-limit reset monitors the temperature of the steam generator and will turn the power off to the unit to

prevent it from overheating. If this occurs, the unit will automatically reset when it has had enough time to

cool prior to returning to operation. If this occurs on a regular basis it may be a sign of a larger problem,

call your service agent or Star Manufacturing at

314-678-6303.

TOP LOADING COVER STOP

SETTINGS

Top Loading Fast Steamer models (FS1 &

FS2) are designed with adjustable cover

stops located on the back of the units. As

shown here you can adjust your unit's

top cover between an opening of 60°

- 90°.

90 degrees

60 degrees

Cover

Stop

IL1366

Program Button Factory Presets

1234

TCT 20 sec 40 sec 1 min 1.30 min

SIT 20 sec 40 sec 40 sec 40 sec

SST .5 sec .5 sec .5 sec .5 sec

PROGRAMMING SPECIFICATIONS / RANGE

TCT Total Cook Time 0 to 99.59 minutes

SIT Shot Interval Time .5sec to 10 minutes

SST Steam Shot Time .1 sec to 5.minutes

TSP Temp Set Point

9

2M-Z10887 Owners Manual Fast Steamers

CLEANING

DO NOT USE CAUSTIC CLEANERS,

USE A MILD DETERGENT TO WIPE DOWN EXTERIOR SURFACES, CLEAN

WITH DAMP CLOTH

Daily

1. Turn the unit OFF & unplug the unit from its power source before proceeding with any service

or cleaning procedure.

2. Remove and clean the removable items listed on the maintenance components illustration for

your specic model. Clean using warm water and mild detergent. DRY parts completely.

3. Wipe the exterior or the steamer with a damp cloth, then wipe dry. Note: drying all pieces

after cleaning will protect your nish from discoloration, any discoloration as a result from not

drying the equipment is not covered under warranty

4. Reinstall the unit, beginning with the Steam Vent.

Monthly

The Star Fast Steamer generates instant steam by means of its open generator, however the mineral

deposits in the water are left behind. A certain amount of deposits are needed for proper operation,

but a build-up of calcium & mineral deposits may cause poor performance. It is important to properly

maintain you steamer to ensure quality operation. Depending on your specic water conditions and

possibly any water ltration systems, you may need to clean your steamer more or less frequently.

DO NOT IMMERSE OR LET THE UNIT STAND IN WATER. DO NOT HOSE

DOWNTHE UNIT. KEEP THE UNIT AWAY FROM RUNNING WATER.

DO NOT SPLASH THE CONTROL HOUSING

CERTAIN WATER CONDITIONS MAY REQUIRE MORE FREQUENT CLEANING.

BEFORE CLEANING MAKE SURE POWER IS TURNED OFF AND UNIT IS

UNPLUGGED.

IF A CHEMICAL CLEANER / DELIMER IS USED, BE CERTAIN IS IT SAFE FOR

CAST ALUMINUM. FOLLOW PROCEDURES, PRECAUTIONS PROVIDED WITH

THAT SPECIFIC PRODUCT.

