IQ41x Series Controllers Installation Instructions - Mounting TG201250 Issue 13, 04-Feb-2020. Applies to v4.30 1

Installation Instructions - Mounting

IQ41x

Series Controllers

Important: Retain these instructions

These instructions shall be used by trained service

personnel only. If the equipment is used in a manner not

specied by these instructions, the protection provided by the

equipment may be impaired. https://partners.trendcontrols.com

GB DE DK FIES FR

IT NL NO RU

PL SE

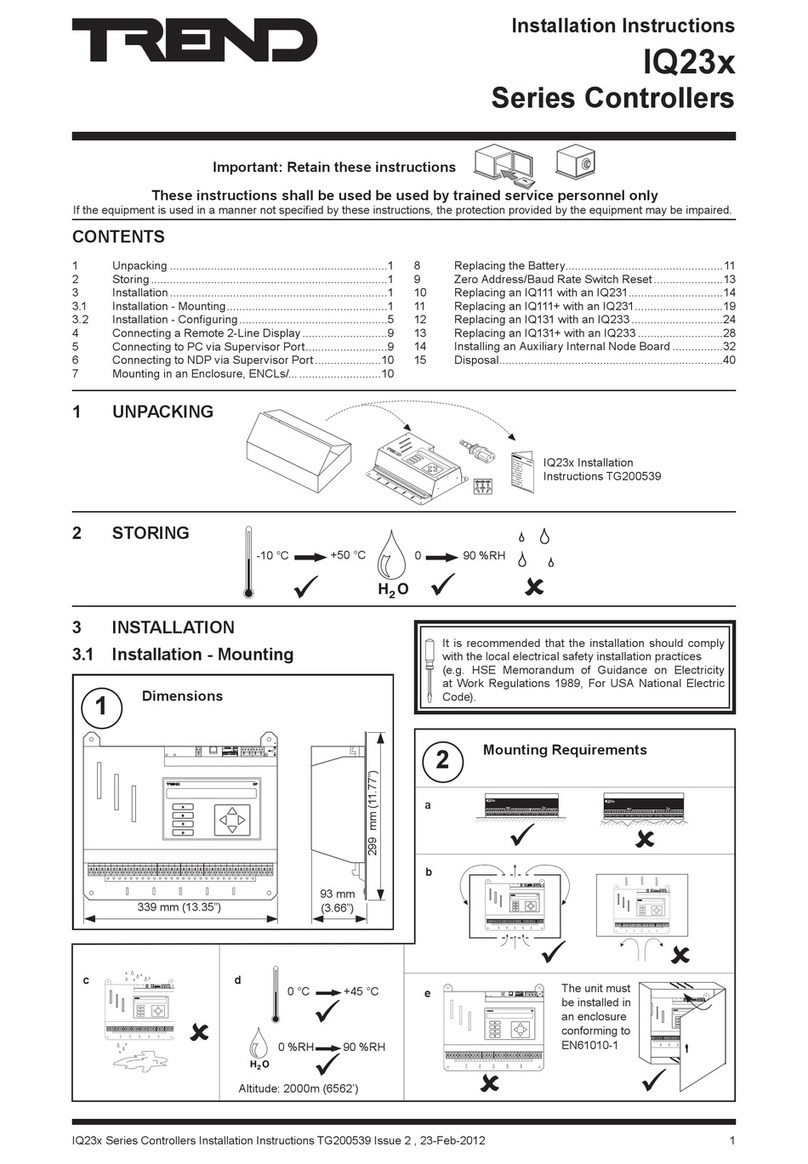

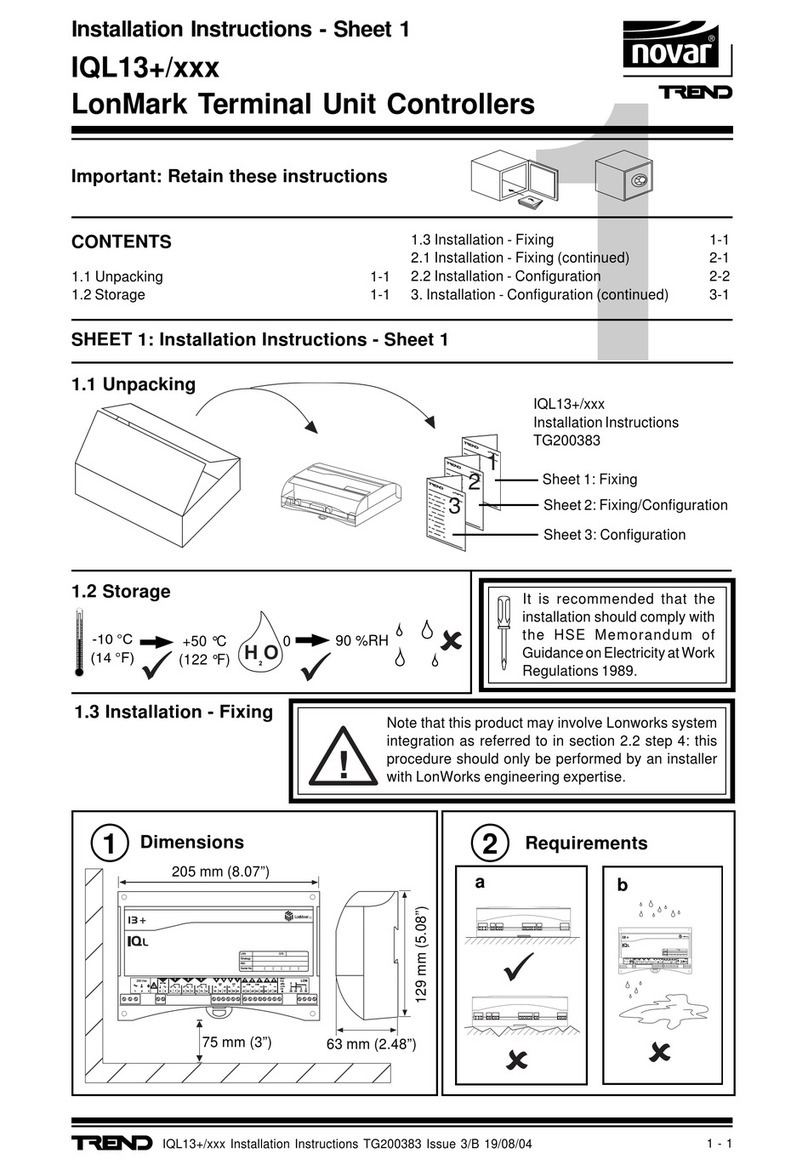

