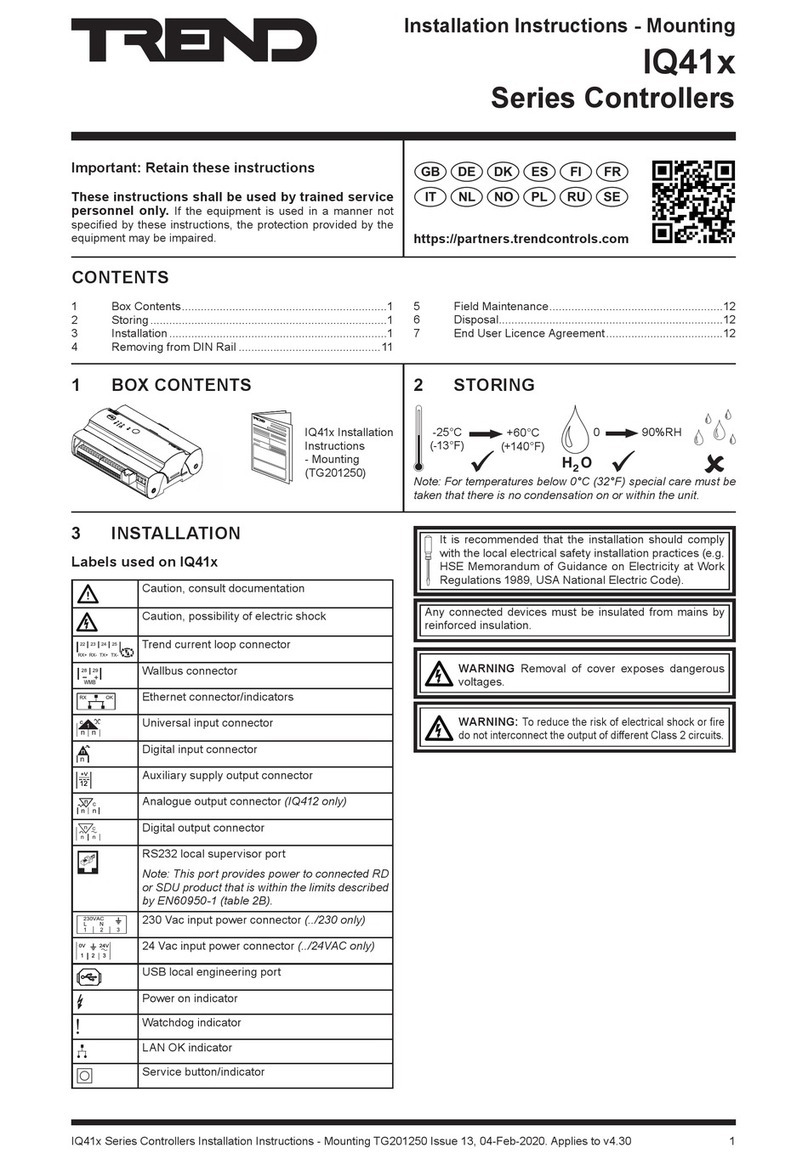

StarLogixs PressMate User manual

Page1

27 Young Street

Deepwater. N.S.W. 2371

Australia.

Phone: (02) 67 345 262

Fax: (02) 67 345 020

www.starlogixs.com.au

PRESSMATECONTROLLER

SERVICE MANUAL

R

For Use By Authorised Service Agents

Models covered by this manual:

SL100A1—Single Phase 2.2kW Motor

SL100A3–Three Phase 2.2kW Motor

SL200-Three Phase 4kW Motor

SL400-Three Phase 5.5.kW Motor

Page2

NOTES

Page3

CONTENTS

Owners Manual

Introduction…………………………………………………..4

Important Safety Notice…………………………………….5

Location of Controls and Switches………………………..6

Basic Operating Proceedures……………………………..7

Motor Operation…………………………………………….8

Optional Extras……………………………………………...8

Basic Servicing……………………………………………...9

Copyright…………………………………………………...10

Specifications……………………………………………...10

Warranty…………………………………………………....11

Service Manual

The Hydraulic Pressure Switch………………………......12

The Full Bale Switch……………………………………....13

The Infra-Red Detection System………………………...14

The Hydraulic Valve Energisation Method……………...14

Machine Protection Features in Controller……………..15

Controller Active LED….………………………………….16

Electric Motor Control……….…………………………… 16

Options Plug Loop-Back………….…………………… .16

Trouble-shooting

No Power…………………………………………….17

Baler Won’t Cycle……………………………….18-19

Baler Continually Cycles…………………………...20

Baler Won’t Eject…………………………………....21

Main Wiring Diagram……………………………………...22

Connector Pin-Out...……………………………………....23

Motor Contactor And Overload Relay Details…………. 24

Spare Parts List………………………………………… 25

Distributor List……………………………………………..26

Proceedure to Change Power Block…………………….29

Proceedure to Change Interlocked Door Switch……….30

Proceedure to Change PCB……………………………...31

Set-up Tactile Swtiches in Relation to Touch-Pad……..33

Category III Safety Changes……………………………..34

Category III Wiring Diagram…………………………… 35

Page4

Thankyou

For choosing a Starlogixs PressMate Controller.