CAUTION

WARNING

WARNING

CAUTION

CAUTION

10

2M-Z10887 Owners Manual Fast Steamers

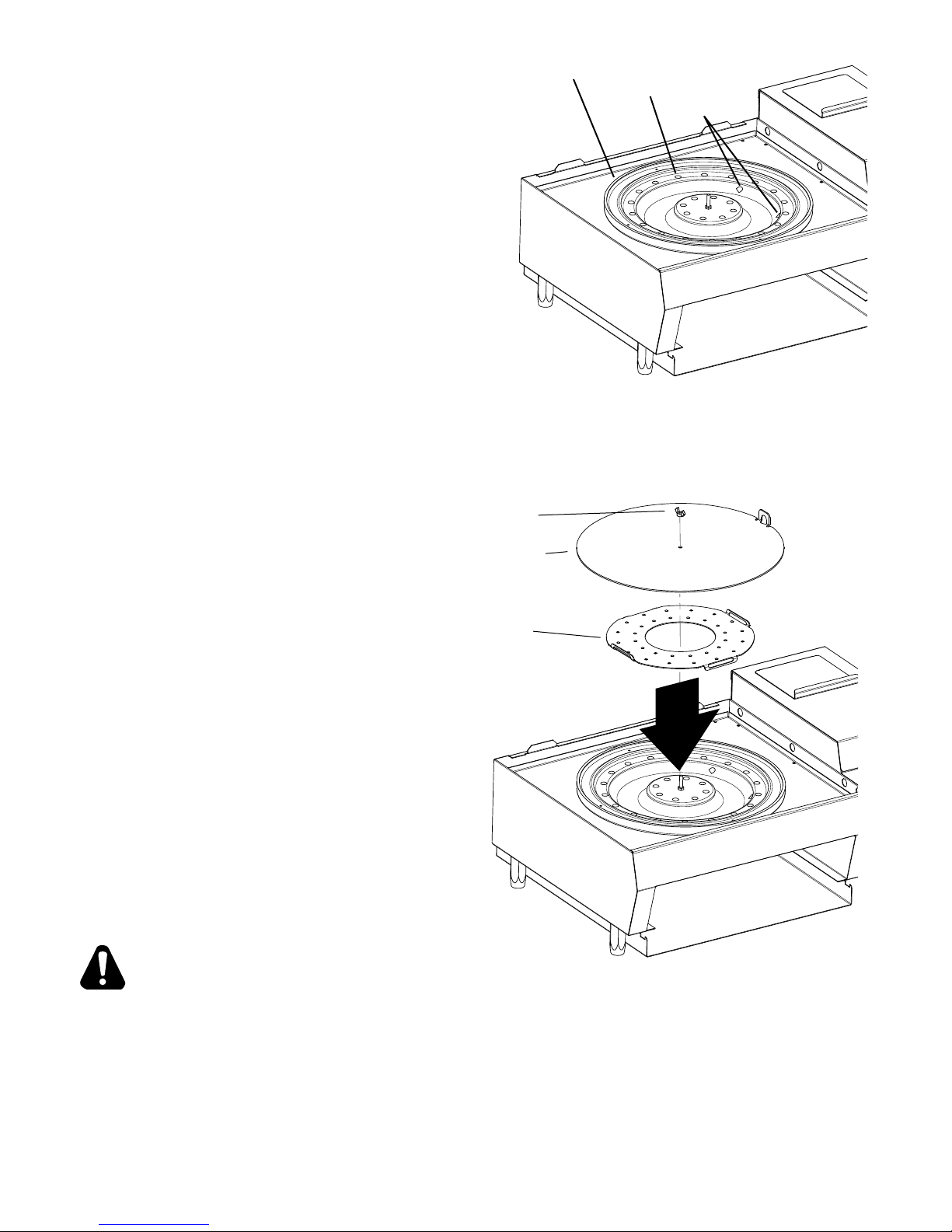

Cleaning Steam Generator

1. Turn the unit OFF & unplug the unit from its

power source.

2. Remove and clean the removable items

listed on the maintenance components

illustration for your specic model. Clean

using warm water and mild detergent.

DRY parts completely.

3. With the steam generator cool, use a wire

brush or scrapper to loosen the mineral/

calcium deposits on the generator surface

and steam ports. Remove the loose built-

up particles from the surface and wipe area

clean with damp cloth and reassemble the

unit.

NOTE: A certain amount of calcium deposits

are needed on the steam generator to ensure

proper steaming characteristics. If during

cleaning, the surface becomes free of all

calcium/mineral deposits, add tap water to the

generator surface and allow it to boil off. In

soft water conditions, a small amount of

lime will season it. (Seasoning Mixture,

.75 oz. baking soda, .75 oz. lime, 1 quart

water), use enough to cover bottom of the

steam generator, turn unit on and allow to

evaporate.

