EMTEST CNI 503 Series Technical Document

Manual

f o r O p e r a t i n g

CNI 503 / CNI 501

3-phase coupling decoupling network

CNI 503x

CNI 503 A series

CNI 503 B series

1-phase coupling decoupling network

CNI 501x

Testing of electronic modules with EFT/burst, 1.2/50s Surge or

Ring Wave pulses up to 10kV, 5kA

The CNI 503 couples the surge and burst pulses from the

impulses generators UCS 500Nx to a three phase test object

(coupling as per. IEC or ANSI standard).

The CNI 503 is controlled from EM Test transient generator of

the Series 500 (UCS 500Nx, VCS 500Nx, EFT 500Nx).

Burst, Surge and

Ringwave Pulse as per.

–IEC 61000-4-4

–IEC 61000-4-5

–IEC 61000-4-12

–ANSI

Version:

3.32 / 28.06.2016

the benchmark for emc

Replaces:

3.31 / 14.06.2016

Filename:

UserManual-CNI503-E-V3.32.doc

Printdate:

28.06.16

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 2 / 41

EM TEST (Switzerland) GmbH

Sternenhofstrasse 15

4153 Reinach BL1

Switzerland

Phone : +41 61 717 91 91

Fax : +41 61 717 91 99

URL : http://www.emtest.com

Copyright © 2016 EM TEST (Switzerland) GmbH

. All right reserved.

Specifications subject to change

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 3 / 41

Contents

1. List of coupling networks.............................................................................................................................5

1.1. Coupling networks for IEC pulses.........................................................................................................5

1.2. Coupling networks as per IEC, ANSI and Ringwave............................................................................6

1.3. Special Coupling networks....................................................................................................................7

2. Operating Functions .....................................................................................................................................8

2.1. Front view..............................................................................................................................................8

2.2. Rear side...............................................................................................................................................9

2.3. CNI 501 S1..........................................................................................................................................10

3. General .........................................................................................................................................................11

3.1. Coupling modes ..................................................................................................................................11

3.2. Coupling to Signal Lines .....................................................................................................................11

4. Technical Data CNI 503 ................................................................................................................................12

4.1. EUT power supply...............................................................................................................................12

4.2. DC current capability of CNI 503Nx....................................................................................................13

4.3. Technical data special CNI 503 ..........................................................................................................14

4.4. General................................................................................................................................................15

4.5. Test level with Burst as per IEC 61000-4-4 Ed.2................................................................................16

4.6. Decoupling inductors for surge pulse..................................................................................................16

5. Operation......................................................................................................................................................17

5.1. Power supply input (EUT)...................................................................................................................17

5.2. Synchronization...................................................................................................................................17

5.3. Connection of DC Equipment..............................................................................................................18

5.4. Operation with CNI coupler or generator internal CDN ......................................................................19

6. Test set up....................................................................................................................................................20

6.1. Grounding............................................................................................................................................21

6.2. Surge coupling to CNV504 / 508 network for surge to signal- and data-lines....................................22

6.2.1. Burst coupling to HFK capacitive coupling clamp for signal- and data lines ......................................22

6.3. Test setup CNI 503 with UCS500N5E and UCS500N5V generators.................................................23

6.4. Test setup CNI 501 / 503 with EFT 500/800 and VCS 500 generators..............................................24

6.5. test setup with CNI 501 BS3 or CNI 503B7.5.....................................................................................25

7. ANSI Coupling (option)...............................................................................................................................26

8. CNI 503 Rack Mountain...............................................................................................................................27

9. Special coupling networks.........................................................................................................................28

9.1. CNI 501B9...........................................................................................................................................28

9.1.1. Operating elements.............................................................................................................................28

9.1.2. Technical Data ....................................................................................................................................29

9.1.3. AC Application.....................................................................................................................................29

9.1.4. DC Application.....................................................................................................................................30

9.1.5. Schematics..........................................................................................................................................30

10. Maintenance and calibration......................................................................................................................31

10.1. General................................................................................................................................................31

10.2. Calibration and Verification.................................................................................................................31

10.2.1. Factory calibration..........................................................................................................................31

10.2.2. Guideline to determine the calibration period of EM Test instrumentation ....................................31

10.2.3. Calibration of Accessories made by passive components only:....................................................31

10.2.4. Periodically In-house verification....................................................................................................31

11. Delivery Groups...........................................................................................................................................32

11.1. Basic equipment..................................................................................................................................32

11.2. Accessories and options .....................................................................................................................32

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 4 / 41

12. Appendix ......................................................................................................................................................33

12.1. Declaration of CE-Conformity .............................................................................................................33

12.2. Connectors..........................................................................................................................................34

12.2.1. 32 A plugs and connectors 4mm from Multi Contact .....................................................................34

12.2.2. 100 A plugs and connectors 6mm from Multi Contact ...................................................................34

12.2.3. Multi Contact MC Locking system (AR-system).............................................................................35

12.2.4. 100 A DC plugs and connectors from Multi Contact......................................................................35

12.3. General diagram ................................................................................................................................36

12.4. Inrush current.....................................................................................................................................41

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 5 / 41

1.

List of coupling networks

1.1.

Coupling networks for IEC pulses

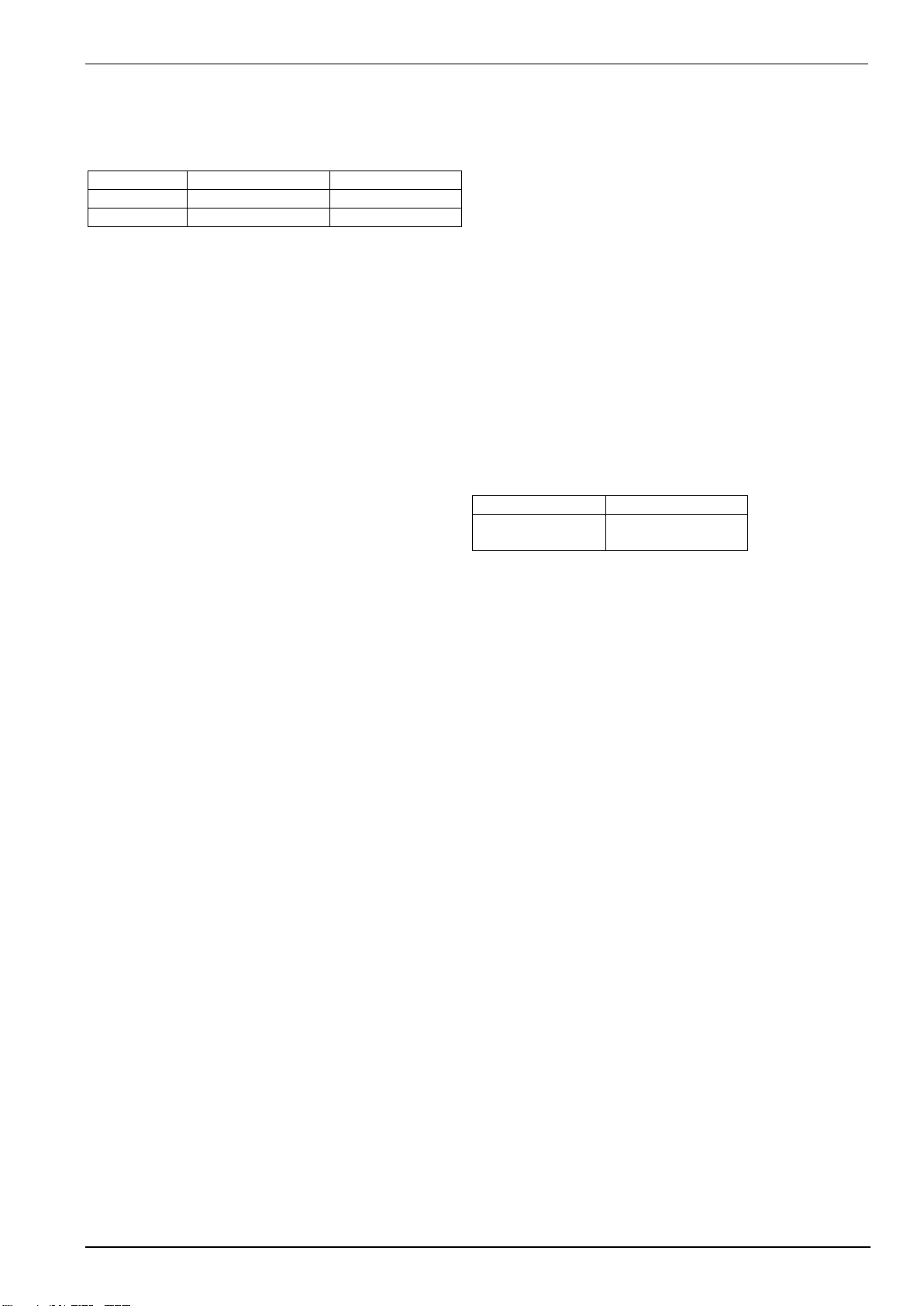

Device

Impulse Phase Supply rated Current ac

Remarks

CNI 501

5.5kV 1 250V 32A

48V/32A dc

CNI 501 S1

5.5kV 1 250V 100A

75V/100A dc

CNI 503 A

5.5kV 3 3x480V 16A

CNI 503 A2

5.5kV 3 3x480V 32A

CNI 503 A3

5.5kV 3 3x480V 63A

RACK required

CNI 503 A4

5.5kV 3 3x480V 100A

RACK required

CNI 503 A4.1

5.5kV 3 3x440V 100A

EN 50121-4

CNI 503 A5

7kV 3 3x480V 16A

CNI 503 A7

7kV 3 3x480V 32A

CNI 503 A8

7kV 3 3x480V 63A

RACK required

CNI 503 A9

7kV 3 3x480V 100A

RACK required

CNI 503 A10

8kV 3 3x480V 16A

CNI 503 A12

8kV 3 3x480V 32A

CNI 503 A13

8kV 3 3x480V 63A

RACK required

CNI 503 A14

8kV 3 3x480V 100A

RACK required

CNI 503 A16

10kV 3 3x480V 16A

CNI 503 A18

10kV 3 3x480V 32A

CNI 503 A19

10kV 3 3x480V 63A

RACK required

CNI 503 A20

10kV 3 3x480V 100A

RACK required

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 6 / 41

1.2.