For operating this Controller properly, please take some time to read this owners man-

ual thoroughly before starting operation of your Autobaler.

Keep this manual handy for future reference.

OWNERS MANUAL

CAUTION

IMPORTANT NOTICE

Should you leave your Autobaler unattended for a period of time,

it is strongly recommended that you switch the power off and re-

move the key.

Page5

IMPORTANT NOTICE

Should you leave your Autobaler unattended for a period of time, it is strongly

recommended that you switch the power off and remove the key.

•The StarLogixs PressMate Controller provides vital safety features in your press.

If the Controller has been damaged always have it checked by an approved ser-

vice agent before operating the press.

•Check all power leads and plugs for damage. If damage is found switch off and

disconnect from supply, and have repaired by an approved service agent.

•The ‘door closed’ sensors are critical to the safe operation of the press. If they

are damaged or the mechanism driving them is damaged never attempt to use

the press before calling an approved service agent.

•The Controller has lethal voltages inside.

•Never open or attempt to service.

•Never remove or attempt to remove the back cover.

•No user serviceable parts or adjustments inside.

•Do not directly expose Controller to rain or high pressure water jets.

IMPORTANT SAFETY NOTICE

Page6

LOCATION OF CONTROLS AND SWITCHES

Page7

1. Switch on Power Key Switch and check that Emergency Stop Button is not depressed

(rotate to release). The Power LED should illuminate.

2. Close press doors. If door is not properly shut the Door LED will remain illuminated and

the only function that will work is the bale eject.

3. Press Retract Keypad and the Up LED will illuminate, the electric motor will start, and after

a 4 second delay the pressing fingers will move upwards to their retracted position and

stay there.

4. After filling pressing compartment and hopper with material, press the Cycle Keypad. The

Active LED will commence flashing indicating the press has entered its automatic mode.

The Down LED will illuminate and the pressing fingers will move downward compressing

material. If the Infra-red sensors detect material in the press hopper the machine will auto-

matically cycle until the hopper is cleared. Alternatively the operator can manually initiate

another cycle by pressing the Cycle Keypad.

5. The press will continue to operate automatically until a full bale condition is detected. The

last pressing cycle is completed and an audible beeper and the full bale light are acti-

vated! The Infra-Red sensors will stop causing the press to cycle, but the operator can

cause further cycles by pressing the Cycle Keypad. This allows material already in the

hopper to be compressed.

6. After tying-off the bale (see press manual) the top press door must be shut. Pressing

the Retract Keypad will cause Up LED to illuminate and the pressing fingers to move up-

wards to their retracted position, and stay there. If this does not occur check door is shut

properly (Door LED should not be illuminated.)

BASIC OPERATING PROCEEDURES

IMPORTANT Read this procedure in conjunction with

procedures in your press manual.

NOTE: To guard against accidental operation the keypad must be pressed and held for

about 1 second before the Controller responds.

CAUTION

Page8

The PressMate Controller intelligently controls the electric motor for maximum energy

efficiency. If the press completes an operation and no new functions are required in the

next 16 seconds the motor is stopped.

If the motor has stopped and a press function is required the motor automatically starts,

but press functions are suspended for 4 seconds allowing the motor to start under no

load and stablise at its running speed.

MOTOR OPERATION

The StarLogixs PressMate Controller is supplied with an options connector, which has

a loop-back plug fitted. If this plug is removed an option kit must be fitted or the control-

ler will not function.

Two option kits are available:

Remote Control Kit

This kit allows the machine to be operated from a remote operator panel and provides

Cycle, Eject, Retract keys.

In addition it allows for monitoring of a secondary safety door or device, and also pro-

vides a full bale light.

The standard kit provides 5 meters (15 feet) of cable between the PressMate Controller

and the remote operator panel. For more details contact your local sales agent.

Auxiliary Control Kit

Your StarLogixs Controller has an auxiliary relay fitted, which changes state when a full

bale is detected. This can be used for simple control of external devices like cardboard

conveyor, systems in assembly line.