Excessive Mineral Build-up

4. Use a delimer solution, which is safe

for cast aluminum, on the steam

generator surface. Follow the

instruction provide with the delimer

solution.

5. Use a dry towel or sponge to remove

the delimer solution, then rinse with

clean water.

6. Install the diffuser, generator cover

secure with the wing nut as shown

here.

6. Plug the steamer power cord into

the power supply, and turn unit on.

7. Allow unit to reach operating

temperature.

KEEP HANDS AND FACE AWAY

FROM THE UNIT WHEN OPERATING THE UNIT. STEAM ESCAPING IS VERY

HOT.

8. Push the Green "Steam Shot" button several times to operate the steamer.

This removes any delimer solution from the generator surface.

9. Turn unit off, reinstall all remaining parts and return unit to operation.

Steam Generator

Steam Ports

Water Inlet

IL1359

Wing Nut

Generator

Cover

Diffuser

IL1377

Above: Inspect these area making sure they are

clean of deposits.

Below: Reinstall these parts before foperating the

steam feature during the cleaning procedure.

CAUTION

11

2M-Z10887 Owners Manual Fast Steamers

Rack

Spatula

Drip Pan

Food Compartment

Steam Generator

Steam Ports

Diffuser

Generator Cover

Top Cover

Steam Vent

Wing Nut

Liner

Typical Front Loading Steamer Shown

IL1352

CLEANING FRONT LOADING STEAMER COMPONENTS ILLUSTRATION

12

OPERATION TROUBLESHOOTING

If unit still does not operate contact the factory or one of its representatives or a local service

company for service or required maintenance.

DIAGNOSTICS FOR ELECTRONIC CONTROL STEAMERS

No Heat/No Steam

Shorted Temperature Probe

Less than 50 Ohms of resistance, if

a temperature probe is detected, the

output power will be shut-off to all relays.

Press the “TEMP” switch,

the LED will display

“PrOB”

Open-Circuit Temperature Probe if a temperature probe is detected, the

output power will be shut-off to all relays.

Press the “TEMP” switch,

the LED will display

“PrOB”

Relay Malfunction

If relay malfunction is detected when the

temperature is below 150°F (66°C) for

30 minutes or reaches 500°F (260°C).

The output power will be shut-off to both

relays unit the error no longer occurs.

The display will blink

“rELY”

Heat / No Steam Temperature To Cool Probe Temperature is 200°F (93°C) less

than the programmed set point.

Program & Heat Indicator

Light will Flash.

13

2M-4497-2 11/21/14

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

*Pop-Up Toasters

*Butter Dispensers

*Pretzel Merchandisers

(Model 16PD-A Only)

*Pastry Display Cabinets

*Nacho Chip Merchandisers

*Accessories of any kind

*Sneeze Guards

*Pizza Ovens

(Model PO12 Only)

*Heat Lamps

*Pumps-Manual

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in which

the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the transportation

company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

>Star will not assume any responsibility for loss of revenue.

>On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the Ultra-Max, Hot Plates, Griddles, Charbroilers is (3) years parts & labor.

* The warranty period for the Star-Max, Charbroilers, Griddles, Hot Plates, Fryers & Finishing Oven is (2) years parts & labor.

*The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* ThewarrantyperiodfortheChrome-MaxGriddlesisve(5)yearsonthegriddlesurface.Seedetailedwarrantyprovidedwithunit.

*The warranty period for Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Dura-Teccoatingsfromimpropercleaning,maintenance,useofmetallicutensils,orabrasivecleaners,abrasivepads,productidentiersand

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

>This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

>This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

>This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

>This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted, the labor to replace the part is NOT warranted.

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Traveltimeandmileagerenderedbeyondthe50mileradiuslimit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damagesduetoimproperinstallation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resettingofcircuitbreakersorsafetycontrolsorresetbuttons

16. Replacementofbulbs

17. Replacementoffuses

18. Repairofdamagecreatedduringtransit,delivery,&

installationORcreatedbyactsofGod

* TheModel510FD,510FFFryer.