Coupling networks as per IEC, ANSI and Ringwave

Device

Impulse Phase Supply rated Current ac

Remarks

CNI 503 B5

7kV 3 3x480V 16A

CNI 503 B7

7kV 3 3x480V 32A

CNI 503 B8

7kV 3 3x480V 63A

RACK required

CNI 503 B9

7kV 3 3x480V 100A

RACK required

Device

Imp Phase Supply AC

Remarks

CNI 501 B9

7kV 1 AC 250V 100A

DC 75V 100A

- IEC 61000-4-5, ANSI/IEEE C62.41

- TEST ON function (possibility for Emergency Switch and

no Warning lamp control!!!)

CNI 503 B7.2

7kV 3 AC 3x480V 32A

DC 1000V 32A

- IEC 61000-4-5, ANSI/IEEE C62.41

- No TEST ON function (no possibility for an

Emergency Switch and no Warning lamp control!!!)

CNI 503 B7.3

7kV 3 AC 3x480V 32A

DC 1000V 32A

- IEC 61000-4-5, ANSI/IEEE C62.41

- TEST ON function (possibility for Emergency Switch and

Warning lamp control)

- Needs a rack to be ordered separately

CNI 503 B7.4

7kV 3 AC 3x690V 32A

DC 1000V 32A

- IEC 61000-4-5, ANSI/IEEE C62.41

- No TEST ON function (no possibility for an

Emergency Switch and no Warning lamp control!!!)

- Needs a UCS 500N7.2 or UCS 500N7.7

CNI 503 B7.5

7kV 3 AC 3x690V 32A

DC 1000V 32A

- IEC 61000-4-5, ANSI/IEEE C62.41

- TEST ON function (possibility for Emergency Switch and

Warning lamp control)

- Needs a UCS 500N7.2 or UCS 500N7.7 and a rack

CNI 503 B9.2

7kV 3 AC 3x480V 100A

DC 1000V 100A

- IEC 61000-4-5, ANSI/IEEE C62.41

- No TEST ON function (possibility for Emergency Switch

and Warning lamp control)

- Needs a rack to be ordered separately

CNI 503 B9.6

7kV 3 AC 3x480V 100A

DC 1000V 100A

- IEC 61000-4-5, ANSI/IEEE C62.41

- TEST ON function (no possibility for an

Emergency Switch and no Warning lamp control!!!)

- Needs a rack to be ordered separately

Coupling networks for the US are generally specified for a 3 phase power mains supply of 3x480Vrms.

It is forbidden to disconnect the plug in DC operation under voltage.

Risk of a stationary spark!

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 7 / 41

1.3.

Special Coupling networks

Device

Impulse Phase Supply rated Current ac

Remarks

CNI 503 A.1

5.5kV 3 3x690V 16A

needs a UCS 500N5.2

CNI 503A S1

5.5kV 3 3x690V 16A

CNI 503A S2

5.5kV 3 3x690V 32A

CNI 503 A2.1

5.5kV 3 3x690V 32A

needs a UCS 500N5.2

CNI 503 A2.2

5.5kV 3 3x480V / DC 1000V 32A

No TEST ON function

CNI 503 A2.6

5.5kV 3 3x480V / DC 1000V 32A

With TEST ON function

500 VDC / 150 A

CNI 503A2.10

5.5kV 3 3x690V / DC 1000V 32A

No TEST ON function

CNI 503A3.1

5.5kV 3 3x690V 63A

requires MRAC or RAC 1000V dc

CNI 503A S3

5.5kV 3 3x690V 63A

requires MRAC or RAC

CNI 503A S4

5.5kV 3 3x690V 100A

requires MRAC or RAC

CNI 503B S1

7kV 3 3x690V 16A

CNI 503B S2

7kV 3 3x690V 32A

CNI 503B S3

7kV 3 3x690V 63A

requires MRAC or RAC

CNI 503B S4

7kV 3 3x690V 100A

requires MRAC or RAC

CNI 503B S7

7kV 3 3x208V 32A 400Hz

Burst 6.0kV

CNI 503 A14.1

8kV 3 3x480V 100A

requires Rack 32 or 34 UH

CNI 503 A12 S2

8kV 3 3x690V 32A

IEC @ANSI-B coupling (manual)

CNI 503 A16 S1

10kV 3 3x690V 16A

CNI 503A S22

4.4kV 3 3x480V 200A

requires MRAC or RAC

CNI 501B S3

7kV 1 250V 1000 VDC 32A

Ohne Test ON Function,

CNI 501 S4

10kV 1 250V 10A

CNI 501 S6

10kV 1 250V 16A

Generator impedance 2Ω

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 8 / 41

2.

Operating Functions

2.1.

Front view

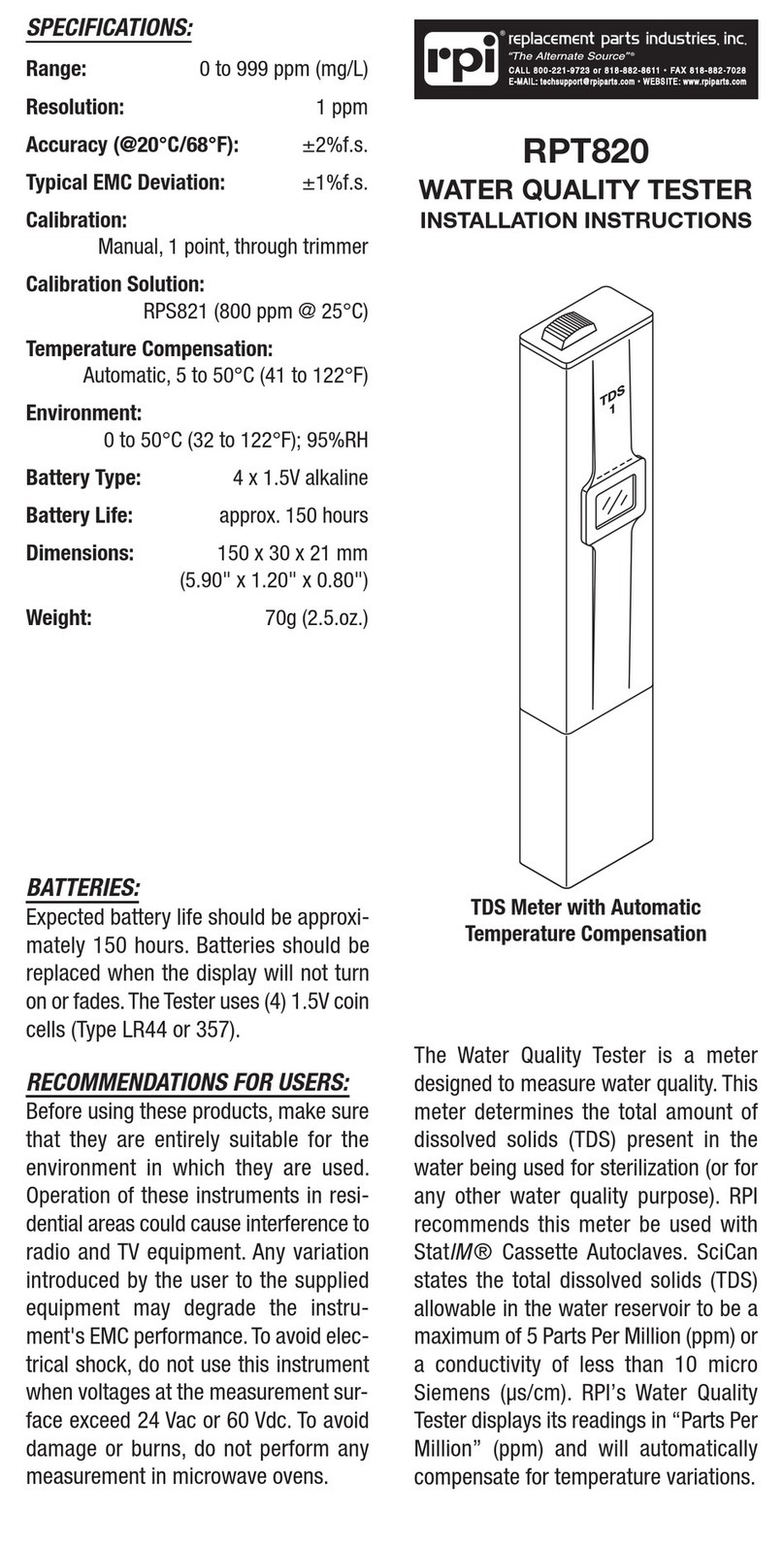

Figure 2.1: CNI 503 font view ( model for 4kV )

1"TEST ON

2Switching ANSI -IEC

3EFT output to HFK coupling clamp

4HV output for ext. surge coupling networks

5COM output for ext. surge coupling networks

6DUT Output L1/DC+, L2, L3, N/DC-, PE

7Earth plug for EFT burst verification

8LED display Pulse (EFT / 50HFK / Surge)

9LED display couplings

10 EFT input from UCS 500Mx / EFT 500/800

1 Button Test On

Press this button to connect the power mains supply to the EUT via the built in relay switch. The yellow light in the button

indicates the switched mains to the EUT.