In addition 24Vac lines are available, thus providing all necessary requirements for driv-

ing motor contactors. Always consult your local sales agent before implementing this

option because incorrectly rated loads could seriously damage your Controller.

OPTIONAL EXTRAS

Page9

The StarLogixs PressMate Controller is a state of the art electronic control system that

is designed for long service free life.

No part of the controller is serviceable, and should never be opened because there are

dangerous voltages inside.

However, some basic service can be performed by the operator, as detailed below :

1. No Power

•Check that the mains outlet is working properly. Test by plugging another machine

into the outlet. If there is a fault with the outlet call a qualified electrician.

Never try to make repairs to mains equipment.

•Check the fuse located on the bottom of the Controller. If it is blown only replace

with a 4A MGC glass fuse. Use of an incorrect fuse may result in serious damage

to the Controller, and will void your warranty.

•If the fuse continuously blows call for service.

2. Press Continually Cycles

•Sometimes material in the pressing hopper can stick to the lens surface of the In-

fra-Red detector. Clean lens with a soft cloth dampened with water and a mild de-

tergent.

•Never use abrasive pads or harsh chemicals on the lens.

3. Electric Motor Cuts Out

•Your StarLogixs Controller is fitted with a thermal overload relay to protect the elec-

tric motor. This unit is an auto-resetting type, and will reset after about 1 minute. If

the motor continually cuts-out there is a fault and you should call for service.

BASIC SERVICING

Page10

Copyright 2001 by StarLogixs Pty. Ltd.

All rights reserved. The contents of this document, Controller front panel artwork,

printed circuit board artwork, and firmware (programs contained in Controller inte-

grated circuits) are subject to copyright and can not be reproduced, transmitted tran-

scribed, stored in a retrieval system, or translated into any language or computer

language, in any form or any means, electronic, mechanical, magnetic, optical,

chemical, manual, or otherwise, without prior written consent from StarLogixs Pty.

Ltd.

COPYRIGHT

SPECIFICATIONS

Power Supply:415V ac 50Hz 20A

: (240Vac 50Hz 20A for SL100A1)

Control & Sensor Power Supply: 24Vdc fully mains isolated.

Motor Rating: SL100A1-2.2kW Single Phase

SL100A3-2.2kW Three Phase

SL200—4kW Three Phase

SL400—5.5 kW Three Phase

Motor Protection: Auto resetting thermal overload relay.

Panel Fuse: 4A MGC 32mm Glass Type.

Hopper Detection System: Infra Red encoded beam type.

Door Closed Detection: Mechanical limit switch and interlocked safety door switch.

Panel Sealing: Protected to IP62.

Electrical Safety:

•Mains equipment enclosed in fully earthed metal case.

•Sealed plugs and entry points on mains leads to motor and supply.

•All control and sensor wiring is mains isolated.

Page11

WARRANTY

Your StarLogixs PressMate Controller is guaranteed against faulty

workmanship or components for a period of twelve months after the purchase

date. For warranty contact your local sales agent with proof of purchase

date.

This warranty does not cover damage or failure cause by or attributable to Acts

of God, abuse, misuse, improper maintenance, lightning or other incidence of

excessive voltage or any repairs other than those provided by an author-

ised StarLogixs service facility, or transportation costs.

StarLogixs is not responsible or liable for indirect, special, or consequential

damages arising out of or in connection with the use or performance of the Con-

troller or other damages with respect to any economic loss, loss of property,

loss of revenues or profit, or cost of removal, installation or reinstallation.

There will be charges rendered for repairs to the product made after the expira-

tion of the aforesaid twelve month warranty period.

* This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Page12

The hydraulic pressure switch is pre-adjusted, and field adjustment is

not recommended. The switch set-point is adjusted to be about

150psi below the hydraulic system by-pass pressure.

There are no mechanical sensors to detect the end of stroke of the

main hydraulic cylinders. The Controller detects these positions by

monitoring the hydraulic pressure switch state and combining this

with the direction the cylinders are being driven, thus detecting end of

cylinder stroke and if the cylinder is retracted or extended.

Electrically the pressure switch is normally open, and closes when

the set-point pressure is applied. The electrical circuit is as below:

THE HYDRAULIC PRESSURE SWITCH

When the power is switched on the Controller looses its memory of

the cylinder position, and the cylinders are always retracted when the

cycle button is first pressed after the power is switched back on.