* TheModel526TOAToasterOven.

* TheModelJ4R,4oz.PopcornMachine.

*TheModel518CMA&526CMACheeseMelter.

* TheModel12MC&15MC&18MCPHotFoodMerchandisers.

* TheModel12NCPW&15NCPWNachoChip/PopcornWarmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* AllQCS/RCSSeriesToastersexcept Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

14

2M-Z10887 Owners Manual Fast Steamers

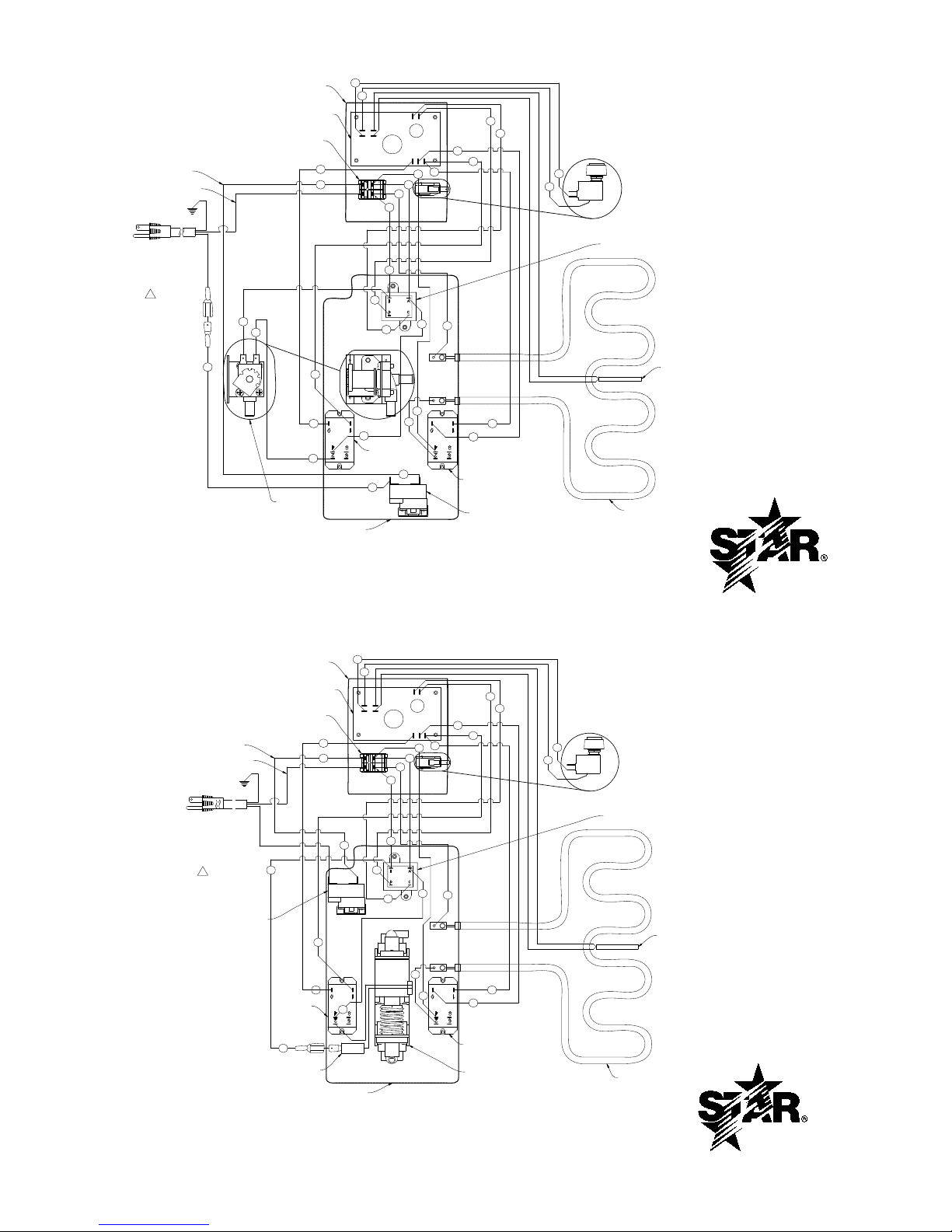

SK2250 Rev. C 8/30/2007

Sheet 1 of 8

WIRING DIAGRAM

FS1DT & FS2DT

COMPLETE

A

4

2

E11

E12

E1

E2

E3 E4

E7 E6 E5

RTD PROBE

1

NC3

N02 COM

6

5

2

7

3

3

3

7

8

B

B

A

3

89

1

1

1

2

2

1

2

6

5

ELECTRONIC

CONTROL

(BACK SIDE)

PUSH BUTTON

POWER

SWITCH

HEATER RELAY

HIGH LIMIT

THERMOSTAT

TRANSFORMER

120V/10V

120V

SOLENOID

CONTROL BOX

MOUNTING PLATE

CONTROL PANEL

MOUNTING PLATE

HEATING

ELEMENT

4

BLACK WIRE (TYP)

WHITE WIRE (TYP)

SOLENOID

RELAY

10

10

10

10

CORDSET

120V: NEMA 5-15P

(SHOWN)

120VC: NEMA 5-20P

(NOT SHOWN)

B

SK2250 Rev. C 8/30/2007

Sheet 2 of 8

WIRING DIAGRAM

FS1RT & FS2RT

COMPLETE

2

E11

E12

E1

E2

E3 E4

E7 E6 E5

RTD PROBE

1

NC3

N02 COM

6

5

2

7

3

3

3

7

8

B

3

8

9

1

1

1

2

2

1

2

6

5

ELECTRONIC

