Static Power iSTS B1 User manual

iSTS

Model B1

User Manual

19-inch Rack Mount Static Transfer Switch

iSTS B1 –User Manual R12

STATIC POWER Pty Ltd

ABN 42 101 765 913

iSTS

B1 –User Manual

Post to:

Box 2003

Research Delivery centre

Research, VIC 3095 - Australia

Manufactured at:

5 Candlebark Court

Research, VIC 3095

Australia

Contact us:

+61 3 9437 0494

support@staticpower.com.au

www.staticpower.com.au

CONTENTS

1. SAFETY INSTRUCTIONS

2

1.1 Introduction

2

1.2 Transport, Storage, Unpacking

2

1.3 Installation

2

1.4 Fire Regulations

3

1.5 Standards Applied & Conformity

3

1.6 Warranty

3

2. SYSTEM OVERVIEW & OPERATION

4

2.1 Description

4

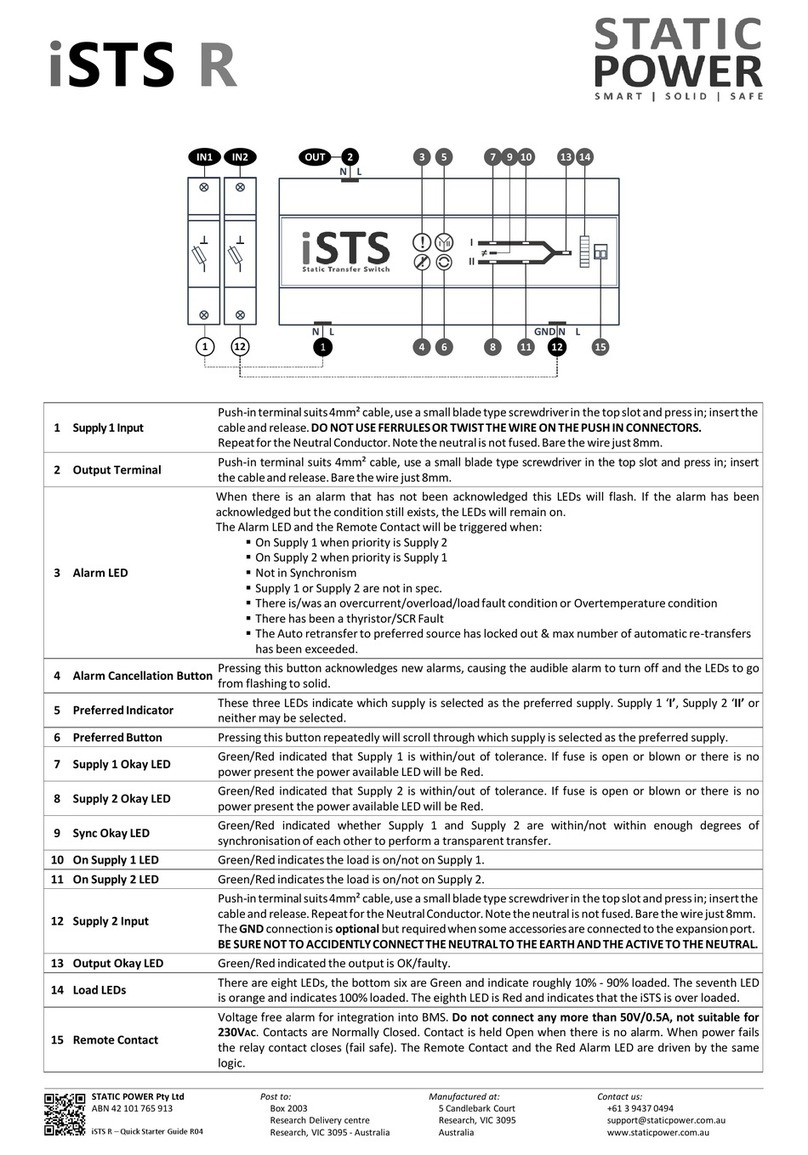

2.2 Line Diagram

4

2.3 Inputs & Output

5

2.4 Front Panel Overview & Operations

6

3. OPERATION

6

3.1 Safety

6

3.2 Installation

7

3.3 Terminating Cables to the iSTS

7

3.4 Synchronism

7

3.5 Start-up

7

3.6 Display Screens

8

3.7 Remote Contacts

10

3.8 Confirm Operation

11

3.9 Maintenance Bypass Procedure

11

3.10 Operational Parameters

13

4. WEB BROWSER INTERFACE

13

4.1 Connection to a Network

13

4.2 Connecting to a PC

14

4.3 Connecting to the Web Server

14

4.4 Control Panel

16

4.5 Email

17

4.6 Advanced Settings

18

4.7 Input Steady State Settings

19

4.8 Input Transient Settings

20

4.9 Output Settings

21

5. FAULT DIAGNOSIS

22

5.1 Fault Codes

22

5.2 Load Fault

22

6. RECOMMENDED MAINTENANCE SCHEDULE

23

7. SPECIFICATIONS

24

iSTS B1

–User Manual

Page 1

1

. SAFETY INSTRUCTIONS

1

.1 Introduction

Some

aspects of this manuals contents may differ to the equipment as supplied due to technical

improvements,

specific

model variations etc. If in any doubt in respect to the procedures and safety issues consult

the

manufacturer

and do not proceed until clarification is received.

This

manual contains important instructions that should be followed and fully understood before proceeding

and

commissioning

and operation to prevent harm to personnel and equipment.

Installation

and commissioning should be carried out only by qualified and experienced electricians.

The

iSTS

should be operated by technically qualified personnel that are authorized, experienced and have

knowledge

and

understanding of the equipment and the critical loads, using the documented procedures.

Read

this whole document thoroughly. Understand every aspect before proceeding. Request further assistance

if

you

do not understand any aspect of the operation of the iSTS. Support and contact numbers are at the end