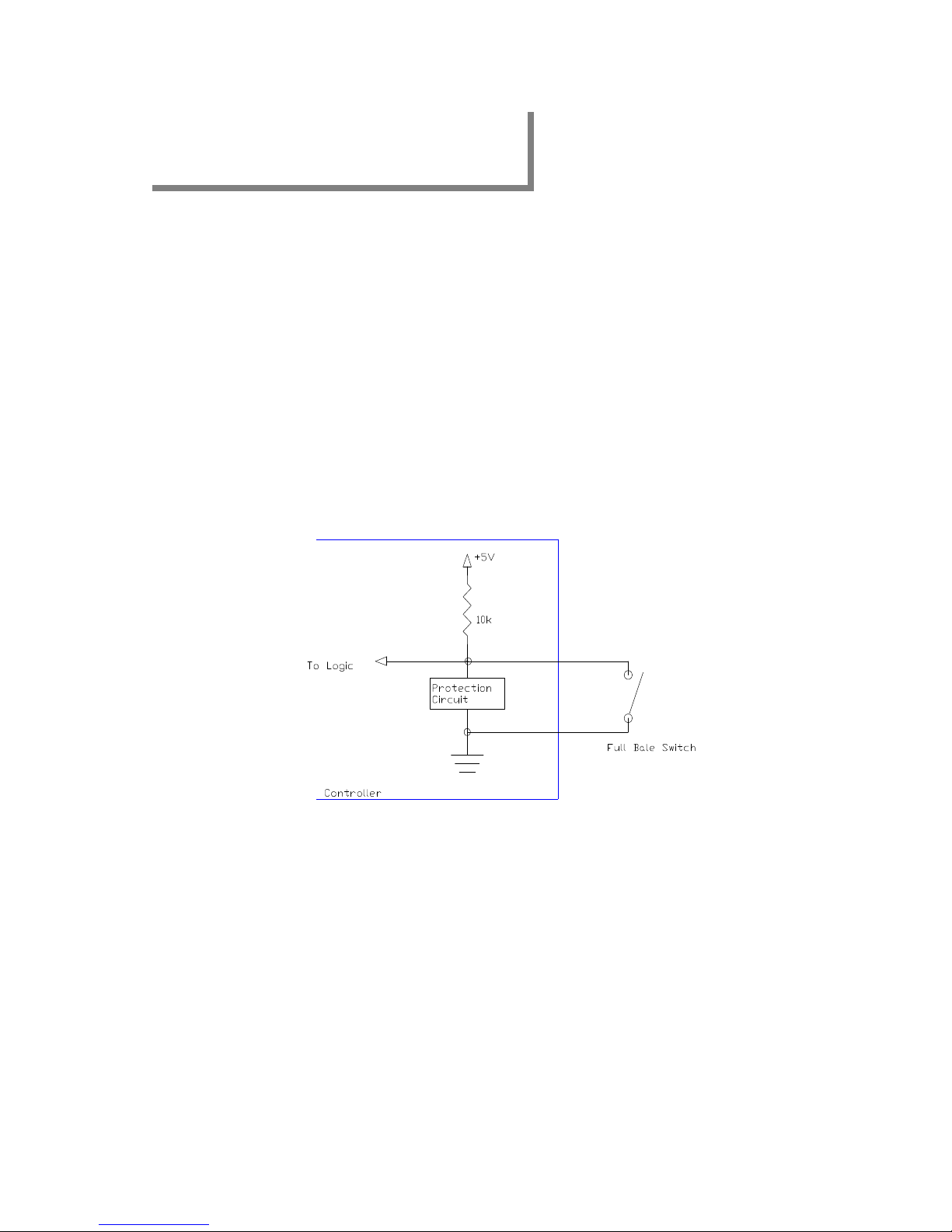

Page13

The full bale limit switch is situated on the front left-hand corner of

the press, and detects if the left-hand cylinder is fully retracted

when the pressure switch closes.

If the pressure switch closes before the cylinder fully retracts then

the material in the pressing chamber is carrying the total applied

load and the bale is full. It is assumed that the material under the

left-hand and right-hand pressing finger sets is evenly distributed in

the pressing chamber, so only one finger set is monitored by the full

bale switch. The full bale switch is normally closed, with the con-

tacts opening when the left-hand cylinder fully retracts. The electri-

cal circuit is as below:

The baler is designed to complete its cycle and stop with the pressing fingers

holding load onto the material in the hopper. There is sufficient internal leak-

age in the hydraulic system to allow the pressing fingers to creep up over time

and possibly give a false full bale indication. To prevent this the Controller only

monitors the full bale switch for 32 seconds after the pressing fingers stop in

the down position.

When a full bale is detected a warning lamp illuminates and a beeper sounds.

