Starline CDe120 User manual

CDe120

RACK CONVEYOR C/W DRYER

OPERATOR MANUAL

25/09/2018 Washtech CDe120 Operator Manual 1

25/09/2018 Washtech CDe120 Operator Manual 2

Warnings

Before installation and commissioning, you must read the safety instructions and

warnings carefully and all the warning labels attached to the equipment.

Equipment contains dangerous voltages and can be hazardous if installed or

operated incorrectly. Non-compliance with warnings or failure to follow the

instructions contained in this manual can result in loss of life, severe personal

injury or serious damage to property.

Before installation or repair, you must read the instructions and warnings

carefully and all the warning labels attached to the equipment.

All service/repair work must be carried out by qualified personnel only and

ensure compliance with all local codes and standards including AS/NZS 3500.1.

Important Information

Failure to comply (even partially) with the instructions given in this manual will

invalidate the product warranty and relieves the manufacturer of any

responsibility.

The alteration of machine operation, design or the replacement of parts not

approved by the manufacturer may void warranties and approvals.

This machine is intended for commercial use only.

Contents

2. Warning

3. Safety Instructions

4. Installation Diagram

5. Installation Instructions

7. Installation Checklist

8. Installation Troubleshooting

9. Operator Use Guide

10. Operator Care – Wash Zone

11. Operator Care – Rinse Zone

12. Operator Care - Curtains

13. Operator Troubleshooting

14. AVB Connections

15. Schematic Diagram

16. Dryer Schematic

17. Accessories

18. Notes

We have checked that the contents of this document correspond to the model described. There

may be discrepancies nevertheless, and no guarantee can be given that they are completely

identical. The information contained in this document is reviewed regularly and any necessary

changes will be included in the next edition. We welcome suggestions for improvement.

Document subject to change without prior notice.

Information supplied in this manual is copyright. No part of this work may be reproduced or

copied in any form or by any means, electronic or mechanical without the express permission of

the author / publisher.

25/09/2018 Washtech CDe120 Operator Manual 3

Installation

•Use qualified, skilled personnel.

•Follow installation instructions.

•Connect to correct voltage and supply current.

•Provide fully accessible Electrical Isolation Switch & water supply valves.

Training and Supervision

•Read and Understand the Operating instructions and train all staff.

•This appliance must not be operated by children or infirm persons.

•Machine panels must only be removed by suitably qualified and trained personnel – internal

hazards include live electrics and very hot surfaces.

•No part of this appliance is not intended for use as a stepladder – do not stand on open door.

Hot Surfaces

•Some surfaces may be hot or very hot.

Chemicals

•Commercial dishwashing detergents are hazardous – handle with care.

•Read and follow the safety information found on the labels of detergent containers and

Material Safety Data Sheets.

•Use protective eyewear and clothing if decanting containers.

Hot Water

•Do not put hands in wash water which may be over 60°C and contain hazardous caustic

detergent.

•Rinse water can be over 90°C.

•Door safety switches are designed for emergency use only.

Cleaning

•Do not hose down the machine or splash water over the exterior.

•Watch for broken glass etc when cleaning the inside of the machine.

Warnings

Equipment contains dangerous voltages and can be hazardous if installed or

operated incorrectly. Non-compliance with Warnings or failure to follow the

instructions contained in this manual can result in loss of life, severe personal

injury or serious damage to property.

Installation and servicing must be carried out by a suitably qualified person in

compliance with all local codes and standards including AS/NZS 3500.1.