CONTROL

(BACK SIDE)

PUSH BUTTON

POWER

SWITCH

HEATER RELAY

TRANSFORMER

120V/10V

PUMP

RELAY

CONTROL BOX

MOUNTING PLATE

CONTROL PANEL

MOUNTING PLATE

B

120V PUMP

2

DIODE AND WIRE

PART OF PUMP HEATING

ELEMENT

BLACK WIRE (TYP)

WHITE WIRE (TYP)

HIGH LIMIT

THERMOSTAT

10

10

10

10

CORDSET

120V: NEMA 5-15P

(SHOWN)

120VC: NEMA 5-20P

(NOT SHOWN)

B

15

2M-Z10887 Owners Manual Fast Steamers

SK2250 Rev. C 8/30/2007

Sheet 3 of 8

WIRING DIAGRAM

FS1D & FS2D

1

1

2

2

4

2

NC3

N02 COM

PUSH BUTTON

A

B

2

1

3

4

CONTROL BOX

MOUNTING PLATE

HIGH LIMIT

THERMOSTAT

STEAM GENERATOR

THERMOSTAT

HEATING

ELEMENT

120V SOLENOID

(SHOWN ON SIDE)

POWER

SWITCH

CONTROL PANEL

MOUNTING PLATE

BLACK WIRE (TYP)

WHITE WIRE (TYP)

CORDSET

120V: NEMA 5-15P

(SHOWN)

120VC: NEMA 5-20P

(NOT SHOWN)

B

3

1

A

C

C

WIRING DIAGRAM

FS1R & FS2R

SK2250 Rev. C 8/30/2007

Sheet 4 of 8

1

1

2

2

NC3

N02 COM

PUSH BUTTON

B

2

1

3

CONTROL BOX

MOUNTING PLATE

STEAM GENERATOR THERMOSTAT

STD MOUNTED ABOVE HIGH LIMIT

HEATING

ELEMENT

POWER

SWITCH

CONTROL PANEL

MOUNTING PLATE

3

1

B

STEAM GENERATOER HIGH LIMIT THERMOSTAT

STD MOUNTING BELOW THERMOSTAT

2

BLACK WIRE (TYP)

