Sivu 3 / 23

Table of contents

General.................................................................................................................................................2

Read before use ...................................................................................................................................2

1. DECLARATION OF CONFORMITY......................................................................................................4

2. PURPOSE OF USE..............................................................................................................................5

3. SAFETY PRECAUTIONS......................................................................................................................5

4. IDENTIFICATION INFORMATION AND SPAREPARTS ........................................................................7

4.1. Identification plate ............................................................................................................................ 7

4.2. Maintenance services........................................................................................................................ 7

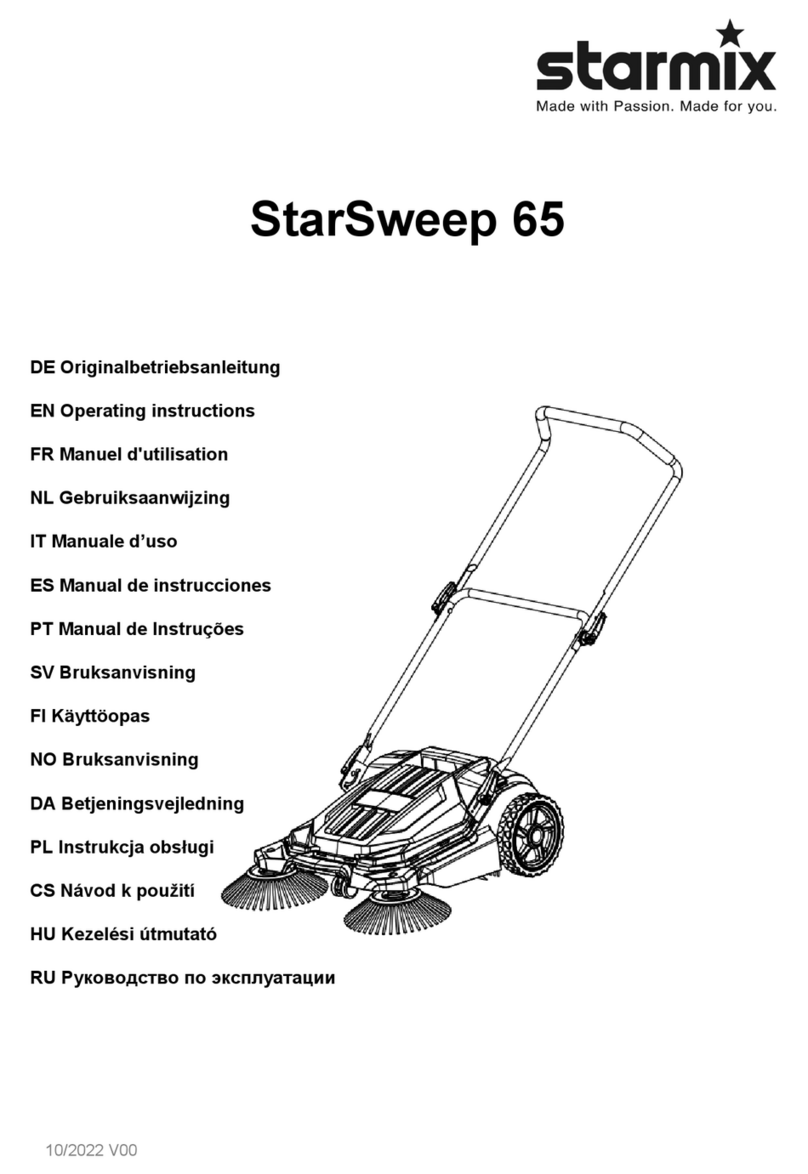

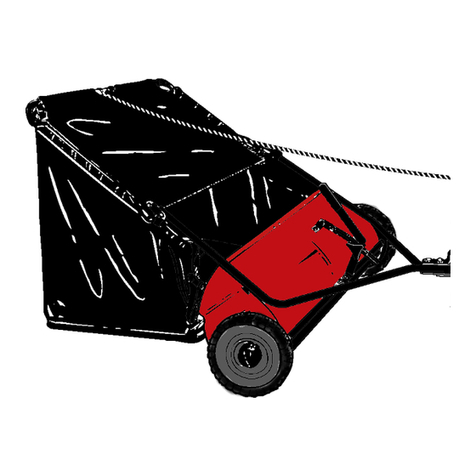

5. MAIN PARTS OF THE COLLECTING SWEEPER...................................................................................8

6. ATTACHING THE COLLECTING SWEEPER........................................................................................10

6.1. Attaching the collecting sweeper to a base machine...................................................................... 10

7. OPERATING THE COLLECTING SWEEPER........................................................................................11

7.1. Operating manual............................................................................................................................ 11

7.2. Adjusting the height of the broom roller ........................................................................................ 12

7.3. Adjusting the side brushes .............................................................................................................. 13

7.4. Replacing the brush rings ................................................................................................................ 14

7.5. Replacing the side brushes.............................................................................................................. 16

7.6. Transferring the collecting sweeper................................................................................................ 16

7.7. Detaching the collecting sweeper ................................................................................................... 16

7.8. Irrigation system.............................................................................................................................. 17

7.9. Accessories for the collecting sweeper ........................................................................................... 17

8. MAINTENANCE OF THE COLLECTING SWEEPER.............................................................................18

8.1. General safety precautions for the use and maintenance.............................................................. 18

8.2. Tightening torque............................................................................................................................ 18

8.3. Daily maintenance........................................................................................................................... 18

8.4. Maintenance after first 10 hours of operation ............................................................................... 18

8.5. Maintenance at 50-working hour intervals or on a weekly basis ................................................... 19

8.6. Lubrication points............................................................................................................................ 19

9. HYDRAULICS...................................................................................................................................20

9.1. 2-hose hydraulics............................................................................................................................. 20

9.2. 4-hose hydraulics............................................................................................................................. 22

10. WARRANTY POLICY ......................................................................................................................23