StarLogixs GateKeeper RR-07 User manual

Operating Instructions

GateKeeper

Remote System

Complies To:

AS/NZS4251.1.1999

FCCPart15(B)

N10728

R

For Rev2.0 Units

Receiver Model: RR-07

Remote Model : RT-07

Contents

1. Remote Set-up……..…………………….…....3

2. Receiver Set-up…………………………….…4

3. Control unction…….………………….……5

4. Range and Interference…………………..…..5

5. Receiver Connector Pin-Outs……………...6

6. Standard Receiver Wiring Connections….6

7. Switching Inductive Loads……………...…..7

8. Driving an Electric Motor-

Reversible Direction………………………….9

9. Trouble Shooting……………………………..10

10. Specifications………………………………….11

4 Or Less Controlled Devices

You only require one remote.

Leave it set on the factory default

Low Channel range.

5 to 8 Controlled Devices

You will require two remotes with

one set on Low Channel and the

other on High Channel.

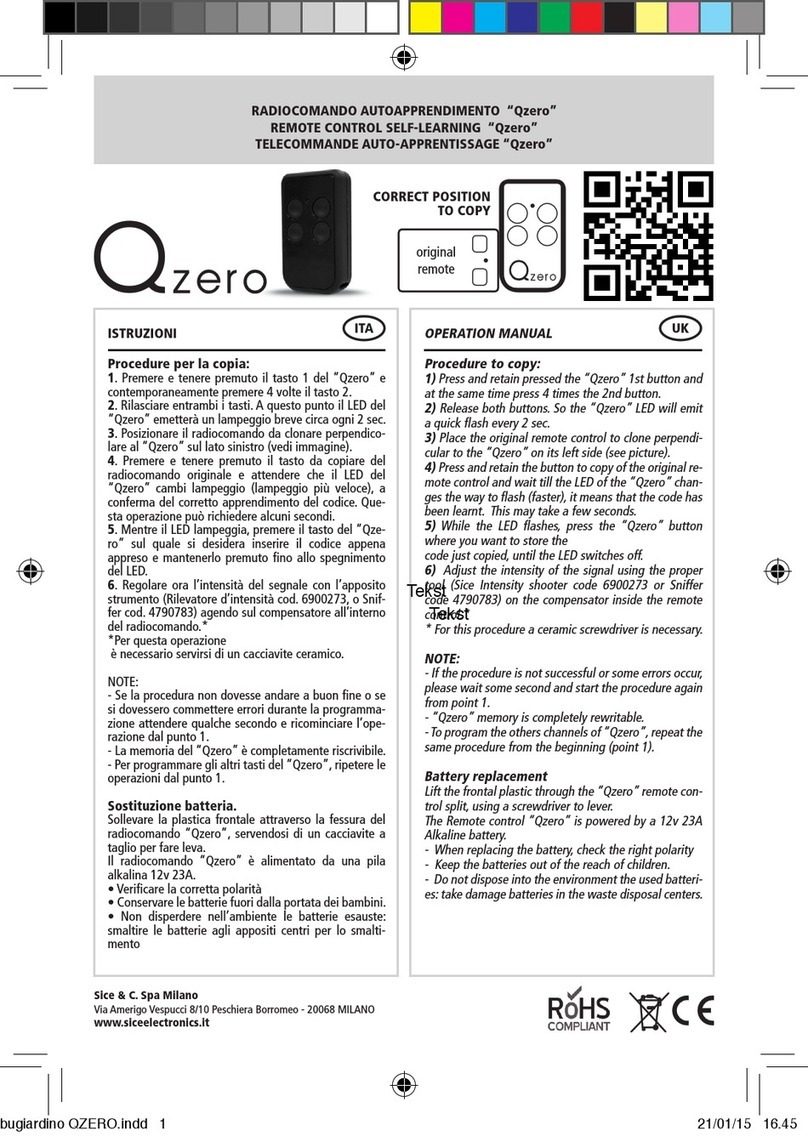

A) Remove the battery lid and

remove both batteries.

B) Remove 2 screws from

enclosure back. Rotate

enclosure front up as shown.

Take care not to damage or

pull on the touch pad wire

tail.

C) Set jumper shunt to the two

pins on the channel select

jumper closest to the ‘High

Ch’ label on the circuit board.

D) Re-assemble the unit in

reverse order to disassembly

1.

