Static Power iMax G User manual

STATIC POWER Pty Ltd

ABN 42 101 765 913

iSTS G R02 –User Manual

Post to:

Box 2003

Research Delivery centre

Research, VIC 3095 - Australia

Manufactured at:

5 Candlebark Court

Research, VIC 3095

Australia

Contact us:

+61 3 9437 0494

support@staticpower.com.au

www.staticpower.com.au

User Manual

Stand-alone Static Transfer Switch

iSTS G –User Manual Page 1

CONTENTS

1. SAFETY INSTRUCTIONS 3

1.1 Introduction 3

1.2 Transport, Storage, Unpacking 3

1.3 Installation 4

1.4 Fire Regulation 4

1.5 Warranty 4

2. SYSTEM OVERVIEW & OPERATION 5

2.1 Description 5

2.2 Overview 5

2.3 Operational Parameters 6

2.4 Line Diagram: Single Phase and 2 Phases, Common Neutral 6

2.5 Line Diagram: 3 Phases, Neutral available and not switched 7

2.6 Line Diagram: 3 Phases, Neutral switched 7

3. OPERATION 8

3.1 Safety 8

3.2 Synchronism 8

3.3 Installation 9

3.4 Cable Termination to the iSTS 10

3.5 Commissioning 10

4. USER INTERFACE 12

4.1 Preferred Switch 12

4.2 Override Switch 12

4.3 Remote Connection Port 13

5. DISPLAY SCREEN 14

5.1 Home Screen 14

5.2 Status & Alarms 14

5.3 Mimic Display 14

5.4 Manual Transfers 15

5.5 Variables 15

5.6 Events 16

5.7 Control Screen 16

5.8 Settings 17

5.9 Time & Date 17

5.10 Calibration 18

5.11 Steady State 18

5.12 Transient State 19

5.13 Output 19

5.14 Communication 20

6. WEB BROWSER INTERFACE 21

6.1 Connection to a Network 21

6.2 Connecting to a PC 21

6.3 Connecting to the Web Server 22

6.4 Control Panel 23

6.5 Email 25

6.6 Advanced Settings 26

6.7 Input Steady State Settings 27

6.8 Input Transient Settings 28

iMAX G

iSTS G –User Manual Page 2

6.9 Output Settings 29

7. MAINTENANCE BYPASS 31

7.1 Overview 31

7.2 Using the OVERRIDE switch 31

7.3 Maintenance Bypass Procedure 31

7.4 Reinstatement from Maintenance Bypass Procedure 32

8. FAULT DIAGNOSIS 33

8.1 Fault Codes 33

8.2 Load Fault 33

9. RECOMMENDED MAINTENANCE SCHEDULE 34

10. SPECIFICATIONS 35

iSTS G –User Manual Page 3

1. SAFETY INSTRUCTIONS

1.1 Introduction

Some aspects of this manual contents may differ to the equipment as supplied due to technical improvements, specific

model variations etc. If in any doubt in respect to the procedures and safety issues consult the manufacturer and do not

proceed until clarification is received.

This manual contains important instructions that should be followed and fully understood before proceeding and

commissioning and operation to prevent harm to personnel and equipment.

Installation and commissioning should be carried out only by qualified and experienced electricians. The iSTS should be

operated by technically qualified personnel that are authorized, experienced, and have knowledge and understanding

of the equipment and the critical loads, using the documented procedures.

Read this whole document thoroughly. Understand every aspect before proceeding. Request further assistance if you do

not understand any aspect of the operation of the iSTS. Support and contact numbers are at the end of the manual.

These instructions cover normal operation in the automatic as well as in manual modes. Special operating conditions,

such as short circuit tests, input supplies, etc., are not covered in this document. These operations require comprehensive

knowledge of the overall system and should be carried out by properly qualified, skilled, and competent service

personnel only.

1.2 Transport, Storage, Unpacking

Procedure for Receiving Shipment:

▪If the ShockWatch indicator is RED, it does not mean that damage has occurred, it only indicates that the

carton received an impact or movement. If the indicator on the label is RED, make a notation to that effect on

the bill of lading or delivery receipt or document. Examine contents immediately for possible damage. If

damage is discovered, inform carrier immediately and follow normal procedure for a carrier inspection and

filing of a concealed damage claim.