2 Button ANSI / IEC (Option)

This button changes the coupling between ANSI coupling and IEC coupling.

LED disabled: IEC coupling 2L-L or L-N 10L-PE, N-PE

LED enabled: ANSI coupling 2all couplings

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 9 / 41

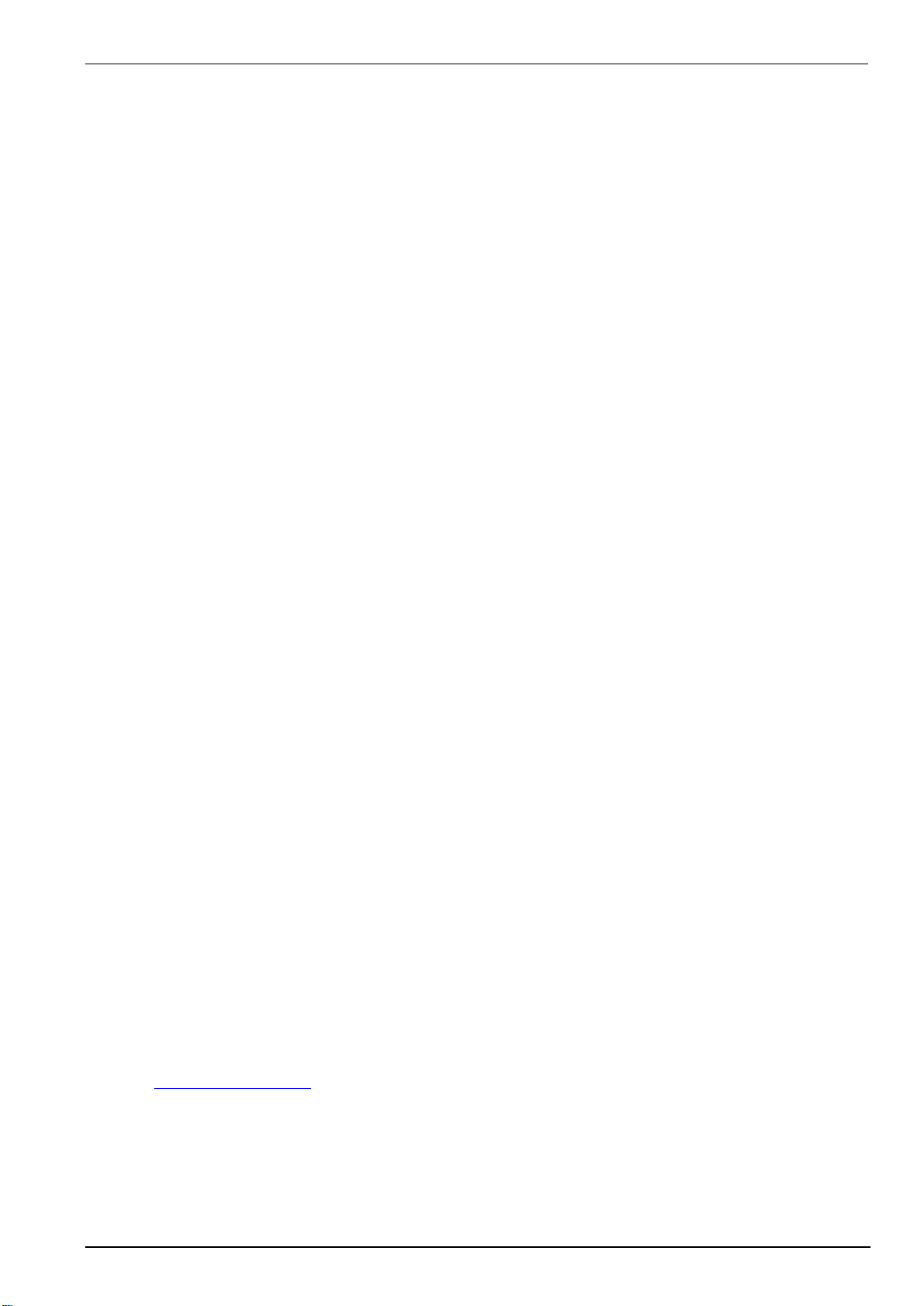

2.2.

Rear side

Figure 2.2: Rear side CNI 503 (4kV version)

Figure 2.3: CNI 503 Rear side (> 4kV version)

1EUT power L1, L2, L3

2EUT power N

3EUT power PE

4Ground Reference

5HV Input from generator

5HV Input from generator

6COM Input from generator

7 Power switch with fuse

8Voltage selector 230V / 115V

9 CN control input from UCS generator

10 CN control input from EFT and or VCS generator

If the CNI 503 includes two or more CN interfaces for UCS500NE and UCS500NV, only one

generator is allowed to communicate to the CNI 503. In case that all remote control input, for UCS

(9) and EFT/VCS (10), are included in the CNI 503 the operator has to take care that either the

UCS or the EFT/VCS is controlling the CNI.

A simultaneous operation by more than one generators is not allowed.

The CN control input is available in two different versions.

- Interface to generators of the series UCS 500xx

- Interface to generators of the series EFT 500x and or VCS500x

The connectors have different pin configurations. Therefore each generator

must be plugged in as signed at the rear panel.

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 10 / 41

2.3.

CNI 501 S1

Figure 2.3: Front side CNI 501 S1 with AC / DC switch

Figure 2.4: CNI 501 S1 rear side

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 11 / 41

3.

General

The coupling network has to couple the transients well defined to the lines of a power supply system. The coupling is

realized by discrete coupling capacitors, having a sufficient voltage capability and bandwidth. The specification is

given in IEC 61000-4-4, IEC 61000-4-5, IEC 61000-4-12 and ANSI.

There are different coupling network models available:

Model

Burst

Surge IEC

Surge ANSI

Ringwave

CNI 503B

X

X

X

X

CNI 503A

X

X

--

--

CNV 503

--

X

--

--

CNE 503

X

--

--

--

CNI 501

X

X

--

--

The coupling/decoupling network is divided in two parts:

- The decoupling and filtering unit

- The coupling unit

The decoupling unit has to

-To decouple the low impedance power mains supply from the test setup.

-protect other equipment which is connected to the power mains supply

But which is not part of the test set-up.

The coupling network superimposes the transients to the lines of a power supplysystem, AC as well as DC supply.

3.1.

Coupling modes

The test can be conducted with different coupling modes.

61000-4-5 Surge immunity requirements

- Line or lines to protective earth (unsymmetrical) e.g. L1-PE; L1+L2+L3+N-PE

- Line to Line (symmetrical) e.g. L1-L2 or L3-N

61000-4-4 Electrical fast transients

Line or lines to reference ground. All combinations are possible. The protective earth (PE) is regarded as equal to

all other lines and therefore is tested as all other lines

3.2.

