Status Instruments DM640X Series User manual

Page 1 of 4

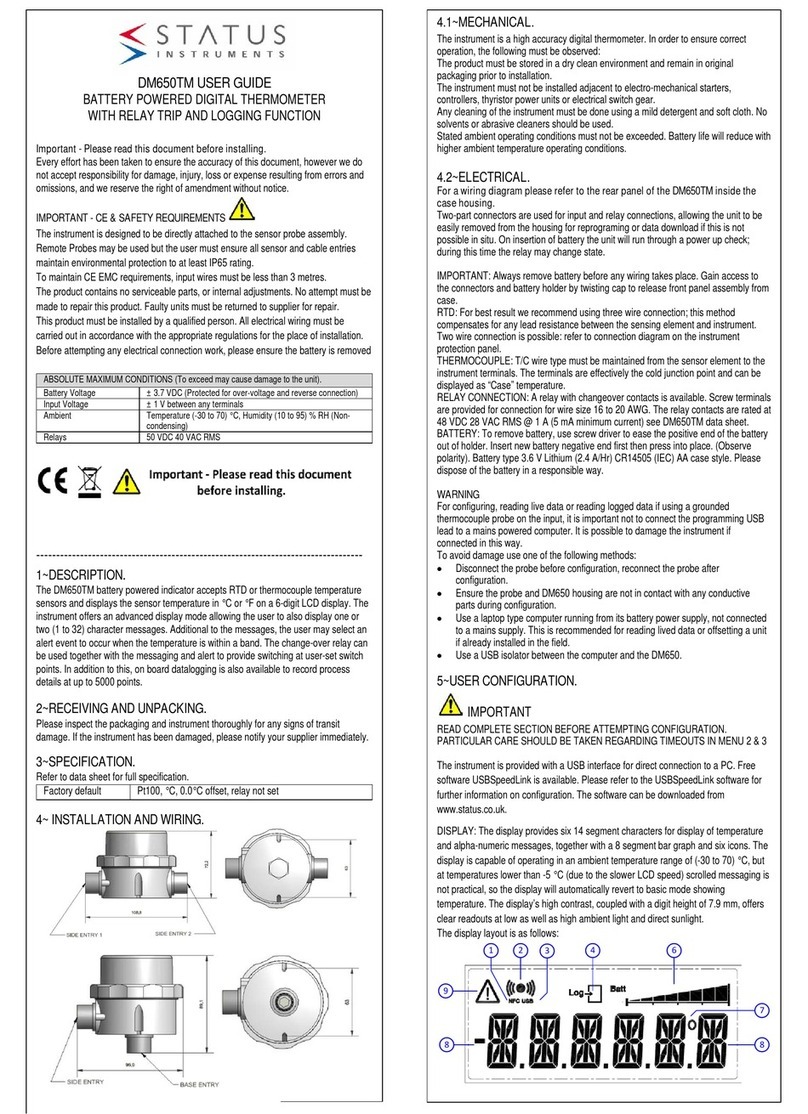

1.0 DESCRIPTION

The DM640X series of intrinsically safe battery powered temperature indicators are

designed to work with industrial standard temperature sensors. The DM640XP variant

accepts a RTD (pt100) sensor, whilethe DM640XTC accepts a thermocouple sensor.

The sensor type, temperature units and other flexible configuration settings are

selectable via a simple to use menu system, navigated by the use of three push-button

keys located on the rear of the display. This is described in detail further on in this guide.

The entire assembly is encapsulated into a cap that fits directly onto the Status SCH4

series of connecting heads. Please refer to the SCH4 data sheet for further information.

2.0 RECEIVING AND UNPACKING

Please inspect the packaging and instrument thoroughly for any signs of transit damage.

If the instrument has been damaged, please notify your supplier immediately.

