Static Power iSTS R User manual

iSTS

ModelR

UserManual

RailMountStaticTransferSwitch

iSTSR– UserManualR02

STATICPOWERPtyLtd

ABN42101765913

iSTSR– UserManual

Postto:

Box2003

ResearchDeliverycentre

Research,VIC3095‐ Australia

Manufacturedat:

5CandlebarkCourt

Research,VIC3095

Australia

Contactus:

+61394370494

www.staticpower.com.au

CONTENTS

1.SAFETYINSTRUCTIONS 2

1.1Introduction 2

1.2Transport,Storage,Unpacking 2

1.3Installation 2

1.4ElectricalConnection 3

1.5Synchronism 3

1.6FireRegulations 3

1.7StandardsApplied&Conformity 3

1.8Warranty 4

2.SYSTEMOVERVIEW&OPERATION 4

2.1Description 4

2.2LineDiagram 4

2.3Overview&Operations 5

2.4OperationalParameters 6

3.INSTALLATION 6

3.1Safety 6

3.2Synchronism 7

3.3RemoteMonitoringRelay 7

3.4Setup 7

3.5Start‐up 7

3.6ConfirmOperation 7

3.7LoadFault 8

3.8DiagnosticGuide 8

4.RECOMMENDEDMAINTENANCESCHEDULE 9

5.SPECIFICATIONS 9

iSTSR– UserManual Page1

1. SAFETY INSTRUCTIONS

1.1 Introduction

Some aspects of this manuals contents may differ to the equipment as supplied due to technical improvements,

specific model variations etc. If in any doubt in respect to the procedures and safety issues consult the

manufacturer and do not proceed until clarification is received.

This manual contains important instructions that should be followed and fully understood before proceeding and

commissioning and operation to prevent harm to personnel and equipment.

Installation and commissioning should be carried out only by qualified and experienced electricians. The

iSTS should be operated by technically qualified personnel that are authorized, experienced and have knowledge

and understanding of the equipment and the critical loads, using the documented procedures.

Read this whole document thoroughly. Understand every aspect before proceeding. Request further assistance if

you do not understand any aspect of the operation of the iSTS. Support and contact numbers are at the end of

the manual.

These instructions cover normal operation in the automatic as well as in manual modes. Special operating

conditions, such as short circuit tests, input supplies, etc., are not covered in this document. These operations

require comprehensive knowledge of the overall system and should be carried out by properly qualified, skilled

and competent service personnel only.

1.2 Transport, Storage, Unpacking

Procedure for Receiving Shipment:

If the packaging is damaged unpack carefully and inspect the unit. We recommend that if there is any sign of

mechanical damage that the unit not be powered up; but, returned for re‐processing

If damage is discovered, inform carrier immediately and follow normal procedure for a carrier inspection and

filing of a concealed damage claim to the courier or your insurance company.

Take a picture of the carton and contents as a record.

If the packaging is OK, then please keep the packaging in a secure place in case the unit needs to be returned

for repair.

1.3 Installation

The following instructions are provided for the personal safety of operators and also for the protection of the

described product and connected equipment.

Observe the prescribed accident prevention and safety rules for the specific application.

When installing the iSTS strictly observe all information on technical data and operating conditions. Comply

with all warnings, and strictly follow the procedures and practices as described in this manual.

This iSTS is intended to be used in a controlled indoor environment and free of conductive contaminants and

protected against animal intrusion.

It is important that the unit has adequate ventilation. Maintain air movement around and through the unit.

Do not block the air vents or restrict airflow over the heatsinks.

The unit must be placed in a sufficiently ventilated area; the ambient temperature should not exceed 35°C

(95°F).

Do not install the iSTS in an excessively humid environment or near water, relative humidity should not

exceed 90% at 20°C (68°F).

Avoid spilling liquids or dropping any foreign object into the iSTS.

Once the connections have been made on the terminals, all terminal covers must be replaced before

operation.

Connecting cables must be supported.

Earth connection must be checked for safe function after assembly.

iSTSR– UserManual Page2

iSTS R

1.4 Electrical Connection

For cable up to 4mm²

All cables connecting to the iSTS should be supported and must not put any strain on the point of connection

within the iSTS.

