Static Solutions OHM-STAT RT-1000 Instruction Manual

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

OHM-STAT

®

RT-1000

OWNERS MANUAL & OPERATION GUIDE

RESISTIVITY, RESISTANCE, ELECTRICAL GROUND, RTT, RTG,

VOLUME RESISTANCE, TEMPERATURE, HUMIDITY METER.

WILL TEST MATERIALS, CHAIRS, SMOCKS FOR ELECTRICAL

PROPERTIES ACCORDING TO EOS 20/20 SPECIFICATIONS.

Note: This manual is in the process of being updated.

*This instrument is no longer supplied with an external power supply as they were rarely used.

*The majority of the referenced ANSI ESD Test Standards in this document have been updated.

*Please us ANSI ESD S20.20-2014 for the latest standards and TR-53 for the latest test methods

Click Here to Purchase this Item from an Authorized Distributor that provides one full year of

Tech support in using this device at no charge!

Static Solutions Inc.

331 Boston Post Road-East

Marlboro, Massachusetts 01752

Tel: 508.480.0700

Fax: 508.485.3353

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

TABLE OF CONTENTS

Contents Page.

Cover

Table of contents

Test Procedures 1

Features- Operations - Surface Resistivity 2

Concentric ring- surface resistance 3

Surface to ground- calibration 4

Specifications 5

Warranty 6.

Questions and answers 7-10

CalibrationProcedure 11

ANSI/ESD S20.20-1999 12-29

ESD - STM 12.1 - 1997 30-38

ESD - S20.20 - 1995 39-51

RT 1000 Accessories 52-53

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

1

Static Solutions Inc.

Ohm- Stat RT-1000

Digital Resistivity/Resistance/Temperature/Humidity Meter

Description:

The Ohm-Stat RT-1000 Resistance, resistivity ,temperature,

humidity Test kit is easy to operate, compact, lightweight,

portable meter designed to measure temperature, humidity and

electricalresistivity/resistance. Usingbothinternal and external

test probes, the meter will measure resistivity, resistance to

ground, resistance between two points according to EOS/ ESD

association standards- S4.1, S6.1, S7.1, S11.11 and European

standard CECC-EN 1000/15. With the accessory probes the

meter can test the electrical circuitry of the building, ESD

chairs, and smocks. Additional probes are available to measure

heel straps, wrist straps, and small parts using miniature probes,

and a concentric ring probe.

Test Procedures

Specific industries, which

require accurate

measurements, will dictate

the correct test procedures.

The procedure outlined in

the Product Test Bulletin is

specifically used in the

electronics industry where

the EOS/ESD and CECC

procedures predominate. It

is recommended that the

other industry procedures

may be more appropriate

for your industry. These

include UL, ASTM, ,

specifications such as MIL-

HDBK-263, EIA-1S-5-A,

ASTM D-257, and ASTM

F-150. Failure to measure

relative humidity and

temperature at the time of

testingis in non-compliance

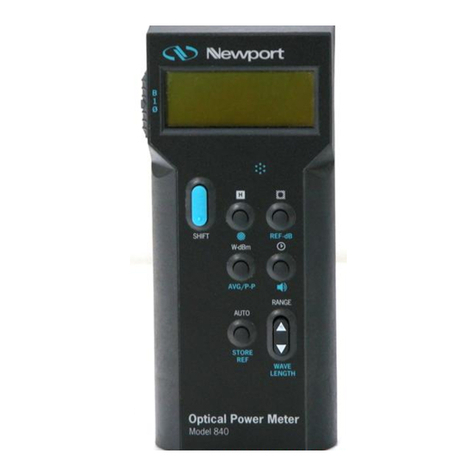

with ANSI/ESD-S7.1. Figure 1

Ohm-Stat RT-1000

Megohmmeter

All materials must be tested on an insulated surface to avoid

misleading measurements. This is especially true with non-

homogeneous and multiplayer materials. It is possible to actually

measure down through the dissipative surface layer and then along

the inner conductive layer and back up through the dissipative

layer. This is why it is technically not correct to include a surface

resistivity layer measurement value for two layer materials. Always

measure material thickness when measuring electrical properties

because thickness, temperature, and relative humidity can and will

affect the resistance/resistivity readings.

StaticSolutions , Inc.

Ohm-StatRT-1000Megohmmeter

MeterTestKitContents:

1 Ohm-Stat RT-1000Resistance-Resistivity-

Humidity-Temperature Meter

1 Blow Molded, Foam Lined Travel Case

1Concentric Ring Probe. (Optional)

25 lb. 2.5 inch DiameterTest probes.

1ChairProbe

2Smock Probes

2 Coil cords. 6 foot Test Grounding Leads.

1 Grounding Cord and Clip

1 9-volt battery

1 Ground Test Adapter

1 Product Instruction Bulletin

1 AC PowerAdapter- positive center, 120-

volt input, and 9-12 volt 200 mA output.

Miniature, 220 volts adapter, hand and

floor probes are available as options.

As with all high quality test equipment

proper storage and correct use of the

Ohm-StatRT-1000isrequired.

CAUTION: Because the AC power

adapter will charge the battery,ONLYUSE

a rechargeable battery when operating

theAC adapter with the meter.