▪If the packaging is damaged unpack carefully and inspect the unit. We recommend that if there is any sign of

mechanical damage that the unit not be powered up; but, returned for re-processing.

▪If damage is discovered, inform carrier immediately and follow normal procedure for a carrier inspection and

filing of a concealed damage claim to the courier or your insurance company.

▪Take a picture of the carton and contents as a record.

▪If the packaging is OK, then please keep the packaging in a secure place in case the unit needs to be returned

for repair.

iMAX G

iSTS G –User Manual Page 4

1.3 Installation

The following instructions are provided for the personal safety of operators and for the protection of the described

product and connected equipment.

▪Observe the prescribed accident prevention and safety rules for the specific application.

▪When installing the iSTS strictly observe all information on technical data and operating conditions. Comply

with all warnings, and strictly follow the procedures and practices as described in this manual.

▪This iSTS is intended to be used in a controlled indoor environment and free of conductive contaminants and

protected against animal intrusion.

▪It is important that the unit has adequate ventilation. Maintain air movement around and through the unit.

Do not block the air vents or restrict airflow over the heatsinks.

▪The unit must be placed in a sufficiently ventilated area; the ambient temperature should not exceed 45°C

(113°F).

▪Do not install the iSTS in an excessively humid environment or near water, relative humidity should not exceed

90% at 20°C (68°F).

▪Avoid spilling liquids or dropping any foreign object into the iSTS.

▪Once the connections have been made on the terminals, all terminal covers must be replaced before

operation.

▪Connecting cables must be supported.

▪Earth connection must be checked for safe function after assembly.

1.4 Fire Regulation

Should a fire break out inside the system a fire extinguisher with CO2 or similar non-conductive, non-corrosive and inert

gas must be used. Do not inhale vapours.

1.5 Warranty

Static Power operating through its authorised agents warrants that the standard products will be free of defects in

materials and workmanship for a period of 24 months after the date of invoice, or such other period as may be specified.

This warranty does not cover failures of the product which result from incorrect installation, misuse, alterations by

persons other than authorized agents or abnormal operating conditions.

More about warranty: staticpower.com.au/wp-content/uploads/2019/11/Warranty-Statement.pdf

iSTS G –User Manual Page 5

2. SYSTEM OVERVIEW & OPERATION

2.1 Description

A Static Transfer Switch (STS) provides seamless switching between two power sources to provide interrupted power to

a critical load.

The iSTS continuously monitors the supply sources for failure or degeneration and switches automatically to the alternate

source as required to protect the load against failure. The break in the supply transition is so short that it is not seen by

the critical load. This switching process is undertaken as a break before make transfer, preventing overlapping which

can cause large and unpredictable currents. In 2 and 4-pole models, all the active conductors and the neutral are

switched. In 3-pole models, only the active phases are switched. Thyristors are used to undertake the switching process.

In the case of downstream load fault conditions, the fault current drawn from the supply may degrade or damage the

supply sources: as a consequence, should a fault current exist in the load the iSTS will inhibit a transfer to the alternate

source even if this causes source supply degradation or loss. This is to ensure that the fault will not be transferred to the

alternate supply with the possibility of degrading both sources.