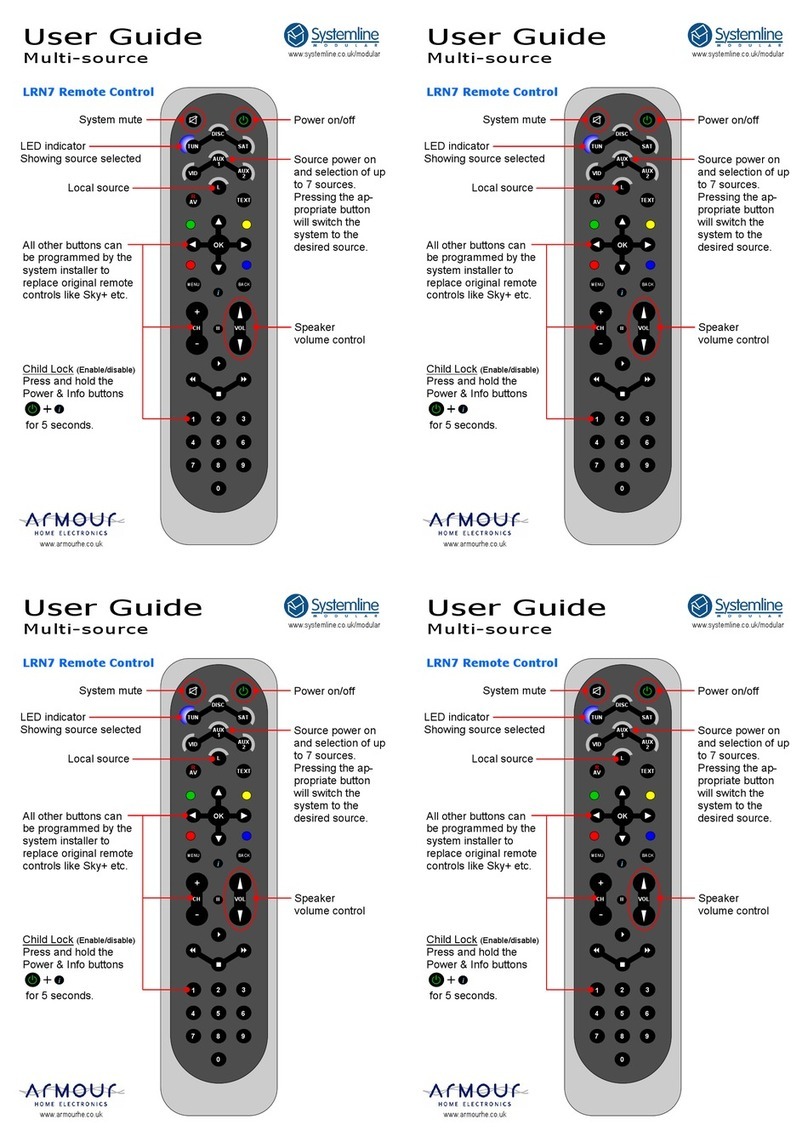

1) Select a channel you wish to associate

with a controlled device. Note a

channel is a horizontal pair of keys,

one for open and the other for close.

2) The high channel number is on the

upper left corner of the key, and the

low channel number is on the lower

right corner of the key. (See above for

selecting high or low channel). This

channel number is required in the

receiver set-up.

Remote Set-up

Note: the SEND light should illuminate

when the Remote is transmitting.

Remember: after you have selected a pair

of keys for a function, place supplied

stickers on the keys to indicate their

function.

2

Changing to High Channel Mode

If two remotes are being used and they are more than 50 meters apart it should be

possible to operate them both in low channel mode. Only change one to high chan-

nel if they interfere with each other—that is intermittent or unpredictable response

when both remotes are operated.

Selecting a Channel

A) Remove 4 screws and remove case lid.

B) Using a small flat blade screwdriver rotate the channel switch until

the arrow points at the channel number selected in Step 2 of remote

set-up.

C) Refit the case lid. Take care to ensure lid seal is in place.

Note 1: Power must be off when adjusting the channel switch.

Note 2: When the case lid is removed four holes next to the case lid

screw holes can be accessed for mounting the unit. Only use

these holes—DO NOT drill any extra holes in the case.

2. Receiver Set-up

3

Setting the Receiver Channel

3. Control unction

All functions on the remote unit are a 'dead-man' type operation. That is - the

function only works while the key is held depressed. As soon as the key is

released the device being controlled will stop.

The Close key on the remote will drive N/O 1 on the receiver.

The Open key on the remote will drive N/O 2 on the receiver.

4.

.

Range and Interference

The system should work with the remote unit up to 15 meters from the

receiver. In many cases it may be possible to obtain adequate function at

greater distances. Obstacles like steel buildings and metal structures

between the remote and receiver may adversely impact on reliable

operation.

The system depends on a low power 433.92MHz radio link, and strong radio

transmitters in this frequency region may block communication. UHF two

way radios could be one such source of interference.

This system is NOT designed to be used in any safety critical

application. The safety rating of the system would be Category I as

specified by AS4024.1.

5

The GateKeeper System has been designed to be flexible and configur-

able thus enabling its use in many applications without modification. The

receiver has simple connection options that should allow for all common

actuator wiring configurations.

Note: the ‘actuator’ is whatever device the receiver has to drive to

cause the controlled device to move. For example pneumatic or

hydraulic solenoid coils, electric motors etc.

Wire entry is via a waterproof cable gland and it is recommended to use

a circular cable, so as to allow a good environmental seal. Farnell 388-

4650 seven core 0.75mm

2

or similar flex would be suitable. Also it is ad-

vised to crimp a bootlace ferrule (Farnell 997-2080 or similar) to each

conductor before fitting to PCB connectors.