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

2

A

Ohm-StatRT-1000 METER DESIGN FEATURES

A

Test Button- The round black button will turn on the power. When depressed

and held down with reasonable force the resistance/resistivity, humidity, and

temperature values are displayed on the screen for approximately 30 seconds.

HOLDTHEBUTTONDOWNUNTILTHEVALUESAREDISPLAYED.Atthe

completion of the test the power will turn off automatically.

B

Selector Switch- The switch selects the desired applied test voltage of either

10 or 100 volts.

10 volts should be used

between 1X 10

3

- 9.9 X 10

5

ohms.You can over ride the D

range by selecting the 10 or C

100 volt switch per EOS

standards.

100 volts should be used to H

measure between

1 X10

6

–1 X10

13

ohms per

EOS standards.

If the battery is too low to

give accurate readings the G

LCDwilldisplay“Low

Battery” B

If the resistivity is below 103

ohms/sq., the LCD will

Display “less than 1K”. F

If the reading is over 1012

Battery Compartment- This

F compartment houses a 9 volt battery

which must be installed prior to use.

Use a 9 volt alkaline battery for long

life. Do not use the alkaline battery if

the power battery is used. If the

power adapter is used a rechargeable

battery is recommended.

GParallel Test Probes- These

probes located on the bottom of the

meter are used to measure surface

resistiviy in ohms/sq. units. These

probes are made from a highly

conductive, low durometer elastomer.

Care should be taken to avoid harsh

solvents and extreme abrasion.

Occasional cleaning with a mild soap

and water solution will extend the life

of the probe feet. If damage does

occur, these probes are replaceable

for a nominal charge. The probes are

fabricated with an internal and

external brass rails.

HCase- The meter case is molded

from a high impact ABS polymer.

Simple cleaning with a mild soap and

watersolutionwillremovealldirtand

ohms/sq. the LCD will Figure 2 - Features of the Ohm - Stat RT 1000 debris.

display “more than 2 X 10 12 . Temperature - Humidity - Resistance Meter

If the reading is over 106ohms/sq. the LCD will display “change to

100 volt setting” if the setting is set on 10 volts. If the reading is

under 106ohms/sq. the LCD will display “change to 10 volts “if the

meter voltage switch is set on 100 volts.

C

External Test Jacks- The external 3.5 mm monaural jacks on the

top right of the meter are used to attach the two coil cords to the

2.5 inch-5 lb. probes These probes are used to test resistance

and RTT and RTG. When the 3.5 mm plugs are inserted into the

jacks the parallel resistivity probes on the bottom of the meter

are deactivated. Insert the banana plug end of the cords into the

5 lb, 2.5 inch probes.

D

AC PowerAdapter- This plug allows the meter to be used witha

center positive 9-12 volts 200 mA output power adapter. The

input may be either 110 volts or 220 voltsAC .

E

Ground Shield Jack- Because of the possibility of 60 cycles

electrical noise and possible interference caused by the two

external coil cords acting like antennae the straight wire ground

cord is supplied. This shield ground jack is located on the top

left on the meter. This interference occurs at the higher resistance

values 10 10-10 12ohms.

Operation:

Prior to testing, ensure that surfaces to be tested are

clean and free of contaminants.

Surface Resistivity:

Parallel Probe Resistivity Method

The parallel resistivity probe method, complies with

ASTM D-257. It is used to give fast electrical

resistivity measurements on flat homogeneous

materials. It may be used on multiplayer materials, but

this should be noted along with the temperature and

humidity values on the data report.

A. Place the meter on the desired surface

to be tested.

A.

Move switch to the desired test voltage position,

either 10 or 100 volts.

B.

Press and hold down the test power button until

the resistance/resistivity and temperature and

humidity values appears on the LCD screen. This

will occur in about 15-20 seconds as specified in

ANSI/ESD standards.

E

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

3

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

ConcentricRingProbeResistivityMethod

(Optionaltestprobeaccessory)

Insert both coil cords using the monaural plugs into the 3.5

mm meterjackson thetoprightof theRT-1000 meter.Attach

the banana plug coil cord terminations into the concentric

ring probe. Place the probe onto the surface to be tested.

Press the test button and wait until the values appear in

approximately 15-20 seconds. The correct temperature,

humidity,andresistivitywillbedisplayedon theLCDscreen.

The resistivity value displayed MUST be multiplied by a

factor of 10 to achieve the correct test value. These values

will read in ohms/sq. e.g. 3.5 X10 4 ohms/sq. (displayed

value.) .The actual resistivity value will be 3.5 X 10 5 ohms/

sq.

SurfaceResistanceMeasurements(RTT)

ThisprocedurewhichcomplieswithEOS/ESD-S4.1measures

resistance between two points independent of a groundable

point. Procedures vary regarding sample preparation, probe

preparation, and spacing of the 5 pound probes.

A.

Connect the monaural plug ends of the test leads into

the 3.5 mm jacks of the meter. Connect the banana plug

ends of the test coil cords into the 5 pound, 2.5 inch

diameter probes.

B.

Place both probes on the material according to the ANSI

EOS/ESD test procedures.

C.

Select the correct test voltage position. Over 1 X 10 6

ohms use 100 volts. Under 1 X 10 6 ohms use 10 volts.

The meter will inform you on the LCD for incorrect

voltage positions.