3.0 SPECIFICATION @ 20 °C

DM640XP

Accuracy ±0.2°C ± 0.1% of reading (Plus sensor error)

Resolution 0.1 °C

Measuring range (-100 to 800) °C

Stability Zero 0.01°C /°C

Span 0.005%/°C

Sensor 3 wire Pt100 to BS EN 60751(adjustable), or Ni120

Lead effect 10per leg insignificant effect

Units °C (default) or °F

Sensor type Pt100 (default) or Ni120

DM640XTC

Accuracy ± 0.1% of FS ± 0.5°C (plus sensor)

Resolution 0.1 °C

Measuring range See table below

Stability Zero 0.02°C /°C

Span 0.01%/°C

Cold Junction Accuracy ±0.05°C/°C

Units °C (default) or °F

Sensor type K (default), T, J, N, R, S, E, F

Sensor Range (°C)

K-200 to 1370

T-210 to 400

J-100 to 1200

N-180 to 1300

R * -10 to 1760

S * -10 to 1760

E-200 to 1000

F-100 to 600

* For type R and S sensors accuracy only applies between 800 and 1760 °C

DM640X General

Display 4 digit LCD

Battery Life > 1 year @ 20°C ambient

Battery type special battery refer to section 4

Ambient Temperature (-10 to 50) °C

ATEX Approval Refer to section 6

EMC Approval Tested to BS EN 61326

Mechanical Low profile SCH4Head ABS, IP67 rating when used with

base unit

Connection Sensor three way screw terminal block to accept 18-22 AWG

wire

4.0 INSTALLATION AND WIRING

4.1 Configuration

Warning The DM640X configuration operation must not be performed in the

hazardous area, return unit to the safe area for this operation.

Fit the battery as described in section 4.4, then follow the simple configuration menu

shown on pages 3 & 4, using the INC, DEC and CYC key (see Fig 2) to navigate. This

procedure can be performed with or without the sensor connected. If the DM640X has

been configured for ° F, then affix the °F legend to the front panel, over the °C symbol.

4.2 Enclosure

The SCH4 case offers various options for sensor entry. Please refer to the SCH4 data

sheet for further details. The sensor may be fixed directly to the SCH4 housing, or

remotely connected using cable and gland. All external cabling/sensor entries must

maintain IP67 rating.

4.3 Wiring

The DM640X series is provided with a two part connector block, this allows for the cap

assembly to be un-plugged from the sensor for maintenance, whilein the hazardous

area. Refer to the internal product label (Fig2) for the correct sensor connection details.

On the DM640X TC version, to maintain correct operation of the automatic cold junction

correction, ensure the thermocouple wires are either connected directly into the terminal

block or connected using the correct type of thermocouple extension wires.

On the DM640XP variant ensure three sensor wires are of the same type and length.

Cable length must be no greater than 10 metres to comply with CE certification.

4.4 Battery

BATTERY WARNING !!!

Important The battery must only be replaced in the safe area !!

Fire, Explosion and severe burn hazard. Do not Recharge, Crush,

Disassemble, Heat above 100°C (212°F), Incinerate or expose contents to

water.

Never short circuit the battery.

Disposal, the battery may be regulated by national and local regulations.

Please follow the instructions of the proper regulator.

The battery must only be replaced with a Tekcell SB-AA11 manufactured by

vitzo cell, available from either Status Instruments or your local distributor,

part number 28-302-0036-00.