WHITE WIRE (TYP)

CORDSET

120V: NEMA 5-15P

(SHOWN)

120VC: NEMA 5-20P

(NOT SHOWN)

16

2M-Z10887 Owners Manual Fast Steamers

SK2250 Rev. C 8/30/2007

WIRING DIAGRAM

FSFDT Sheet 5 of 8

NEMA 6-20P

CORDSET

FOR 208/240V

E11

E12

E1

E2

E3 E4

E7 E6 E5

RTD PROBE

NC3

N02 COM

6

5

2

7

3

3

3

7

8

B

3

8

9

1

1

1

2

2

2

6

5

ELECTRONIC

CONTROL

(BACK SIDE)

PUSH BUTTON

POWER

SWITCH

HEATER RELAY

TRANSFORMER

230V/10V

CONTROL BOX

MOUNTING PLATE

CONTROL PANEL

MOUNTING PLATE

1

5

5

6

HEATING

ELEMENT

SOLENOID

STD

MOUNTING

POSITION

(SHOWN ON

SIDE).

4

4

A

B

A

SOLENOID

RELAY

12 V

SOLENOID HIGH LIMIT

THERMOSTAT

BLACK WIRE (TYP)

WHITE WIRE (TYP)

10

10

10

10

SK2250 Rev. C 8/30/2007

Sheet 6 of 8

WIRING DIAGRAM

FSFD

NEMA 6-20P

1

1

2

2

B

3

1

A

5

2

NC3

N02 COM

PUSH BUTTON

A

CORDSET FOR

208/240V

B

2

4

3

5

CONTROL BOX

MOUNTING PLATE

HIGH LIMIT

THERMOSTAT

STEAM GENERATOR

THERMOSTAT

HEATING

ELEMENT

POWER

SWITCH

CONTROL PANEL

MOUNTING PLATE

12 V SOLENOID

(SHOWN ON SIDE)

6

64

BLACK WIRE (TYP)

WHITE WIRE (TYP)

C

C

17

2M-Z10887 Owners Manual Fast Steamers

SK2250 Rev. A 8/3/2007

Sheet 7 of 8

WIRING DIAGRAM

FSFRT

NEMA 6-20P

CORDSET

FOR 208/240V

E11

E12

E1

E2

E3 E4

E7 E6 E5

RTD PROBE

NC3

N02 COM

6

5

2

7

3

3

3

7

8

B

3

8

9

1

1

1

2

2

2

6

5

ELECTRONIC

CONTROL

(BACK SIDE)

PUSH BUTTON

POWER

SWITCH

HEATER RELAY

TRANSFORMER

40 VA 230V/12V

PUMP

RELAY

CONTROL BOX

MOUNTING PLATE

CONTROL PANEL

MOUNTING PLATE

B

12V PUMP

6

DIODE AND WIRE

PART OF PUMP

1

SEE

DETAIL

A

5

5

6

HEATING

ELEMENT

A & B - 1/4" MALE

W/BLACK WIRE LEADS

C & D - 3/16" MALE

W/WHITE WIRE LEADS

DETAIL A

TRANSFORMER

INLINE FUSEHOLDER

W/4AMP FUSE

HIGH LIMIT

THERMOSTAT

BLACK WIRE (TYP)

WHITE WIRE (TYP)

10

10

10

10

WIRING DIAGRAM

FSFR

SK2250 Rev. C 8/30/2007

Sheet 8 of 8

NEMA 6-20P

1

1

2

2

NC3

N02 COM

PUSH BUTTON

CORDSET FOR

208/240V

B

2

3

CONTROL BOX

MOUNTING PLATE

STEAM GENERATOR THERMOSTAT

STD MOUNTED ABOVE HIGH LIMIT

HEATING

ELEMENT

POWER

SWITCH

CONTROL PANEL

MOUNTING PLATE

3

1

B

STEAM GENERATOER HIGH LIMIT THERMOSTAT

STD MOUNTING BELOW THERMOSTAT

2

SEE

DETAIL

A

1

DIODE AND WIRE

PART OF PUMP

INLINE FUSEHOLDER

W/4AMP FUSE

12 V PUMP

BLACK WIRE (TYP)