A. Press and hold the test button until power is applied to

the meter and a resistance, humidity, temperature value

is displayed on the LCD screen. This may take 20-30

seconds. When the button is released the displayed value

willremainonthe screenautomatically for 20-30 seconds

with no battery drain. At high resistance values and to

minimize line current interference the use of the enclosed

shield ground cord is recommended.

Figure3 - Concentric Ring Probe

Figure 4 - Ohm - Stat RT-1000 Point to Point (RTT) test.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

4

Information Solutions Strategies and Innovations

Static Solutions Inc.

Surface-To-GroundMeasurements(RTG)

This procedure measures the surface resistance between a ground point

on the material surface and specific positions on the material being tested.

This procedure complies with the EOS/ESD S4.1 test standard.

A.

Meter setup. With both test leads connected to the meter attach the

alligator clip to one banana plug and the other end to the 2.5 inch,

5 pound weight probe.

B.

Attach the alligator clip to a known electrical ground such as a ground

snap on the mat or the electrical ground of the building. Position the

probe on the surface to be tested in accordance with the desired test

procedure.

C.

Press the test button until the resistivity, humidity, and temperature

test values are displayed on the LCD screen. These readings will

conform to: EIA, EOS/ESD, ANSI, IEC-93, CECC, and ASTM test

procedures. When performing tests, especially with higher resistance

materials, be sure the test lead wires do not touch each other or overlap

and that your hands are not in contact with the probes or wires during

the actual touching of the materials. This will ensure accurate readings

and prevent interference cross talk.

Figure 5 Ohm Stat - RT 1000 Point to ground (RTG) test

CalibrationandMaintenance

The Ohm-Stat

RT-1000 requires no service or maintenance except

for an occasional cleaning of the rubber on the internal and external

test probes. A mild soap and water solution will remove dirt or other

harmful contaminants from both the rubber probes and the meter

case. Harsher solvents will affect the rubber probes and therefore

should not be used. When the meter is not used for an extended

period of time remove the battery and the coil cords to prevent

damage due to battery leakage and probe jack damage. Do not use a

alkaline 9 volt battery with the AC/DC power converter. If a power

converter is used a re-chargeable battery is recommended.

The Ohm-Stat RT-1000 is calibrated to NIST traceable standards at

the factory. The calibration is done by using NIST traceable 1%

resistors , hygrometer and thermometer.. This method assures many

years of long life and accurate readings. Attaching 1% resistors to

the probes will verify this accuracy.

Figure 6 Ohm Stat CB - 9900 Calibration box

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

5

Resistivity Test Ranges

1 X 10

3

–9 X 10

6

ohms @ 10 volts

1 X 10

6

–9 X 10

12

ohms @ 100 volts

Power-BatterySupply

A 9 volt battery is supplied. If a

rechargeable battery is used, the

recharging can be done inside

the meter.

The 12 volt power supply is

both a adapter and a recharging

device. With a 9 volt alkaline

battery the expected life is

approximately 30 hours or 5000

twenty second measurements.

Using an adapter not designed

for this meter may cause serious

damage negating the warranty

on the meter. Only a 110 volt

DC, center positive 200 mA

adapter is recommended.

A low battery indicator will

alert the user to replace a weak

battery.

If a weak battery is not replaced

the meter may continue to give

test readings, but these readings

should not be considered

accurate.

OperatingConditions:

320F-1000 F(00C-380 C)

Display:

Two inline, thirty two .20" characters are

alpha numeric. The LCD displays

all test results simultaneously.

MeterWeight:

10.2 oz. (289 mg.). Meter and battery

only.

12lbs.(5.476kg.) includingmeter,

adapter, probes, leads, and case.

Dimensions :

7.50inch( 19.05cm) L

4.00inch(10.16cm) W

1.5inch(3.81cm) H.

Probes:

Two 2.87 inch (7.2 cm)

long parallel, conductive

rubber re-placeable probes

on the bottom of the meter

case. They conform to

ASTM,ANSI,andCECC

standards.

Two 5 pound (2.27 kg.),

2.5 inch(6.4cm)diameter,

conductive Shore A 50-60

durometer external rubber

external probes-enclosed.

Two smock clip test

probes- are enclosed

One 8 inch X 12 inch

stainless steel probe to be

used to test chairs and

shoes are enclosed

One ground tester to

check on the electrical

ground is enclosed

OPTIONAL

ACCESSORIES.

One 5 pound concentric

ring probe conforming to

EOS/ESD,ANSIandCECC

standards.

One 2 inch diameter ,6

inch long, dual probe to be

used to test the electrical

resistance of shoes and

wrist strap readings.

One miniature resistance

probe.

CurrentLimit:

1milliampDCcurrent for 10 volts

0.1 milliampDCcurrentfor100volts.

Accuracy:

10

3

–10

8

ohms +/-10%

10

9

-

10

10

ohms +/-15%

10

11

- 10

12

ohms +/-25%

Zero:

Automatic zeroing.

PowerSwitch:

Momentary on, press button

Automatic zeroing

OperatingConditions:

32

0

F-100

0

F(0

0

-38

0

C)

Information Solutions Strategies and Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

6

WarrantyExclusion:

Figure 8 Powered byAC (110 Volts or 220 Volts) or 9 volt battery

Theforegoingexpresswarrantyis madeinlieuof other product warrantiesexpressandimplied,includingmerchantability

andfitnessfor aparticularpurposewhicharespecificallyordirectly disclaimed.

