Status Instruments DM650TM User manual

D2605-01-02

DM650TM USER GUIDE

BATTERY POWERED DIGITAL THERMOMETER

WITH RELAY TRIP AND LOGGING FUNCTION

Important - Please read this document before installing.

Everyeffort has been taken toensure theaccuracy of this document, however we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right ofamendment without notice.

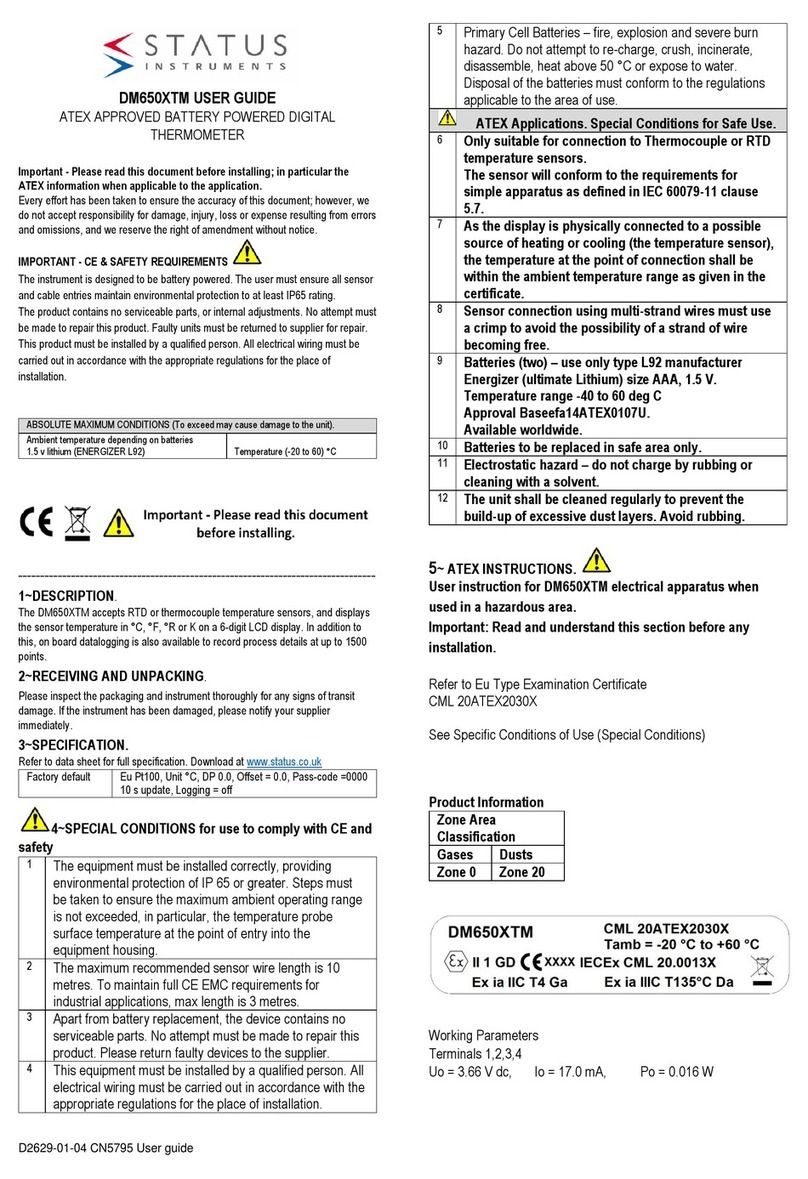

IMPORTANT - CE & SAFETY REQUIREMENTS

The instrument is designed to be directly attached to the sensorprobe assembly.

Remote Probesmay be used butthe user mustensure all sensor and cable entries

maintain environmental protection to at least IP65 rating.

To maintain CE EMC requirements, input wires must be less than 3 metres.

The product contains no serviceable parts, or internal adjustments. No attempt must be

made to repairthis product.Faulty units must be returned to supplier for repair.

This productmust be installed by a qualifiedperson. All electrical wiring must be

carried out in accordance with the appropriate regulations for the place of installation.

Before attempting anyelectrical connection work, pleaseensure the battery is removed

ABSOLUTE MAXIMUM CONDITIONS (To exceed may cause damage to the unit).