of

the

manual.

These

instructions cover normal operation in the automatic as well as in manual modes. Special

operating

conditions,

such as short circuit tests, input supplies, etc., are not covered in this document. These

operations

require

comprehensive knowledge of the overall system and should be carried out by properly qualified,

skilled

and

competent service personnel only.

1

.2 Transport, Storage, Unpacking

Procedure

for Receiving Shipment:

▪If the packaging is damaged unpack carefully and inspect the unit. We recommend that if there is any sign

of

mechanical damage that the unit not be powered up; but, returned for re-processing

▪If damage is discovered, inform carrier immediately and follow normal procedure for a carrier inspection

and

filing of a concealed damage claim to the courier or your insurance company.

▪Take a picture of the carton and contents as a record.

▪If the packaging is OK, then please keep the packaging in a secure place in case the unit needs to be

returned

for repair.

1

.3 Installation

The

following instructions are provided for the personal safety of operators and also for the protection of

the

described

product and connected equipment.

▪Observe the prescribed accident prevention and safety rules for the specific application.

▪When installing the iSTS strictly observe all information on technical data and operating conditions.

Comply

with all warnings, and strictly follow the procedures and practices as described in this manual.

▪This iSTS is intended to be used in a controlled indoor environment and free of conductive contaminants

and

protected against animal intrusion.

▪It is important that the unit has adequate ventilation. Maintain air movement around and through the

unit.

Do not block the air vents or restrict airflow over the heatsinks.

▪The unit must be placed in a sufficiently ventilated area; the ambient temperature should not exceed 40°

C

(104°F).

▪Do not install the iSTS in an excessively humid environment or near water, relative humidity should

not

exceed 90%at 20°C (68°F).

▪Avoid spilling liquids or dropping any foreign object into the iSTS.

▪Once the connections have been made on the terminals, all terminal covers must be replaced

before

operation.

▪Connecting cables must be supported.

▪Earth connection must be checked for safe function after assembly.

iSTS B1

–User Manual

Page 2

iSTS B1

1

.4 Fire Regulations

Should

a fire break out inside the system a fire extinguisher with CO2or Halon must be used. Do not

inhale

vapours

.