Theexpresswarrantywillnotapplytodefectsordamageduetoneglectmisuse,accidents,altercations,operatorfailureto

properly maintain, followinstructions,orfailuretocleanor repair products.

LimitofWarranty:

In noeventwill Static Solutions, Inc. orseller be responsible orliable forspecial, incidental orconsequential losses or

damages,whetherbasedontort,contract,ortheuseorinabilitytousetheproduct.

Beforeusing, theproductusersshalldeterminethesuitabilityofthe productfor theirintended use. The users assume all

riskandliabilitywhatsoeverinconnection therewith.

Fulfillmentof StaticSolutions,Inc.’s warrantyobligationswillbe thecustomer’s exclusiveremedyandStaticSolutions,Inc.

andseller’s limitofliabilityfor anybreachofwarranty orotherwise.

Any questions regarding these procedures or other questions should be directed to our Engineering staff or customer

service representative by calling 508.480.0700. Static Solutions Inc. Static Solutions Inc. 331 Boston Post Road-East

Marlboro. MA. 01752.

Information Solutions Strategies and Innovations

Static Solutions Inc.

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

7

RT-1000 Question and Answers

1. Why is it important to measure temperature and humidity ?

Answer- The humidity and temperature affect the electrical properties ofthe material being tested. The combination of low humidity

and low temperature will give the highest electrical resistance results or slowest dissipation times. At high humidity a thin layer of

water is condensed or absorbed on or in the material being tested. This is true of hydroscopic additives added to a material to

increase the electrical conductivity which is moisture absorbable. At elevated temperatures the mobility of free electrons is increased

thereby increasing the materials conductivity. This is especially true for carnon black , metallic oxides, metals, and other materials

added to a material which must be mobile or in close proximity. When the material is at a lower temperature built in stresses occur

which might increase the resistance due to increased distance between the conductive additives. Thus, humidity and temperature

must be known. It is possible to test or manufacture a material at high humidities and pass all the test specifications. But, when the

customer receives the material and uses it at a lower humidities, or temperature the material fails to pass the specifications.

Thus,causing rejects and loss of product. Another reason why one must measure and record this data is that ANSI/ESD Association

and European CECC recognizes the environmental affects and specifies in their standards that they measured and recorded.

For example bothESD S4.1 ESD Protective Worksurfaces section 6.2.4 and ESD S7.1-1994 Resistaive Characterization of Materials

Floor Materials sections 5.2.4 and 5.3.3 “Also report temperature and relative humidity at the time of testing”. ANSI/EOS/ESD-

S11.11-1993 Surface resistance measurement of Static Dissipative Planar Materials section 11.0 B. “report the conditioning period,

relative humidity, and temeperature.”

All parties must test and record the data using the same parameters in order to avoid problems. The manufacturer, distributor, sales

person, and customer must understand the environmental humidity and temperature parameters in order to not accept out of

specification materials or reject in specification materials. Both of these situations will cost money to rectify.

2. Why and when do you test at either 10 volts or 100 volts ?

Answer:

In previous years people desiring to measure resistivity or resistance had to follow either the ASTM- D 264, ASTM- 991,

or NFPA 56A or NFPA 99. In these procedures people had to test at either 500 or 1000 volts. This caused concern regarding safety

to the person doing the tests. People wanting a smaller low cost meter measured the surface at 9 volts. 9 volts WILL NOT give the

accuracy that you need to perform the tests. In addition a 9 volt meter does not conform to EOS and 20/20 specifications.. At 9 volts

it is impossible to achieve accuracy at values higher than 10 7ohms. These specifications require to measure both the humidity and

temperature. What resulted was confusion. Everybody was doing their own tests.Finally the ESD Association got together to

standardize the test procedures with all the organizations.

What was decided was at values higher than 10 6ohms/square one must test at a constant 100 volts. At values lower than

10

6

ohms/sq. one must use 10 volts. This is explained in ANSI/EOS/ESD standards -S4.1,S7.1 and S11.11

3. Why is an alpha-numeric superior than an analog or LED display ?

Answer: Have you ever tried to interpret a value on an analog scale at high values, especially if your age is over 50 years old and

need glasses. It is very difficult to see and read !! The problem with LED displays are that it is difficult to determine where you are

on a specific decade. The advantage of a digital alpha-numeric display is that you can observe and track trends of a material over

time and it is easy to read and interpret.

4. With the meter can you use rechargeable batteries ?

Answer: Yes, the adapter is both a converter and a in meter re-charger. It is recommended to use only a rechargeable battery with

the power supply and do not use the power supply when using a conventional alkaline battery. It might cause leakage .

5. Can you use the meter without the external probes ?

Answer: Yes. The meter can be used with the built in parallel probes attached at the bottom the meter. This resistivity reading is in

ohms/square. This is a fast and quick way to measure the surface resistivity. This is a good simulation of the ASTM D-257 test

method with the meter power switch activated at a force of 5 pounds of pressure onto the built in parallel probes. Always remove

the coil cords from the meter when not using the external probes or when you use the bottom parallel resistivity probes. Because

there is no such thing as surface resistivity of two layer materials one can do a quick test for immediate evaluations.