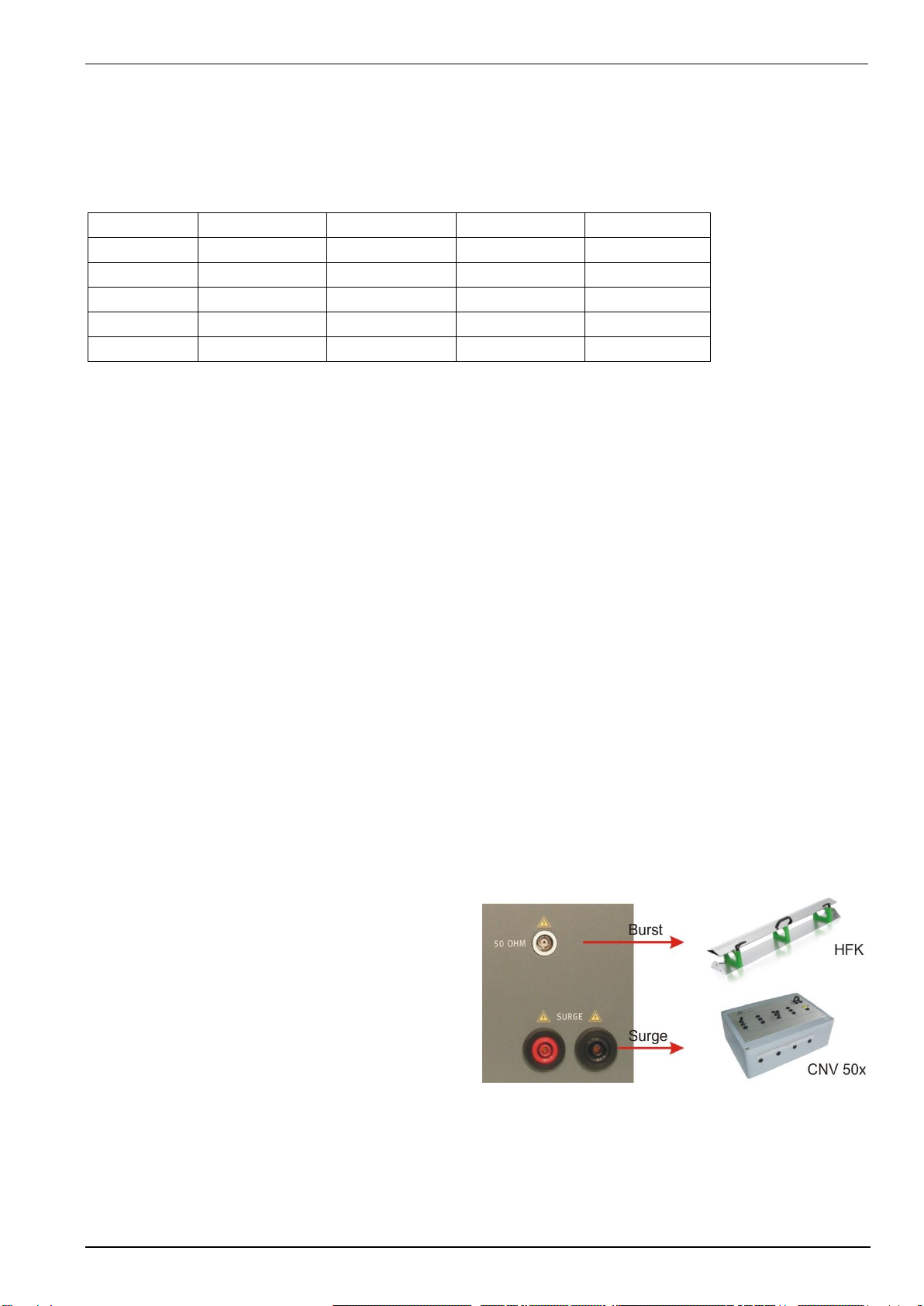

Coupling to Signal Lines

The coupling to I/O lines is generally realized with other

coupling networks than used for power supply lines. The

loading of the I/O lines with big coupling capacitors is

mostly not possible. The data transmission may be

disturbed

For coupling to I/O lines special couplers acc. to IEC

61000-4-5 are available, such as the CNV 504 and the

CNV 508 for four respectively for eight wire systems. For

coupling the EFT transient to signal lines the capacitive

coupling clamp is used. The clamp can also be

connected and controlled via the CNI 503 networks but

normally shall be connected directly to the coaxial output

of the generator itself.

Figure 3.1: External device plug for Burst and Surge

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 12 / 41

4.

Technical Data CNI 503

4.1.

EUT power supply

Pulse peak

Coupling network

EUT supply 50/60Hz

Remarks

voltage

IEC, ANSI,

Ringwave

IEC

Voltage Current ac/dc

ac dc

5.5kV

CNI 501

1x250V 32A

dc 48V/32A

CNI 501 S1

1x250V 100A

dc 75V/100A

5.5kV

CNI 503 A

3x480V 16A

CNI 503 A2

3x480V 32A

CNI 503 A2

3x480V 32A

dc 1000V 32A

CNI 503 A3

3x480V 63A

requires MRAC or RAC

CNI 503 A4

3x480V 100A

requires MRAC or RAC

CNI 503 A5 S22

3x480V 200A

requires MRAC or RAC

CNI 503 A2.10

3x690V, 1000V 32A

No Test ON

CNI 503 A S1

3x690V 16A

CNI 503 A S2

3x690V 32A

CNI 503 A S3

3x690V 63A

requires MRAC or RAC

CNI 503 A S4

3x690V 100A

requires MRAC or RAC

7kV

CNI 503 B5

CNI 503 A5

3x480V 16A

CNI 503 B7

CNI 503 A7

3x480V 32A

CNI 503 B7.2

3x480V, 1000V 32A

No Test ON

CNI 503 B7.3

3x480V, 1000V 32A

Test ON, need MRAC or RAC

CNI 503 B7.4

3x690V, 1000V 32A

No Test ON, need MRAC or RAC

CNI 503 B8

CNI 503 A8

3x480V 63A

requires MRAC or RAC

CNI 501 B9

250V, 75V 100A

6 HU, Test ON

CNI 503 B9

CNI 503 A9

3x480V 100A

requires MRAC or RAC

CNI 503 B9.2

3x480V, 1000V 100A

No Test ON, need MRAC or RAC

CNI 503 B9.6

3x480V, 1000V 100A

Test ON, need MRAC or RAC

CNI 503 B S1

3x690V 16A

CNI 503 B S2

3x690V 32A

CNI 503 B S3

3x690V 63A

requires MRAC or RAC

CNI 503 B S4

3x690V 100A

requires MRAC or RAC

8kV

CNI 503 A10

3x480V 16A

CNI 503 A12

3x480V 32A

CNI 503 A13

3x480V 63A

requires MRAC or RAC

CNI 503 A14

3x480V 100A

requires MRAC or RAC

CNI 503 A14.1

3x480V 100A

requires MRAC or RAC

10kV

CNI 501 S4

1x250V 10A

CNI 501 S6

1x250V 16A

Generator impedance

2Ω

CNI 503 A16

3x480V 16A

CNI 503 A18

3x480V 32A

CNI 503 A19

3x480V 63A

requires MRAC or RAC

CNI 503 A20

3x480V 100A

requires MRAC or RAC

CNI 503 A16 S1

3x690V 16A

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 13 / 41

4.2.

DC current capability of CNI 503Nx

CNI models with a built in ac mains contactor have a reduced dc switching capability. This current rate depends

on the following parameters:

-contactor model

-applied dc voltage

-time constant L/R of the dc circuit

The following list shows the dc current of the most models.

-Internal decoupling inductance 2 x 1.5 mH (16A models)

CNI 503Nx with rated power 3x480V 16A

dc time constant

dc current capability

DC-1 L/R ≤ 1ms

24V DC : 25A

48V DC : 10A

60V DC : 8A

110V DC : 2A

CNI 503Nx with rated power 3x480V 32A

dc time constant

dc current capability

DC-1 L/R ≤ 1ms

24V DC : 40A

48V DC : 23A

60V DC : 18A

110V DC : 8A

220V DC : 1A

DC-3 L/R ≤ 2ms

24V DC : 19A

48V DC : 10A

60V DC : 5A

110V DC : 1.8A

220V DC : 0.3A

CNI 503Nx with rated power 3x480V 63A / 100A

dc time constant

dc current capability

DC-1 L/R ≤ 1ms

24V DC : 70A

48V DC : 60A

75V DC : 60A

110V DC : 8A

220V DC : 6A

DC-3 - DC-5 L/R < 2ms

24V DC : 40A

48V DC : 30A

75V DC : 30A

110V DC : 3A

220V DC : 1A

CNI 503Nx with rated power 3x690V 63A / 100A

dc time constant

dc current capability

DC-1 L/R ≤ 1ms

< 75V DC : 220A

110V DC : 110A

DC-3 - DC-5 (L/R ≤ 15ms)

< 75V DC : 160A

110V DC : 80A

The IEC 60947-4-1 rating system is broken down into different utilization categories that define the value of the

current that the contactor must make, maintain, and break.

DC-1

Non inductive or slightly inductive loads, resistance furnaces, heaters

DC-3

Shunt motors, starting and breaking of a shunt motor during inching or plugging. The time constant

shall be less than or equal to 2 msec. On de-energization, the contactor will break around 2.5 times the

starting current at a voltage that may be higher than the line voltage.

DC-5

Series-motors, starting and breaking of a series motor during inching or plugging. The time constant

being less than or equal to 7.5 msec. On energization, the contactor sees about 2.5 times the nominal

full load current. On de-energization, the contactor breaks the same amount of current at a voltage

which can be equal to the line voltage.

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 14 / 41

4.3.

Technical data special CNI 503

Differences to the standard CNI 503 devices:

Device

Based on

Differences

CNI503 B S7

CNI 503 B7

7 kV 32 A

- 3x208 V; 400 Hz

- Coupling capacitor surge = 1 F

- Inductance per phase = 160 H

- Burst 6.0 kV

For the CNI 503BS7 which is designed for a 400Hz power mains supply

network the series inductors had to be limited to 160uH totally. Then

the pulse duration of the applied surges are reduced furthermore.