1

.5 Standards Applied & Conformity

The

iSTS R conforms to the following standards and European Council Directives:

Standards to which conformity declared:

▪IEC 60950-1

Information

technology equipment Safety - General requirements

▪IEC 62310-1

Static

transfer systems (STS) - General and safety requirements

▪IEC 62310-2

Static

transfer systems (STS) - Electromagnetic compatibility (EMC) requirements

▪IEC 62310-3

Static

transfer systems (STS) - Part 3: Method for specifying performance and

test

requirements

Application of Council Directives:

▪2006/95/EC

Low

Voltage Directive

▪1992/31/EEC

EMC

Directive

▪1993/68/EEC

EMC

Directive amendments

▪2011/65/EU

Hazardous

substances in electrical and electronic equipment - RoHS

iSTS B1

–User Manual

Page 3

The Standards mentioned above fulfil

the requirements for CE marking

Year of CE marking: 2015-2016

1

.6 Warranty

Static

Power operating through its authorised agents warrants that the standard products will be free of

defects

in

materials and workmanship for a period of 24 months after the date of invoice, or such other period as may

be

specified

.

This

warranty does not cover failures of the product which result from incorrect installation, misuse,

alterations

by

persons other than authorized agents or abnormal operating conditions.

More

about warranty: staticpower.com.au/wp-content/uploads/2019/11/Warranty-Statement.pdf

2

. SYSTEM OVERVIEW & OPERATION

2

.1 Description

A

Static Transfer Switch (STS) provides your critical load or single cord (single supply), equipment with

an

alternative

supply source, thus increasing and improving power reliability and availability.

The

iSTS B1 is a 2 pole, single phase 1RU 19-inch rack mount iSTS with a maintenance bypass feature. Both

the

active

conductor and the neutral are switched. Thyristors are used to undertake the switching process. These

are

many

times faster and more reliable than their electromechanical equivalents.

The

STS continuously monitors the supply sources and should the presently connected supply fail or

degenerate

to

not be useable, the critical load is automatically and transparently transferred to the alternate source.

This

switching process is undertaken as a break before make transfer. The break in the supply transition is

so

short

that it is not seen by the critical load.

This

is preferable to a make before break (or overlapping) changeover because when the two supplies

are

different

and connected together large and unpredictable currents would flow between the

sources

degenerating

both supplies and therefore the supply to the critical load.

In

case of downstream fault the iSTS will not transfer the fault to the alternate supply even if the voltage

is

adversely

affected. Once the fault current has cleared the iSTS will resume normal operation protecting

the

critical

loads from voltage disturbances, (10 second settling time).

2

.2 Line Diagram

iSTS B1

–User Manual

Page 4

iSTS B1

2

.3 Inputs & Output

iSTS B1

–User Manual

Page 5

1 2

1 2

OUTPUT SUPPLY

2

.4 Front Panel Overview & Operations

Name

Description

1

Supply 1 Isolator Switch*

Turns incoming Supply 1 ON or OFF.

When switched OFF, power will not go through the STS

circuit and Supply 1 Okay LED will show red.

2

Dedicated General Alarm Contact

3

Remote Contact

Voltage free alarm for integrationinto BMS.

Do not connect any more than 50 V DC 0.5 Amps,

not suitable for 230 V AC.

Contacts are Normally Closed. Contact is held Open when there is no alarm.

When

power fails the relay contact closes (fail safe). The Remote Contact and the red Alarm

LED

are

driven by the same logic.

4

Ethernet Connector*

Use this port to connect the STS to a LAN or directly to a PC using either a straight

-throughor

crossover CAT5 cable with RJ45 8P8C plug 10/100 MB per second.

5

Supply 1 Okay LED

Green/red indicated that Supply 1 is within/out of tolerance.

6

Supply 2 Okay LED

Green/red indicated that Supply 2 is within/out of tolerance.

7

Sync Okay LED

Green/red indicated whether Supply 1 and Supply 2 are within/not within enough degrees of

synchronisation of each other to perform a transparent transfer.

8

On Supply 1 LED

Green/red indicates the load is on/not on Supply 1.

9

On Supply 2 LED

Green/red indicates the load is on/not on Supply 2.

10

Output Okay LED

Green/red indicated the output is OK/faulty.

11

Alarm Cancel/Acknowledge

button

Pressing this button acknowledges new alarms, causing the audible alarm to turn off and the LEDs

to go from flashing to solid.