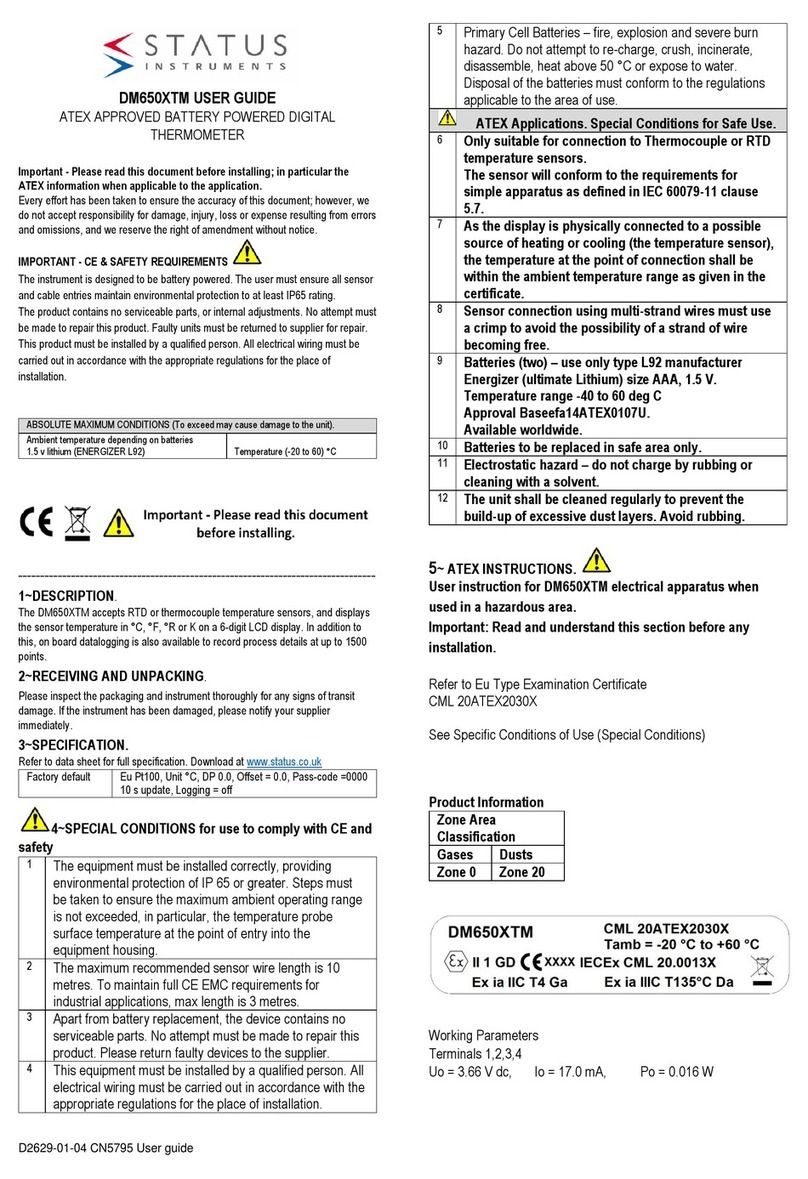

To install battery,:-

First gain access to the cap assembly by unscrewing the SCH4 cap retaining nut

and removing cap from base. Unplug the sensor connect (fig 2item3), then trans-

port the cap assembly to the safe area.

Only when in the safe area, unscrew the two battery cover retaining SHCS screws

(fig 2 items 1) using a suitable key. Then remove the cover (fig 2 item 2).

To remove a fitted battery (fig 2 item 6), ease out the positive end of the battery

from the holder, using a screw driver blade.

To fit battery, insert battery negative into the spring contact end of the battery

holder, then press battery into place. See fig 2 for correct polarity.

Replace the battery cover (Fig 2 item 2) ensure it is fitted the correct way,secure

with the two SHCS retaining screws (fig 2 item 1).

Ensure unit is operating correctly, then transport cap to the application in the

hazardous area.

Re-connect sensor plug (fig 2 item 3),fit cap onto base and secure with nut.

The DM640X contains a battery monitoring system. When the battery approaches the

end of its lifetime (over 1 years under normal conditions), the display will toggle the

message “LO BAT”.

DM640XP & DM640XTC

Intrinsically Safe Battery

Powered Digital Thermometers

Designed, manufactured and supported by:

456 Park Avenue

Scotch Plains, NJ 07076

Tel: 800-700-3272 Fax: 800-700-5468

Email: s[email protected]

Every effort has been taken to ensure the accuracy of this specification, however we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right of amendment without notice

Page 2 of 4

5.0 MAINTENANCE

Warning

The DM640X contains no user serviceable parts apart from the battery.