CNI 503A12S2

- 3x690V 50/60 Hz

- 8 kV Surge

- IEC & ANSI-B Kopplung manuell wählbar

Dimension: 19“, 9 HU

500 mm x 448 mm x 420 mm (LxBxH)

Weight: 48.9 kg

CNI 503 A14.1

- 3x440 V 50/60 Hz

- 8k V Surge

Dimension: 19“, 34 HU Rack

Weight: 181 kg (Rack with CNI 503A14.1 no generators)

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 15 / 41

4.4.

General

DC supply as per tables in 4.2

Coupling modes Surge IEC 61000-4-5

Line to Ground all combinations coupling capacitor 9F Source impedance 12

Line to Line all combinations coupling capacitor 18F Source impedance 2

Output sockets for testing signal and data lines with CNV 504 and CNV 508

Coupling modes Burst IEC 61000-4-4

Line(s) to ground all combinations

Output sockets for capacitive coupling clamp

Remote control

UCS 500; all models Burst and Surge

EFT 500, all models Burst

VCS 500M; all models Surge

Note: In case that all remote control input at the CNI 503 are available and the user has all above

mentioned generators available a simultaneous use of all generators is not allowed.

The operator has to decide either to use the UCS 500 or the EFT/VCS combination of generators.

Power supply

Mains 115 V / 230 V

Fuse 2 A slow blow all models

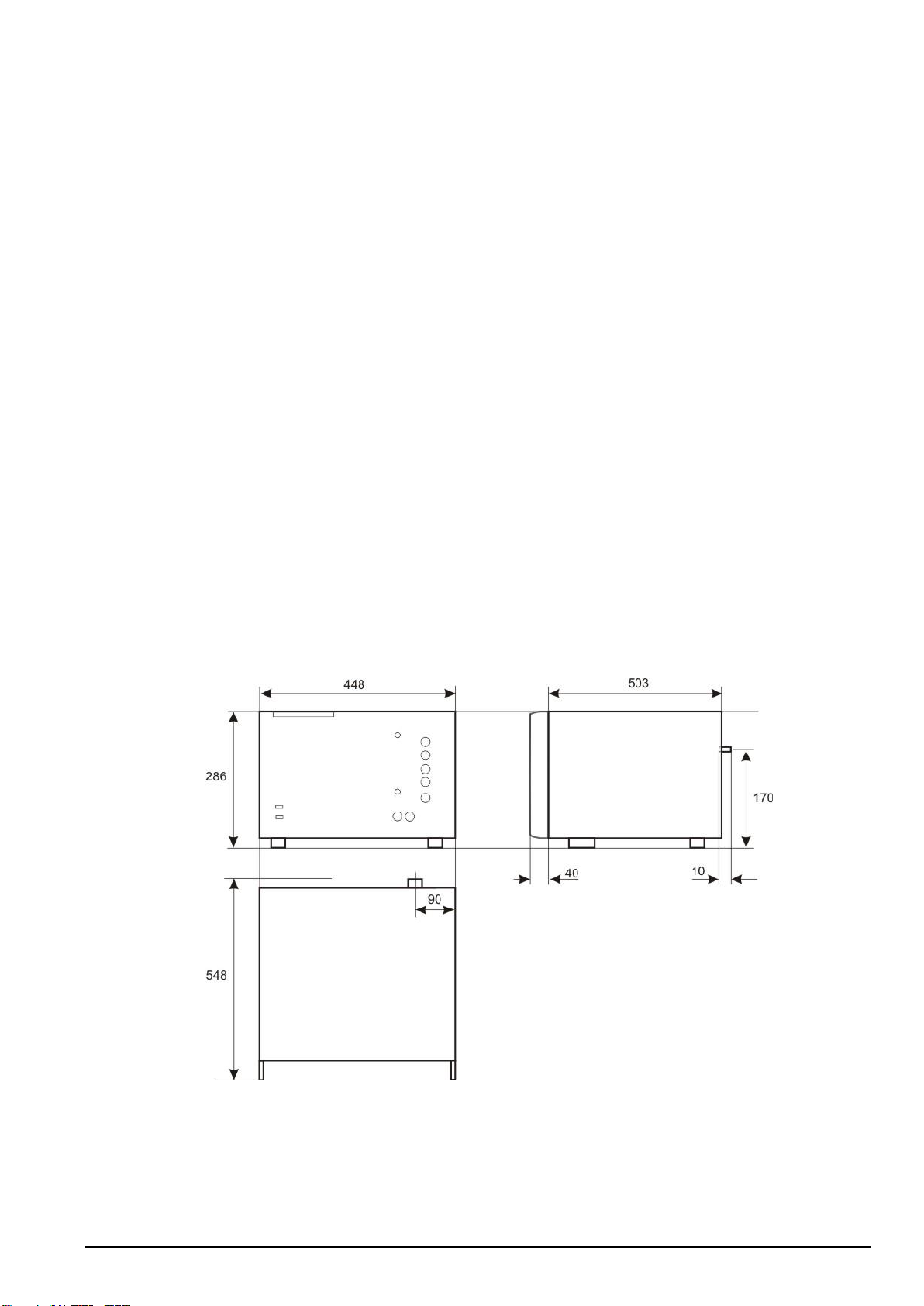

Dimension and weight

Housing 19” 6HU (models up to 32 A all models if not otherwise specified)

Weight 16 A models 3-ph: Approx. 30 kg

32 A models 3-ph: Approx. 45 kg models 1-ph approx. 30 kg

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 16 / 41

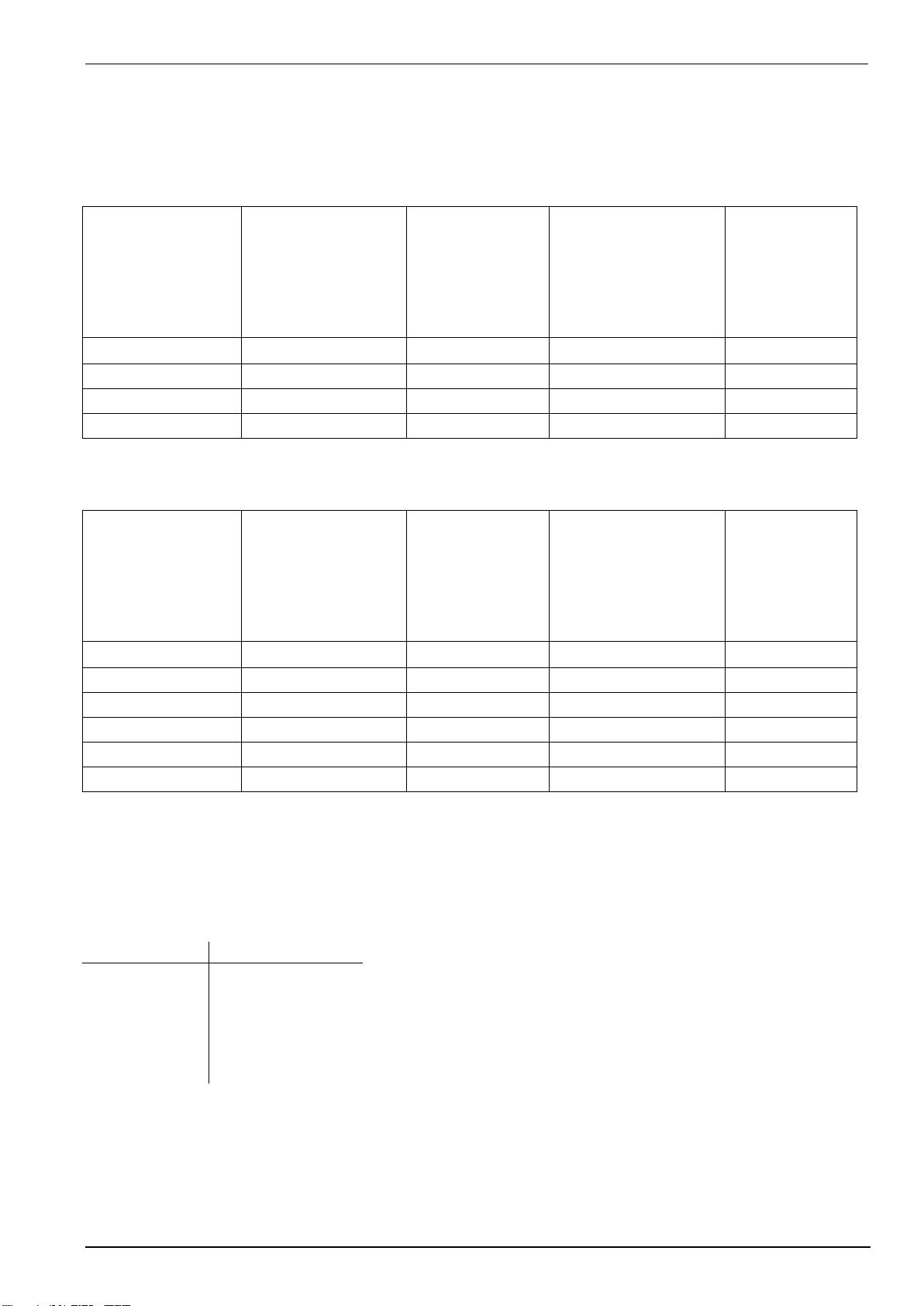

4.5.