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

8

6. When the button is released and the value continues to display will this wear down the battery ?

Answer: No. Once the button is released the display is saved by a capacitor on the screen for a short time. No additional

power is used.

7. Is the meter manufactured inAmerica, England or the Far East ?

Answer:The correct answer isAmerica. Pride, quality, and quick delivery.

8. If I take consecutive readings do I have to re-zero the meter.

Answer: No. The meter is auto zeroing. There is no need to rezero.

9. What is RTT, RTG, volume resistance, resistivity ,concentric ring and bottom of meter parallel resistivity probes.) ?

Answer: RTT is resistance between two points. The values are in ohms. The procedure must conform

to EOS specifications. The humidity and temperature must be recorded. RTG is resistance between

ground and one point. The ground can be the common point ground which is on the mat or another

common ground connected to the wrist straps. Resistance is a better way to determine if the product

will work in actual usage, by actually duplicating the dissipation of static electricity from the worker

or product to the earth ground. Resistance, either surface or volume is a better incoming quality

control test since most of the products being tested is two layers and resistivity does not relate to two

layer mat products. In a two layer mat material the path to ground goes from the surface down to the

conductive layer across then up through the dissipative layer.

Volume resistance tests through the material layers –from the top through the bottom layer.

Resistivity is measured in ohms/square. The test are is usually a small square. The parallel probes on

the bottom measures ohms/square. The concentric ring or guarded electrode does the same but it

avoids stray readings around the ends of the probes and measure inside the two rings. To calculate

the resistivity from resistance multiply the resistance measurements by 10. The conversion factor of

10 is derived from the geometry of the electrode assembly.

10. When is the concentric ring electrode used to measure the resistivity values.

Answer: Because there was a possibility of the applied voltage (either 10 or 100 volts) going

around the parallel probes and giving an incorrect answer a concentric ring probe was developed

and explained in EOS/ESD-S11.11-1993 part 6.1.2. When the concentric ring probe is used a

multiplying factor of 10 must be used. Thus, one takes the reading in ohms (resistance) and

multiply by 10 in order to derive the desired correct answer in ohms/square. (resistivity).

Resistivity is usually perfomed as a quick quality control measurement for smaller dimensions.

Special miniature probes are available for really small limited space dimensions..

11. When the battery gets low can I still use the meter ?

Answer: Yes. The meter will display “low battery” if the battery gets low in power. But even in this situation

the meter will still perform and will still display accurate results. The meter has incorporated a “cut-out” level

in which the meter will stop functioning completely when the power level gets too low to maintain a constant

10 or 100 volts output. Yes, there will be power left in the battery due to a regulator to maintain this correct

level.

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

9

12. If I measure high resistance materials will the applied voltage drop below 100 volts ?

Answer: No ! We are using a voltage converter which maintains constant 100 or 10 volts voltage over the

complete

resistance range. The EOS 20/20 specification says when measuring under 10 6 ohms use 10 volts and when

you test materials over 10 6 ohms use 100 volts.

13. If I damage a parallel probe electrode can they be replaced ?

Answer: Yes. For a nominal charge they can be replaced. When cleaning use a soap and water solution.

14. Inorder to satisfycompaniesachievingISO-9000 certification are our meters NIST and CE marktraceable ?

Answer: The meters come with a NIST certificate when ordered. After one year the meters can be sent back to Static Solutions

for recalibration. The meters are CE mark tested.

15. I have to use the meter overseas . Can the meter be used with a 220-240 volts power supply ?

Answer:Yes. We supply a 120 volts adapter with the meter. In order to use 220 volts an easily purchased 12 volts DC 220 volt AC

adapter can be purchased and used with the meter. Static Solutions can supply this adapter at a nominal charge. Be sure to use a

100-150 milliampfemale2.5mm wide,5.5mmlonmgpositivecenterplug.Alsomakesurethewallplugwillfitintherecepticleofthe

country where the meter will be used. It might make sense to use 9 volts alkaline batteries overseas in order to avoid problems. Do

not use a power adapter when using a alkaline battery. It might leak or explode. When using a power adapter use a rechargeable

battery.

16. If the meter fails to work can it be fixed /?

Answer: Under one year the meter is fully warranted and will be fixed at no charge as long as the meter was not abused or

dropped. Contact the company at 508.480.0700 regarding a return authorization number after the warranty period expires.

17. Where can the meter be used ?

Answer: The meter can be used in all facets of material production including engineering, maintenance, quality

control, incoming inspection, manufacturing, research, or sales departments.

18. What industries can be the meter be used ?

Answer: Photographic , medical, cleanroom, electronics, automotive, pharmaceutical, research and coatings industries.

19. What products can be tested with this meter ?

Answer: Any and all materials that are electrically conductive , dissipative, or antistatic between 1000 ohms and 10 13 ohms.

Items include floor mats, table mats, conductive floor tiles, coatings, floor finishes, bags, containers, smocks, footwear, heel

grounders, wrist straps, and grounding straps.