2.2 Overview

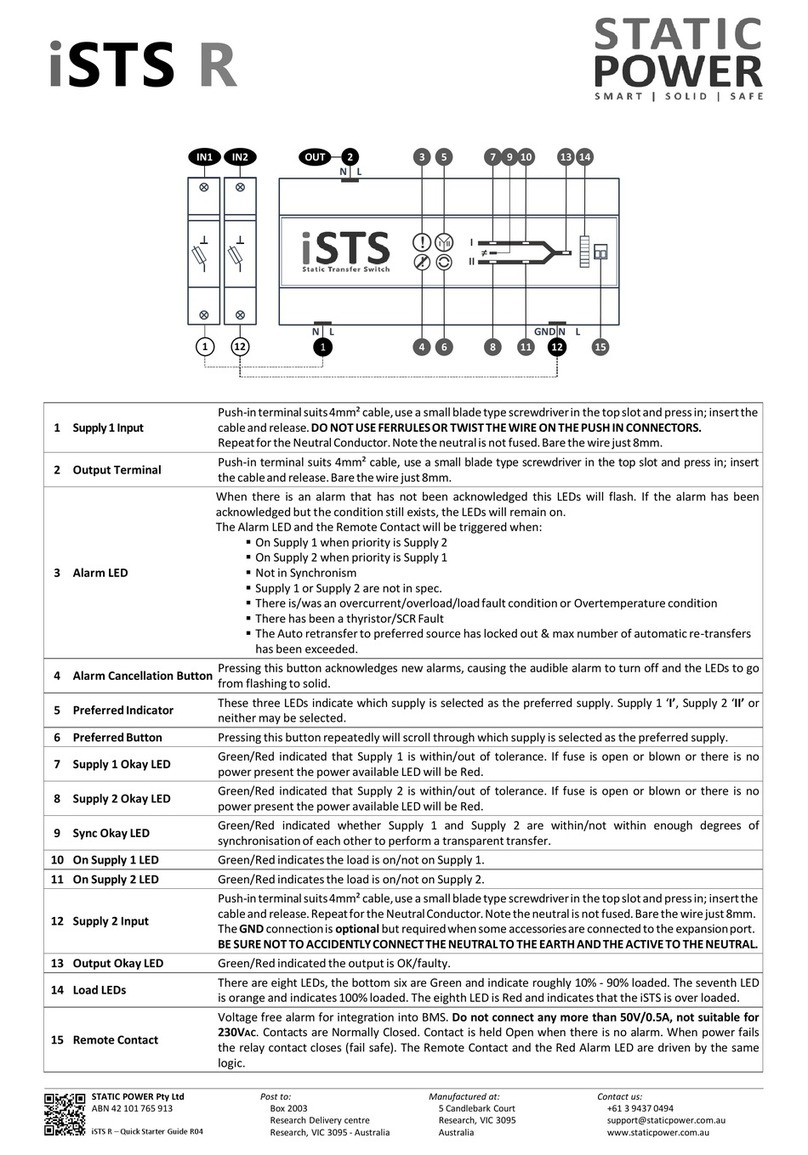

The STS includes a mechanically interlocked maintenance bypass via a 5x circuit breaker array:

iMAX G

iSTS G –User Manual Page 6

2.3 Operational Parameters

Absolute Maximum Values

Min

Max

Input Voltage

110VAC

300VAC/530VAC

Load Current

-

Up to 1600A

Input Synchronisation

-180°

+180°

Ambient Temperature

0°C

+45°C

Recommended Values

Min

Max

Input Voltage

110VAC

177VAC/480VAC

Load Current

15A*

630A to 1600A

Input Synchronisation

-15°

+15°

Ambient Temperature

0°C

+45°C

*Due to the nature of the silicone-controlled rectifiers used in all static transfer switches, some current must be applied to the iSTS to

ensure a clean break during transfers.

Overload Capacity @40°C

Time

125%

10min

150%

30s

5kA

1s

10kA

0.1s

36kA

1 Cycle

2.4 Line Diagram: Single Phase and 2 Phases, Common Neutral

iSTS G –User Manual Page 7

2.5 Line Diagram: 3 Phases, Neutral available and not switched

2.6 Line Diagram: 3 Phases, Neutral switched

iMAX G

iSTS G –User Manual Page 8

3. OPERATION

3.1 Safety

The iSTS is powered from two separate sources. It is important that you install correct signage with procedures

within the enclosure and the immediate vicinity to warn personnel of this aspect and what isolation, checking

and precautionary processes, and procedures need to be adopted to make the iSTS and equipment connected to

the iSTS safe to work on.

This equipment receives power from more than one source. Disconnect output and all input sources of power

from this equipment before servicing.

Do not proceed with the installation or operation of the iSTS if it has been damaged. Carefully inspect the iSTS

for any damage that may have occurred during shipping, unpacking or during and after any installation process.