Test level with Burst as per IEC 61000-4-4 Ed.2.

Burst generators, which comply with the specifications of IEC 61000-4-4 Ed2: 2004, have a limitation of the

maximum output voltage. Then the maximum test level is limited by the number of coupling on several lines.

Please see the following limits:

Coupling

UCS 500 >Vers.3.0

UCS 500M4 >Vers.3.0

UCS 500N4

EFT 500 /

EFT 500 M4

EFT 500N5

UCS 500N5

UCS500M7

UCS 500M6B

UCS500N6

UCS 500M6 >Vers.3.0

UCS 500M6A >Vers.3.0

EFT 500N8

EFT 500 M8

50

4800V

4800V

5500V

7000V

1 coupling any

4800V

4800V

5500V

7000V

2 couplings any

4800V

4800V

5000V

7000V

3 couplings any

4800V

4800V

5000V

7000V

Generator with

CNI 503 / CNE 503

CNI 501

UCS 500 >Vers.3.0

UCS 500M4 >Vers.3.0

UCS 500N4

EFT 500 /

EFT 500 M4

UCS500N5

EFT 500N5

UCS 500N5

UCS500M7

UCS 500M6B

UCS500N6

UCS 500M6 >Vers.3.0

UCS 500M6A >Vers.3.0

EFT 500 M8

50

4800V

4800V

5500V

5500V

1 coupling any

4800V

4800V

5500V

5500V

2 couplings any

4000V

4000V

5000V

5000V

3 couplings any

4000V

4000V

5000V

5000V

4 couplings any

4000V

4000V

4500V

4500V

5 couplings any

4000V

4000V

4500V

4500V

4.6.

Decoupling inductors for surge pulse

To prevent unwanted voltage drops in the coupling/decoupling networks, the value of the decoupling element

generally must be reduced for coupling/decoupling networks rated at >25 A. The Table below shows the reduced

inductor values per line in function of the rated current.

Rated current

Inductance per line

16 A

1.5 mH

32 A

0.75mH

63 A

0.6mH

100 A

0.6mH

200 A

0.3mH

For this case, the “time to half value” of the open-circuit voltage waveform may be reduced in accordance with

Tables 6 and 7 in standard IEC 61000-4-5.

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 17 / 41

5.

Operation

5.1.

Power supply input (EUT)

The power supply input for the EUT is located at the rear side of the coupler. Adapters for customized three phase

connectors have to be realized by the user himself or can be manufactured on customer’s specification.

The output of the power mains supply (surged lines) for the EUT is located at the front panel of the equipment.

5.2.

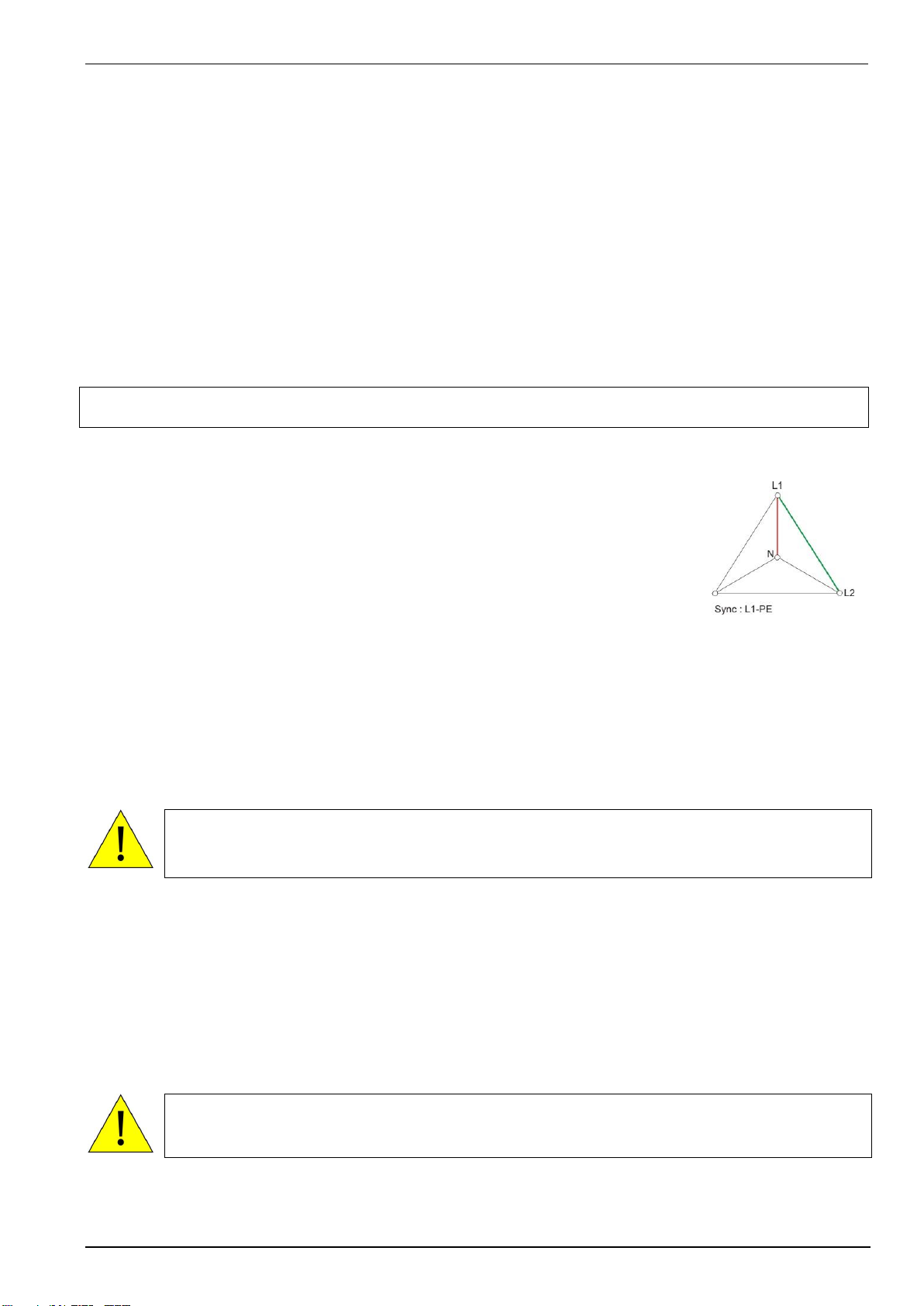

Synchronization

The transients generally must be related to a certain phase angle of the power supply. This is required for the surge

test and optional for the burst test.

The synchronization is normally realized within the VCS, the EFT and the UCS generator and is related to the power

supply input at the rear of the equipment, to phase L or the “Sync” input at the rear panel of the generator.

Then when using external 3ph couplers the generator itself has no power mains supply connected to the input for the

EUT supply at the rear panel.

NOTE: The hardware is designed to synchronize the connected reference phase L to PE.

Phase synchronization angle in star-delta 3-phase system

The Generator synchronizes between the connected Phase Lx to PE. In a 3-phase system

the PE and Neutral are connected together at the supplier’s transformer. The pulse

generator is designed for a 3-phase system in star mode (L1, L2, L3, N, PE).

Then the synchronization in a 3-phase system is perfect for a 3-phase equipment with star

connection. For 3-phase equipment with delta connection the shift the phase angle for

triggering must be adjusted. The graphic in Figure 5.1 shows the different phase angle

between connection L1-N (star-) and L1-L2 (delta mode).

The generator manual describes the method of the phase angle setting of the generator.

Figure 5.1 Phase shift

between star and delta

Using a UCS 500N type

The synchronization is realized within the UCS generator and is related to the sync input at the rear of the UCS 500...

Then when using three phase couplers the UCS has no power at the sync input

Connect sync input of the UCS 500 to the phase L1 of the coupling network with. The UCS synchronizes to

this phase L1.

The sync input of the UCS 500 is referenced to ground (PE). The phase synchronization depends from

the Firmware version and is different.

Important information to the synchronization you can find into the UCS manual

Using a VCS 500 or EFT 500

The synchronization is realized within the VCS 500 or EFT 500 / 800 generators and is related to the power supply

input at the rear of the equipment, to phase L input.

Then when use three phase couplers, the generators have no power supply at the input for the EUT.

Connect phase L1 and neutral N of the power supply input of the coupling network with phase L and

neutral N at the input of the VCS, or EFT. The generator is synchronized to the phase connected at the

input L. Dependant on which phase, L1, L2 or L3 is connected to the generators; the transients are

synchronized to this line.

Connecting two devices VCS 500 and EFT 500 series on CNI network

In case that a Surge generator (VCS 500 series) and a Burst generator (EFT 500 series) are connected

simultaneously, both generators must be switched on. Otherwise the coupling modes might be set false.

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 18 / 41

5.3.

Connection of DC Equipment

For the connection of DC power supplies following connections are provided.