12

Preferred Source Indicator &

Transfer Button

These three LEDs indicate which supply is selectedas the preferred supply. Supply 1 (I), Supply 2

(II) or either (none) may be selected.

Pressing this button repeatedly will scroll through which supply is selected as the preferred

supply.

13

Graphic OLED LCD Interface

Displays Warnings,Load, Variables, Events and Settings (Refer to Display Screens section).

14

NavigationButtons

Use to navigate through menus on the OLED display.

15

Supply 2 Isolator Switch*

Turns incoming Supply 2 ON or OFF. When switched OFF, power will not go through the STS

circuit and Supply 1 Okay LED will show red.

*Optional features

123

7

8

4

5

9

10

11

12

13 14

15

6

3

. OPERATION

3

.1 Safety

The

iSTS is powered from two separate sources. It is important that you install correct signage with

procedures

within

the enclosure and the immediate vicinity to warn personnel of this aspect and what isolation,

checking

and

precautionary processes, and procedures need to be adopted to make the iSTS and equipment

connected

to

the iSTS safe to work on.

This equipment receives power from more than one source.

Disconnect output and all input sources of power from this equipment before servicing.

This

equipment receives power from more than one source. Disconnect output and all input sources of

power

from

this equipment before servicing.

Do

not proceed with the installation or operation of the iSTS if it has been damaged. Carefully inspect the

iSTS

for

any damage that may have occurred during shipping, unpacking or during and after any

installation

process

.

Take

care when handling the iSTS and ensure that it is physically supported during the installation process.

At

the

end of the installation process the iSTS should be firmly and securely bolted within the rack.

Ensure

the cables are securely connected and supported and all covers plates are replaces. There should be

NO

live

exposed or accessible contacts that could cause electrical shock if contact is able to be made. This

is

especially

important when plugging and unplugging the input (Supply 1 or Supply 2) plugs as leakage

currents

could

cause dangerous voltages to appear on the incoming leads which can be a shock hazard and

cause

equipment

damage if contact with other equipment is inadvertently made.

This

equipment is not recommended for installation into environments that utilise RCD earth

leakage

detectors

on the inputs of the static transfer switch.

Where

it is being installed with RCDs care should be taken to select a noise immune type; this will

improve

overall

system reliability.

The

standard iSTS B1 will contribute a maximum of 5mA to earth leakage (transiently & during

switching

between

sources), this will itself not cause any tripping of the RCDs.

The

iSTS B1 has backfeed contactors to ensure that there is no or negligible earth leakage currents if a

supply

source

is removed.

Earth connection is essential before working on circuits or connecting / disconnecting supplies.

Treat AC incoming leads as live if disconnecting from source.

iSTS B1

–User Manual

Page 6

iSTS B1

3

.4 Synchronism

The

smoothest change-over occurs when the supplies are in synchronism, so it is best to make sure the

input

supplies

are in synchronism. Some equipment (like transformers) may saturate when a transfer occurs when

not

in

synchronism. This causes large currents to flow into the load which could cause damage to the

transformer,

trip

protective devices or blow fuses.

The

iSTS is configured by default to have up to 12ms break inserted if the phase difference between the

sources

exceeds

30 degrees.

The

break has been inserted for a safe mode on purpose when the sources are out by more than 30 degrees.

3

.2 Installation

1. Secure the iSTS into your rack by the four holes on the front of the cradle portion.

2. Ensure that the power module portion of the STS is securely mated with the cradle.

3

.3 Cable Termination to the iSTS

1. To access the input and output terminals at the rear of the cradle, remove the 2 screws on each of

the

gland plates and then remove the plate.

2. Cable size is limited to 6mm² (#10). The terminals are suitable for tin-plated stranded cables from 2.5

mm²

to 6mm² (nominal current is 41 Amps). Strip cables to a length of 10mm.

3. Connect Active, Neutral and Earth cables to the respective spring cage terminals as marked on the

board.

Note that the order is not identical for each terminal block. Secure the connections on the terminal

blocks,

torque the screw between 0.5 –0.6Nm. All cables connecting to the iSTS should be supported and

not

weigh the rear of the iSTS or strain the point of connection.

4. All electrical connections are to be realized by properly qualified, skilled and competent service

personnel

only.