The DM640X must not be configured in the hazardous area.

No attempt should be made to repair the DM640X, all units must be returned

to the manufacturer for repair or replacement. Attempted repair or service

may invalidate the explosive protection feature of this equipment.

If re-calibration is required please contact your supplier for further

information. Under certain circumstances, it may be possible to re-calibrate

the device while it is still out in an application.

6.0 ATEX CERTIFICATE

The DM640X have been issued with a EC- type examination certificate, confirming

compliance with the European ATEX directive 94/9/EC for :-

Classification II 1 G D EEx ia IIC T4

The unit bears the Community Mark and subject to local codes of practice, may be

installed in any of the European Economic Area (EEA) Members countries. The

equipment must be installed and maintained in accordance with local requirements for

electrical equipment for use in potentially explosive atmospheres, eg EN60079-14 &

EN60079-17. This instruction sheet describes installation, which confirms with

BSEN60079-14 & BS EN60079-17. When designing systems outside the UK, the local

code of practice should be consulted.

When installed correctly the DM640X series may be used in the following

areas :-

ZONE HAZARDOUS AREA CHARACTERISTIC

worst case

GAS DUST

0 20 Hazard Continuously present

1 21 Hazard likely to occur in normal use

2 22 Hazard not likely to occur and if it does, only for a short time.

Be used in gas groups :-

Group A propane

Group B ethylene

Group C hydrogen

Allowable temperature class

T4 135°C Tamb -20 to 50°C

6.1 ATEX Mark

The DM640X/P and DM640X/TC product labels carry the following information:-

Front Panel Label

Manufacturer Status instruments Ltd

Type DM640X/P DM640X/TC

Explosive protection mark

CE mark

Approval II 1 G D EEx ia IIC T4

Certification reference TRL06ATEX11100X

Internal Label

Serial Number (includes date code)

Type DM640X/TC or DM640X/P

Manufacturer information www.statinst.com

Environmental protection: The equipment must be housed in the SCH4

series of enclosure offering protection to IP67. The enclosure must be

suitable for the atmosphere and environment in which it is installed.

6.2 SPECIALCONDITIONS FOR SAFE USE

ELECTROSTATIC HAZARD. DO NOT CHARGE BY RUBBING OR CLEANING

WITH SOLVENTS.

DO NOT CHANGE BATTERY IN THE HAZARDOUS AREA.

DM640XTC – ONLY SUITABLE FOR CONNECTION TO TYPE K,T,J,R,S,N,E,F

THERMOCOUPLES, THEY SHALL CONFORM TO THE REQUIREMENTS FOR

SIMPLE APPARATUS AS DEFINED IN CLAUSE 5.4 OF EN 50020:2002 AND

THE INPUT PARAMETERS MARKED ON THIS UNIT.

DM640XP – ONLY SUITABLE FOR CONNECTION TO RESISTANCE

TEMPERATURE SENSORS TYPES PT100 , NI120. THEY SHALL CONFORM

TO THE REQUIREMENTS FOR SIMPLE APPARATUS AS DEFINED IN

CLAUSE 5.4 OF EN 50020:2002 AND THE INPUT PARAMETERS MARKED ON

THIS UNIT.

USE ONLY TEKCELL SB-AA11 BATTERY, PART NO 28-302-0036-00.

THE UNIT SHALL BE CLEANED REGULARLY TO PREVENT THE BUILD UP

OF EXCESSIVE DUST LAYERS.

6.3 ENCLOSURE MATERIALS

SCH4 enclosure material – ABS.

SCH4 cap– Polycarbonate.

O ring seals – NBR– Acrylonitrile / Butadiene Rubber (Black).