All electrical connections are to be realized by properly qualified, skilled and competent service / installation

personnel only.

Consider electrical distribution discrimination carefully. The iSTS has two incoming AC power sources; We

recommend that the supplied fuses be installed adjacent to the iSTS. These should discriminate with

downstream protective devices. The upstream iSTS supply breaker/fuse if used should only open if the

downstream device protection is unable to trip or there is a fault within the iSTS or the load.

1.5 Synchronism

The smoothest change‐over occurs when the supplies are in synchronism. If an asynchronous transfer occurs,

large currents may flow into the load which can damage trip & protective devices, blow fuses, saturate and cause

damage to transformers. If possible, it is best to make sure the supplies areinsynchronism.

1.6 Fire Regulations

Should a fire break out inside the system a fire extinguisher with CO2or Halon must be used. Do not inhale

vapours.

1.7 Standards Applied & Conformity

The iSTS R conforms to the following standards and European Council Directives:

Standards to which conformity declared:

IEC 60950‐1 Information technology equipment Safety ‐ General requirements

IEC 62310‐1 Static transfer systems (STS) ‐ General and safety requirements

IEC 62310‐2 Static transfer systems (STS) ‐ Electromagnetic compatibility (EMC) requirements

IEC 62310‐3 Static transfer systems (STS) ‐ Part 3: Method for specifying performance and test

requirements

Application of Council Directives:

2006/95/EC Low Voltage Directive

1992/31/EEC EMC Directive

1993/68/EEC EMC Directive amendments

2011/65/EU Hazardous substances in electrical and electronic equipment ‐RoHS

iSTSR– UserManual Page3

TheStandardsmentionedabovefulfil

therequirementsforCEmarking

YearofCEmarking:2015‐2016

1.8 Warranty

Static Power operating through its authorised agents warrants that the standard products will be free of defects

in materials and workmanship for a period of 24 months after the date of invoice, or such other period as may be

specified.

This warranty does not cover failures of the product which result from incorrect installation, misuse, alterations

by persons other than authorized agents or abnormal operating conditions.

More about warranty: staticpower.com.au/wp‐content/uploads/2019/11/Warranty‐Statement.pdf

2. SYSTEM OVERVIEW & OPERATION

2.1 Description

A Static Transfer Switch (STS) provides your critical load or single cord (single supply), equipment with an

alternative supply source, thus increasing and improving power reliability and availability.

The iSTS R is a 2 pole, single phase DIN Rail mount STS that suits 35mm x 7.5mm rail. Both the active conductor

and the neutral are switched. Thyristors are used to undertake the switching process. These are many times

faster and more reliable than their electromechanical equivalents.

The iSTS continuously monitors the supply sources and should the presently connected supply fail or degenerate

or become useable, the critical load is automatically and transparently transferred to the alternate source.

This switching process is undertaken as a break before make transfer. The break in the supply transition is so

short that it is not seen by the critical load. This is preferable to a make before break (or overlapping) changeover

because when the two supplies are different and connected together large and unpredictable currents would

flow between the sources degenerating both supplies and therefore the supply to the critical load.

In case of downstream fault the iSTS will not transfer the fault to the alternate supply even if the voltage is

adversely affected. Once the fault current has cleared the iSTS will resume normal operation protecting the

critical loads from voltage disturbances, (10 second settling time).