Polarity

3- Phase CNI

1- Phase CNI

+ Pole

L1

L

- Pole

N

N

As DC input the terminals L1 and N must be used. These two plugs are marked at the rear side of with an

additional plus or minus sign.

TEST ON Switch

The switching capacity of conventional AC contactors for DC application is limited. Therefore, the specification for

DC current and voltage are reduced compared to the AC specifications.

If the coupling network should have the same parameters for AC and DC, special mains switch must be installed,

for meet the DC specifications. This costly expansion requires a larger enclosure than the normal version.

Cost- economical coupling networks have no internal DC switches. In this case the user has already installed an

external dc switch, he can use for disconnect the dc supply in case of an emergency.

Coupling networks that require mandatory external DC contactor

The table on the right shows the coupling networks

that require an external power switch mandatory for

DC application.

Type

DC Parameter

CNI 503B7.4

CNI 503B9.2

1000V 32A

1000V 100A

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 19 / 41

5.4.

Operation with CNI coupler or generator internal CDN

The coupling network CNI 503 is operated via the generator UCS / VCS / EFT and its operation panel or via ISM

windows software. Only the different coupling modes can be changed or preselected.

Then it is very important that the control cable between surge generator and coupler, EFT generator and

coupler or UCS and coupler is connected and that the coupler is switched on (power switch at the rear

panel) before the test generators are switched on.

The test generator realizes that a three phase coupler is connected and shows the possible coupling modes in the

display of the generator. The complete system is controlled by the generators operation panel.

If the external coupling network is connected or switched on later than the generator, the generator must be reset by

switching power ON/OFF.

On the front panel of the coupler the user can switch ON/OFF the power supply of the EUT.

Using IEC.control software the coupling matrix is completely controlled by software.

CNI detection

After power ON the UCS / VCS or EFT generator, the devices check if an external CNI is

detected.

CNI detected: Working with external CNI

CNI not detected: Working with internal generator CDN

When changing between internal CDN to external CNI it is necessary to switch OFF/ON the system. When

CNI is not used switch off the CNI before power on the USC500N5

EM TEST CNI 501 / CNI 503

Manual of operation V 3.32 20 / 41

6.

Test set up

When setting up the test national and international regulations regarding human safety have to be guaranteed.

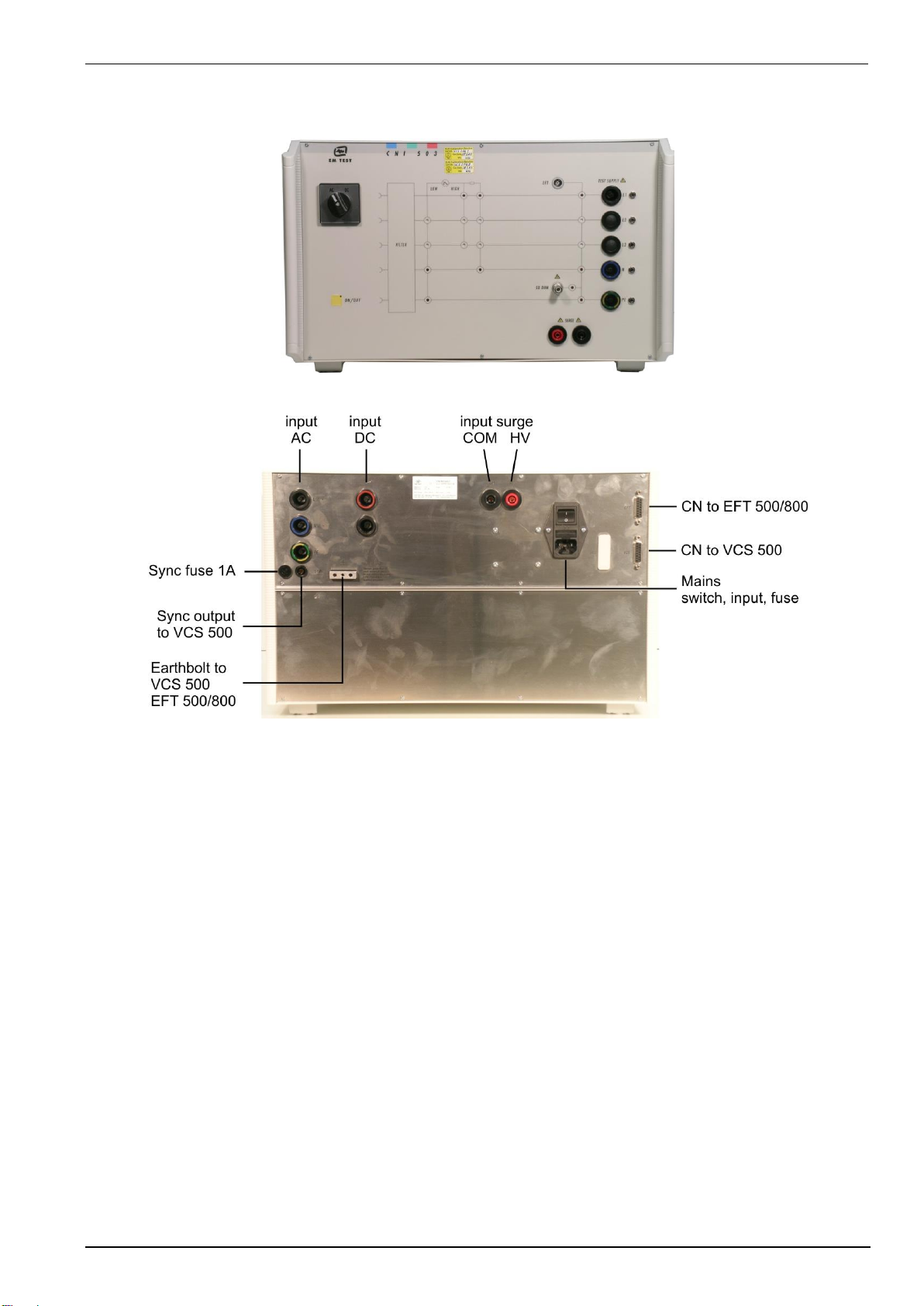

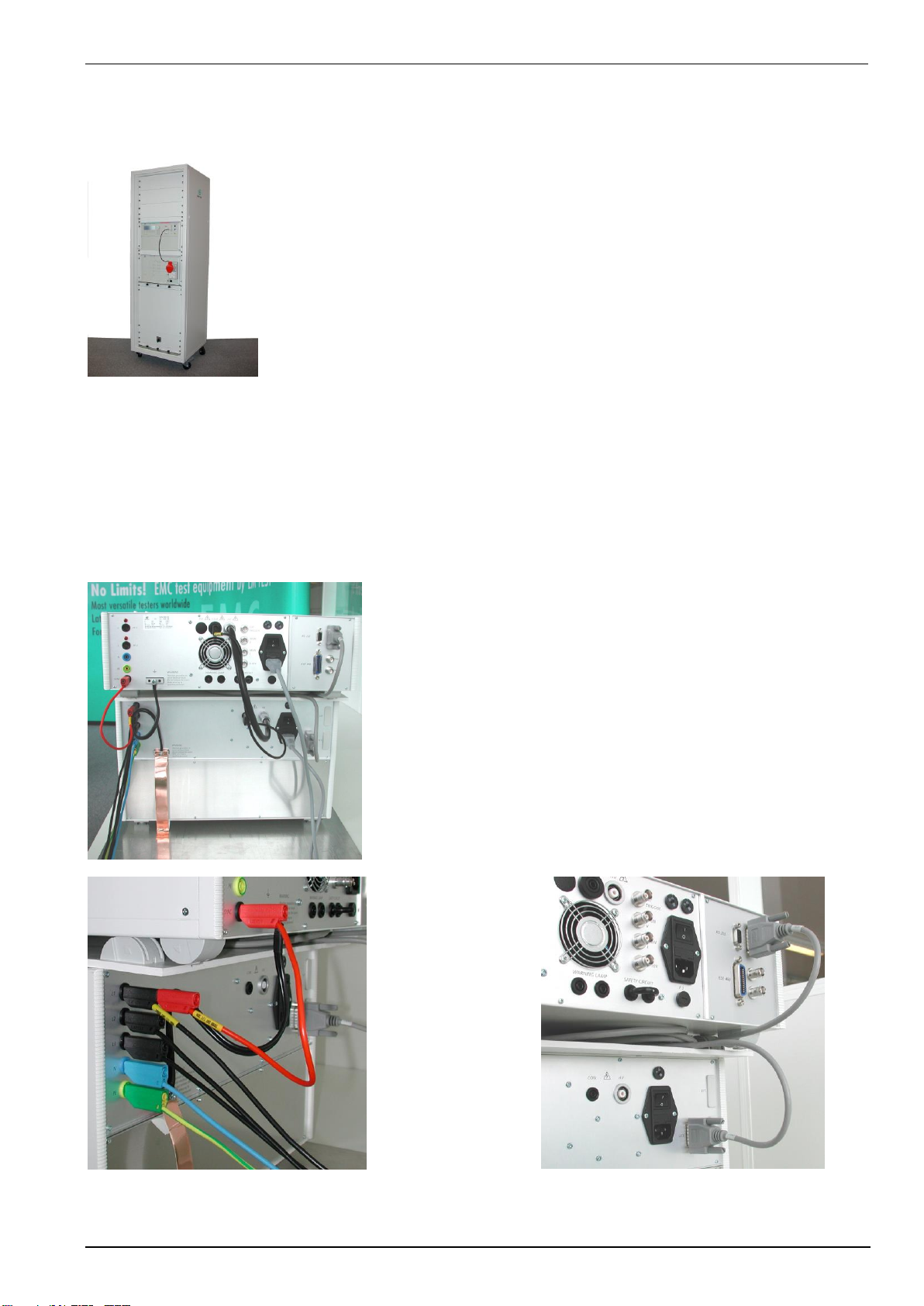

All units, the surge generator, the EFT and the coupling matrix can be installed one

above the other. The coupling matrix should than be used as central output for the

EUT and should be mounted directly onto the ground reference plane. The EFT

has to be installed directly over the coupling matrix to have the output connection

EFT - CNI as short as possible.