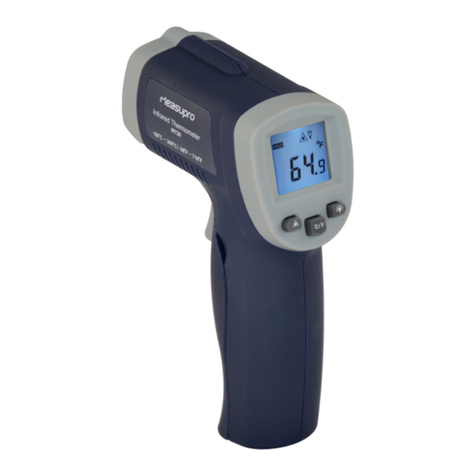

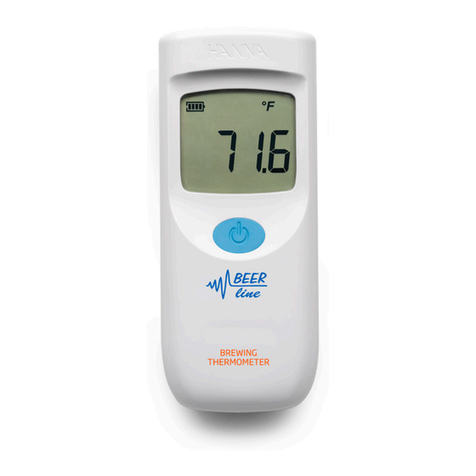

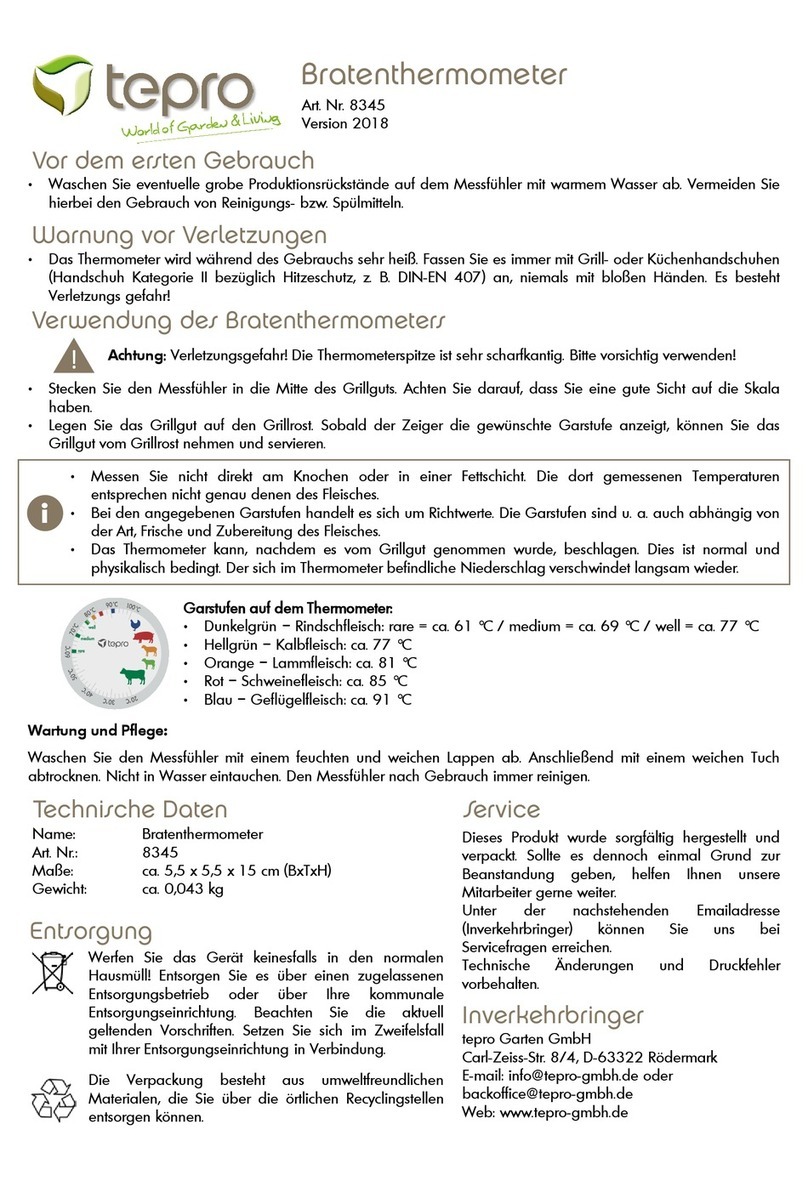

