Status Instruments DM650XTM User manual

D2629-01-04 CN5795 User guide

DM650XTM USER GUIDE

ATEX APPROVED BATTERY POWERED DIGITAL

THERMOMETER

Important - Please read this document before installing; in particular the

ATEX information when applicable to the application.

Every effort has been taken to ensure the accuracy of this document; however, we

do not accept responsibility for damage, injury, loss or expense resulting from errors

and omissions, and we reserve the right of amendment without notice.

IMPORTANT - CE & SAFETY REQUIREMENTS

The instrument is designed to be battery powered. The user must ensure all sensor

and cable entries maintain environmental protection to at least IP65 rating.

The product contains no serviceable parts, or internal adjustments. No attempt must

be made to repair this product. Faulty units must be returned to supplier for repair.

This product must be installed by a qualified person. All electrical wiring must be

carried out in accordance with the appropriate regulations for the place of

installation.

ABSOLUTE MAXIMUM CONDITIONS (To exceed may cause damage to the unit).

Ambient temperature depending on batteries

1.5 v lithium (ENERGIZER L92)

Temperature (-20 to 60) °C

---------------------------------------------------------------------------------

1~DESCRIPTION.

The DM650XTM accepts RTD or thermocouple temperature sensors, and displays

the sensor temperature in °C, °F, °R or K on a 6-digit LCD display. In addition to

this, on board datalogging is also available to record process details at up to 1500

points.

2~RECEIVING AND UNPACKING.

Please inspect the packaging and instrument thoroughly for any signs of transit

damage. If the instrument has been damaged, please notify your supplier

immediately.

3~SPECIFICATION.

Refer to data sheet for full specification. Download at www.status.co.uk

Factory default

Eu Pt100, Unit °C, DP 0.0, Offset = 0.0, Pass-code =0000

10 s update, Logging = off

4~SPECIAL CONDITIONS for use to comply with CE and

safety

1

The equipment must be installed correctly, providing

environmental protection of IP 65 or greater. Steps must

be taken to ensure the maximum ambient operating range

is not exceeded, in particular, the temperature probe

surface temperature at the point of entry into the

equipment housing.

2

The maximum recommended sensor wire length is 10

metres. To maintain full CE EMC requirements for

industrial applications, max length is 3 metres.

3

Apart from battery replacement, the device contains no

serviceable parts. No attempt must be made to repair this

product. Please return faulty devices to the supplier.

4

This equipment must be installed by a qualified person. All

electrical wiring must be carried out in accordance with the

appropriate regulations for the place of installation.

5

Primary Cell Batteries –fire, explosion and severe burn

hazard. Do not attempt to re-charge, crush, incinerate,

disassemble, heat above 50 °C or expose to water.

Disposal of the batteries must conform to the regulations

applicable to the area of use.

ATEX Applications. Special Conditions for Safe Use.

6

Only suitable for connection to Thermocouple or RTD

temperature sensors.

The sensor will conform to the requirements for

simple apparatus as defined in IEC 60079-11 clause

5.7.

7

As the display is physically connected to a possible

source of heating or cooling (the temperature sensor),

the temperature at the point of connection shall be

within the ambient temperature range as given in the

certificate.

8

Sensor connection using multi-strand wires must use

a crimp to avoid the possibility of a strand of wire

becoming free.

9

Batteries (two) –use only type L92 manufacturer

Energizer (ultimate Lithium) size AAA, 1.5 V.

Temperature range -40 to 60 deg C

Approval Baseefa14ATEX0107U.

Available worldwide.

10

Batteries to be replaced in safe area only.

11

Electrostatic hazard –do not charge by rubbing or

cleaning with a solvent.

12

The unit shall be cleaned regularly to prevent the

build-up of excessive dust layers. Avoid rubbing.

5~ ATEX INSTRUCTIONS.

User instruction for DM650XTM electrical apparatus when

used in a hazardous area.

Important: Read and understand this section before any

installation.

Refer to Eu Type Examination Certificate

CML 20ATEX2030X

See Specific Conditions of Use (Special Conditions)