Safety Instructions

25/09/2018 Washtech CDe120 Operator Manual 4

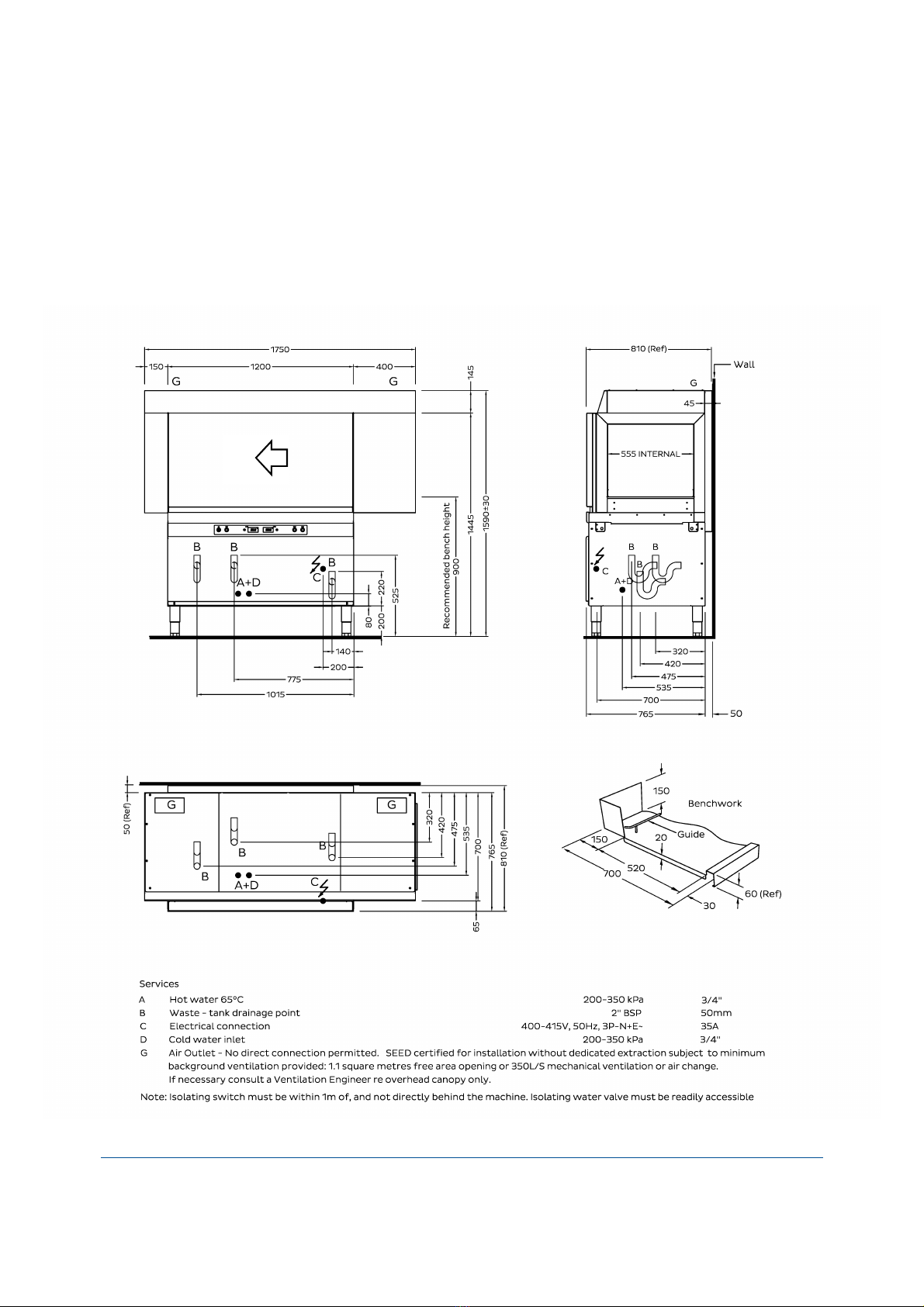

Installation Diagram

CDE120 Installation

•Part #: CDE120 RL Installation

•Date: 28/08/2018

•Version: 1-A

25/09/2018 Washtech CDe120 Operator Manual 5

Machine Positioning

•Unpack machine, check for damage and complete delivery.

•Install machine on sound waterproof self-draining floor and use adjustable feet to level

machine.

NOTE: Failure to level the machine correctly may result in leaking during the cycle,

overflowing from the door sill, poor hygiene through the wash tank not being able to

drain correctly, and/or visibly uneven door.

•Allow room for detergent to one side of machine or in adjacent cupboard. 20 litre container

requires approximately 450H x 250W x 350D, but smaller containers are available from many

suppliers.

Inlet Water Operation - Cold

Incoming water should be within the following standard requirements:

•Temperature: 20°C.

•Connection: 20 mm (3/4” BSP) male

NOTE: Flush supply line before connection. Poor quality supply or excessive water

hardness may affect performance or damage machine – filtration and/or softening is

recommended.

•Flow rate: minimum 20 litres per minute

•Pressure: between 200 and 350 KPa

NOTE: This machine is not equipped with a rinse booster pump as standard and relies on

incoming water pressure to drive the rinse cycle.

NOTE: Above this range fit pressure limiter. Below this range fit a rinse booster pump. Do

not use small diameter plastic supply lines

•Backflow prevention: Watermark approved Atmospheric Vacuum Breaker (AVB) fitted

standard. Watermark Certification #08603

Inlet Water Fill - Hot

Incoming water should be within the following standard requirements:

•Temperature: 65°C.

