en-4

• Some specialty models onto which a heavy

attachment is mounted may not be

equipped with the mast forward tilt con-

trol. Confirm with a Toyota dealer in

advance.

• Once you have mounted or replaced any

attachment on a forklift, ask a Toyota

dealer for an inspection.

• If you use two or more removable attach-

ments alternately, the heaviest one should

be used to carry out matching (SAS set-

ting). Contact your Toyota dealer to

request compatibility matching.

• When attaching an attachment to a model

without forks, the attachment must be

compatible with the model. Contact your

Toyota a dealer to request compatibility

matching.

When the forks are elevated to the maximum

height, a high pressure (relief pressure) may

remain in the lift cylinder. This high pressure

causes the vehicle to judge that it has a high load

even if there is no load. As a result, the mast will

be stopped from tilting forward. In this case,

lower the forks slightly (to release the pressure)

and the mast may be tilted forward.

Active mast rear tilt speed control

• At a high lift height, the mast has a back-

ward tilt speed controller (slow down) irre-

spective of the load. When lowering from a

high lift height to a lower lift height while

tilting the mast backward, the control speed

will not change.

• At a low lift height, the mast can be tilted at

full speed even if there is a load. If the mast

is tilted backward at a low lift height with

the tilt knob switch pressed, the mast has the

backward tilt speed controlled (slowed

down) as long as the tilt lever knob switch is

pressed. (Except mini lever/joy stick mod-

els)

• If the low lift height is then changed to a

high lift height while tilting the mast back-

ward, the control speed will not change as

long as the tilt lever knob switch is pressed.

The mast may be tilted backward at the full

speed so long as the tilt lever knob switch is

not pressed.

Key-lift interlock

When the ignition switch is turned to OFF and

lowering the lift lever, the forks will not lower.

However, by sitting on the normal seated posi-

tion and turning the ignition switch to ON, the

forks will lower even when the engine is off.

(Except mini lever/joy stick models)

Active steering synchronizer

If the steering wheel knob is not angularly

matched with the steer tires, such out-of-posi-

tion will be automatically corrected while turn-

ing the steering wheel. Thus, the knob is kept at

a constant position relative to the steer tires.

If SAS feature should fail:

The SAS models are equipped with a controller,

sensors and various actuators. If any of these are

found not to be operating normally, it will tell

you that:

• Steering wheel knob is out-of-position may

not be corrected.

• Functions such as Automatic forks levelling

control, Active mast front tilt angle control,

Active mast rear tilt speed control may not

be operated.

• Swing lock cylinder may not be unlocked.

If any of the phenomena referred to above

should take place.

• Diagnosis lamp will light up or blink.

• Error code will be displayed in the hour

meter.

Thus, the operator will be informed. In such

an event, move the vehicle to a safe location

and ask a Toyota dealer to inspect and repair.

Action to be taken in emergency

Move the vehicle to a safe location and ask a

Toyota dealer for a repair.

If any phenomenon different from normal oper-

ations (failure to run or the like), among others,

should take place, ask a Toyota dealer for an

inspection.

Once a torque converter model has its control

lever abnormal, it is impossible to manually

operate the vehicle, which need be towed,

accordingly.