Product Information

Zone Area

Classification

Gases

Dusts

Zone 0

Zone 20

Working Parameters

Terminals 1,2,3,4

Uo = 3.66 V dc, Io = 17.0 mA, Po = 0.016 W

D2629-01-04 CN5795 User guide

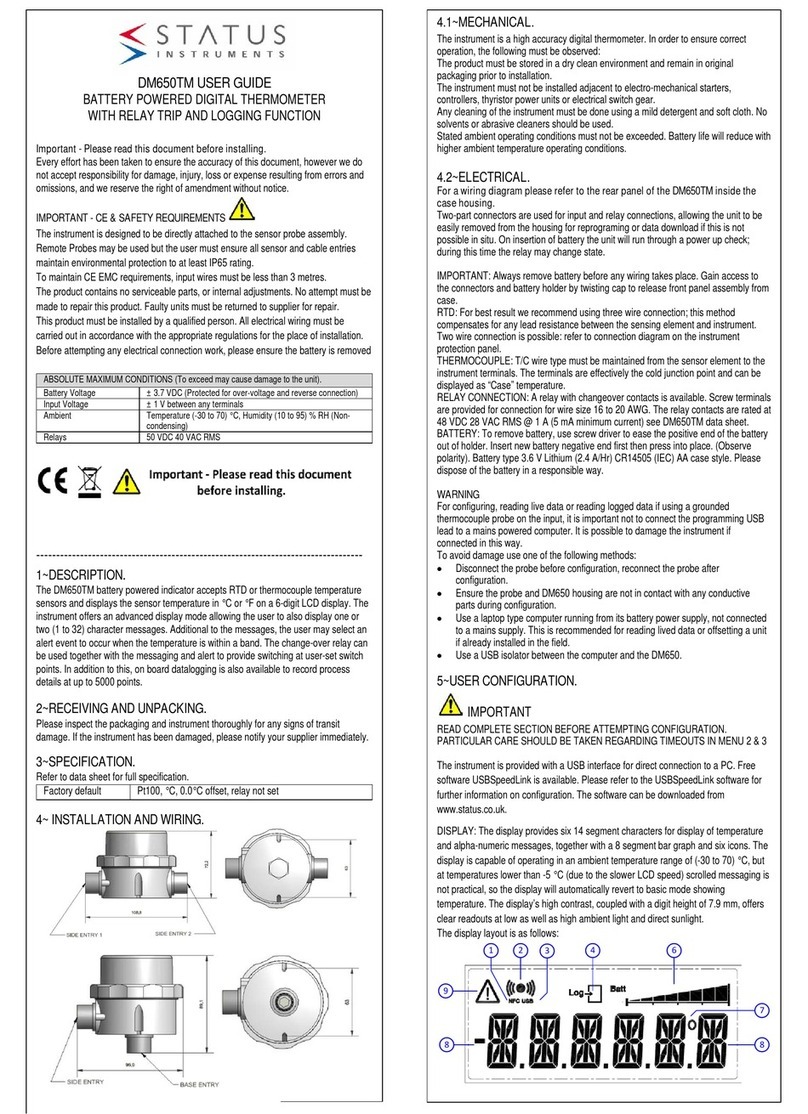

6~INSTALLATION

Figure 1: Back panel battery cover fitted

Figure 2: Back panel battery cover removed

6~1 Battery

ATEX applications use only Energizer L92 batteries, 2

required. Do not use any other type, or mix batteries with any

other type. Batteries must be replaced in the safe area. Follow

the procedure below. When the cap assembly is removed and

disconnected, transport cap assembly to the non-hazardous

area. When the batteries are replaced, be sure the battery

cover is fitted before returning to the hazardous area. Failure

to perform the battery replacement correctly may result in an

unsafe system.

Please observe the above battery warnings. Refer to Figure 2

(Observe polarity). Battery type 1.5 V Lithium ENERGIZER L92

AAA size offering longer life at high temperature: must be used for

ATEX applications.

To fit or replace batteries, use the following procedure:

Note: If fitted, the battery isolation tab will need to be removed

before use.

1

Turn the cap retaining ring anti-clockwise until the ring

releases from the enclosure body.

2

Remove the cap assembly from the enclosure base, un-

plug the 4-way connector. The cap assembly should

now be totally free from the base.

3

For ATEX applications: at this stage, if not already

in a safe area, the cap must be transported to a safe

area.

4

Remove the battery cover by unscrewing the two

retaining screws. If fitted, remove the batteries to be

replaced.

5

Fit new batteries. Observe the polarity symbols marked

on the battery holder.

6

Replace the battery cover, ensure the information label

is visible. Secure the two retaining screws.

7

For Atex applications, return the cap assembly to

the hazardous area.

8

Inspect the cap O ring seal for correct alignment.

Reconnect the 4-way plug and site the cap assembly

back on the case base.

9

Tighten the retaining ring until it stops turning smoothly.

At this point, tighten an additional 1/12 of a turn.

Use the indents on the retaining ring to gauge 1/12 of a

turn as 12 indents are equally spaced around the

retaining ring.

Please dispose of batteries in a responsible way

6~2 Maintenance

The following maintenance is required.:

Battery replacement: the expected battery life in normal

operation well exceeds 1 year; the exact life depends on many

factors such as the number of log reads, response time and the

ambient operating temperature. A low-battery warning is

displayed when the batteries’voltage approaches discharge. It

is recommended at this time the batteries are replaced within a

month.

If required, the device may be cleaned with a damp cloth. For

ATEX applications please refer to “ATEX Applications Special

Conditions for Safe Use” for further information on cleaning.