Battery Voltage

± 3.7VDC (Protected for over-voltage and reverse connection)

Input Voltage

± 1 V between any terminals

Ambient

Temperature (-30 to 70) °C, Humidity (10 to 95) % RH (Non-

condensing)

Relays

50 VDC 40 VAC RMS

----------------------------------------------------------------------------------

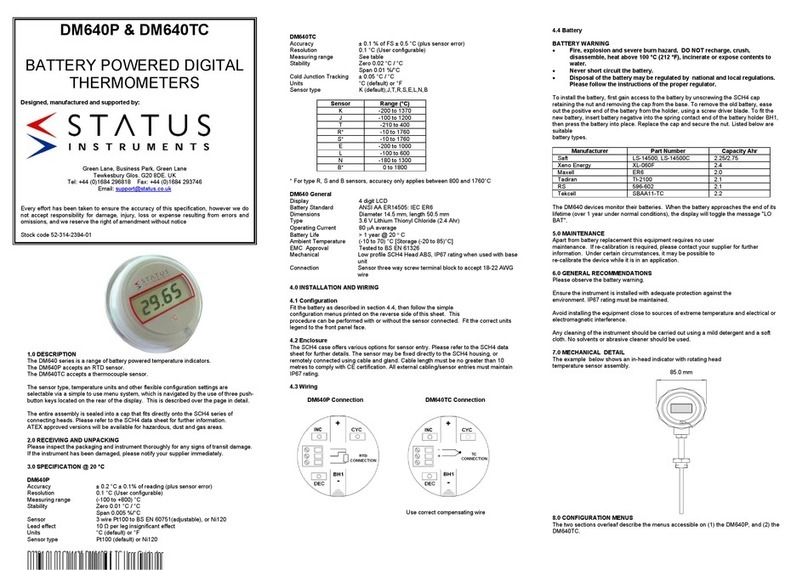

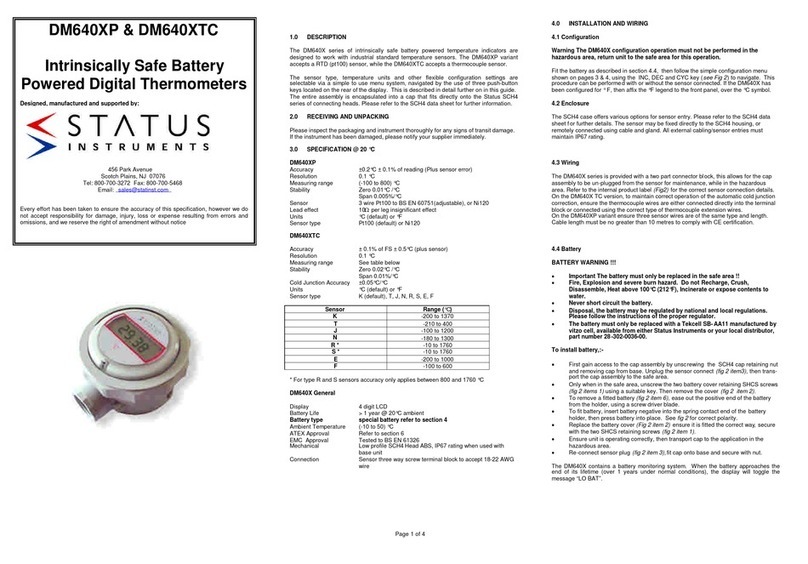

1~DESCRIPTION.

The DM650TM batterypowered indicator accepts RTD orthermocouple temperature

sensors and displaysthe sensor temperature in °C or °F on a 6-digit LCD display. The

instrument offers an advanceddisplay modeallowing theuser to also display one or

two (1 to 32) character messages. Additional to the messages,the usermay select an

alert event to occur when the temperature iswithin a band. The change-over relay can

be used together with the messaging and alert to provide switching at user-set switch

points. In addition to this, on board datalogging is also available to record process

details at up to 5000 points.

2~RECEIVING AND UNPACKING.

Please inspect the packaging and instrument thoroughly for any signs of transit

damage. If the instrument has been damaged, please notify your supplier immediately.