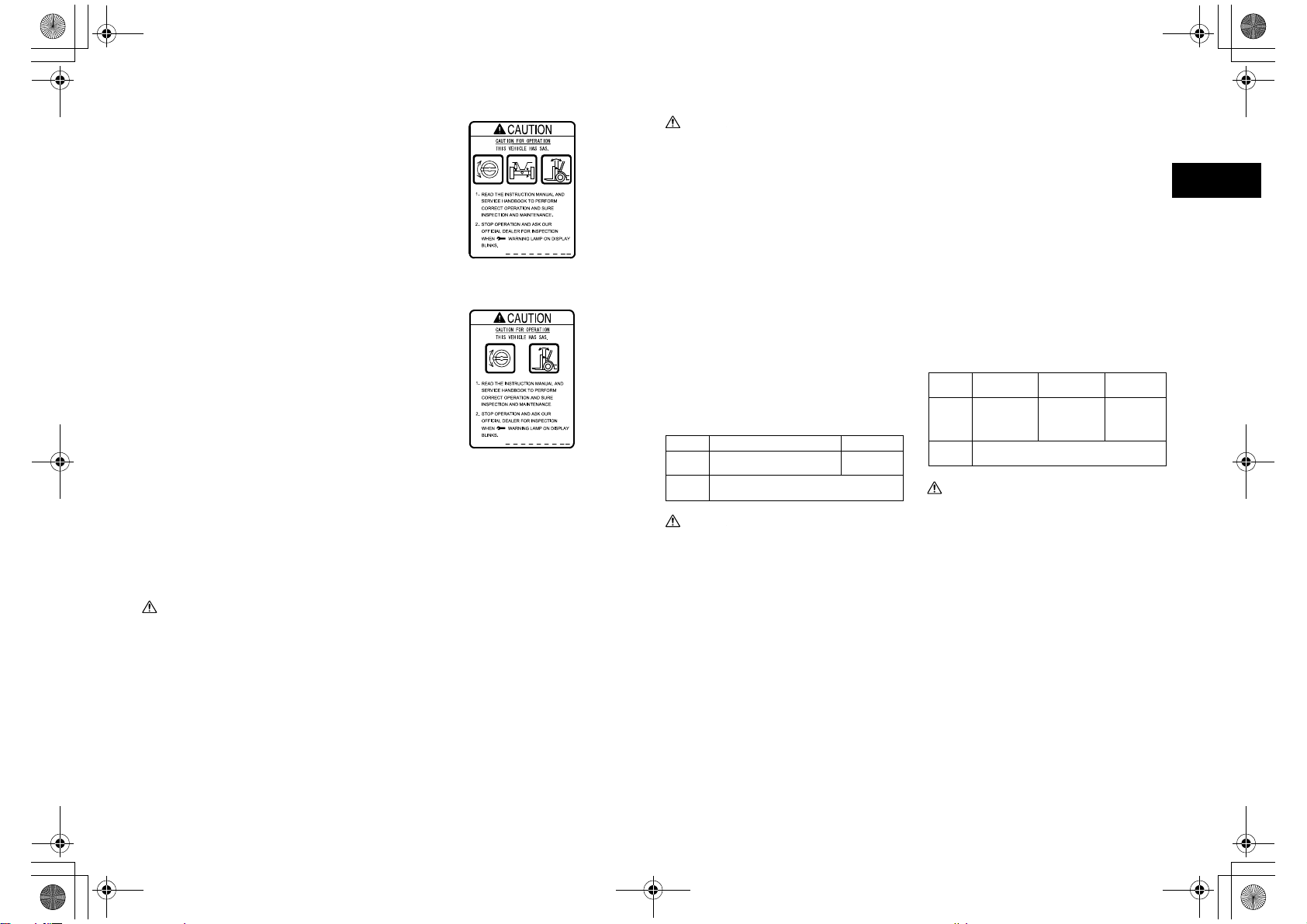

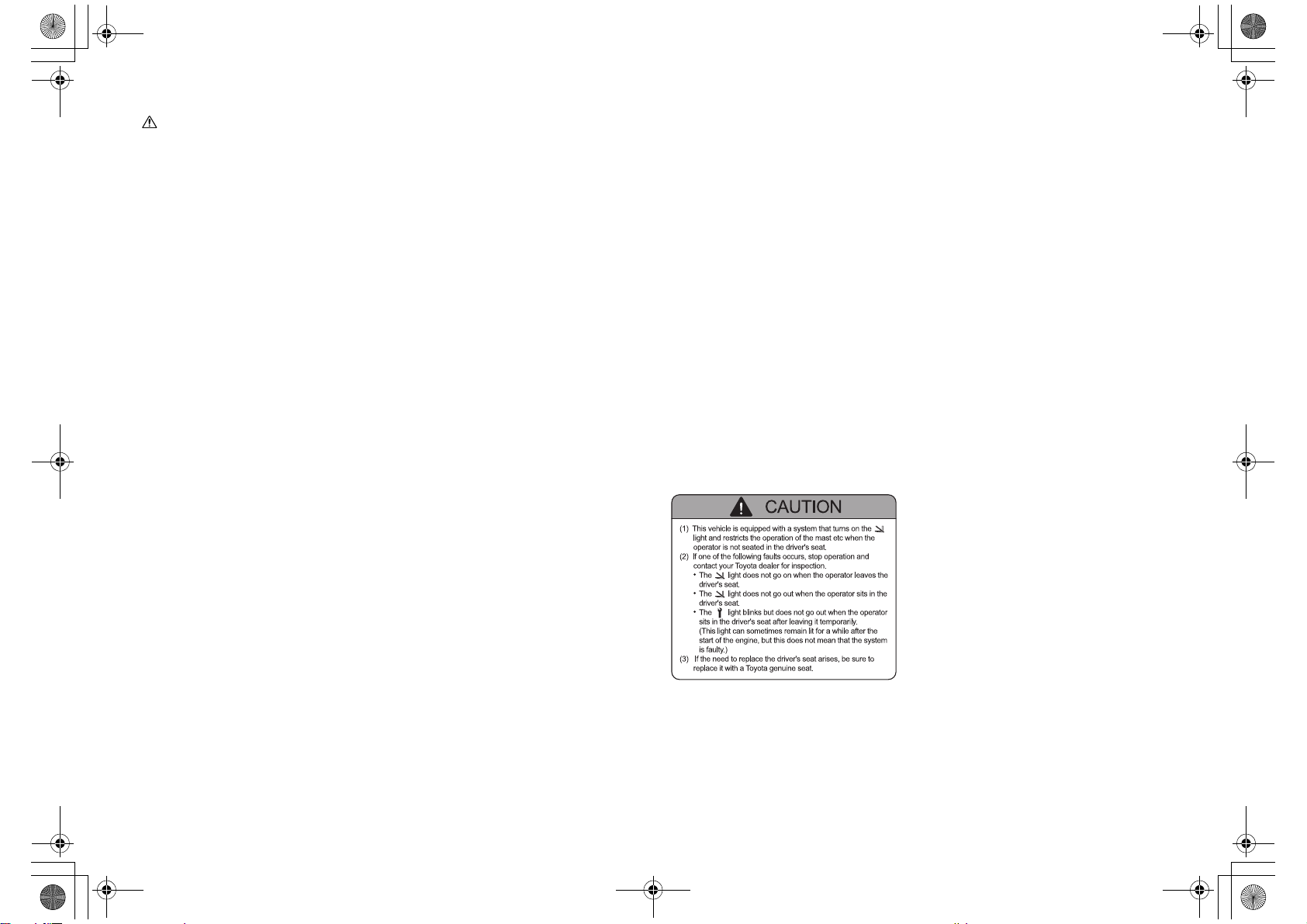

OPS System

The OPS (Operator Presence Sensing) System

prevents traveling and load handling operations

when the operator is not seated in the operator’s

seat.

If the operator leaves the operator’s seat while

the vehicle is operating, the OPS lamp will light

up, and a buzzer will sound for one second to

warn the operator that the OPS System will be

activated. If the operator leaves the operator’s

seat for longer than two seconds, the OPS Sys-

tem will be activated and traveling and load

handling operations will be stopped. However,

if the operator returns to the normal seating

position within two seconds, the OPS System

will not activate and will allow travel and load

handling operations to continue.

Again, if an abnormality occurs to the OPS Sys-

tem, the diagnosis lamp will blink to warn the

operator. In this case, the OPS System may have

malfunctioned. Contact your Toyota dealer to

request an inspection.

This forklift is equipped with an OPS (Operator

Presence Sensing) System. Before operating the

forklift, check that each of the System’s func-

tions is working correctly.

Travel OPS Functions

If the operator leaves the seat while the vehicle

is traveling, the OPS lamp will light up, and two

seconds later, traveling will be stopped. How-

ever, this does not apply the brakes to stop

travel. (If the operator returns to the normal

seating position within 2 seconds, traveling can

be continued.)

If the OPS System is activated while driving up

a slope or incline, the drive to the front wheels is

stopped and consequently the vehicle will roll

back down the slope incline. To avoid this prob-

lem, make sure to sit on the seat at all times.