20. What standards do this meter conform ?

Answer:Themetercantestto thefollowingstandards:EOS/ESD-S4.1,S11.11,S7.1,NFPA-99A,ANSI,UL,ASTM-D-257,

ASTM-F150, Military,EIA-541,andCECC(European)

21. I noticed when I brought the meter in from the cold car the temperature and humidity seemed to be incorrect. Why ?

Answer: It takes approximately ½ hour for the meter to climatize to different environmental conditions before taking a

measurement.Allow the meter to stabilize to ensure the correct reading.

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

10

22. What precautions should I take to ensure correct readings especially at high resistances i.e. 10 11 ohms, 10 12 ohms.

Answer: Do not touch the coiled cords or external probes when taking a reading at high resistance values. In addition do not

have the cords touch each other . The teadings may be higher than the resistance of the wire or probe paint insulation.

23. What solutions should I use to clean the meter or probes ?

Answer: Use a mild detergent water solution. Stronger solvents will attack the meter case and or probe rubber.

24. Why do I need a ground cord ?

Answer: When you are in an electric field (60 cycles AC) or at a potential higher higher than ground it helps to bring the meter

and circuit board to the same potential as the grounded material which is tested. The two cords act like an aerial and will receive

this electrical magnetic and radio interference and cause errors in the measurement. Grounding will eliminate this interference.

25. The meter did not work when I removed the cords from the external probes and tried to measure resistivity. Why ?

Answer: You must remove the cords from the meter to activate the probes on the bottom of the meter. The cords must also be

removed from the meter case. Merely detaching the cords from the probes will not activate the bottom parallel probes. Do not keep

the coil cords in the meter when not using the external probes. Occasionally due to stress the jack will not return to the original

position and the internal probes will not work and a code 20 or other error message will be displayed.

26. The external black rubber probes have tendency to mark white surfaces. What can I do to clean the surfaces

especially in clean rooms.

Answer: Place the probes on the surface and not move them while testing. If the meters are going into as clean room cleaning

off the surface after usage with alcohol is suggested.

27. I was carrying the case and it opened. Why?

Answer: There are two safety locks on the case which must be fully latched in order to prevent premature opening during

travel. Always check the case before carrying it offsite.

28. Can I charge the meter with the power supply?

Answer: Yes and no. You can charge the battery in the case only if you use a rechargeable battery. You CANNOT use an

alkaline battery with the AC adapter. It might cause problems and negates the warranty.

29. Can I use the meter to test chairs, and smocks?

Answer: First read the EOS specifications 12.1 and 2.1 . This will explain the procedures. You must use the correct probes

which are available from Static Solutions and are enclosed in the RT-1000 case.

30. What other accessories are available?

Answer: Probes to measure miniature or small size parts, probes to measure shoes, probes to measure wrist straps, and probes to

measure resistivity by the concentric ring procedure. We also enclose a probe to test whether the electrical ground is accurate.

A calibration boxis also available. This CB-9000 is available from an authorized distributor of Static Solutions. The meter can

be sent back to Static Solutions in order to be calibrated and issued a NIST certificate.

Any questions regarding these procedures or other questions should be directed to our Engineering staff or customer service

representative by calling 508.480.0700. Static Solutions Inc.331 Boston Post Road-East Marlboro. MA. 01752.

Ohm-Stat™ RT-1000

CALIBRATION INSTRUCTIONS

1. Purchase 1%- 103-1012 ohm value resistors, high accuracy relative humidity

hygrometer, and a high accuracy thermometer. The resistors, hygrometer, and

thermometer must be NIST calibrated with a certificate of traceability.

2. Open meter being careful not to disturb or break the two wires connecting the

power button to the circuit board.

3 Observe on the right lower side of the meter printed circuit board three (3)

calibration pots.

4. ALLOW THE METER TO EQUILIBRATE AND NORMALIZE IN THE

ENVIRONMENT FOR 2 HOURS BEFORE TESTING.

5. Using the supplied coil cords attach the alligator clips to the banana plug ends of

the cords.

6. Insert the 3.5mm ends into the meter jacks.

7. Attach the ends of the resistors to the ends of the alligator clips.

8. The top one is for humidity. The middle one is for resistivity. The bottom one is

for temperature. Adjustment is done with a small screwdriver. Clockwise is to

increase the value, counter clockwise is to decrease the value.

9. Press the power button and compare the resistor value, humidity, and

temperature to the parameter to be calibrated.

10. Release the power button and slowly turn the correct adjustment pot.

11. Re-press the power button, and observe the LCD screen.

12. Re-press and adjust the pot if necessary.

13. Close case and tighten the 4 screws.

14. Press the power button to verify that the meter is working.

15. Record serial number and attach a NIST calibration certificate.

16. Record in data base for one year.

There is a conformal coating applied to the circuit board after calibration in order

to prevent inaccurate readings due to high humidity. Turning the adjustment screw

might be difficult. It will not hurt the meter.

***Should calibration traceable to the NIST be required, please call Static Solutions

Inc. directly to arrange for calibration.

