TABLE OF CONTENTS

CORRECT OPERATING PROCEDURE .............................. 1

Load and Vehicle Stability........................................................................2

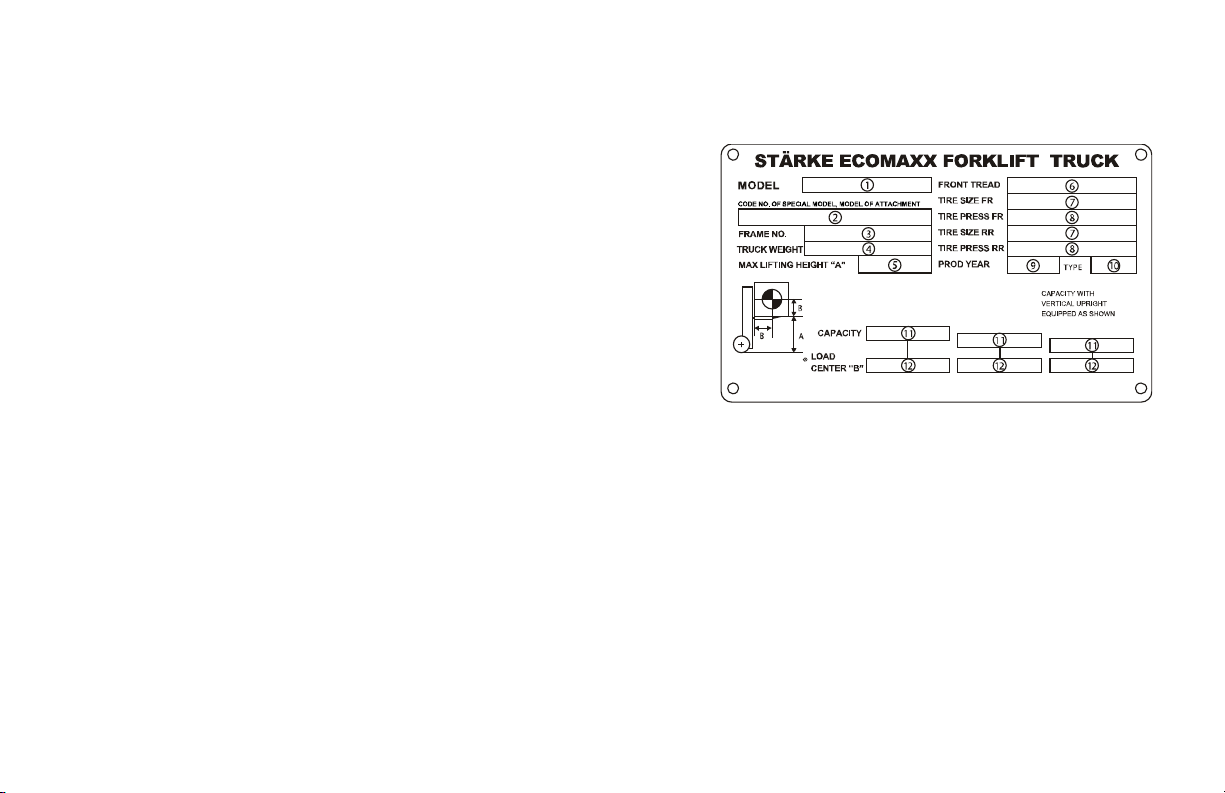

Load Capacity Chart....................................................................................... 2

Handling a New Forklift ...........................................................................5

Engine Starting and Post-Starting Procedures..........................................6

After Starting ................................................................................................. 6

Lift Cylinder Warm-Up....................................................................................6

Vehicle operation.....................................................................................7

Take-Off ........................................................................................................7

Gear Shifting.................................................................................................. 7

Steering ......................................................................................................... 7

Picking-Up Loads...........................................................................................7

Unloading ......................................................................................................8

Stopping and Parking..................................................................................... 8

Road or Surface Conditions .....................................................................9

Snowy or Frozen Surfaces..............................................................................9

Handling in Hot Weather................................................................................. 9

Cold Weather Vehicle Handling....................................................................... 9

SAFETY, TRANSPORTATION & MAINTENANCE ...........11

Conditions for Normal Vehicle Use .........................................................12

Work Environment ....................................................................................... 12

For Engine-Powered Forklifts....................................................................... 12

For Electric-Powered Forklifts ...................................................................... 12

Work Environment Hazards ...................................................................13

Slippery Road Surfaces................................................................................ 13

Rough Ground.............................................................................................. 13

Lighting ....................................................................................................... 13

Noise........................................................................................................... 13

Conditions That Apply When Attachments Are Used ..................................... 13

Information on Operating the Forklift .....................................................14

Qualifications and Training .......................................................................... 14

Fundamental Safety Guidelines.................................................................... 14

Fuel.......................................................................................................16

Fuel Types................................................................................................... 16

Handling of Fuel........................................................................................... 16

Refuelling .................................................................................................... 16

Shipping, Loading and Unloading the Forklift......................................... 18

Lifting the Forklift ........................................................................................ 18

Assembling the Forklift and Mounting Attachments...................................... 19

Towing the Forklift and Moving Incomplete Forklifts..................................... 19

Leaving the Forklift Idle and Long term Storage.....................................20

Care of the Engine Compartment ................................................................. 20

Maintenance of the Brake System ............................................................... 20