NOTE: Excessively high temperatures may damage the solenoid which can result in

flooding should this component fail. High temperature solenoids are available and can be

retrofitted if necessary.

•Connection: 20 mm (3/4” BSP) male

NOTE: Flush supply line before connection. Poor quality supply or excessive water

hardness may affect performance or damage machine – filtration and/or softening is

recommended.

•Flow rate: minimum 20 litres per minute

•Pressure: between 200 and 350 KPa

NOTE: Above this range fit an approved pressure limiter. Below this range fit a rinse

booster pump. Do not use small diameter plastic supply lines

•Backflow prevention: Watermark approved Atmospheric Vacuum Breaker (AVB) fitted

standard. Watermark Certification #08603

Installation Instructions

25/09/2018 Washtech CDe120 Operator Manual 6

Water Quality Requirements

The incoming water should also be within the following parameters:

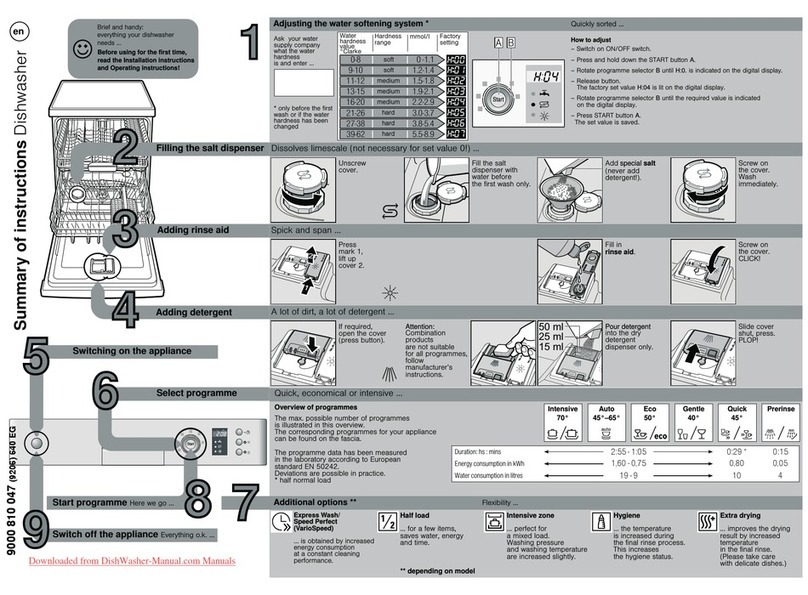

Hardness ppm pH

min 20 7

max 100 8

Ions Cl- SO4Fe Mn Cu Cl2

Max mg/L 100 400 0.1 0.5 0.05 0.1

NOTE: Levels above or below the stated requirements can be expected to increase

component wear and reduce the expected useful life of the dishwasher. If in doubt, it is

best to consult a water specialist and have the incoming water professionally tested and

treated if necessary.

Power

•Electrical supply required is 3p/35A 415V 50Hz via switched outlet adjacent to machine.

NOTE: Equipment contains dangerous voltages and can be hazardous if installed or

operated incorrectly. Non –compliance with warnings or failure to follow the

instructions contained in this manual can result in loss of life, severe personal injury or

serious damage to property.

Chemical

•Detergent and rinse aid pumps are not supplied with the CDe120. We recommend you

consult your chemical supplier and/or a local chemical expert for their recommended

detergent and Rinse Fluid injector pumps.

NOTE: Commercial detergents can be hazardous – read instructions, store safely and

handle with care. Care needs to be taken when changing chemicals, ensuring that the

detergent is not accidentally connected to the rinse fluid inlet line.

NOTE: If uncertain, please consult a chemical specialist for assistance in selecting the

right chemicals and calibrating machine settings to suit this along with your unique site

conditions and requirements.

Waste

•50mm connection required to point B as specified on install diagram. An S-trap must be fitted

on each of these points.

NOTE: Either copper or P.V.C. may be used for the waste connection – P.V.C. is more

resistant to some harsh detergents. Some authorities however suggest that copper is

required because the machine rinses at up to 90°C. It is important to note that rinse

water mixes with the 65°C wash water before discharge and then flows into the sink

trap where the water is further cooled before entering the drainage plumbing. We

recommend consulting your local authority to ensure your site remains compliant.

Installation Checklist

•Complete attached Installation Checklist to ensure machine is installed and running correctly,

and operator is familiar with operating procedures.