For additional information please contact:

United Static Control Products

Email: [email protected]

Prepared and written on: January 5, 2007 by Lenard Cohen

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

12

ANSI/ESD S20.20-1999

for the Development of an

Electrostatic Discharge Control

Program for –

Protection of Electrical and Electronic

Parts, Assemblies and Equipment

(Excluding Electrically Initiated

Explosive Devices)

Electrostatic Discharge Association

7900 Turin Road, Bldg 3, Ste 2

Rome, NY 13440-2069

An American National Standard

Approved August 4, 1999

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

13

ANSI/ESD-S20.20-1999

ESD Association Standardfor the Development of an

Electrostatic Discharge Control

Program for–

Protection of Electrical and Electronic

Parts, Assemblies and Equipment

(Excluding Electrically Initiated

Explosive Devices)

Approved May 16, 1999

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

14

Caution

Notice

ESD Association standards and publications are designed to serve the

public interest by eliminating misunderstandings between manufacturers

and purchasers, facilitating the interchangeability and improvement of

products and assisting the purchaser in selecting and obtaining the

proper product for his particular needs. The existence of such standards

and publications shall not in any respect preclude any member or non-

member of the Association from manufacturing or selling products not

conforming to such standards and publications. Nor shall the fact that a

standard or publication is published by the Association preclude its

voluntary use by non-members of the Association whether the document

is to be used either domestically or internationally. Recommended

standards and publications are adopted by the ESD Association in

accordance with the ANSI Patent policy.

Interpretation of ESD Association Standards: The interpretation of

standards in-so-far as it may relate to a specific product or manufacturer

is a proper matter for the individual company concern and cannot be

undertaken by any person acting for the ESD Association. The ESD

Association Standards Chairman may make comments limited to an

explanation or clarification of the technical language or provisions in a

standard, but not related to its application to specific products and

manufacturers. No other person is authorized to comment on behalf of

the ESD Association on any ESD Association Standard.

Published by:

Electrostatic Discharge Association

7900 Turin Road, Building 3, Suite 2

Rome, NY 13440-2069

Copyright © 1999 by ESD Association

All rights reserved

No part of this publication may be reproduced in any form, in

an electronic retrieval system or otherwise, without the prior

written permission of the publisher.

Printed in the United States of America

ISBN: 1-58537-006-1

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

15

Foreword

(This

foreword

is

not

part

of

ANSI/ESD

Association

Standard

S20-1.29099)

This standard covers the requirements necessary to design, establish, implement, and maintain an

Electrostatic Discharge (ESD) Control Program for activities that: manufacture, process, assemble, install,

package, label, service, test, inspect or otherwise handle electrical or electronic parts, assemblies and

equipment susceptible to damage by electrostatic discharges greater than or equal to 100 volts Human

Body Model (HBM). When handling devices susceptible to less than 100 volts HBM, more stringent ESD

Control Program Technical Requirements may be required, including adjustment of program Technical

Element Recommended Ranges. This document covers the control program requirements and offers

guidance to protect and handle ESD sensitive (ESDS) items, based on the historical experience of both

military and commercial organizations. References include, ESD Association, US Military and ANSI

approved standards for material properties and test methods. The fundamental ESD control principles

that form the basis of this document follow:

A. All conductors in the environment, including personnel, must be bonded or electrically

connected and attached to a known ground or contrived ground (as on shipboard or on

aircraft). This attachment creates an equipotential balance between all items and personnel.

Electrostatic protection can be maintained at a potential above a “zero” voltage ground

potential as long as all items in the system are at the same potential.

B. Necessary non-conductors in the environment cannot lose their electrostatic charge by

attachment to ground. Ionization systems provide neutralization of charges on these

necessary non-conductive items (circuit board materials and some device packages are

examples of necessary non-conductors). Assessment of the ESD hazard created by

electrostatic charges on the necessary non-conductors in the work place is required to ensure

that appropriate actions are implemented, commensurate with risk.

C. Transportation of ESDS items outside an Electrostatic Protected Area (hereafter referred

to as “Protected Area”) requires enclosure in static protective materials, although the type of

material depends on the situation and destination. Inside a Protected Area, low charging and

static dissipative materials may provide adequate protection. Outside a Protected Area, low

charging and static discharge shielding materials are recommended. While these materials

are not discussed in the document, it is important to recognize the differences in their

application.

Any relative motion and physical separation of materials or flow of solids, liquids, or particle-laden gases

can generate electrostatic charges. Common sources of ESD include personnel, items made from

common polymeric materials, and processing equipment. ESD can damage parts by direct contact with a

charged source or by electric fields emanating from charged objects that induce a charge on grounded or

capacitively coupled to ground sensitive items. It is possible to determine device and item susceptibility

by exposure to simulated electronic equivalent discharge circuits. The level of sensitivity determined by

test using these models may not necessarily relate to the level of sensitivity in a real life situation.

However, they are used to establish a baseline of susceptibility data for comparison of devices with

equivalent part numbers from different manufacturers. Three different models are used for

characterization of electronic components - Human Body Model (HBM), Machine Model (MM), and

Charged Device Model (CDM). It is important to recognize that these models, if used alone, are difficult to

apply in terms of specification setting activities. Examples of ESDS parts are microcircuits, discrete

semiconductors, thick and thin film resistors, hybrid devices and piezoelectric crystals.