3~SPECIFICATION.

Referto data sheet forfull specification.

Factory default

Pt100, °C, 0.0°C offset, relay not set

4~ INSTALLATION AND WIRING.

4.1~MECHANICAL.

The instrument is a highaccuracy digital thermometer. In order to ensure correct

operation,the following must be observed:

The product must be stored in a dryclean environment and remain in original

packaging prior to installation.

The instrument must not be installed adjacentto electro-mechanical starters,

controllers, thyristor power units or electrical switch gear.

Any cleaning ofthe instrument must be doneusing a mild detergent and softcloth.No

solvents or abrasive cleanersshould be used.

Stated ambientoperating conditions mustnot be exceeded. Battery life will reduce with

higher ambient temperature operating conditions.

4.2~ELECTRICAL.

For a wiring diagramplease refer to the rear panel of the DM650TM inside the

case housing.

Two-part connectors are used for input and relayconnections, allowing the unit to be

easily removed from the housing for reprograming or data download if this is not

possible in situ. On insertionof battery theunit will run through a power up check;

during this time the relay may change state.

IMPORTANT: Always remove battery before any wiring takes place. Gain access to

the connectors and battery holder by twisting cap to release front panel assemblyfrom

case.

RTD: Forbest result we recommend using three wire connection; this method

compensates for any lead resistance between the sensing element and instrument.

Two wire connection is possible: refer to connection diagramon the instrument

protection panel.

THERMOCOUPLE: T/C wire type must be maintained from the sensor element to the

instrument terminals. The terminalsare effectively the cold junction point and can be

displayed as “Case” temperature.

RELAY CONNECTION: A relaywith changeover contacts is available. Screw terminals

are provided forconnection for wire size 16 to 20 AWG.The relay contacts are rated at

48VDC 28 VAC RMS @ 1 A (5 mAminimum current) see DM650TMdata sheet.

BATTERY: To remove battery, use screw driver to ease the positive endof thebattery

out of holder. Insert new battery negative end first then press into place. (Observe

polarity).Batterytype 3.6 V Lithium (2.4 A/Hr) CR14505 (IEC) AA case style. Please

dispose of the batteryin a responsible way.

WARNING

For configuring, reading live data or reading logged data if using a grounded

thermocouple probe on the input, it isimportant not to connect the programming USB

lead to a mainspowered computer. It is possible to damage the instrument if

connected in this way.

To avoid damage use one of the following methods:

•Disconnect the probe before configuration, reconnect the probeafter

configuration.

•Ensure the probe and DM650 housing are not in contact with any conductive

partsduring configuration.

•Use a laptop type computer running from its battery power supply, not connected

to a mains supply. This isrecommended for reading liveddata oroffsetting a unit

if already installed in the field.

•Use a USB isolator between the computerandtheDM650.

5~USER CONFIGURATION.

IMPORTANT

READ COMPLETE SECTION BEFORE ATTEMPTING CONFIGURATION.

PARTICULAR CARE SHOULD BE TAKEN REGARDINGTIMEOUTS IN MENU 2 & 3

The instrument is provided with a USB interface for direct connection to a PC. Free

software USBSpeedLink is available.Please referto the USBSpeedLink software for

further informationon configuration. The software can bedownloaded from

www.status.co.uk.

DISPLAY: The display provides six 14 segment characters for display of temperature

and alpha-numeric messages, together with a 8 segmentbar graph and six icons. The

display is capable of operating in an ambient temperature range of (-30 to 70) °C, but

at temperatures lower than -5 °C (due to the slower LCD speed) scrolled messaging is

not practical, so the display will automatically revert to basic mode showing

temperature.The display’s high contrast, coupled with a digit height of 7.9 mm,offers

clear readouts at low as well as high ambient light and direct sunlight.

The display layout is as follows:

9

1 2 34 6

8

7

8

D2605-01-02

5~USER CONFIGURATION (continued).

1. NFC - The Symbol is on when a NFC field is detected. When a detected field is lost the symbol

will turn off after a few seconds.

2. TRANSMIT/RECEIVE: Symbol on when either NFC or USB communication is active.

3. USB: Symbol on when USB port is connected to a PC. Please note battery is not required during

configuration.