The surge generator VCS can be mounted besides or onto the other units. The UCS has

to be mounted directly above the CNI due to the short HV cable.

It is recommended to connect the simulator to the ground reference plane of the test

set-up.

Figure 6.1: Example of a test rack with UCS 500M6 and CNI 503

Connect the following cables between the generator and coupling network

- Control cable UCS - CNI (15 pole SubD connector

- Control cable EFT - CNI (15 pole SubD connector)

Control cable VCS - CNI (15 pole SubD connector)

- High voltage cable, UCV / VCS - CNI (rear panel)

- High voltage common UCS / VCS - CNI (rear panel)

- High voltage cable, coaxial EFT - CNI (front panel)

(Black safety laboratory cable)

Additionally the coupling network needs a power mains supplyof 115V /230V at the rear.

Connection of CNI / CNV 503:

1. Connect the earth connection from UCS 500 to the CNI 503 with

the delivered brass connector plate (fig 6.7.) or the two parallel

cables (fig 6.6). This reference ground and must be connected

with the reference ground of the test set-up.

2. Connect the HV and COM connectors for transmit the surge

pulses to the CNI 503.

3. Connect DUT power supply L1 to the AC synchronization of the

UCS 500

4. CN cable for control the couplings from the impulse generator. For

reduce the interference’s we propose to roll up the cable and put it

between the UCS500 and the CNI 503

Figure 6.2: Connections UCS 500 –CNI 503

Figure 6.3 : Connection line power and sync to UCS 500

Figure 6.4 : Connection the CN cable

This manual suits for next models

56

Table of contents

Other EMTEST Test Equipment manuals

EMTEST

EMTEST dito User manual

EMTEST

EMTEST variac-NX 1-260-16 User manual

EMTEST

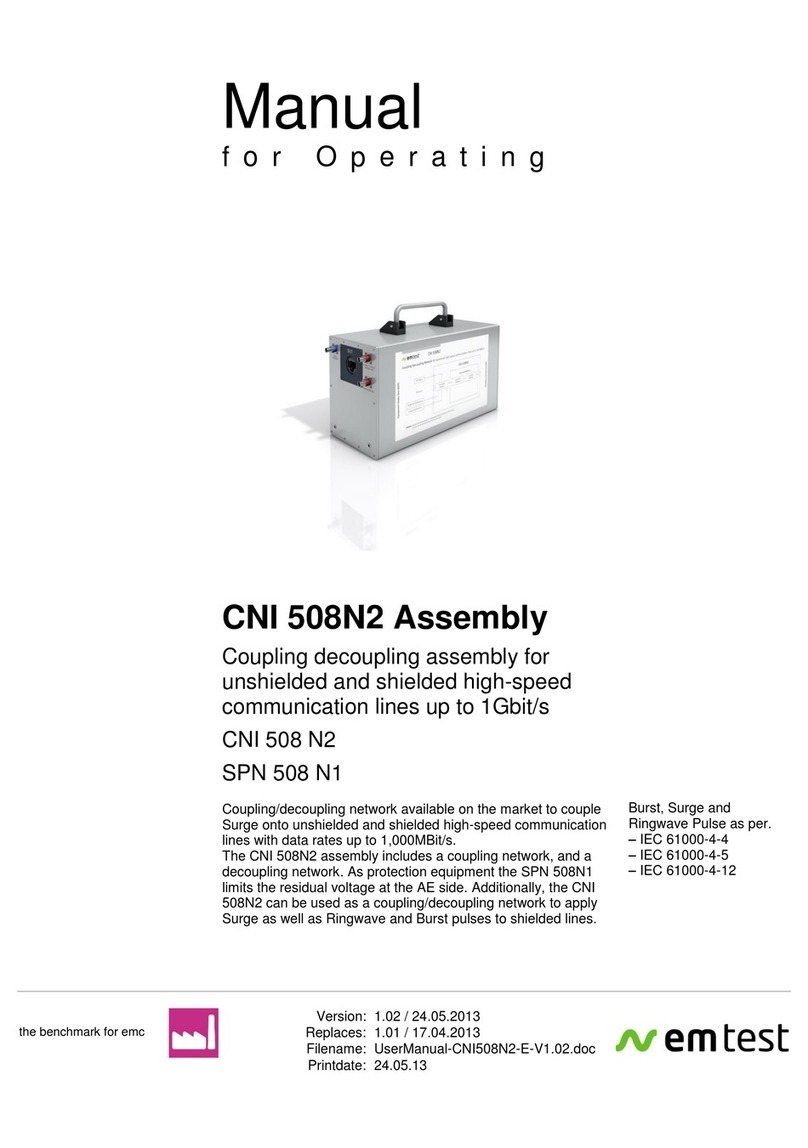

EMTEST CNI 508 N2 User manual

EMTEST

EMTEST esd NX30 User manual

EMTEST

EMTEST AN 200 Series Instruction Manual

EMTEST

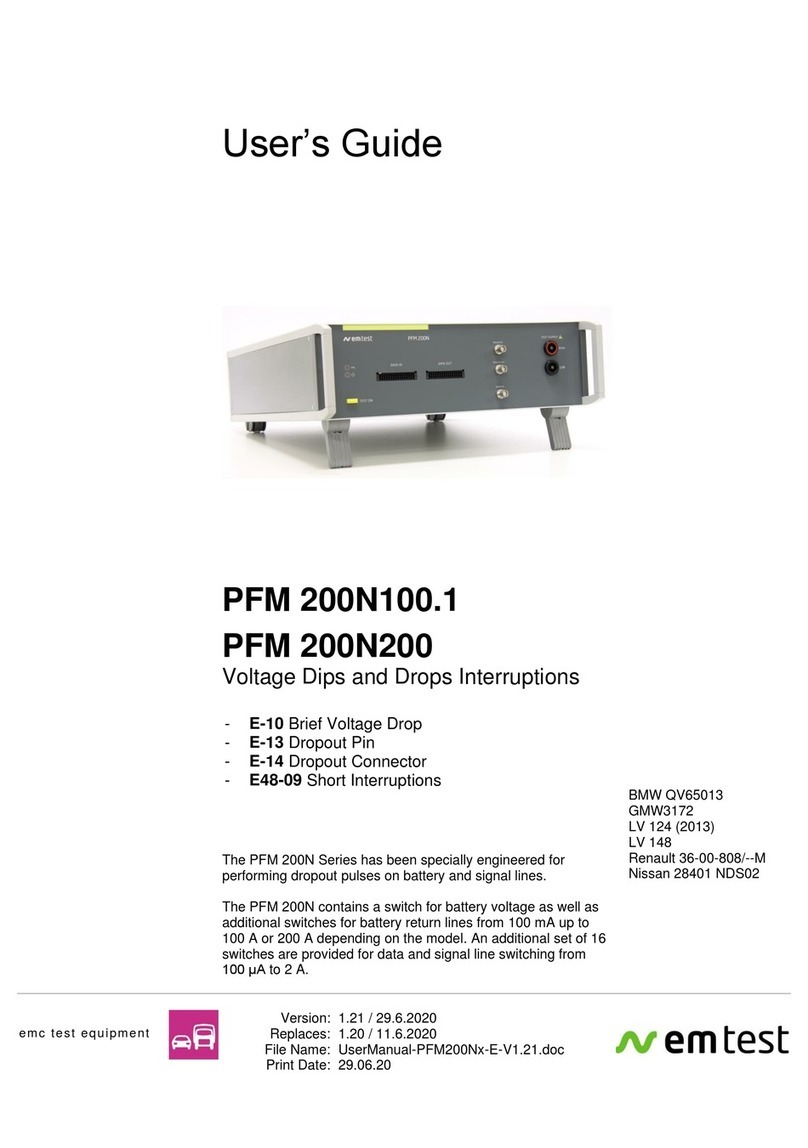

EMTEST PFM 200N200 User manual

EMTEST

EMTEST VDS 200Q10 Series User manual

EMTEST

EMTEST PFM 200N100.1 User manual

EMTEST

EMTEST CWS 500A / 75 User manual

EMTEST

EMTEST PFS 200N Series Instruction Manual