If more than 2 seconds has elapsed, apply the

brakes, return the control lever to the neutral

position and sit on the seat again.

Load Handling OPS Function

Forklifts with a standard lever

If the operator leaves the seat during operations,

the OPS lamp will light up, and two seconds

later, load handling operations will be stopped.

(If the operator returns to normal seating posi-

tion within 2 seconds, loading can be contin-

ued.) If the operator leaves the seat while

operating the control lever, loading can be con-

tinued for 2-4 seconds.

If load-handling OPS is activated when the lift

lever is in the lowering position, move the lever

to a position other than the lowering position

and return to the normal seated position to deac-

tivate load handling OPS. If load-handling OPS

is activated when the lift lever is in a position

other than the lowering position, load handling

OPS is deactivated 1 second after the operator

returns to the normal seated position.

Forklifts with a mini lever/joy stick lever

(Option)

If the operator leaves the seat during load han-

dling operations, the OPS lamp will light up,

and two seconds later, load handling operations

will be stopped. (If the operator returns to the

seat within 2 seconds, load handling operations

can be continued.)

To resume load handling functions, return to the

seat and return all of the levers to the neutral

position.

OPS Operation Functions

If the operator leaves the seat, a buzzer will

sound for approx. one second (“pii”) and the

OPS lamp will light up and inform the operator

that the OPS System is active. If the operator

returns to the normal seating position, the OPS

lamp will turn off.

01_A5028-0EA04_En.fm 4 ページ 2012年12月6日 木曜日 午後12時42分