4. LOG: Not used

5. Not used

6. BAR GRAPH: Indicates the state of the logger. The condition is dependent on the selected

logger mode, either Single or Rolling mode.

Single Mode (Log to the maximum number of logs then stop)

Start of Log Mid Log End of Log (alternating)

Rolling Mode (Log to the maximum number of logs then as each new log is taken the oldest log is

discarded)

Start of Log Mid Log Rolled over Log (max bar toggles)

7. DEG: Degree symbol “°” used to indicate either °C or °F on the last digit.

8. DIGITS: Six-digit 14 segment display with – sign, range 9999.9 to -9999.9. Advanced mode

offers two temperature-dependent 32-character message options.

9. WARNING ICON: This symbol will toggle on and off to indicate a warning. The warning symbol

will be active either when the sensor signal is out of range, not connected or when the battery is low.

!

USBSLogLink CONFIGURATION SOFTWARE

LIVE DEVICE READING TAB

Display

Live temperature value

RETRIEVE LOGGED DATA TAB

Download andgraph recorded loggeddata

CONFIGURE LOGGER

Set new log (rolling or fixed), interval time,number of logs, delay start

Enter(tag and contact), reset (maxand min) Sync clock

SETTINGS

Save log location, °C, °F

5~USER CONFIGURATION (continued).

USBSpeedLink CONFIGURATION SOFTWARE

SENSOR TAB

Select

Input type, sensoroff-set

Pre-set Sensor Signal to Set-Point the input value can be fixed to a pre-

determined value, the messaging display and relay willrespond accordingly.

DM650TM configuration software (SensorOptionsTab).

RELAY OPTIONS TAB

Select

Select relayoperation, set -point, dead band, relay name

BASIC DISPLAY OPTIONS TAB

Select

Display units, resolution, Zero set-point

Select

LED Options for battery, relay

ADVANCED DISPLAY OPTIONS TAB

Select

Message bands, custom messages

Use this software tab to set up advancedscrolling user messaging

OTHER DEVICE OPTIONS TAB

Enter

Tag, contact details

Enter

Android passkey (protect logged data)

Enter

Device location

Read/clear

Maximum and minimum reading

Synchronise

Clock

This document is subject to change without notice. No responsibility is taken for errors.

Status Instruments Ltd, Status Business Park, Gannaway Lane, Tewkesbury,

Gloucestershire, UK, GL20 8FD

Web Page: www.status.co.uk, Email: sales@status.co.uk

Technical Support: support@status.co.uk

Tel:+44 (0) 1684 296818, Fax: +44 (0) 1684 293746

MULTIFUNCTION ALERT LED

The alert LED normal state is off, on alert the LED will emit a intense

white light pulse every 5 seconds. The LED can be programmed to

pulse on any of the following combined events:

Mode Description

No events The LED never operates, extending battery life.

(Factory default setting)

Battery Alert on low battery detect.

Trip Alert when relay 1 trip is on.

Temperature In advanced mode only the alert LED can be made to

alert in any one of eight user-set temperature bands. Example, to

alert operator when temperature is outside a safe operating range.

The function of the alert LED can be further enhanced with the option

of displaying an alert message in advanced display mode.

NFC LOGGER INTERFACE

The NFC interface allows the instrument to communicate with an

Android device using NFC connectivity.

The prime function of the interface is to read logged data from the

device using a free app, which is available for downloading to

Android devices.

The app allows the user to read existing logs, change the log

manifest, start a new log, synchronise the instrument clock and reset

the maximum/minimum/average readings. Logs can run to a fixed

number and stop or continually roll over, up to 5000 log points can be

recorded. The start of the log can be delayed up to one month.

Note: For larger logs the data may take over a minute to fully

download via the NFC interface.

USB LOGGER INTERFACE (connector inside housing)

The USB interface allows the instrument to communicate with a PC

running the USBLogLink software

The prime function of the interface is to read logged data from the

device using free software available to download.

The software allows the user to read existing logs, change the log

manifest, start a new log, synchronise the instrument clock and reset

the maximum/minimum readings.

USBLogLink is available from the manufacturer or supplier.

Other Status Instruments Thermometer manuals