WHITE WIRE (TYP)

A & B - 1/4" MALE

W/BLACK WIRE LEADS

C & D - 3/16" MALE

W/WHITE WIRE LEADS

DETAIL A

TRANSFORMER

B

18

2M-Z10887 Owners Manual Fast Steamers

STAR MANUFACTURING INTERNATIONAL, INC.

Front Loading Steamer Main Body Assembly

Rev. B 1/18/13SK2276

MODEL: FSF

FSFRT Exploded

SK2276

1

3

2

4

18

5

8

6

12

13

11

10

9

11

14

7

15

16

17

20

19

21 22

19

2M-Z10887 Owners Manual Fast Steamers

PARTS LIST August 31, 2009, Rev. E

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 1

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

MODEL: FSFR, FSFD, FSFRT, FSFDT, Front Loading Fast Steamer Main Body

Fig NO Part Number Qty Description Application

1 C9-Z10101 1 TOP FRONT LOADING

2 2C-Z10133 2 NUT, WING 10-24 SS FRONT LOADING

3 C9-Z10095 1 COVER, CASTING FRONT LOADING

4 C9-Z10096 1 DISPERSER FRONT LOADING

5 2C-08-07-0285 1 SCREW 10-24X3/4X3/8 TYPE 2 HEX DBL END STL FRONT LOADING

6 C9-Z10069 1 RACK, WIRE STEAMER FRONT LOADING

6 C9-FS0313 1 LINER ASSEMBLY FSF STEAMER FRONT LOADING

7 C9-FS0373 1 SPATULA ASSEMBLY FRONT LOADING

8 2B-Z10069 1 SPATULA WIRE ASSY FRONT LOADING

9 2C-Z11259 1 BOLT CARRIAGE 3/8-16X1” SS FRONT LOADING

10 2A-Z11257 1 SPATULA HANDLE TUBE FRONT LOADING

11 2A-Z11258 2 SPATULA ANGLED WASHER FRONT LOADING

12 C9-Z10103 1 SPATULA FRONT LOADING

13 C9-Z9990 1 SPATULA FRONT FRONT LOADING

14 2R-09-WB-0027 1 HANDLE-BLK 3/8-16 HD698 FRONT LOADING

15 C9-Z10105 1 DRIP TRAY FRONT LOADING

16 2C-Z6925 6 SCREW,#8 X.5 TEK HW SS FRONT LOADING

17 C9-Z11250 1 DRIP TRAY SUPPORT FSF FRONT LOADING

18 2A-Z9989 4 FOOT, 2” STEAMER FRONT LOADING

19 2c-200015 2 SCREW, 8-32 X 3/8 KNURLED BR FRONT LOADING

20 C9-FS0301 1 VENT ASSEMBLY FRONT LOADING

21 C9-FS0344 1 FSF CASTING ASSEMBLY 208V FRONT LOADING 208V

21 C9-FS0345 1 FSF CASTING ASSEMBLY 230V FRONT LOADING 230/240V

22 2C-3033 12 SCREW-MACH 8-32X3/4 NPST FRONT LOADING

20

2M-Z10887 Owners Manual Fast Steamers

STAR MANUFACTURING INTERNATIONAL, INC.

Main Body Assembly

Rev. A 10/25/11SK2281

MODEL FS1 & FS2

1

2

345

6

7

8

10

9

11

12

13

14

17

16 15

16

20

22

21

18

23

24

19

21

Other manuals for FS1R

1

This manual suits for next models

11

Table of contents

Other Star Electric Steamer manuals