Receiver Connector Pin-outs 5.

The receiver connectors are located on the receiver printed circuit board.

The pin-out is shown below. The receiver must be powered by a stable

12V dc power source. The receiver has an internal self-resetting fuse, but

it is also advisable to fit an in-line 1 amp fast blow fuse in the +ve power

wire.

6

Connector Pin-Out

Switching Inductive Loads

No special precautions are necessary when switching inductive loads

(that is things like solenoid coils). Protection circuitry is built into the re-

ceiver, and will work with AC or DC loads.

7.

Connection is as below:

7

Standard Receiver Wiring Connections 6.

The above wiring scheme should work for most applications, however

the normally open relay contacts in the Receiver can be wired in vari-

ous other circuit layouts depending on specific electrical requirements.

The exact design of specialised applications is beyond the scope of

this document.

Note: it is not possible to switch voltages greater than 12v dc or

ac. The relay contacts in the receiver have a protection circuit

that will not work above 12v. If it is necessary to switch higher

voltages then the receiver contacts must be wired to control ex

ternal switching relays.

8. Driving an Electric Motor - Reversible Direction

If the motor is 12v then the motor power source and the receiver power

source could be the same unit. Separate power sources allow for differ-

ent motor voltages. To allow the motor to be reversed using this scheme

the motor must be a DC type. Also note that this system requires two sin-

gle pole double throw relays mounted externally to the receiver unit. The

relay contacts and motor power source should have sufficient rated cur-

rent capacity at full motor load. Also no protection fuses are shown, but

must be fitted as deemed appropriate to protect the motor, motor power

source, relay contacts and wiring.

Motors with large inertial loads will take some time to ‘run-down’ and in

the process can generate considerable energy. When the motor is de-

energised the relay contacts are as shown above and currents can circu-

late through the N/C contacts of the external relays during the ‘run-down’

time. The relay contacts and wiring must be rated for this condition, or

some form of energy control and dissipation circuit fitted. 9

9

.

Trouble Shooting

No Function

1) Ensure the remote unit has fresh batteries. Only use quality AA

alkaline type dry cell batteries.

2) Ensure the receiver unit is powered with a 12V dc supply, and that

the supply is capable of supplying the current requirements of any

actuators fitted. Check that the power LED is illuminated. Check polarity

of supply voltage to receiver.

3) Double check the channel has been set correctly on the receiver.

4) Check that the correct channel range (high or low) is selected with

the jumper in the remote unit.

5) Observe the receiver LED's while pressing the open or closed key of

the associated channel on the remote. If the LED's light then the

problem is most likely to be in the wiring between the receiver and the

actuators ( or in the actuator system it's-self ).

Poor Control Range

1) Ensure the remote unit has fresh batteries. Only use quality AA

alkaline type dry cell batteries.

2) Check that the path between the remote and the receiver is not

obstructed by large metallic obstacles.

3) Check that no other high powered radio transmitters are operating

nearby.

10

10. Specifications

Remote Unit

Transmission Frequency 433.92MHz

Transmission Bandwidth 100kHz

Transmission Power 3dBm

Power Supply 3 x AAA Batteries

Standby Current Draw 4uA

Transmit Current Draw 4mA

Low Band Channels 6

High Band Channels 6

Channel Encoding Digital PWM

Dimensions 117x78x24mm

Weight (including batteries) 140g

Environmental Sealing IP55

Receiver Unit

Receive Frequency 433.92MHz

Receive Sensitivity -104dBm

Channels 12

Channel Decoding Digital

Dimensions 100x100x55mm

Environmental Sealing IP65

11

Your Sales Agent:

Warranty

Your StarLogixs GateKeeper Remote System is guaranteed against faulty

workmanship or components for a period of twelve months after the purchase

date. For warranty contact your local sales agent with proof of purchase date.

This warranty does not cover damage or failure cause by or attributable to Acts of

God, abuse, misuse, improper maintenance, lightning or other incidence of

excessive voltage or any repairs other than those provided by an authorised

StarLogixs service facility, or transportation costs.

StarLogixs is not responsible or liable for indirect, special, or consequential

damages arising out of or in connection with the use or performance of the system

or other damages with respect to any economic loss, loss of property, loss of

revenues or profit, or cost of removal, installation or reinstallation.

There will be charges rendered for repairs to the product made after the expiration

of the aforesaid twelve month warranty period.

•This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Copyright

Copyright 2001 by Starlogixs Pty Ltd.

All rights reserved.

The contents of this document, GateKeeper Remote System, front panel artwork, printed

circuit board artwork, and firmware (programs contained in the GateKeeper Remote System

integrated circuits) are subject to copyright and can not be reproduced, transmitted into any

language or computer language, in any form or any means, electronic, mechanical, magnetic,

optical, chemical, manual, or otherwise, without prior written consent from Starlogixs Pty. Ltd.

Trademarks

The symbols

are subject to Australian and international Trademark registrations, and their use is expressly

prohibited without written consent from Starlogixs Pty Ltd.

GateKeeper and

This manual suits for next models

1

Table of contents