5. Before applying power to the iSTS, make sure that the rated voltage for the unit corresponds to the

ratings

plate and the local supply voltage.

When

working on live STS, be sure to comply with the applicable standards and national accident

prevention

rules

.

3

.5 Start-up

NOTE

: Due to the nature of SCRs (silicon controlled rectifiers) some load of around 0.5A is required for

correct

operation

. Before testing the operation of this iSTS, make sure this load is applied to the output.

1. Ensure that your two input sources are within the tolerances.

2. Apply power to both input sources. There will be a short 15 second start-up period, after which the

iSTS

will begin powering your load.

3. Confirm that the load is receiving power. Check that LEDs on the mimic are correctly representing

the

supply status and load.

NOTE

: Only the On Supply 1 LED or On Supply 2 LED should be red, not both.

iSTS B1

–User Manual

Page 7

3

.6 Display Screen

HOME

SCREEN

iSTS B1

–User Manual

Page 8

1 2

543

Name

Description

1

Preferred Supply Status

Shows the preferred supply and the status of the source connected to the load

2

Load Indicator

Bar and percentage represent the current capacity of the STS that is being used

3

Output Status

Indicates the status of the output

4

Inactive Supply Status

Indicates the status of the supply that is not connected to the load

5

Priority Alarm

The message displayed will be the most important alarm (refer to Event Codes in the Fault Diagnosis

section)

VARIABLE

SCREEN

1 2 3

Name

Description

1

Line Stats

Lists the Voltage, Current, Powerand Power Factor for Supply 1, Supply 2 and Output across each phase

line (Single phase units will only show L1)

2

Frequency

Shows the frequency of the input supplies

3

Sync

This is the difference between the frequencies of Supply 1 and 2 in degrees

iSTS B1

iSTS B1

–User Manual

Page 9

EVENTS

SCREEN

Use

Up and Down to scroll through 200 logged events. Once the buffer is full, the oldest events will fall from

the

buffer

and get replaced by any new events. Refer to Event Codes section under Fault Diagnosis for

code

descriptions

.

SETTING

SCREEN

To

enter a passcode, use the navigation buttons left and right to change digits and up and down to change

the

value

.

Entering the default passcode 000gives access to the Time & Date settings screen.

Entering the default passcode 123gives access to the TCP/IP settings screen.

IP

Allocation can be set to Static and entered manually, or set to Dynamic (DHCP) where the device will

be

assigned

an IP address automatically. Refer to the Web Interface section for instructions on accessing

advance

settings

.

3

.7 Remote Contacts

Provide

physical separation between control circuits and power circuits to avoid confusion and

reduce

interference

. Ensure all control wiring is protected and securely supported to avoid inadvertent removed

whilst

other

equipment is being installed or removed within the enclosure.

If

connecting to this we recommend using a 20 way ribbon cable (length suitable for application) and a

ribbon

cable

terminal break-out connector (not supplied) similar to that shown below

The

relays can switch up to 50VDC.

Remote

contacts are wet contacts and do not require external voltage to be applied.

iSTS B1

–User Manual

Page 10

iSTS B1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PINS CONNECTION FUNCTION

1 to 2 Normally Open Load Fault

3 to 2 Normally Closed Load Fault

4 to 5 Normally Open General Alarm

6 to 5 Normally Closed General Alarm

7 to 8 Normally Open Not in Sync

9 to 8 Normally Closed Not in Sync

10 to 11 Normally Open ON B (Supply 2)

12 to 11 Normally Closed ON B (Supply 2)

13 to 14 Normally Open ON A (Supply 1)

15 to 14 Normally Closed ON A (Supply 1)

16 to 19 REMOTE CONTACT Emergency power off

17 to 19 REMOTE CONTACT Transfer to Supply 1

18 to 19 REMOTE CONTACT Transfer to Supply 2

DECIDATED GENERAL ALARM CONTACT

This terminal is normally closed. It will open when a fault is detected.

REMOTE BMS CONTACTS

iSTS B1

–User Manual

Page 11

3

.8 Confirm Operation

1. Press the Preferred Button to highlight ‘I’ on the Preferred Indicator. Wait (aprox. 3s) or the STS to

transfer

to Supply 1, if is not already on Supply 1. On Supply 1 LED will turn green.