Take care when handling the iSTS and ensure that it is physically supported during the installation process. At

the end of the installation process the iSTS should be firmly and securely bolted within the rack.

Ensure the cables are securely connected and supported and all covers plates are replaced. There should be NO

live exposed or accessible contacts that could cause electrical shock if contact is able to be made. This unit is

designed for fixed wiring installation only.

This equipment is not suitable for installation into environments that utilise RCD earth leakage detectors on the

inputs of the static transfer switch. Consult Static Power for special considerations.

1. EARTH CONNECTION IS ESSENTIAL BEFORE WORKING ON CIRCUITS

2. OR CONNECTING / DISCONNECTING SUPPLIES.

3. TREAT AC INCOMING LEADS AS LIVE IF DISCONNECTING FROM SOURCE.

3.2 Synchronism

The smoothest change-over occurs when the supplies are in synchronism, so it is best to make sure the input supplies

are in synchronism. Some equipment (like transformers) may saturate when a transfer occurs when not in synchronism.

This causes large currents to flow into the load which could cause damage to the transformer, trip protective devices or

blow fuses.

The iSTS is configured to optimize the transfers. Manual transfers by default have uninterrupted transfers, however, at

greater phase displacements (up to ±180 degrees) a break of up to 12ms is inserted.

iSTS G –User Manual Page 9

3.3 Installation

▪The STS unit should be bolted to the floor using the provided mounting rails.

▪The STS should have at least 100mm of space between the back, sides and any walls, with 1400mm in front of the

STS, as shown in the diagram below

1400mm 100mm

100mm

100mm

iMAX G

iSTS G –User Manual Page 10

3.4 Cable Termination to the iSTS

It is important that the cables are run in accordance with any local regulations. The cable entry space may be at the top

or bottom depending on the unit. The gland plate covering the cable entry space must have a hole cut into it to fit the

cable runs. All data cable is run to the User Interface panel. The data cables should not be run close to the power cables

(>50mm).

It is important that all cables are terminated using lugs and that the lugs are fastened to the terminal blocks with the

supplied bolts. The terminals will accommodate either a standard M10 or M16 cable lug.

The bolts should be torqued to 10Nm (7.5lb ft). Once the cables have been terminated, care should be taken to double

check that the cables have been placed in the correct position.

Connect cables to the locations marked with arrows.

When working on live iSTS, be sure to comply with the applicable national accident prevention rules.

3.5 Commissioning

Power-up Test: This section covers the steps required for the initial power up of the iSTS. As always care should be taken

when dealing with live voltages. A test load of at least 15A is required.

1. Start with both input supplies off. If the unit has isolation breakers these should be off.

2. Connect Load.

3. Turn on Supply 1 (S1) and measure the voltages across the phases to neutral. Check that the electronics starts-up.

Then turn S1 off.

4. Turn on Supply 2 (S2) and measure the voltages across the phases to neutral. Check that the electronics starts-up.

Then turn S2 off.

5. Turn on Q1 and Q2.

6. Turn on S1; check the voltages on the User Interface (UI) LCD.

7. Turn on S2; then check voltages on the UI LCD.

8. Turn on Q3; input supply may dip causing a transfer.

9. With the unit on S1 (manually transfer if necessary); measure the voltage of the output and measure the

current/load on each phase.

10. Confirm these values on the UI LCD.

11. Transfer to S2; Measure the voltage of the output and measure the current/load on each phase.

iSTS G –User Manual Page 11

12. Confirm these values on the UI LCD.

13. Simulate supply failures and observe the unit transfer: ie. While on S1, fail S1; while on S2, fail S2. Observe that

the STS transfers okay.

14. Review the event list. Taking note of any COMMS or SCR events.

After initial power up: After a few seconds the display screen will power up and you will be prompted to enter the date

and time. We strongly encourage the setting of the date and time so that real time event correlation can be undertaken.

The Real Time Clock is backed up by a battery clock.

The ALARM should not be active. If it is, check the following states:

▪ON Supply 1 when priority is Supply 2

▪ON Supply 2 when priority is Supply 1

▪Supply 1 or Supply 2 are not in spec.