Installation Instructions

Check Notes

DELIVERY

SUPPLIED COMPLETE? CHECK THERE HAS NOT BEEN ANY TRANSIT DAMAGE

POSITION

LEVEL AND STABLE? ON SOUND, WATERPROOF, SELF-DRAINING FLOOR

WATER

ISOLATOR VALVE FITTED? ACCESSIBLE, ALL FITTINGS SOUND, AND NO LEAKS

TEMPERATURE CORRECT %1.& 9#6'4+0.'6Ĺ%*16 9#6'4+0.'6Ĺ%

PRESSURE CORRECT (200 – 350 kPa)? LIMITER FITTED IF ABOVE RANGE, RINSE PUMP IF BELOW

FLOW RATE CORRECT (> 20L per min)? RINSE PUMP FITTED IF BELOW REQUIREMENT

QUALITY WITHIN REQUIREMENTS? FILTER OR SOFTENER IN PLACE IF OUTSIDE REQUIREMENTS

POWER

ISOLATING SWITCH (3p/35A 415V 50Hz)? FITTED, FUNCTIONAL AND ACCESSIBLE

CORRECT SUPPLY VOLTAGE, CURRENT, CIRCUIT BREAKER ALL CORRECT

WASTE

CONNECTION TO 50mm PIPE? CORRECT CONNECTION TO PLUMBING.

SUITABLE AIR GAP? REFER OPERATOR MANUAL.

CHEMICALS

CHEMICAL NAME CONTAINER NO LEAKS PRIMED CALIBRATED

DETERGENT

RINSE FLUID

MACHINE OPERATION

MACHINE RUNNING CORRECTLY? MULTIPLE CYCLES RUN, NO ISSUES

CHEMICAL DOSAGE CORRECT? CORRECTLY FLOWING INTO MACHINE, NO FOAMING

ALL OPERATIONS CORRECT? FILL LEVEL CORRECT, NO DRAINAGE ISSUES

OPERATOR TRAINING

ENSURE THAT THE CUSTOMER HAS BEEN GIVEN THE OPERATION MANUAL AND WALL CHART, AND IS AWARE OF THE

IMPORTANCE OF BOTH USING AND CLEANING THE MACHINE CORRECTLY.

START UP

PRE-RINSE AND RACKING BETTER TO RINSE PLATES THAN REMOVE WASTE FROM MACHINE

MACHINE USE AND CYCLE SELECTION USE LONG CYCLE WHERE POSSIBLE

DRAINING THE MACHINE DRAIN THE MACHINE DAILY

SHUT-DOWN AND DAILY CLEANING CHECK WASH ELEMENTS HAVE COOLED BEFORE CLEANING

WEEKLY MAINTENANCE FULL MACHINE CLEAN INCLUDING WASH/RINSE ARMS

PLANNED SERVICNG IMPORTANCE OF HAVING MACHINE SERVICED REGULARLY

25/09/2018 Washtech CDe120 Operator Manual 7

Installation Checklist

25/09/2018 Washtech CDe120 Operator Manual 8

Installation Troubleshooting

Machine not starting or filling

•Ensure water supply to machine is turned on.

•Ensure power supply to machine is turned on.

•Check that the water inlet hose isn’t twisted or kinked.

Poor wash results

•Check that there are adequate pre-rinse processes in place.

•Ensure high quality non-foaming commercial dishwasher detergent has been connected at

the correct dosage for your site, water quality and application. If uncertain, consult a

chemical specialist.

•Ensure that the wash temperature is between 60°C and 65°C.

Chemical residue on items after the cycle

•Check water pressure, this is likely too low and below the minimum 200kPa required.

•Check that nothing is obstructing the wash & rinse arms.

•Check the rinse fluid dosage is not too high. If uncertain, please consult a chemical specialist.

Dishwasher is foaming

•Ensure high quality non-foaming commercial dishwasher detergent has been connected at

the correct dosage for your site and application. If uncertain, please consult a chemical

specialist.

•#NNQYYCUJYCVGTVQJGCVVQCVNGCUVĹ%RTKQTVQUVCTVKPIVJGHKTUVE[ENGCUUQOGEQOOGTEKCN

dishwasher chemical will foam at low temperatures.

•Low water pressure can result in above average detergent concentrations. As low water

pressure also impacts rinse results, we recommended this is solved by installing a rinse pump

rather than compensating by reducing chemical dosages.