2. Turn off Supply 1. Confirm that the STS transfers to Supply 2. On Supply 2 LED will turn green.

3. Turn on Supply 1. Confirm that the STS automatically transfers to Supply 1 after a 3 second delay. On

supply 1 LED will turn green.

4. Press the Preferred Button to highlight ‘II’ on the Preferred Indicator. Wait for the STS to transfer

to

Supply 2. On Supply 2 LED will turn green.

5. Turn off Supply 2. Confirm that the STS transfers to Supply 1. On Supply 1 LED will turn green.

6. Turn on Supply 2. Confirm that the STS automatically transfers to Supply 2 after a 3 second delay.

On

Supply 1 LED will turn green.

7. The operational test is complete. You can now select a preferred supply if any.

3

.9 Maintenance Bypass Procedure

To

put the STS into maintenance bypass mode requires access to the Maintenance Bypass Switch located at

the

rear

of the unit.

Bypass

Mode on Supply 1

1. Use the TRANSFER pushbutton on the front of the unit to transfer the load to Supply 1.

2. TURN OFF Supply 2 using the isolator switch on the front of the unit.

3. Finally operate the Maintenance Bypass Switch at the rear by turning to position 1. The unit will now be

in

bypass mode on Supply 1.

Bypass

Mode on Supply 2

1. Use the TRANSFER pushbutton on the front of the unit to transfer the load to Supply 2.

2. TURN OFF Supply 1 using the isolator switch on the front of the unit.

3. Finally operate the Maintenance Bypass at the rear by turning to position 2. The unit will now be in

bypass

mode on Supply 2.

Removing

the Power Module

Once

the unit is in maintenance bypass mode on either Supply 1 or 2, the power module can be removed.

To

remove

the module, make sure the bypass cradle is secure then use the tabs on the sides of the module to pull

it

out

from the cradle.

1 2

Reinstatement

from Maintenance Bypass Procedure

1. Reconnect the power module to the bypass cradle. Take care to ensure the connectors on both

sections

are aligned and the sections mate together securely.

2. Turn on both Supply 1 and Supply 2 isolator switches located at the front of the unit. Wait for the unit

to

start up. The Supply 1 and 2 OK LEDs on the mimic will be green to indicate that both supplies are active

in

the STS.

3. Finally operate the bypass switch, returning it to the middle position.

4. The unit will now be normal operation mode.

iSTS B1

–User Manual

Page 12

iSTS B1

iSTS B1

–User Manual

Page 13

3

.10 Operational Parameters

Absolute Maximum Values

Min

Max

Input

Voltage

-

277

VAC

Load

Current

-

16

Aor 32A

Input

Synchronisation

-180

°

+

180°

Ambient

Temperature

-20

°C

45

°C

Recommended Values

Min

Max

Input

Voltage

110

VAC

277

VAC

Load

Current

0

.5A*

16

Aor 32A

Input

Synchronisation

-15

°

+

15°

Ambient

Temperature

0

°C

30

°C

*Due

to the nature of the silicone controlled rectifiers used in all static transfer switches, some current must be applied to

the

iSTS

to ensure a clean break during transfers.

Overload Capacity

Load

Time

100

A

30

s

250

A

1

s

400

A

0

.1s

2000

A

1

cycle

4

. WEB BROWSER INTERFACE

Connecting

to the LAN interface can be done two different ways with a RJ45 Cat5 Ethernet cable:

▪To a Network hub/switch using a straight-through cable.

▪To aPC using a cross-over cable (most PCs can now work with a straight-though cable).

4

.1 Connection to a Network

By

default the STS uses DHCP to have the IP information assigned automatically after the Ethernet cable

is

plugged

in at both ends, this process can take up to several seconds to complete. If your network does not

have

a

DHCP server or if you wish to use a static IP, you can change the IP Allocation on the Communications

Settings

screen

shown below (or the Control Panel page on the Web server).

Use

navigation buttons on the unit and move to the Settings menu, enter the passcode 1 2 3 to access

TCP/IP

settings

. Setting IP Allocation to Static allows for manual input of IP address, subnet and gateway.