Fig. 1 Front Panel label

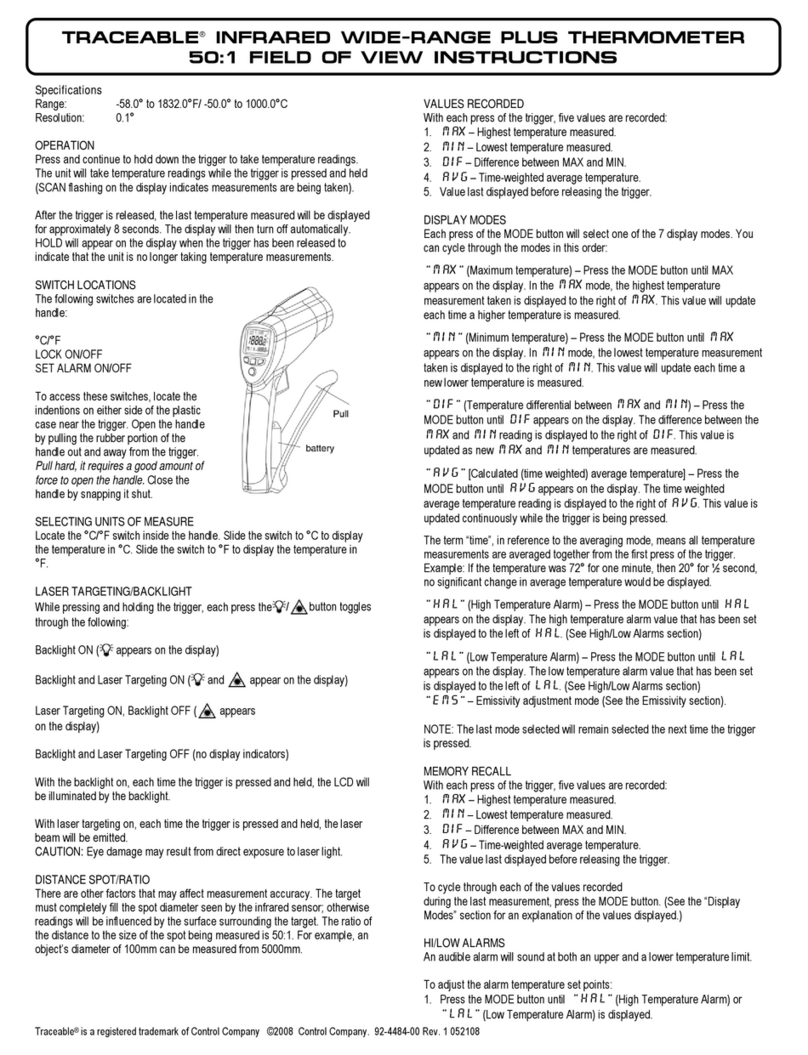

Fig 2 Rear view

0891

DM640 X /TC

!