Also the baler will not automatically cycle if the infra-red sensor beam in the

pressing hopper is blocked. However the baler will still cycle if the cycle button

is pressed allowing the operator to finish-off the bale. The options plug on the

Controller has a set of internal Controller relay contacts available and these

change state when a full bale is detected. In some installations this feature is

used to control a material feed system.

THE FULL BALE SWITCH

Page14

The infra-red detection system detects material in the pressing hopper

and if the Controller is active and the bale not full will cause the press to

cycle until the beam is cleared (i.e. no material in pressing hopper.)

It is a transmissive type system with the IR Transmitter located on the

back of the press and the receiver inside the Controller. Dirty or

scratched lenses will cause the press to continually cycle.

It should be noted that +24Vdc is supplied to one side of the valve coil

at all times that the Controller is on. The other side of the coil will have

24V on it if the valve is off and approximately 0V is the valve is on. The

+24Vdc line is normal if the voltage is between 22Vdc and 24Vdc.

THE INFRA-RED DETECTION SYSTEM

The hydraulic valve coils are rated at 24V dc. All voltages on valve coils

and sensors are fully mains isolated and do not constitute a shock haz-

ard.

The electrical circuit is as below:

THE HYDRAULIC VALVE ENERGISATION METHOD

Page15

The Controller incorporates a number of features to protect the ma-

chine from sensor faults. The two main features are:

•Excessive Cycling

If the infra-red detection beam becomes obstructed and cycling of the

baler does not clear the obstruction, then an unattended baler may

continually cycle causing unnecessary machine wear. To overcome

this problem the Controller counts machine cycles and when they

reach 128 cycles the Controller becomes inactive. To re-commence

cycling an operator must now press the cycle button. The cycle

counter is reset if the press door is opened.

•Failed Pressure Switch

If a pressure switch failed so that it did not close when the set-point

pressure was reached, then an unattended baler could continually en-

ergise the valve coil, with the oil forced across the system by-pass

valve. This would rapidly heat the hydraulic oil and cause damage. If

the up or down valve coil is energised continuously for more than 64

seconds when the Controller is active, then an internal fault flag is set

and the Controller becomes inactive. To recommence operation the

operator must press the cycle button, and the fault will now be ob-

served. If no action is taken to repair the fault the press will again shut

down after 64 seconds.

MACHINE PROTECTION FEATURES IN CONTROLLER

The Controller is fitted with two door safety switches. The OMRON

D4DS-1SFS switch can only be activated y its D4DS-K1 Key,which is

fixed to a mechanism on the top door. Either opening the top door or

pressing the Emergency Bar will withdraw the key from the switch. Also

fitted to the side of the Controller is an OMROM Z15GQ22B limit switch

which is closed by a striker plate fixed to the top door.

The two switches operate on completely separate circuits in the Con-

troller and both must be closed for the Controller to sense that the top

door is shut. This provides a fully redundant safety back-up switching

system. A door open condition is indicated by illumination of the DOOR

LED on the Controller.

DOOR SAFETY SWITCHES

Page16

The Controller co-ordinates the electric motor function. If the motor has

stopped and some press action is required, then the motor is started

but all hydraulic valve drive signals are suspended for approximately 4

seconds to allow the motor to stablise at its operating speed under no

mechanical load. Further press actions while the motor is running do

not incur the 4 second delay.

At the completion of press actions the motor runs for a further 16 to 20

seconds. This avoids rapidly stopping and starting of the motor when

brief interruptions in press actions occur.

ELECTRIC MOTOR CONTROL

The second LED from the top on the Controller is the active LED. This

indicates if the Controller is in full automatic mode. If the LED is flash-

ing the Controller will start the electric motor and cycle the press if the

infra-red detection beam is interrupted. For safety reasons the Control-

ler is always inactive when the power is switched on, when the press

doors are open and after the doors are shut. Pressing the emergency

bar halts press operation and also forces it to the inactive state. To en-

ter the active state the press doors must be shut, emergency bar re-

leased and the operator must press (and hold for approximately 0.5

seconds) the cycle button.

THE CONTROLLER ACTIVE LED

OPTIONS PLUG LOOP-BACK

The Controller options socket has a plug fitted which contains a loop-

back connection across the auxiliary door switch pins. The door

open LED will remain on and most press functions will be disabled if

the options plug is removed.

The Controller options socket provides a means for connecting an

optional remote control kit or auxiliary control kit as mentioned in the

owners manual section of this document.