COMMUNICATION SETTINGS

4

.2 Connecting to aPC

When

connecting directly to a PC, both the STS and PC must have statically assigned IP addresses on the

same

subnet

. Set the IP address of the STS in the Communications screen described earlier. By default this is

IP:

192

.168.1.2 with Mask: 255.255.255.0

To

set the IP address of your computer in Windows 7 go to: Network and Sharing Centre Change

adapter

settings,

right-click the network interface Properties. Select TCP/IPv4 Properties. Change the values to

match

as

shown below and click OK, you soon should be connected to your device.

For

other operating systems, please refer to the OS networking manual.

iSTS B1

–User Manual

Page 14

iSTS B1

4

.3 Connecting to the Web Server

To

use a ping test to confirm the connection on a PC, run command prompt (CMD) and type ping (space) then

the

IP

address of the device then press enter.

Entering

the IP address into the web browser address bar brings up the web server home page. If the DHCP

/

address

have not yet been registered on your network you may need to remove the cable for 5 to 10

seconds

and

reconnect the cable, this in turn should re-register the device on the network.

The

home page displays the connected supply, supply preference, variables and events list that can be

scrolled

through

using the arrows provided. From the home page, gain access to the Control panel by clicking

Open

Control

Panel and enter following username and password:

.

Username: admin

Password: 1234

iSTS B1

–User Manual

Page 15

WEB SERVER HOME PAGE

4

.4 Control Panel

On

the Control Panel page, many more options become available:

•Viewing utilisation

•Ability to transfer supply

•Setting the preferred supply

•Setting the name and location information

•Adjusting the time and date

•Setting the IP address

NOTE

: You must press update for the information to be saved on the device

iSTS B1

–User Manual

Page 16

iSTS B1

Transferring

the Supply

Clicking

on the “Transfer Supply” will change to the alternate supply. If that supply is faulty the transfer will

not

occur

.

Set

Preferred

The

iSTS will stay connected to the preferred supply until there is a failure. In the case of the supply failing,

the

STS

will switch to the alternate supply and then switch back to the preferred after the fault is cleared.

When

None

is selected, the iSTS will not revert back to the other supply after switching.

Unit

Details

Enter

a name for the device under “Name:”and the location it is stored at under “location:”this should be

done

so

you can differentiate between different static transfer switches.

Date

and Time Settings

Enter

the date and time, this should only be required once. We strongly encourage setting the correct time

and

date

so that the real time event correlation can be undertaken. After pressing update the details will be

stored

into

the unit. The real time clock is thereafter backed up by a battery cell

IP

Address Settings

The

default settings is set to DHCP mode “On”, when this is set to “Off” then the other options become

available

to

change. From here you can change the IP, Mask and the Gateway. After pressing update these details will

be

saved

on the unit.

CONTROL PANEL SCREEN

iSTS B1

–User Manual

Page 17

4

.5 Email

The

Email tab allows you to turn on the email notification service. When a certain event occurs the unit will

send

an

email to notify the user. The email takes the following format:

STS01 –LVL5

Supply 1 Fault - 05/05/2014 13:01:42

Server

Settings

This

is the SMTP server that the unit will use to send the email. You need to provide the Server Address,

Server

Port,

User name or email, and a password.

Note

: this cannot be an SSL SMTP server.

Recipient

Email

This

is where the email notification will be sent. It can be the same as the above email.

Email

List

In

this section you can select which event types should trigger an email notification to be sent.

EMAIL SCREEN

iSTS B1

–User Manual

Page 18

iSTS B1

4

.6 Advanced Settings

SETTINGS SCREEN

NOTE: The STS has been shipped with factory defaults. These are the most reliable settings for correct stable

operation. These settings should only be changed under the certain operating conditions and it is advised that you

consult with us before doing so, as wrong settings can make the system unstable and damage equipment.

Table of contents

Other Static Power Switch manuals

Static Power

Static Power iSTS G User manual

Static Power

Static Power iSTS C User manual

Static Power

Static Power iSTS R User manual

Static Power

Static Power iSTS R User manual

Static Power

Static Power iMax G User manual

Static Power

Static Power iSTS W User manual

Static Power

Static Power iSTS F1 User manual

Static Power

Static Power iSTS F3 User manual