2.2 Line Diagram

iSTSR– UserManual Page4

iSTS R

2.3 Overview & Operations

iSTSR– UserManual Page5

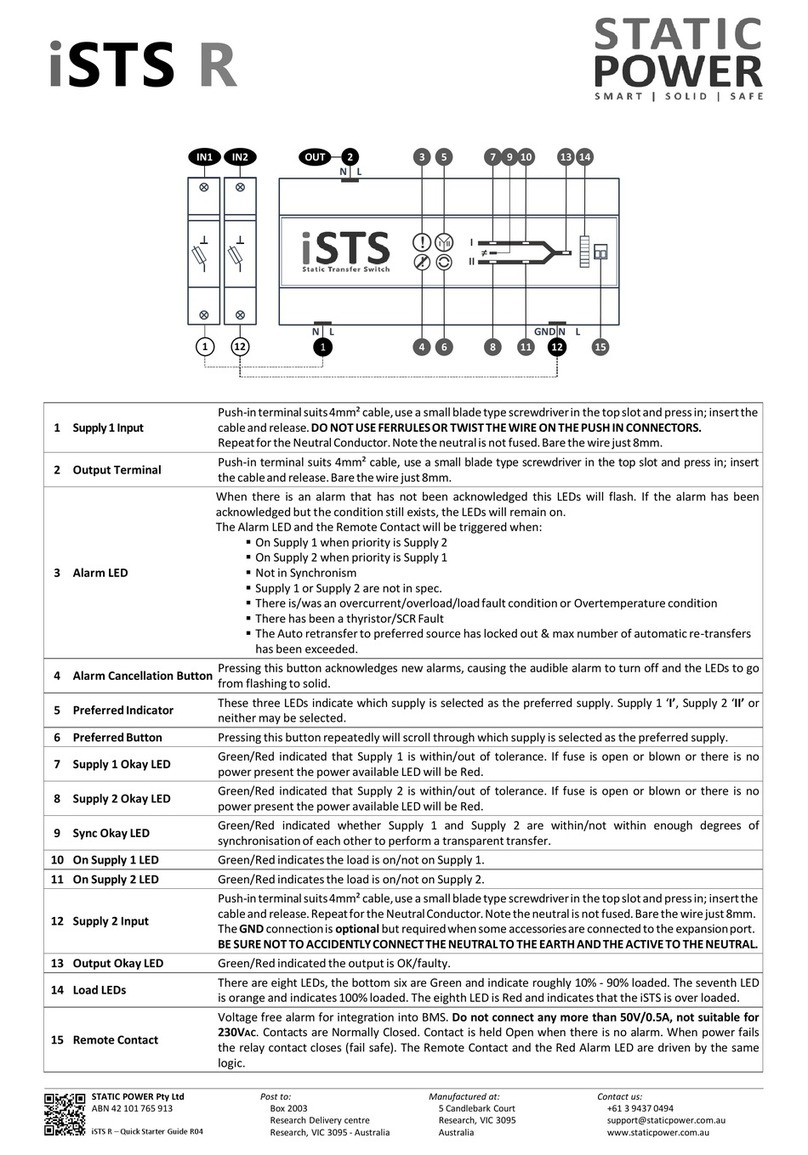

1 Supply1Input

Push‐interminalsuits4mm²cable,useasmallbladetypescrewdriverinthetopslotandpressin;insert

thecableandrelease.

RepeatfortheNeutralConductor.Notetheneutralisnotfused.Barethewirejust8mm.

2 OutputTerminal Push‐in terminal suits 4mm² cable, use a small blade type screwdriver in the top slot and press in;

insert the cable and release. Bare the wire just 8mm.

3AlarmLED

When there is an alarm that has not been acknowledged this LEDs will flash. If the alarm has been

acknowledged but the condition still exists, the LEDs will remain on.

The Alarm LED and the Remote Contact will be triggered when:

OnSupply1whenpriorityisSupply2

OnSupply2whenpriorityisSupply1

NotinSynchronism

Supply1orSupply2arenotinspec.

Thereis/wasanovercurrent/overload/loadfaultconditionorOvertemperaturecondition

Therehasbeenathyristor/SCRFault

TheAutoretransfertopreferredsourcehaslockedout&maxnumberofautomaticre‐

transfershasbeenexceeded.

4 AlarmCancellationButton Pressing this button acknowledges new alarms, causing the audible alarm toturnoffandtheLEDsto

go from flashing to solid.

5 PreferredIndicator These three LEDs indicate which supply is selected as the preferred supply. Supply 1 ‘I’, Supply 2 ‘II’

or neither may be selected.

6 PreferredButton Pressing this button repeatedly will scroll through which supply is selected as the preferred supply.

7 Supply1OkayLED Green/Red indicated that Supply 1 is within/out of tolerance. If fuse is open or blown or there is no

power present the power available LED will be Red.

8 Supply2OkayLED Green/Red indicated that Supply 2 is within/out of tolerance. If fuse is open or blown or there is no

power present the power available LED will be Red.