Other equipment in the kitchen has needed filters or has scale

•Due to the high temperatures in dishwashers, scale will build up in the wash tank, on the arms

and in the rinse tank. The incoming water should be treated. If uncertain, please consult a

water specialist.

Other equipment in the kitchen has needed an RO water filter

•As with the Combi-Oven, high chloride levels will do irreversible damage to a number of the

components inside a commercial dishwasher. The incoming water should be appropriately

treated. If uncertain, please consult a water specialist.

Pawl drive not operating

•Clear the area around the limit switch on the roller table.

•Adjust the clutch tension of the Pawl Drive motor, the Pawl drive clutch tension can be

tightened by turning the 2 nuts at the bottom of the pawl drive shaft clockwise or loosened

by turning the 2 nuts anticlockwise.

(Note: the tension must be at a level where a person can grab the pawl drive with both hands

and stop the pawl drive motion).

Too much steam escaping the machine

•$[FGHCWNVVJGYCUJVJGTOQUVCVKUUGVVQĹ%TGFWEGVJKUVGORGTCVWTGĹ%KHTGSWKTGF

•Check the hot/cold water solenoids connections are connected to the correct water mains

outlet.

Grinding noise escaping from the machine

•Wash pump rotation must be checked after installation to ensure correct direction (excessive

noise and damage with incorrect direction)

Machine stops and refills during the commissioning stage

•Fit the curtains according to the Operator Care – curtain diagram (page 13).

•Ensure the Scrap Trays are fitted in the Wash and Rinse Zones.