www .statu s.co.uk

S/No 000000 - 0101

-

+

1

1

2

4

3

+

-

6

BATTERY COVER REMOVED

BAT TERY COVER FITTE D

Page 3 of 4

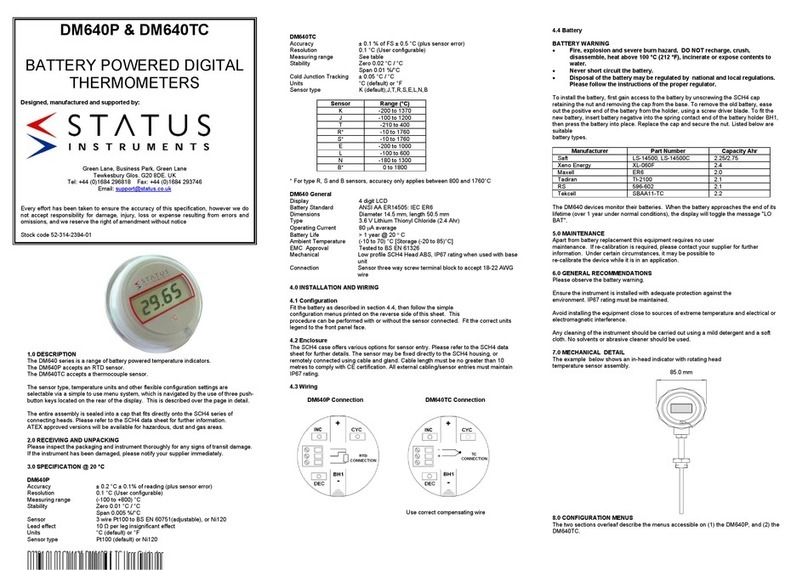

DM640P Configuration Menu Guide

60 s

HOUR

then

When cycling around menu,

the title (e.g. type, unit etc.) is

displayed for a second, then

the menu entry is displayed

ready for editing. Then use

INC/DEC to move through the

entries in a list, or to edit a real

number.

8.8.8.8

RUN-TIME

decp

8888.

888.8

88.88

8.888

Choose the position of the

decimal place in run-time

The device will return from

menu-mode to run-time if no

button is pressed for the

time selected here

Choose RTD type. If USER is

chosen, Pt100 BS EN30751

linearisation is used, but the 0

& 100C calibration points are

shifted by a user-configurable

amount.

TYPE

P100

N120

USER

unit

De9c

de9f

Choose

temperature

units

OFST

88.88

After the input processing stage

where electrical input has been

linearized to produce a

temperature, the temperature is

offset by the number entered

here.

Cycle around menu

PASS

88.88

If non-zero, the user will be

prompted for this number in

order to enter the menu from

run-time.

If no buttons are pressed for a minute or more, the device assumes run-time mode.

The LCD shows the temperature (if the input is in range) or shows or to indicate over/under range.

In order to access menu configuration mode, the user must pressENTer followed immediately by CYCle .

In order to exit the menu and return to run-time, a user must press ESCape .

There are three buttons, which the operator must press in various combinations in order to configure

and/or calibrate the device. These buttons are located on the underside of the indicator’s circuit board.

Viewed from the front, the three buttons (CYCle ,

INCrement and DECrement ) are shown

in black and located as shown in the diagram to the left.

Pressing 2 buttons simultaneously causes ENTer

or ESCape actions.

CYC INC

DEC

8.8.8.8

INCrement menu entry

DECrement menu entry

ENTer to confirm entry, or:

CYCle to reject and move on

tout

Page 4 of 4

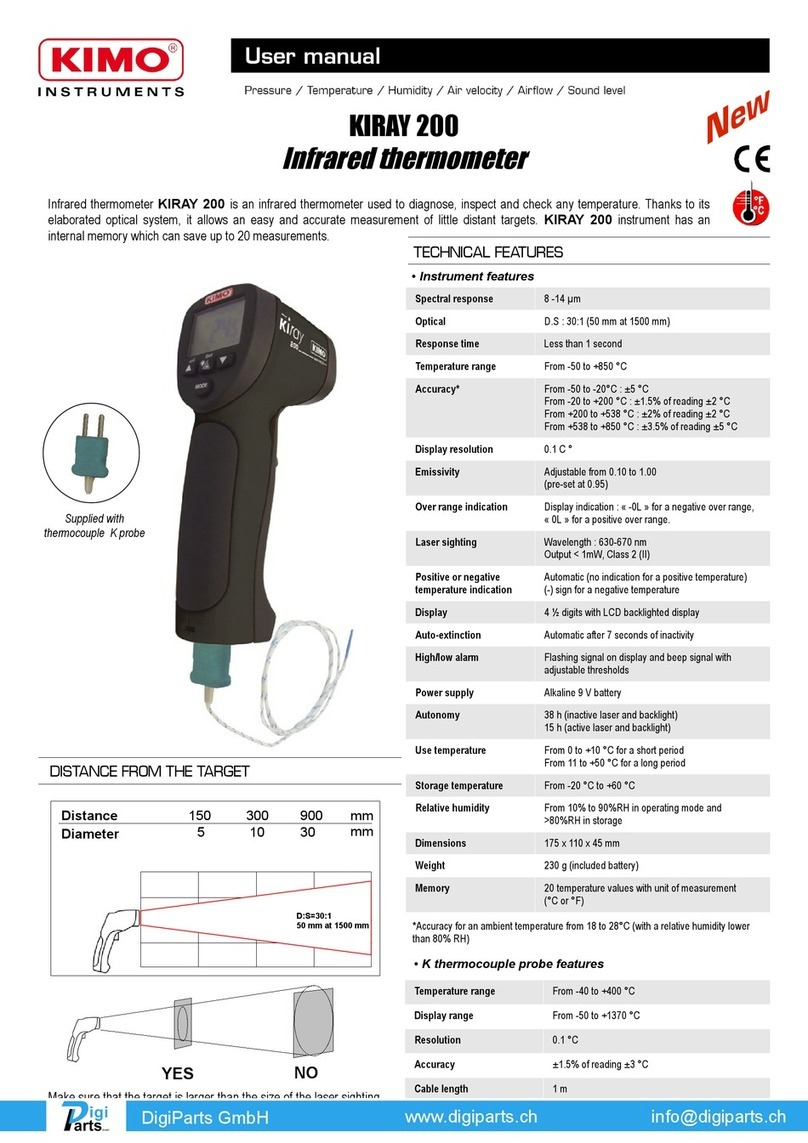

DM640TC Configuration Menu Guide

60 s

HOUR

then

When cycling around menu,

the title (e.g. type, unit etc.) is

displayed for a second, then

the menu entry is displayed

ready for editing. Then use

INC/DEC to move through the

entries in a list, or to edit a real

number.

8.8.8.8

RUN-TIME

decp

8888.

888.8

88.88

8.888

Choose the position of the

decimal place in run-time

The device will return from

menu-mode to run-time if no

button is pressed for the

time selected here

Choose TC

type

cA

J

T

R

S

E

L

N

B

TYPE unit

De9c

de9f

Choose

temperature

units

OFST

88.88

After the input processing stage

where electrical input has been

linearized to produce a

temperature, the temperature is

offset by the number entered

here.

Cycle around menu

PASS

88.88

If non-zero, the user will be

prompted for this number in

order to enter the menu from

run-time.

If no buttons are pressed for a minute or more, thedevice assumes run-time mode.

The LCD shows the temperature (if the input is in range) or shows or to indicate over/under range.

In order to access menu configuration mode, the user must press ENTer followed immediately byCYCle .

In order to exit the menu and return to run-time, a user must press ESCape .

There are three buttons, which the operator must press in various combinations in order to configure

and/or calibrate the device. These buttons are located on the underside of the indicator’s circuit board.

Viewed from the front, the three buttons (CYCle ,

INCrement and DECrement ) are shown

in black and located as shown in the diagram to the left.

Pressing 2 buttons simultaneously causes ENTer

orESCape actions.

CYC INC

DEC

8.8.8.8

INCrement menu entry

DECrement menu entry

ENTer to confirm entry, or:

CYCle to reject and move on

tout

This manual suits for next models

2

Other Status Instruments Thermometer manuals