9 SyncOkayLED Green/Red indicated whether Supply 1 and Supply 2 are within/not within enough degrees of

synchronisation of each other to perform a transparent transfer.

10 OnSupply1LED Green/Red indicates the load is on/not on Supply 1.

11 OnSupply2LED Green/Red indicates the load is on/not on Supply 2.

12 Supply2Input

Push‐interminalsuits4mm²cable,useasmallbladetypescrewdriverinthetopslotandpressin;insert

thecableandrelease.

RepeatfortheNeutralConductor.Notetheneutralisnotfused.Barethewirejust8mm.

13 OutputOkayLED Green/Red indicated the output is OK/faulty.

14 LoadLEDs

There are eight LEDs, the bottom six are Green and indicate roughly 10% ‐ 90% loaded. The seventh

LED is orange and indicates 100% loaded. The eighth LED is Red and indicates that the iSTS is over

loaded.

15 RemoteContact

Voltage free alarm for integration into BMS. Do not connect any more than 50V/0.5A, not suitable

for 230VAC. Contacts are Normally Closed. Contact is held Open when there is no alarm. When power

fails the relay contact closes (fail safe). The Remote Contact and the Red Alarm LED are driven by the

same logic.

2 3 5 7 9 10 13 14

!III

!

I

II

≠

1F

14 6 8 11 12 15

121

NP

NP

NP

IN1 IN2 OUT

2.4 Operational Parameters

Absolute Maximum Values

Min Max

Input Voltage ‐ 265V

Load Current ‐ 16A

Input Synchronisation ‐180° +180°

Ambient Temperature ‐20°C 35°C

Recommended Values

Min Max

Input Voltage 210V 255V

Load Current 1A* 16A

Input Synchronisation ‐15° +15°

Ambient Temperature 0°C 35°C

*Due to the nature of the silicone controlled rectifiers used in all static transfer switches, some current must be applied to the

iSTS to ensure a clean break during transfers.

Overload Capacity

Load Time

32A 30s

50A 10s

63A 1s

300A 1 cycle

3. INSTALLATION

3.1 Safety

The iSTS is powered from two separate sources. Relevant signage and procedures shall be in place.

This equipment receives power from more than one source. Disconnect output and all input sources of power

from this equipment before servicing.

Do not proceed with the installation or operation of the iSTS if it has been damaged. Carefully inspect the iSTS for

any damage that may have occurred during shipping, unpacking or during and after any installation process. Take

care when handling the iSTS and ensure that it is physically supported during the installation process. At the end

of the installation process the iSTS should be firmly and securely fixed to the rail.

The iSTS R is supplied with 2 Din Rail Mounted Fuse‐switch disconnectors complete with cylindrical fuse‐links

(10x38 type aR ‐ 16/20A) and these should be placed adjacent to the “iSTS R”. Ensure that there is sufficient

space between the iSTS and the fuse holders and adjacent equipment for cooling of the iSTS.

The iSTS and fuses should be mounted only vertically.

Ensure the cables are securely connected and supported. There should be NO live exposed or accessible contacts

that could cause electrical shock if contact is able to be made. Leakage currents could cause dangerous voltages

to appear on the incoming leads which can be a shock hazard and cause equipment damage if contact with other

equipment is inadvertently made.

This equipment is not suitable for installation into environments that utilise RCD earth leakage detectors on the

inputs of the static transfer switch.

Treat AC incoming leads as live if disconnecting from source.

iSTSR– UserManual Page6

iSTS R

3.2 Synchronism

The smoothest change‐over occurs when the supplies are in synchronism, so it is best to make sure the input

supplies are in synchronism. Some equipment (like transformers) may saturate when a transfer occurs when not

in synchronism. This causes large currents to flow into the load which could cause damage to the transformer,

trip protective devices or blow fuses.

The iSTS is configured by default to have a 12ms break inserted if the phase difference between the sources

exceeds 30 degrees.

The break has been inserted for a safe mode on purpose when the sources are out by more than 30 degrees.

3.3 Remote Monitoring Relay

Contacts are normally closed. Contact is held open when there is no alarm. Do not connect any more than

50V/0.5A, not suitable for 230VAC.