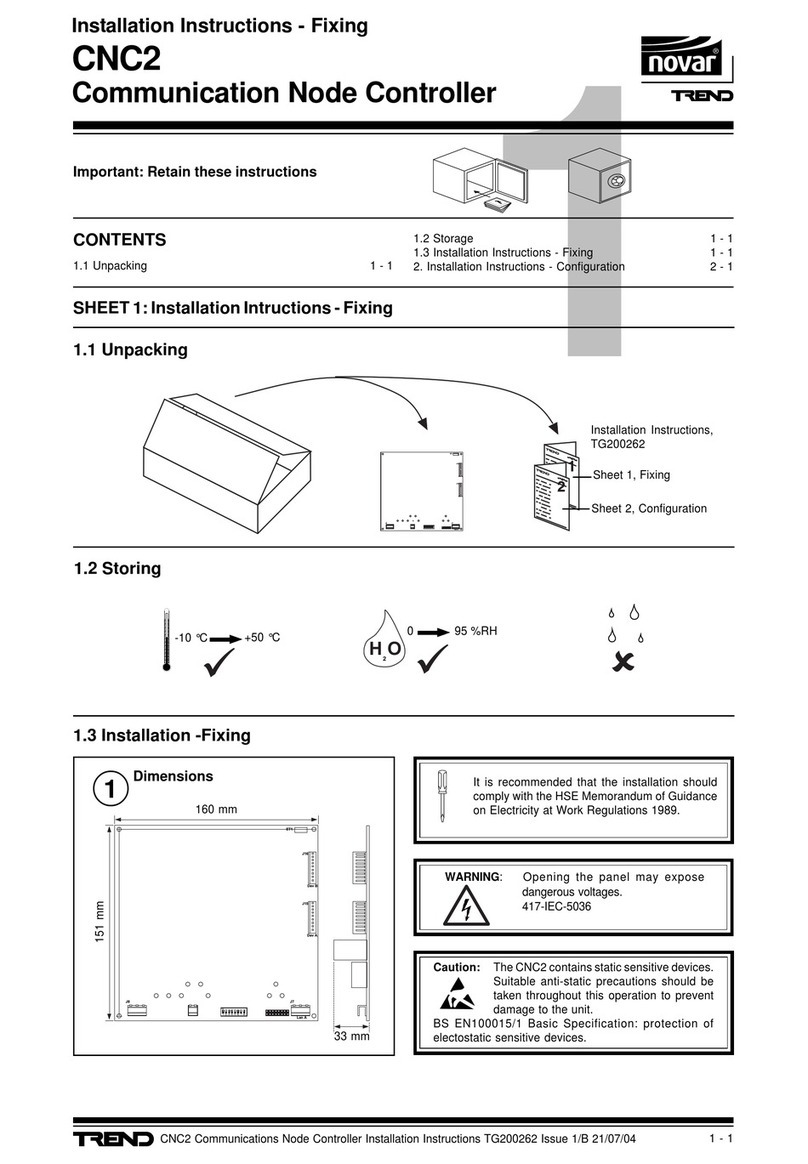

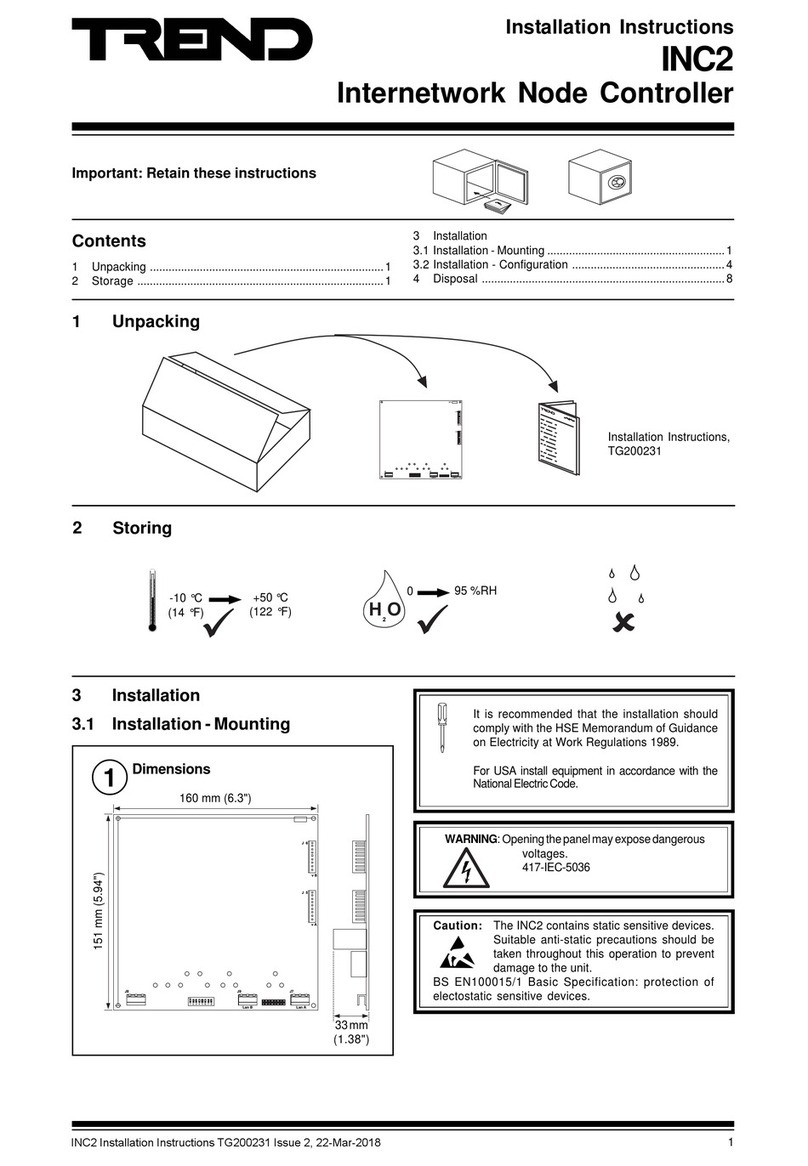

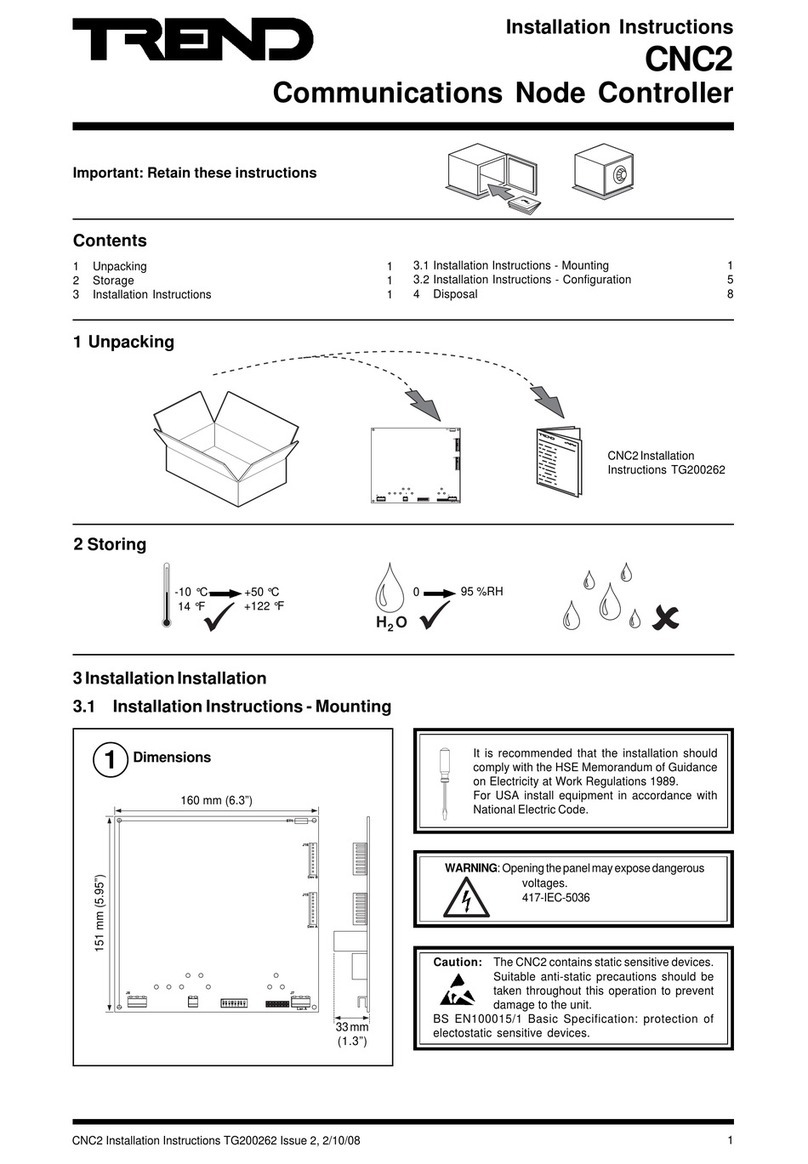

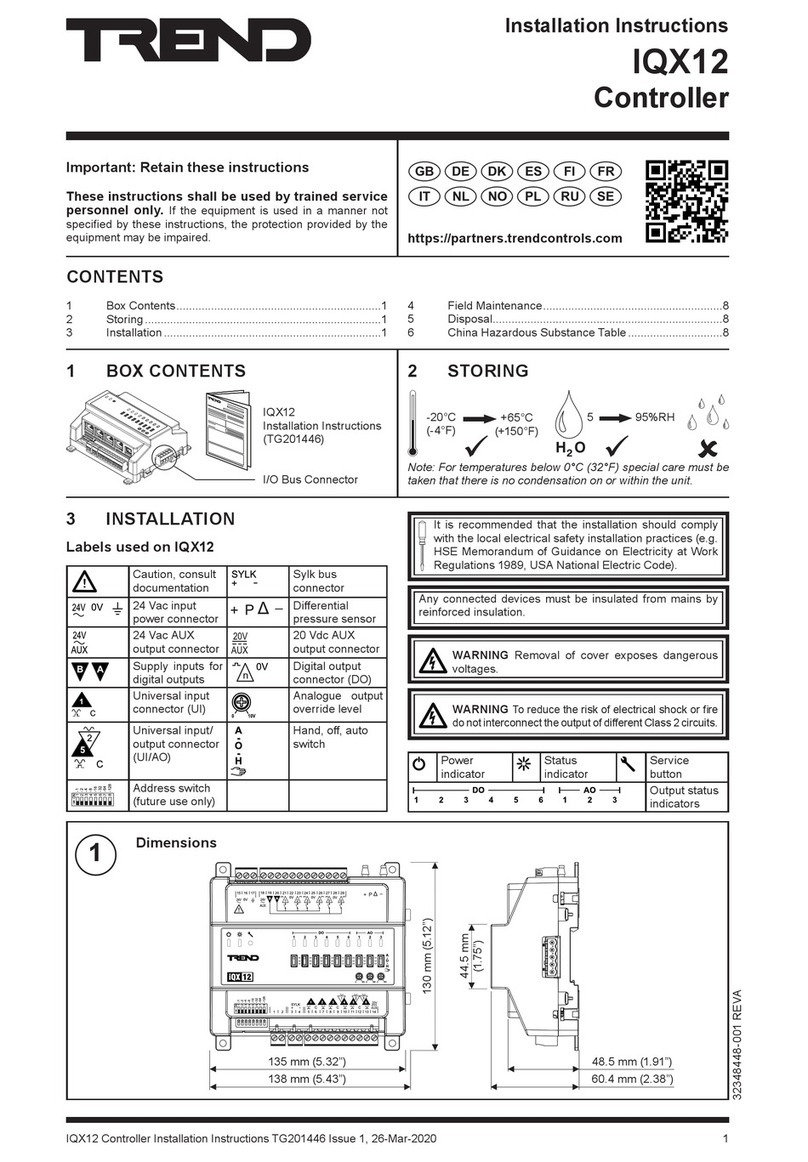

3 INSTALLATION