▪Override Switch is in position 1 or 2

▪Supply 1 & 2 are not in synchronism

▪The unit is too hot (thermal bi-metal switch on H.S. activated)

▪There is / was an overcurrent/ overload / load fault condition

iMAX G

iSTS G –User Manual Page 12

4. USER INTERFACE

4.1 Preferred Switch

This switch allows the preferred source to be set to Supply 1, Supply 2 or None (0), which will take affect only when the

preferred source is set to None (0) on the iSTS software. Refer to the Web Interface section for instructions on changing

the preferred source through LAN connectivity.

If the iSTS has transferred the critical load to the alternate source, the iSTS will automatically transfer back to the preferred

again when the preferred source is within tolerance and after a pre-set settling delay, typically 4 seconds.

4.2 Override Switch

Setting the override switch to 1 or 2 will force the iSTS to stay on that supply even if faults are detected on that source.

This switch overrides all other settings. It should not be used to transfer the critical load between sources (a break may

result).

NOTE: The override provides control logic bypass only, it does not provide an alternative path for the load power.

WARNING! The override switch initiates instantaneous transfers and may transfer faults to the load.

WARNING! Never attempt to operate the OVERRIDE switch if the supplies are not in synchronism. There is no

interlock to prevent the switch from being operated when the supplies are not available or not in synchronism.

Refer to the LCD variables display and mimic diagram to check the synchronism state, (SYNC LED will be RED,

variables display will show degrees out of synchronism. Only operate when less than 10 degrees). If the control

is not operating, you may need to use other means to determine that the supplies are in synchronism. Do not

operate the OVERRIDE switch onto an absent supply.

iSTS G –User Manual Page 13

4.3 Remote Connection Port

The relays can switch up to 220VDC and 250VAC up to 1A.

Remote contacts are wet contacts and do not require external voltage to be applied.

PINS

CONNECTION

FUNCTION

1 to 2

Normally Open

Load Fault

3 to 2

Normally Closed

Load Fault

4 to 5

Normally Open

General Alarm

6 to 5

Normally Closed

General Alarm

7 to 8

Normally Open

Not in Sync

9 to 8

Normally Closed

Not in Sync

10 to 11

Normally Open

ON B (Supply 2)

12 to 11

Normally Closed

ON B (Supply 2)

13 to 14

Normally Open

ON A (Supply 1)

15 to 14

Normally Closed

ON A (Supply 1)

16 to 19

REMOTE CONTACT

Emergency power off

17 to 19

REMOTE CONTACT

Transfer to Supply 1

18 to 19

REMOTE CONTACT

Transfer to Supply 2

19 20 21 22 23 24 25 26

10 11 12 13 14 15 16 17 18

1 2 3 4 5 6 7 8 9

iMAX G

iSTS G –User Manual Page 14

5. DISPLAY SCREEN

5.1 Home Screen

A colour touch-screen LCD provides the user with an easy to navigate real-time information and control interface.

Touch feedback is indicated by an audible ‘beep’.

5.2 Status & Alarms

The Home/Status screen shows a mimic diagram and status indication as text. This is the default screen, and a period of

inactivity will result in the LCD returning to this location.

The mimic diagram allows easy identification of state changes, showing system status. All states are bicolour where green

indicates the normal, or ‘on’ state.

5.3 Mimic Display

The availability of supply 1 and 2 is indicated by their respective bar on the mimic diagram.

The synchronization hold-off bar between the two sources on the mimic diagram is located between the two supply

bars. Green is in synchronism.

The area directly before the two bars converge shows which supply is online.

iSTS G –User Manual Page 15

5.4 Manual Transfers

Press and hold the transfer button for 3 seconds to affect a transfer. This transfer touch zone can be removed if

desired (to make the install more secure) via the “Control” menu and selecting the “Allow Transfer”, “OFF” option. The

unit can still be transferred using the priority switch at the rear of the STS.

5.5 Variables

The Variables screen shows the following:

▪Output Voltage (phase to neutral / phase)

▪Output Current

▪Output Power Factor.

▪Output Power (kW).

▪Output Power (kVA)

▪Frequency for each source

Source 1 Input Voltage

▪Source 2 Input Voltage

▪Phase Angle between Sources 1 & 2

These variables refresh approximately every three seconds.