Provide physical separation between control circuits and power circuits to reduce interference. Make sure that all

control wiring is protected and securely supported so that it is not inadvertently unplugged or removed whilst

other equipment is being installed or removed within the enclosure.

3.4 Setup

a) Ensure that the two input sources are within tolerance, and that they are in synchronism (±5% of rated

voltage, <10% THD, <15°phase difference).

b) Connect your critical load to the OUTPUT. NOTE: Due to the nature of Silicone Controlled Rectifiers (SCRs),

some load (~0.5A) is required for correct operation.

c) Connect the sources to SUPPLY 1 and SUPPLY 2. If you wish to Confirm Operation you will need to be able to

switch both sources on and off.

3.6 Confirm Operation

a) Use the Preferred Button to highlight ‘I’ on the Preferred Indicator. Wait for the On Supply 1 LED to turn

green (if is not already).

b) Turn OFF Supply 1, and confirm that the iSTS transfers to ‘II’ (On Supply 2 LED ‐ green).

c) Turn ON Supply 1, and confirm that the iSTS auto transfers to Supply 1 after a 3 second delay (On Supply 1

LED ‐ green).

d) Use the Preferred Button to highlight ‘II’. Wait for the iSTS to transfer to Supply 2 (On Supply 2 LED ‐ green).

e) Turn OFF Supply 2, and confirm that the iSTS transfers to Supply 1 (On Supply 1 LED ‐ green).

f) Turn ON Supply 2, and confirm that the iSTS auto transfers to Supply 2 after a 3 second delay (On Supply 1

LED ‐ green).

g) Select your preferred supply if any.

3.5 Start‐up

a) Apply power to both input sources.

b) There will be a short (15 sec) start‐up period, after which the iSTS will begin powering your load.

c) Confirm that the load is receiving power.

d) Ensure that LEDs are correctly representing the supply status and load. NOTE: Only On Supply 1 LED or On

Supply 2 LED should be red.

iSTSR– UserManual Page7

3.7 Load Fault

In case of sustained high current output load faults, the iSTS will inhibit a transfer to the alternate supply even if

this means degradation or loss of source supply. It is therefore imperative that you ensure that the discrimination

with downstream and upstream protective devices ensures that the downstream protective device always clears

the fault first.

In case that all output is lost the faulty equipment should be located and removed from the iSTS output before

re‐instatement of power.

If the unit is inoperable then it should be returned to the manufacturer for repair or replacement.

iSTSR– UserManual Page8

iSTS R

3.8 Diagnostic Guide

Before starting this guide it is important that you are familiar with the unit and have read the iSTS R User

Manual.

Overview

The diagnostic mode is used to view important events that have occurred on the STS. Up to 32 previous

events are recorded, once 32 events are present the oldest event is pushed out to make room for the incoming

event.

Diagnostic mode entry and exit

To enter or exit diagnostic mode press and hold the Alarm button for 2 seconds. You will hear a quick double

beep upon successful entry and exit.

Front panel overview and navigation

In diagnostic mode the following changes to the user interface decal apply.

Previous Navigates to the previous event in the list

Next Navigates to the next event in the list

Event Position Display where you are in the list (start, middle, end)

Event Code Represent the event code in binary, starting with bit 0 at the bottom

Event description and codes

Code Event Description

15 S1 Fault Supply 1 transient or average fault detected

14 S2 Fault Supply 2 transient or average fault detected

13 Output Average Fault Output average voltage out of range

12 Output Transient Fault Output voltage transient condition

11 S1 SCR OC Supply 1 SCR open circuit detected

10 S1 SCR SC Supply 1 SCR short circuit detected

9S2 SCR OC Supply 2 SCR open circuit detected

8S2 SCR SC Supply 2 SCR short circuit detected

7S1 Active Supply 1 is feeding the output

6S2 Active Supply 2 is feeding the output

5Transfer Inhibit Transfer inhibit condition caused by unstable or overloaded supply