25/09/2018 Washtech CDe120 Operator Manual 9

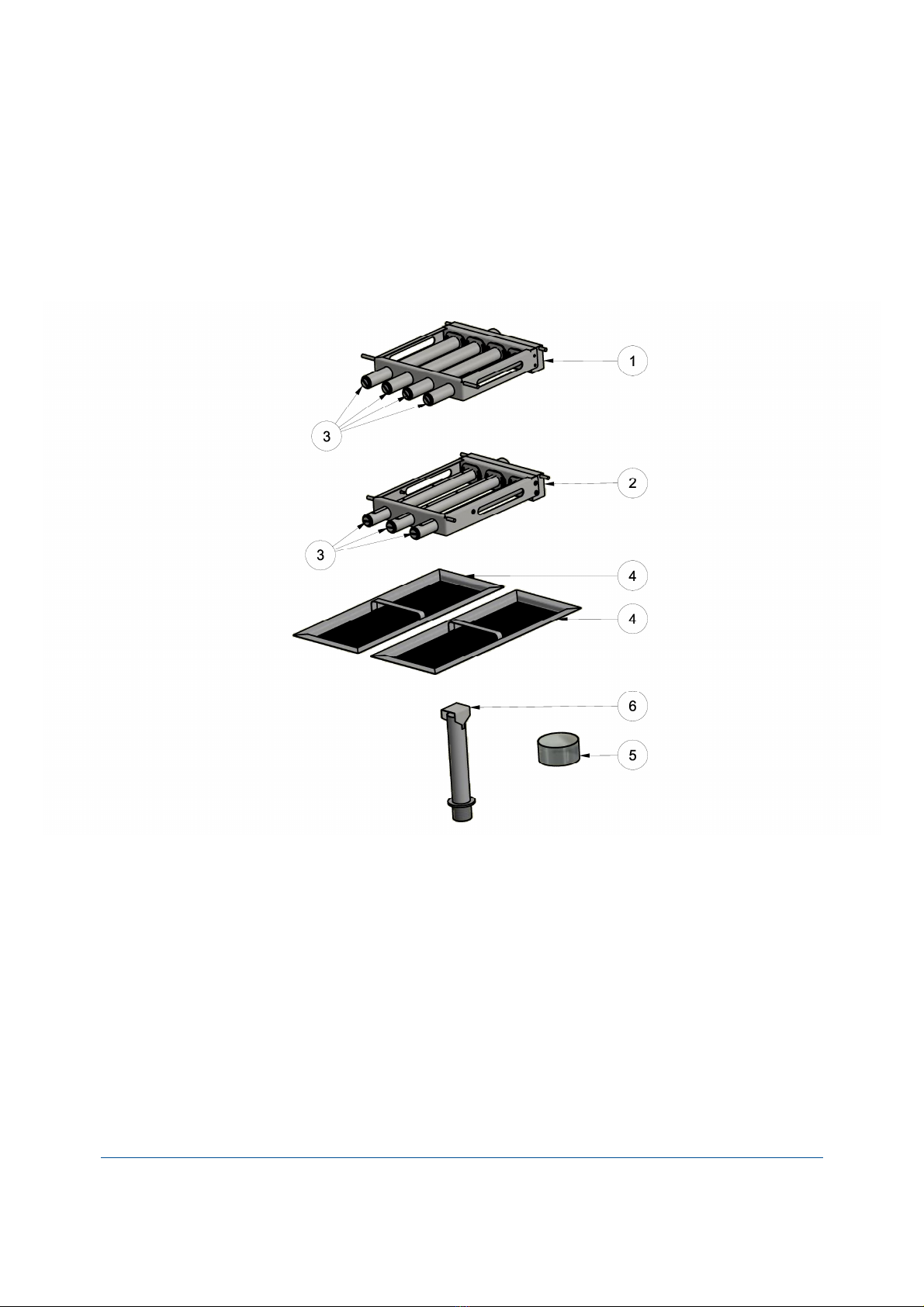

Operator Use Guide

START

•Turn on at wall.

•Wash Zone:

Fit Wash Pump Inlet Filter (5).

Drain Upstand (6) .

Scrap Trays (4).

•Rinse Zone:

Rinse Pump Filter(13) .

Scrap Trays (12).

•Shut all doors and turn wall and Machine Power on.

•Machine begins filling. Full light amber when tanks are full.

•Ready light glows amber when the machine is up to required temperature.

OPERATION

•Press Start button to operate machine.

•Cycle light glows green while the machine is running.

•Cycle light glows green while machine operates.

•Stack one rack with items. Using a second empty rack, push the first rack into the inlet

zone of the machine - ensure the rack is pushed fully into the inlet to engage pawl drive.

•Repeat for all consecutive racks.

•For quicker washing, press Fast button to toggle faster washing speed.

NOTE: Pumps and conveyor will stop operating if the machine is left idle for 2 minutes. To

restart the pump and conveyor simply feed a new rack into the inlet of the machine.

SHUT DOWN – END OF EACH DAY

•Press Stop button

•Take out Drain Upstands to gravity drain the machine.

•When tanks are visibly empty switch Power button off.

•Proceed with Operator Care Wash Zone and Rinse Zone cleaning instructions.

SUGGESTED BEST PRACTICE

Pre-rinse Scrape and/or rinse trays, plates & glasses in cool water

Chemical Use a good quality non foaming commercial detergent and drying agent – do

not use domestic detergents which will cause the machine to foam

25/09/2018 Washtech CDe120 Operator Manual 10

Operator Care – Wash Zone

CDE120 Wash Zone

•Part #: CDE120 Wash Zone

•Date: 28/08/2018

•Version: 1-A

Daily Cleaning

•Remove Scrap Trays (4) and clean with a brush and water to clear grid.

•Remove Wash Pump Inlet Filter (5) and clean with a brush and water to clear grid.

•Return Scrap Trays (4) , Drain Upstand (6) and Wash Pump Inlet Filter (5) to the machine.

Weekly Cleaning

•To be done in conjunction with Daily cleaning.

•Remove Lower Wash Arms (2) – lift up to unhook the arm and then withdraw.

•Remove Upper Wash Arms (1) – push the cap up and then withdraw.

•Remove End Cap Screws (3) from Wash Arms using a blunt object.

•Flush Arms (1 & 2) with water. Use a toothpick or paper clip if necessary to clear jets.

•Return the Wash Pump Inlet Filter (5), the Drain Upstand (6), Scrap Trays (4),

Lower Wash Arms (2) and Upper Wash Arms (1) to the machine.

25/09/2018 Washtech CDe120 Operator Manual 11

Operator Care – Rinse Zone

CDE120 Rinse Zone

•Part #: CDE120 Rinse Zone

•Date: 28/08/2018

•Version: 1-A

Daily Cleaning

•Remove Scrap Trays (12) and clean with a brush and water to clear grid.

•Remove Rinse Pump Filter (13) and clean with a brush and water to clear grid.

•Return Scrap Trays (12) and Rinse Pump Filter (13) to the machine.

Weekly Cleaning

•To be done in conjunction with Daily cleaning.

•Remove Lower Rinse Arms (9 & 10) – lift up to unhook the arm and then withdraw.

•Remove Upper Rinse Arms (7 & 8) – push the cap up and then withdraw.

•Remove End Cap Screws (11) from Rinse Arms using a blunt object.

•Flush Arms (7, 8, 9, 10) with water. Use a toothpick or paper clip if necessary to clear jets.