230

231

230

100

23

23

0.99

1: 50.0Hz

0°

230

231

230

100

23

23

0.99

2: 50.0Hz

230

231

230

100

23

23

0.99

iMAX G

iSTS G –User Manual Page 16

5.6 Events

Up to 200 events can be stored. Once the list is full, the oldest events are pushed from the bottom of the list and are

replaced by any new events. See the Fault Codes section for more information.

5.7 Control Screen

The control interface provides access to essential parameters and set-up information:

▪Alarm Reset: Clears persistent alarms (such as SCR Short or SCR Open).

▪Alarm Sound: Enables/Disables the alarm sound.

▪Status Screen: Normal/Safe. Enables/Disables the transfer touch zone on the status screen.

▪Preferred Source: Sets the preferred source supply (supply 1, supply 2 or none). This will only make changes

when the hardware preferred switch (at the rear of the unit) is set to ‘0’ (middle position)

▪Sync Break Override: Sets the break time (in ms) for an out of sync transfer

▪Auto Re-Transfer: Sets the STS to transfer back to the preferred supply automatically after a self-initiated

(non-manual) transfer.

▪Timer: Sets the delay (in seconds) between the preferred supply being recognized as OK, and the transfer

attempt back to that supply.

iSTS G –User Manual Page 17

▪Sync Break & Mode Angle Detection Setting: Provides access to adjust the allowable not in synchronism

transfer. (Default is 30° and is adjustable between 5° –180°), Manual transfers are inhibited when supplies are

outside this range, however, automatic transfers will experience a 50ms break, settable (0 –150ms)

5.8 Settings

This menu item provides a facility for adjusting STS settings and calibrations.

Passcode: Enter the passcode (1234) and press return.

CAUTION! The iSTS has been shipped with factory defaults. These are the most reliable settings for correct stable

operation. The settings should not be changed unless the user has a full understanding of the consequences. Consult

Static Power prior to changing any settings. All iSTS settings always must be wider than the source that is supplying the

iSTS.

5.9 Time & Date

Use the scroll key to access the parameter then the up & down keys to set the desired parameter values. Parameters

are set as soon as they are entered.

Real time clock is battery backed up using re-chargeable Lithium battery. If left for more than 48 hours the battery will

fully discharge & stored display information will be lost. Battery re-charge time can be up to 100 hours.

iMAX G

iSTS G –User Manual Page 18

5.10 Calibration

This sub-menu is used to adjust accuracy of displayed variables (only ±3 volts). Follow the prompts, read the value with

properly calibrated meters, and enter them into the Actual column. Parameters are set as soon as they are entered.

5.11 Steady State

The following screens show the available options. The Auto settings apply to normal iSTS operation (unattended). The

Manual setting are referenced when the iSTS is manually operated (Manual user transfer requests).

Supply 1/2 Steady State High

Sets the tolerance of steady state over-voltage conditions, as a percentage

of rated voltage.

Supply 1/2 Steady State Low

Sets the tolerance of steady state under-voltage conditions, as a percentage

of rated voltage.

Steady State Pause

Sets the time for what is considered steady state, in seconds

Phase Normal

Sets the phase difference of the two supplies, in degrees, of what is

considered a ‘warning’ condition.

Phase Fault

Sets the phase difference of the two supplies, in degrees, of what is

considered a ‘fault’ condition.

iSTS G –User Manual Page 19

Phase Break

Sets the break time, in ms, that the STS will observe during a transfer while

the Phase Fault condition is active.

5.12 Transient State

Supply 1/2 Transient High

Sets the tolerance of transient (sub cycle) voltage spike fault tolerance, as a

percentage of rated voltage.

Supply 1/2 Transient Low

Sets the transient (sub cycle) voltage dip fault tolerance, as a percentage of

rated voltage.

Transient Pause

Sets the number of consecutive samples that must be out of tolerance

before a transient fault is flagged. (1 sample = 1/64th of a second)

RETransfer Pause

Sets the pause, in seconds, that will be observed between re-transfer

attempts

RETransfer Tries

Sets the number of fast, consecutive re-transfers that will be tolerated before

a re-transfer lockout will be activated.