4Sync Fault Supply 1 and Supply 2 out of sync

3Overload Fault Output load current above nominal rating

2Preferred Change User has changed preferred supply

1Fire S1 Internal logic is activating Supply 1

0Fire S2 Internal logic is activating Supply 2

5. SPECIFICATIONS

iSTSR– UserManual Page9

Currentrating 1Ph:16Amax

Voltagerating 115Vor230V±10%

Type 1‐Phase/2‐Pole

Frequency 50Hzand60Hz,±10%‐ Autodetection

Transfertype Break‐Before‐MakezerocurrenttransferbyThyristors/SCR

Breaktime Synchronous:upto¼cycle‐ Asynchronous:12ms

MTBF >500,000hours

Isolation Nosourceisolation

Display LEDmimicdecalwithloadindicator

Interface Preferredsupplyselection,SourcetransferselectionandAlarmcancelbutton

Contact Onevoltagefreegeneralalarmcontact

Inputoption Upto4mm2terminals

Outputoption Upto4mm2terminals

DimensionsHxWxD 60x215x90mm

Weight 0.7kg

Temperature 0– 35°C

IPrating IP30

Detection Digital:<1ms

Asynchronousbreaktime Upto12ms

Loading 0‐ 100%@35°Cambient

Deviceratings 56ARMS ,1200V,300Afor1cycle

Overload@40°Cambient 32Afor30s

63Afor1s

100Afor2cycle

300Afor1cycle

Faultcurrentsetting 250%peakwithloadfaulttransferinhibit

Protection ExternalDINrailmountedfuseisolator10x38mm– 16/20AtypeaR

Powerfactor Nopracticallimit

MaxTHDV 10%‐ Maxallowablesourcevoltagedistortion

Crestfactor 3:1

dV/dtmax 800V/μs

Cooling Redundantfans

Humidity@40°Cambient 5– 95%non‐condensing

Regulatoryapprovals IEC62310‐1,2,3‐ IEC60950‐ IEC61000‐6‐1,2,3,4– CE– RCM‐ ULCapable‐ RoHS

Standardwarranty 24monthsoffsiterepairorreplacementpolicy

Specificationsaresubjecttochangewithoutnotice

4. RECOMMENDED MAINTENANCE SCHEDULE

Once per month check the status of the LEDs on the front panel of the iSTS. The LEDs on the mimic should be

Green. The LEDs of the load indicator at the right of the decal should all be Green. If there Orange or Red

LEDs on the bar graph then the iSTS is being overloaded.

Once every 6 months, (sooner if the environment is bad), vacuum dust from grills at top and bottom of unit.

Inspect cable / plug connections for overheating.

Please contact Static Power for help with troubleshooting and parts replacement.

End

Middle

Start

8

4

2

1

EVENT

1+2+4=7

“S1Active”

POSITION

Start

End

Middle

Start

8

4

2

1

EVENT

1+4+8=13

“Output

Average

Fault”

POSITION

End

End

Middle

Start

8

4

2

1

EVENT

4

“SyncFault”

POSITION

End

Eventsandcodeexamples

STATICPOWERPtyLtd

ABN42101765913

iSTSR– UserManual

Postto:

Box2003

ResearchDeliverycentre

Research,VIC3095‐ Australia

Manufacturedat:

5CandlebarkCourt

Research,VIC3095

Australia

Contactus:

+61394370494

www.staticpower.com.au

Other manuals for iSTS R

2

Table of contents

Other Static Power Switch manuals

Static Power

Static Power iSTS G User manual

Static Power

Static Power iMax G User manual

Static Power

Static Power iSTS W User manual

Static Power

Static Power iSTS C User manual

Static Power

Static Power iSTS B1 User manual

Static Power

Static Power iSTS F3 User manual

Static Power

Static Power iSTS R User manual

Static Power

Static Power iSTS F1 User manual

Popular Switch manuals by other brands

OEZ

OEZ FH00-3 Series Instructions for use

Trader

Trader PMBUSW instructions

ANTAIRA

ANTAIRA LNX-1202G-10G-SFP user manual

HMS

HMS Anybus AWB5001 Safety and Compliance Information

Cabletron Systems

Cabletron Systems SmartStack STS-8SU Installation and user guide

D-Link

D-Link DGS-1008P Quick installation guide