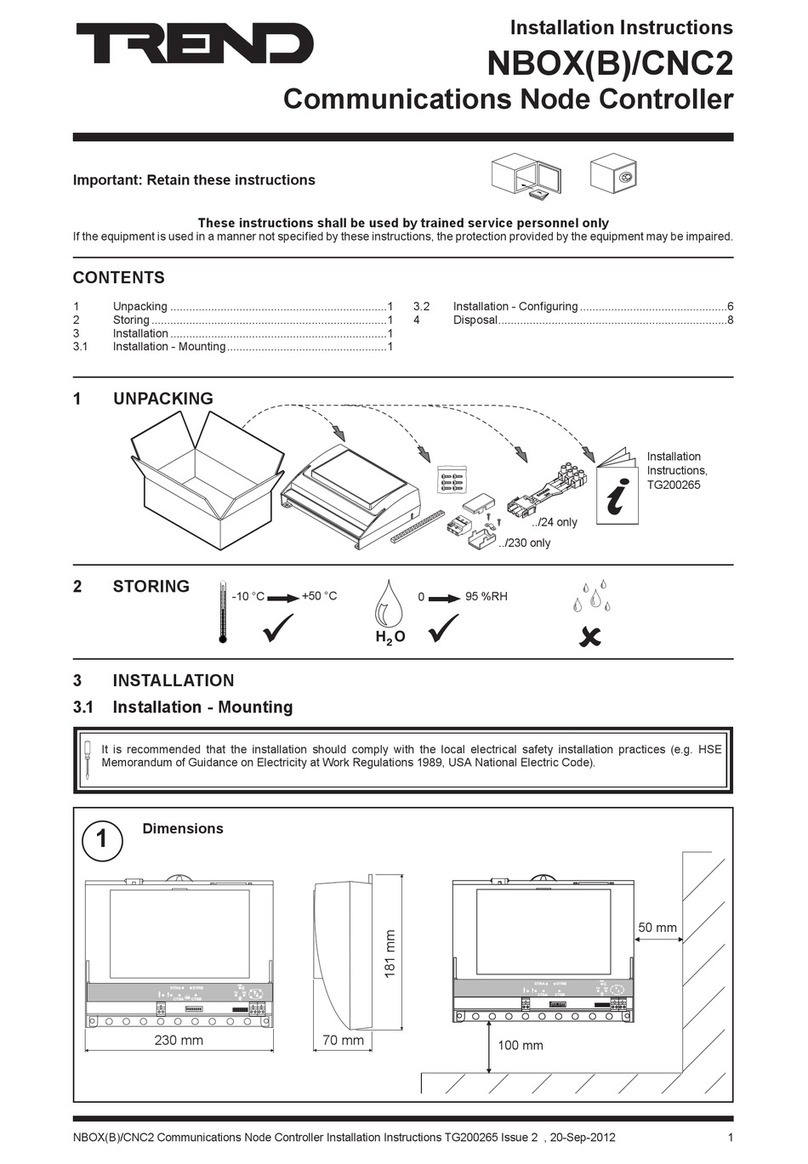

1 BOX CONTENTS 2 STORING

It is recommended that the installation should comply

with the local electrical safety installation practices (e.g.