5.13 Output

Table of contents

Other Static Power Switch manuals

Static Power

Static Power iSTS B1 User manual

Static Power

Static Power iSTS R User manual

Static Power

Static Power iSTS F3 User manual

Static Power

Static Power iSTS W User manual

Static Power

Static Power iSTS C User manual

Static Power

Static Power iSTS G User manual

Static Power

Static Power iSTS F1 User manual

Static Power

Static Power iSTS R User manual

Popular Switch manuals by other brands

GarrettCom

GarrettCom Magnum 6K16-Series Installation and user guide

Heathkit

Heathkit Heathkit HD-1234 Assembly and operating instructions

HP

HP ProCurve 4100 Series Replacement instructions

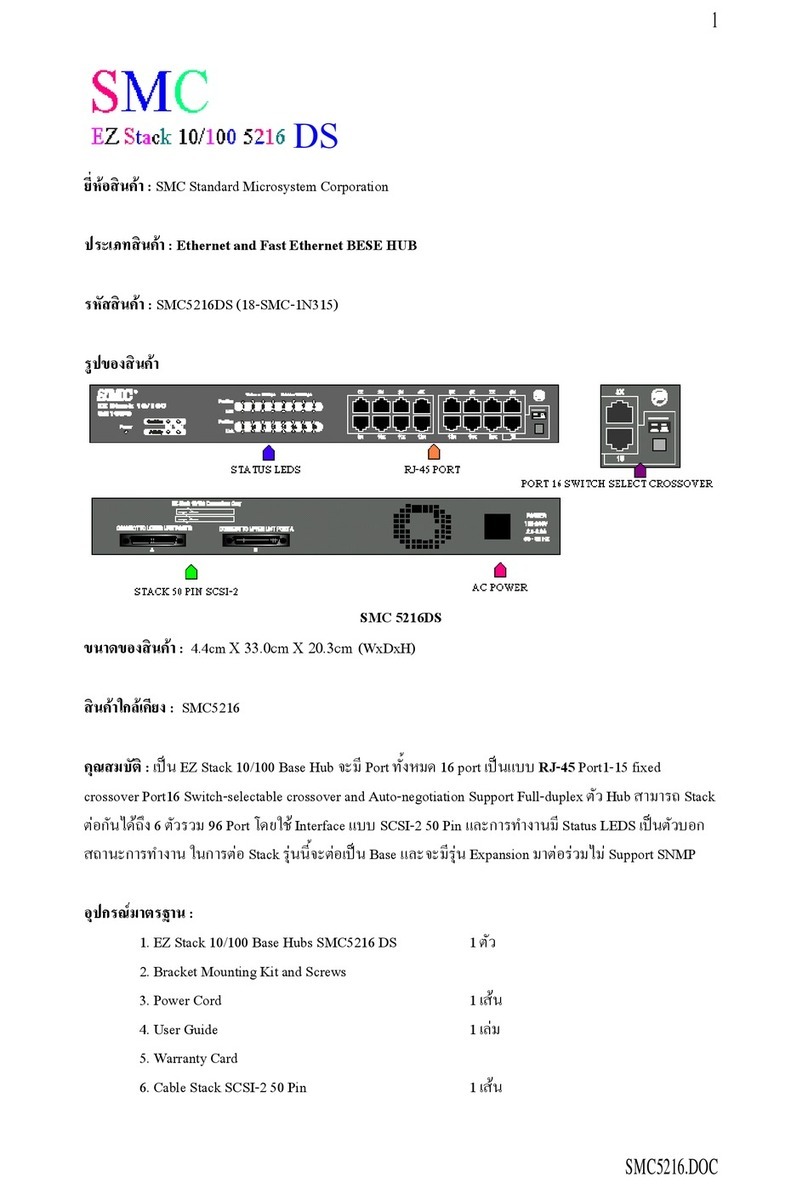

SMC Networks

SMC Networks SMC EZ Stack 10/100 SMC5216 Specification sheet

INSTEON

INSTEON 2243-222 quick start guide

Niko

Niko 91004 Series user manual