The device uses advanced circuitry and high stability

components to maintain accuracy. For recalibration, the device

must be returned to the supplier for factory calibration. A single

point offset trim is provided to cancel any sensor error if

required.

The device contains no other user-serviceable parts. Please

return faulty units to your supplier for factory repair or

replacement.

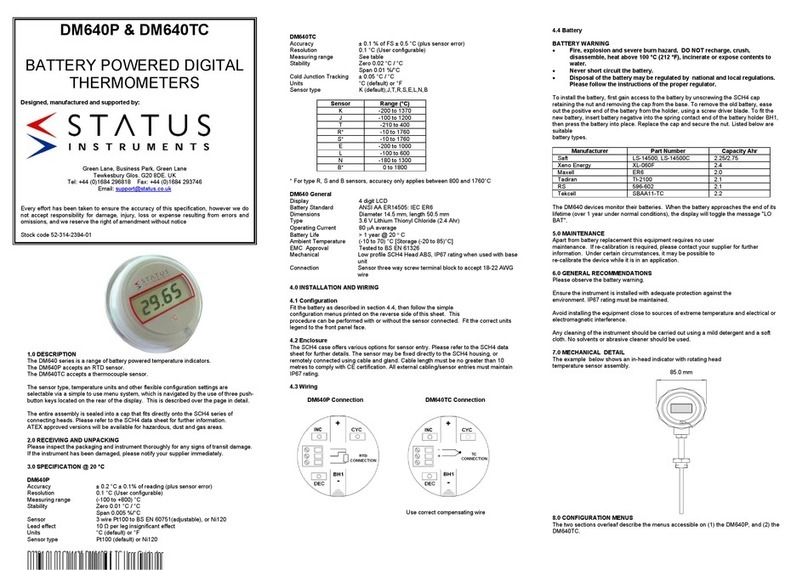

6~3 Sensor wiring

Figure 3: Connection diagram

Important –unplug the 4-way sensor connector from the

device during wiring, re-connect when wiring is complete.

Ensure the sensor wires are long enough (80 to 100 mm) to

allow easy access for reconnecting the plug to the device and,

if required, access to the configuration switch.

D2629-01-04 CN5795 User guide

6~3 Sensor wiring (continued)

General –the instrument is designed to be directly attached to the

sensor probe assembly. Remote Probes may be used but the user

must ensure all sensor entries maintain environmental protection to

at least IP65 rating. To comply with CE EMC requirements the

sensor wires should be no longer than 3 metres. When using an

RTD, for best results we recommend using three-wire connection;

this method compensates for any lead resistance between the

sensing element and instrument. Two-wire RTD connection is

possible by linking pins 1 and 3: refer to Figure 3.

Thermocouple wire type must be maintained from the sensor

element to the instrument terminals. The terminals are effectively

the cold junction point and can be displayed as “Tamb” ambient

temperature.

7~USER CONFIGURATION.

IMPORTANT

READ COMPLETE SECTION BEFORE ATTEMPTING

CONFIGURATION

The device is configured using a single push button and a series of

menus displayed on the LCD screen. The push button is internally

located and is intended for configuration and commissioning

operations only. The device may be supplied pre-configured if

requested at the time of purchase. Refer to the configuration

section for further details.

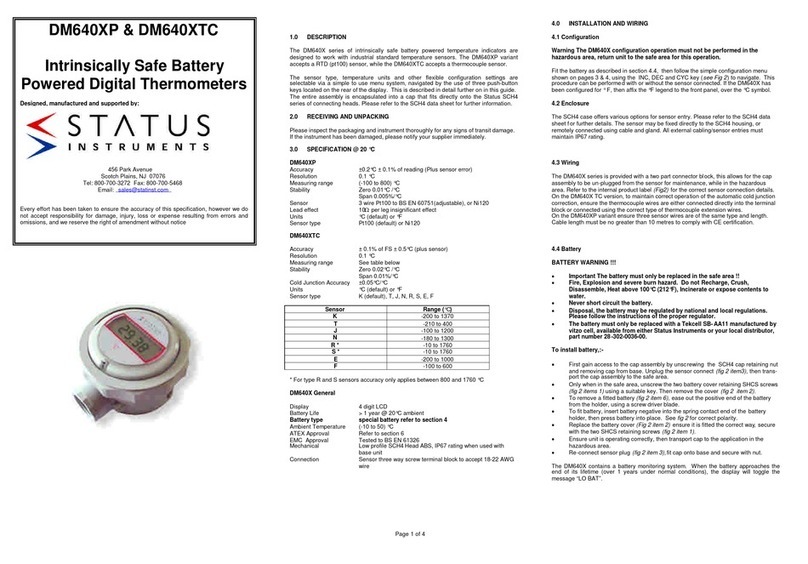

7~1 Display information

Figure 4: Display layout

1 NFC icon active when NFC field is detected.

2 Comms icon active during communication.

3 Log bar. The log bar will show the percentage of logs taken up to

the maximum.