Page17

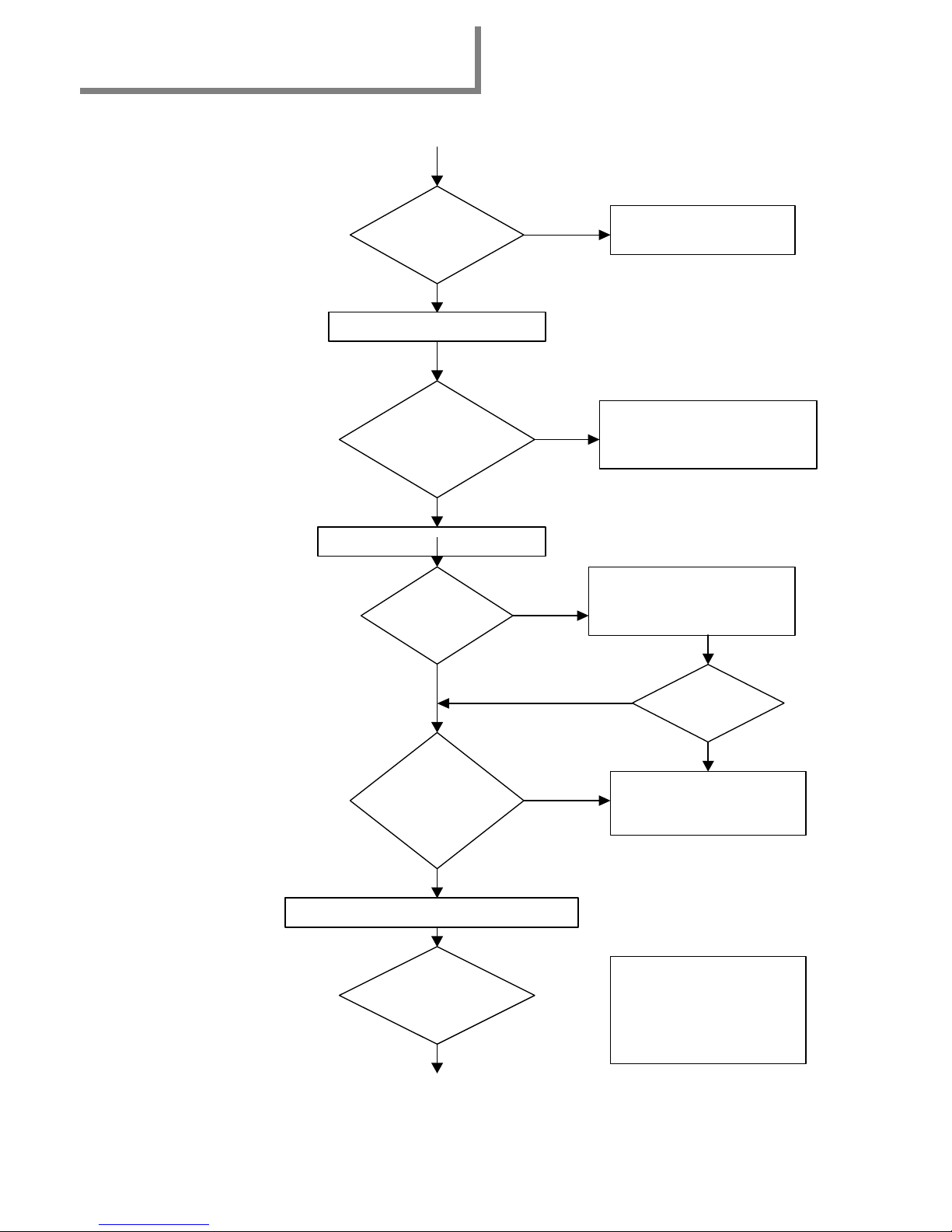

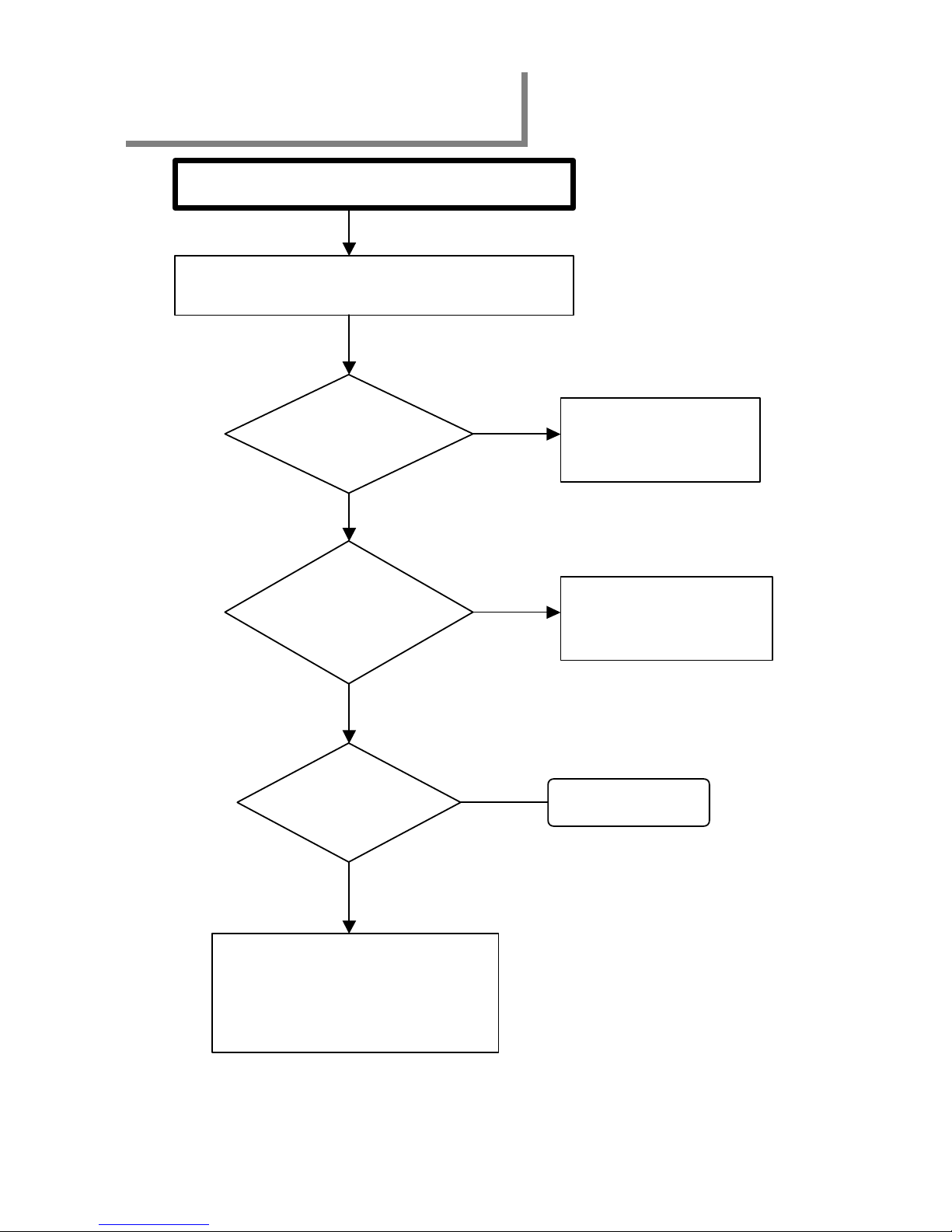

TROUBLE-SHOOTING

NO POWER

Plug another machine into the wall socket power

Is the socket

powered ?

Call Electrician

Disconn

ect press plug from wall socket and thoroughly check entire length of

power cable and cable to motor for damage

Leads

O.K.?

Rotate Emergency Stop Button clockwise to release and check key switch is on

Is Controller

Light On?

Check fuse on the bottom

of the Controller

Is fuse

blown?

Replace

fuse.

If fuse blows

again check

wiring to

valve coils

Shut press doors and

check emergency bar not

jammed

Press Down or Cycle

button

Does Press

Start?

Baler O.K.

Hold Eject

Button

Does Press

Start ?

Door Switch Fault.