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

16

Beneficial comments (recommendations, additions, deletions) and any pertinent data which may be of

use in improving this document should be addressed to:

ESD Association

7900 Turin Road, Bldg 3, Ste 2

Rome, NY 13440-2069

Committee Members:

Steve Gerken, Co-Chairman

USAF Dave Leeson, Co-Chairman

Motorola SSG David E. Swenson

3M

Anthony Klinowski

Boeing Garry McGuire

NASA (Hernandez Engineering) Ronald J. Gibson

Celestica International

Thomas Mohler,

Raytheon Systems Corporation

Additional Contributing Individuals:

Ronald L. Johnson

Intel Robert Parr

Consultant Joel Weidendorf

Consultant

Donald E. Cross

USN Sheryl Zayic

Boeing Robert Cummings

NASA

Jeffrey Scanlon

ASC John T. Kinnear Jr.

IBM Ralph Myers

ASC

ii

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

17

Table of Contents

1. PURPOSE.................................................................................................................................................1

2. SCOPE .................................................................................................................................................... 1.

3. REFERENCED PUBLICATIONS.............................................................................................................1

4. DEFINITIONS ............................................................................................................................................2

5. PERSONNEL SAFETY............................................................................................................................ 2.

6. ESD CONTROL PROGRAM................................................................................................................... 2.

6.0.1. ESD Control Program Requirements..............................................................................................2

6.0.2. ESD Control Program Guidance.....................................................................................................3

6.0.3. Tailoring...........................................................................................................................................3

6.1. ESD CONTROL PROGRAM ADMINISTRATIVE REQUIREMENTS.......................................................3

6.1.1. ESD Control Program Plan .............................................................................................................3

6.1.1.1. ESD Control Program Plan Requirement.................................................................................................3

6.1.1.2. ESD Control Program Plan Guidance ......................................................................................................3

6.1.2. Training Plan ...................................................................................................................................3

6.1.2.1. Training Plan Requirement.......................................................................................................................3

6.1.2.2. Training Plan Guidance............................................................................................................................3

6.1.3. Compliance Verification Plan..........................................................................................................3

6.1.3.1. Compliance Verification Plan Requirement..............................................................................................3

6.1.3.2. Compliance Verification Plan Guidance ...................................................................................................4

6.2. ESD CONTROL PROGRAM PLAN TECHNICAL REQUIREMENTS ......................................................4

6.2.1. Grounding / Bonding Systems ........................................................................................................4

6.2.1.1. Grounding / Bonding Systems Requirements...........................................................................................4

6.2.1.2. Grounding / Bonding Systems Guidance..................................................................................................4

6.2.2. Personnel Grounding ......................................................................................................................4

6.2.2.1. Personnel Grounding Requirements ........................................................................................................4

6.2.2.2. Personnel Grounding Guidance ...............................................................................................................4

6.2.3. Protected Areas...............................................................................................................................4

6.2.3.1. Protected Areas Requirement..................................................................................................................4

6.2.3.2. Protected Areas Guidance .......................................................................................................................5

6.2.4. Packaging........................................................................................................................................5

6.2.4.1. Packaging Requirements .........................................................................................................................5

6.2.4.2. Packaging Guidance ................................................................................................................................5

6.2.5. Marking............................................................................................................................................6

6.2.5.1. ESDS Assemblies and Equipment ...........................................................................................................5

6.2.5.2. Packaging.................................................................................................................................................5

6.2.6. Equipment .......................................................................................................................................5

6.2.6.1. AC Powered Tools ...................................................................................................................................5

6.2.6.2. Battery Powered and Pneumatic Hand Tools...........................................................................................6

6.2.6.3. Automated Handlers.................................................................................................................................6

6.2.7. Handling ..........................................................................................................................................6

6.2.7.1. Handling Procedure Requirements ..........................................................................................................6

6.2.7.2. Handling Procedure Guidance .................................................................................................................6

7. APPENDIX A- SENSITIVITY TESTING......................................................................................9..

7.1. ESD SENSITIVITY TESTING..................................................................................................................................................9

7.1.1. Human Body Model Sensitivity: ......................................................................................................9

7.1.2. Machine Model Sensitivity:..............................................................................................................9

7.1.3. Charged Device Model Sensitivity: .................................................................................................9

7.2. ASSEMBLY, EQUIPMENT AND DESIGN HARDENING ........................................................................................................10

7.2.1. Assembly, Equipment and Design Hardening Guidance:............................................................ 10

7.2.2. Direct Contact, Non-Operating Assembly, Body/Finger or Hand/Metal Tests:............................ 10

7.2.3. Direct Contact Operating Equipment Hand/Metal Test:............................................................... 10

7.2.4. Indirect Contact, Operating Equipment Furniture Model Test:..................................................... 10

Information

Solutions Strategiesand Innovations

Static Solutions Inc.

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

www.staticsolutions.com

18

8. APPENDIX B- RELATED DOCUMENTS..............................................................................................1.1

8.1. MILITARY/U.S. GOVERNMENT............................................................................................................................................11

8.2. INDUSTRY STANDARDS.........................................................................................................................................................11

Table of Tables

TABLE 1 ESD CONTROL PROGRAM TECHNICAL REQUIREMENTS SUMMARY .......................................................................7

TABLE 2 ESD SUSCEPTIBILITY TEST REFERENCES FOR DEVICES.........................................................................................9

TABLE 3 ESD SUSCEPTIBILITY TEST REFERENCES FOR ASSEMBLIES AND EQUIPMENT..................................................10