4 Warning Symbol

7~2 Push-button Configuration

A single push-button is provided together with

a simple configuration menu for configuration.

The following variables can be configured:

sensor type, temperature unit, decimal place

and offset.

Single press, in display mode to enter the menu lists.

The configuration settings are presented as a series of menu lists.

A single press (click) from display mode is used to enter the

configuration menu lists.

The order of the menu lists options is as follows:

•Sensor type.

•Display unit.

•Decimal place.

•Response time.

•Offset.

•Pass code.

Long Press > 2 seconds, in configuration mode

To advance through the menu option lists, press continuously for

over 2 seconds. This action is used to advance to the next option

in the menu list and to confirm a selection, and when a variable

has been selected.

Single press and Double press, in configuration mode

A single press (click) from configuration mode. This action steps

through the selected menu list variable, e.g. sensor menu list

variable = Pt100 Eu, single press will select Pt100 US. A double

press steps through the list in reverse order.

No press > 12 seconds, in configuration mode

To escape from the configuration menu, allow a period of 12

seconds with no button action.

Alternatively, stepping through the menu list options will return the

device to the run mode.

SENSO R CON FIGURAT ION

Pt100 Eu, Pt100 US

Ni120, Ni100

Cu100, Cu53

Thermocoupl e type

K, J, E, N, T, R, S, L, B

T AMB (amb ient case

temperature)

DISPLAY MODE

UN ITS CO NFIGU RATION

°C

°F

Kelvin

Single

Press

Doubl e

Press

Double

Press

DP CONFIGURAT ION

0.0

0.00

Double

Press

Doubl e

Press

Single

Press SET OFFSET

Range

(-10.0 to 10.0)

Set Up

Add 0.1

Set Down

Subtract 0.1

DISPLAY MODE

To E scap e Wai t 12 s econd s

With no bu tton Action

Press

Press > 2 s

Press > 2 s

Press > 2 s

PASS C

Press > 2 s

Set each digit i n turn

Press > 2 advances to next digit

Single

Press

To Escap e Wai t 12 second s

With no bu tton Action

Press > 2 s

RESPONSE TIME

5,10,30,60 s

Press > 2 s

Double

Press

Single

Press

Single

Press

Single

Press

Figure 5: configuration menu flow diagram.

D2629-01-04 CN5795 User guide

IMPORTANT

NFC functions are only to be carried out in the safe area or with a

suitably approved ATEX NFC device.

7~3 NFCLink software configuration

The NFC interface allows the instrument to communicate with an

Android device using NFC connectivity.

The prime function of the interface is to configure the device using

the free app, which is available for downloading to Android

devices.

The app allows the user to set the parameters shown in the

configuration screen (below).

Tag No and Contact are free type fields, saved onto the device.

Latitude and Longitude can be used to add the unit’s location

which is added to the log in the NFCLogLink software.

Read process screen showing maximum and minimum values

since the last clear command.

Configuration screen

7~4 NFC Loglink configuration software

The NFC interface allows the instrument to communicate with an

Android device using NFC connectivity.

The prime function of the interface is to read logged data from the

device using the free app, which is available for downloading to

Android devices.

The app allows the user to read existing logs, change the log

manifest, start a new log, synchronise the instrument clock and

reset the maximum/minimum readings.

Logs can run to a fixed number and stop or continually roll over. Up

to 1500 log points can be recorded. The start of the log can be

delayed up to one month.

Data from NFCLogLink can be viewed on screen as a graph or

table and can also be saved to a csv file.

Note: For larger logs the data may take over a minute to fully

download via the NFC interface.

Note: Not all Android devices fully implement the near field

communication (NFC) standard and may not hold the full 1500 log

points.

Main NFCLogLink screen

Graph view in NFCLogLink

Data table view in NFCLogLink

Download Status Instruments apps from the Google Play Store.

Status Instruments Ltd, Status Business Park, Gannaway Lane, Tewkesbury,

Gloucestershire, UK, GL20 8FD

Web Page: www.status.co.uk,

Email: sales@status.co.uk

Tel: +44 (0) 1684 296818, Fax: +44 (0) 1684 293746

Other Status Instruments Thermometer manuals

Popular Thermometer manuals by other brands

CO/Tech

CO/Tech E0201ST2H2 Original instructions

Easy@Home

Easy@Home NCT-301 Faq

FLORABEST

FLORABEST FFGT 433 A1 Operating instructions and safety instructions

sauermann

sauermann KIRAY 100 user manual

Dwyer Instruments

Dwyer Instruments IR4 Series quick start guide

VOLTCRAFT

VOLTCRAFT IR 500-8S SE operating instructions