:Possible

Controller

Fault

Replace/repair

cables

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Page18

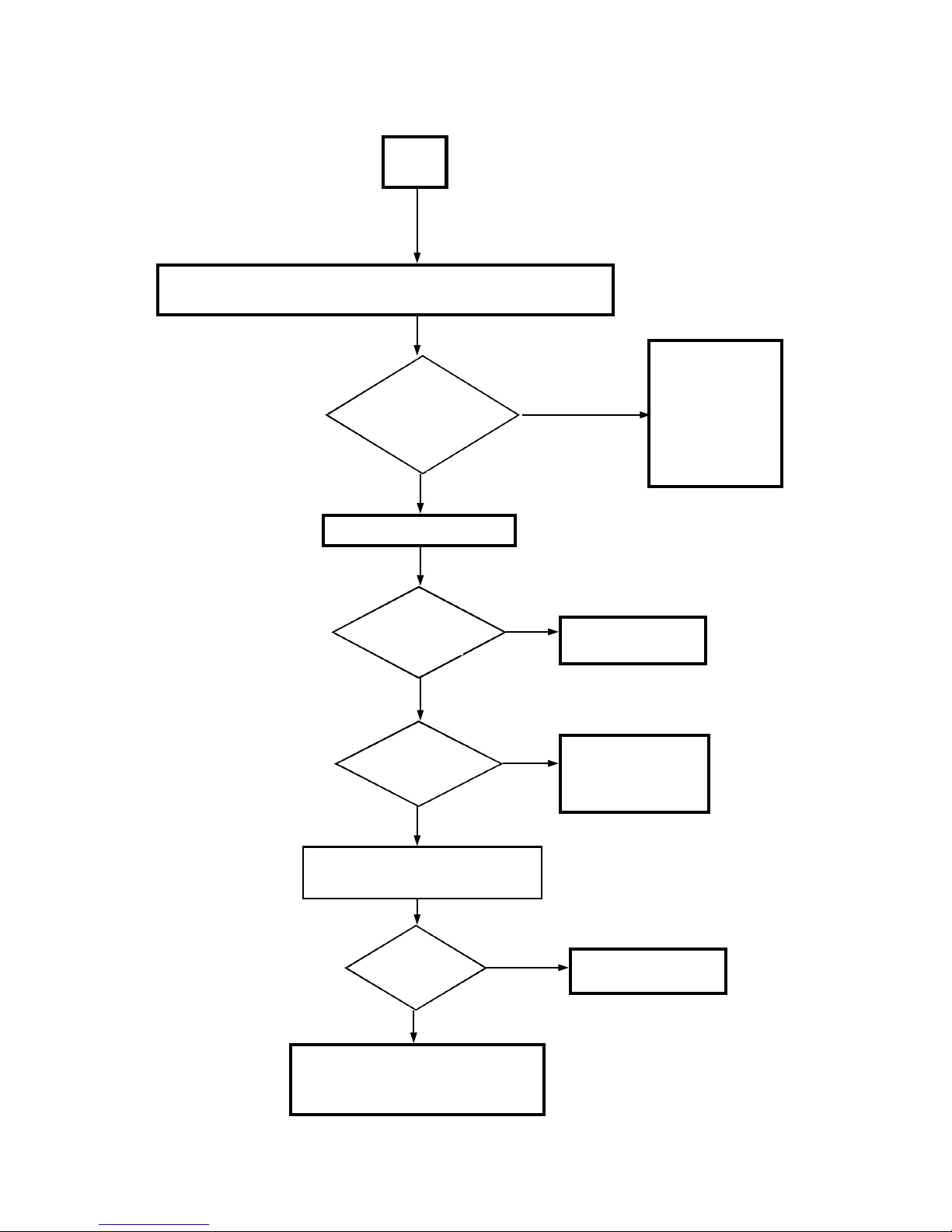

TROUBLE-SHOOTING

NO

YES

YES

NO

NO

YES YES

NO

NO

YES

Power

Light On?

Refer to No Power

Flow Chart

Shut Press Doors

Door

Open LED

illuminated

Fault in door switch or

Emergency Bar

Press cycle button

Motor

Starts?

Motor

Starts?

Wait 4 seconds after motor starts

Cycles

Down?

Wait 5 minutes for

auto-resetting overload

relay

Down LED

Illuminated

?

Possible F

aulty Control

Panel/ Motor Wiring or

Electric Motor

Check down valve coil

continuity and wiring.

Check for +24dc at

valve coil

Page19

Fingers fully

Extended?

Down LED stays

illuminated ?

YES

NO

A

Wait for hydraulic cylinder to reach the end of its stroke

Press Up or Cycle Button

Check hydraulic

system pressure-

Replace faulty pres-

sure

Switch

Check wiring to

pressure switch

Up LED

Illuminated? Possible Controller

Fault

Cycles

Up?

Check up valve coil

Continuity and wiring

& check for +24V dc

Observe finger position at the end of

the up cycle

Press should cycle down and stay in the

down position if there is no material in

the hopper blocking the eye beam

Faulty Pressure Switch

YES

YES

YES

NO

NO

NO

Page20

BALER CONTINUALLY CYCLES

Switch power on, shut press doors and press

down or cycle button

Press cycles?

Refer to Baler Won't

Cycle Flow Chart

Material

Blocking

Eye Beam?

Press should cycle

until eye beam is

cleared

Press

cycles? Baler O.K.

-

Clean eye lens covers

-Replace lens covers if

damaged or scratched

-Check wiring to eye

TROUBLE-SHOOTING

NO

NO

NO

YES

YES

YES

Table of contents