•Return the Rinse Pump Filter (13), Scrap Trays (12), Lower Rinse Arms (9 & 10) and

Upper Rinse Arms (7 & 8) to the machine.

25/09/2018 Washtech CDe120 Operator Manual 12

Operator Care - Curtains

CDE120 Curtains

•Part #: CDE120 RL Curtains

•Date: 28/08/2018

•Version: 1-A

Types Of Curtains

1. Long anti splash curtain 600 x 475 (Part number: 840 90011)

2. Medium anti splash curtain 600 x 230 (Part number: 840 90012)

3. Short anti splash curtain 600 x 150 (Part number: 840 90013)

The Purpose of Curtains:

•To keep the heat inside the zones of the machine

•To stop water splashing from one zone to another. This prevents wash and rinse water

mixing. If this happens the water quality will be reduced.

•Curtains must be placed in their correct positions to work properly. They must also be the

correct way around.

•Broken curtains need to be replaced promptly.

Weekly Cleaning

•Remove curtains from hooks

•Place each curtain into a dishrack and wash through the machine

25/09/2018 Washtech CDe120 Operator Manual 13

Operator Troubleshooting

Issue Cause

POOR PRE-SCRAPING

CARRY OVER OF SOAP FROM SINK

OVERLOADING RACKS

POOR MACHINE CARE

JETS BLOCKED OR ARMS OBSTRUCTED

CURTAINS NOT FITTED CORRECTLY

WATER SUPPLY PRESSURE LOW

POOR WATER QUALITY**

RINSE TEMPERATURE LOW <75Ĺ%

PAWL DRIVE NOT OPERATING

CRASHING SOUND AGAINST DOOR

DISHES NOT CLEAN

STAINING

FOAMING

PROTEIN BLOOM

DIRTY MACHINE

FOOD RESIDUE ON WARE

FILM/SPOTS ON WARE

DETERGENT RESIDUE

GREASY FILM/NO FIZZ

WET WASHWARE

SCALE BUILD UP IN MACHINE

FILTERS ON OTHER EQUIPMENT

LIMIT SWITCH ACTIVATED

WASH ARM NOT FITTED PROPERLY

MACHINE STOPS & REFILLS CONSTANTLY

Likely cause Possible cause

* For issues most likely due to incorrect chemical dosages or other chemical issues, we

recommend you consult your chemical supplier and/or a local chemical expert prior to calling

in a dishwasher technician.

** For issues that are likely due to poor water quality (scale building up, filters being required

on other kitchen equipment etc.), we recommend you consult a local water specialist prior to

calling in a dishwasher technician.

IF PROBLEMS PERSIST CONTACT MOFFAT SERVICE ON 1300 264 217

25/09/2018 Washtech CDe120 Operator Manual 14

AVB Connections

CDE120 AVB Connections

•Part #: CDE120 AVB Connections

•Date: 28/08/2018

•Version: 1-A

The CDe120 are supplied with Atmospheric Vacuum Breaker as the source of backflow

prevention to prevent contamination of supply water as required. These AVBs and associated

systems within the CDe120 have been tested and confirmed as compliant with latest WMTS

101:2016 – Appliances (low hazard rating).

Washtech holds Watermark Certification in Australia for plumbing safety for its products as per

Watermark Licence Number WMKT08603. This certification has been held since 29th March 2000

and was most recently reissued on the 24th of July 2017.

No additional backflow prevention devices are required to be installed with Washtech

dishwashers.

Purpose of each AVB

AVB 1

Water Source: Cold water supply

Water Output: Heat Recovery Unit

AVB 2:

Water Source: Heat Recovery Unit

Water Output: Rinse tank

AVB 3:

Water Source: Hot water supply

Water Output: Wash tank

25/09/2018 Washtech CDe120 Operator Manual 15

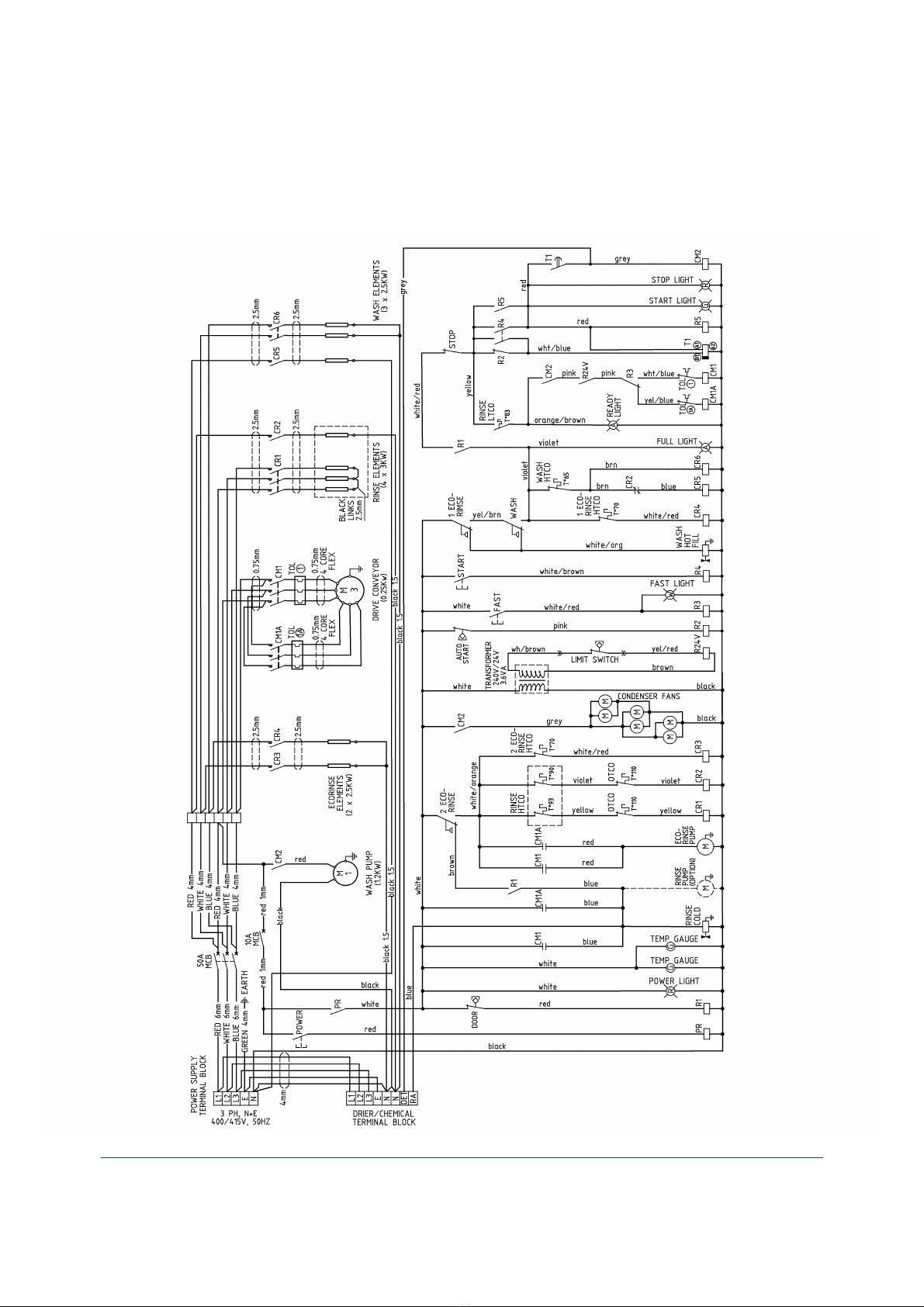

Schematic Diagram

CDE120 Schematic Diagram

•Part #: CDE120 Schematic Diagram

•Date: 28/08/2018

•Version: 1-C

25/09/2018 Washtech CDe120 Operator Manual 16

Accessories

CDE120 Accessories

•Part #: CDE120 ACW

•Date: 28/08/2018

•Version: 1-A

25/09/2018 Washtech CDe120 Operator Manual 17

Notes

25/09/2018 Washtech CDe120 Operator Manual 18

Notes

Information supplied in this manual is copyright. No

part of this work may be reproduced or copied in any

form or by any means, electronic or

mechanical without the express permission of the

author/publisher

Manufactured in New Zealand by Washtech Ltd.

414 Rosebank Road

Avondale

Auckland 1026

New Zealand

PO Box 90548, Auckland

24HR Service 0800 Starline

Tel 09 829 0930

Fax 09 829 0935

E-mail [email protected]

web www.starline.co.nz

ISO9001

All Washtech products are designed and

manufactured by Washtech using the

internationally recognised ISO9001 quality

management system, covering design,

manufacture and final inspection, ensuring

consistent high quality at all times.

In line with policy to continually develop and

improve its products, Washtech Ltd reserves the

right to change specifications and design without

prior notice.

Table of contents

Other Starline Dishwasher manuals