HSE Memorandum of Guidance on Electricity at Work

Regulations 1989, USA National Electric Code).

CONTENTS

1 Box Contents.................................................................1

2 Storing ...........................................................................1

3 Installation .....................................................................1

4 Removing from DIN Rail .............................................11

Note: For temperatures below 0°C (32°F) special care must be

taken that there is no condensation on or within the unit.

IQ41x Installation

Instructions

- Mounting

(TG201250)

5 Field Maintenance.......................................................12

6 Disposal.......................................................................12

7 End User Licence Agreement.....................................12

Any connected devices must be insulated from mains by

reinforced insulation.

+60°C

(+140°F)

0

-25°C

(-13°F)

90%RH

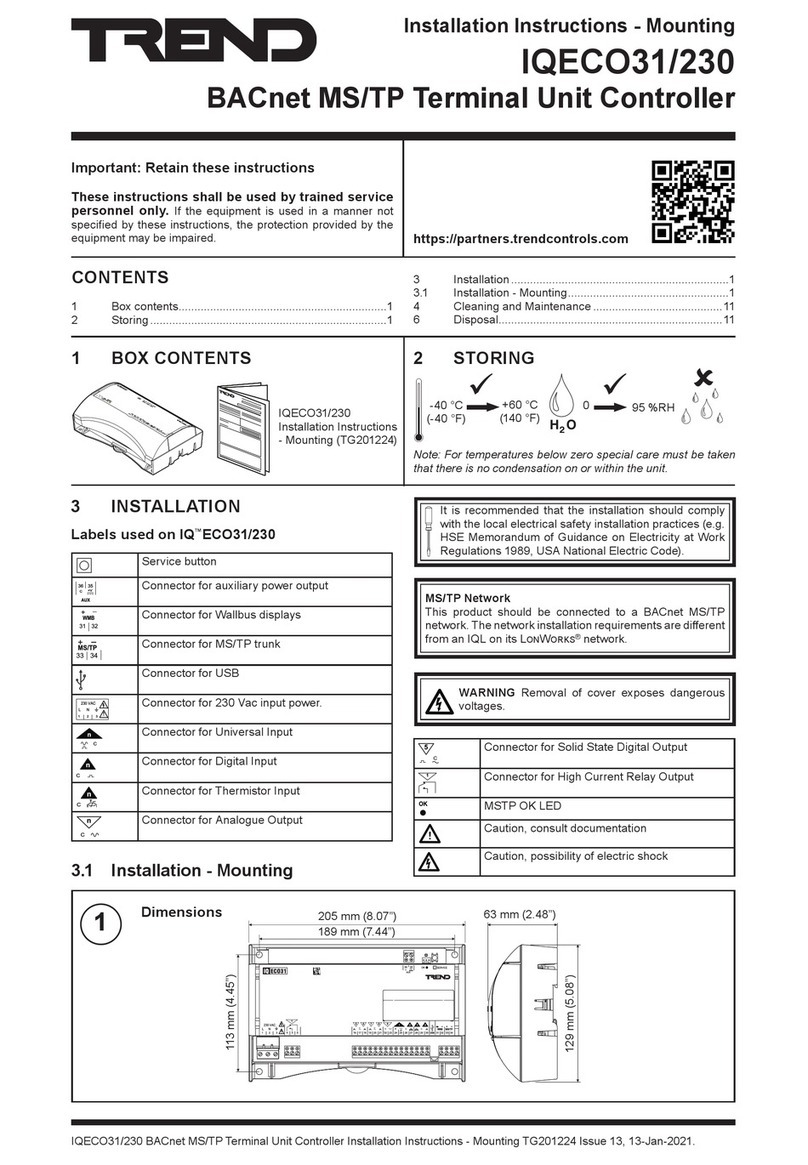

Labels used on IQ41x

Caution, consult documentation

Caution, possibility of electric shock

Trend current loop connector

Ethernet connector/indicators

Universal input connector

12

+V

Auxiliary supply output connector

C

Analogue output connector

(IQ412 only)

RS232 local supervisor port

Note: This port provides power to connected RD

or SDU product that is within the limits described

by EN60950-1 (table 2B).

230 Vac input power connector (../230 only)

0V 24V

24 Vac input power connector (../24VAC only)

USB local engineering port

WARNING Removal of cover exposes dangerous

voltages.

WARNING:

To reduce the risk of electrical shock or re

do not interconnect the output of dierent Class 2 circuits

.