StayFresh 4H11560US User manual

stayfreshfreezedry.com

1

Stay Fresh Home Freeze Dryer

MODEL 4H11560US

stayfreshfreezedry.com

2

1. Specifications ......................................................................................................................... 4

2. Installation Guide ................................................................................................................... 6

3. Freeze-Drying Process ............................................................................................................ 9

Freezing ...................................................................................................................................... 9

Main drying ................................................................................................................................ 9

Final drying ................................................................................................................................. 9

4. Food Preparation ................................................................................................................. 10

5. Automated Freeze-Drying .................................................................................................... 11

Freeze-drying unfrozen food without the temperature probe ................................................ 12

Freeze-drying unfrozen food with temperature probe ............................................................ 14

Freeze-drying frozen food without temperature probe .......................................................... 16

Freeze-drying frozen food with temperature probe ................................................................ 18

Freeze-drying candies .............................................................................................................. 20

Increase or decrease final dry hours ........................................................................................ 22

Pause and resume the drying process ..................................................................................... 24

What to do after drying is complete ........................................................................................ 25

Troubleshoot vacuum error messages ..................................................................................... 27

6. Defrosting ............................................................................................................................. 29

7. Advanced Freeze-Drying ...................................................................................................... 31

Manual freeze-drying ............................................................................................................... 31

Pre-set curve freeze-drying ...................................................................................................... 32

8. Freeze-Dryer Settings ........................................................................................................... 34

Set parameters ......................................................................................................................... 34

Download data ......................................................................................................................... 34

Set temperature ....................................................................................................................... 34

System reboot .......................................................................................................................... 34

Touch calibration ..................................................................................................................... 35

Reset time ................................................................................................................................ 35

stayfreshfreezedry.com

3

9. Vacuum Pump Oil Change .................................................................................................... 36

10. Touch Screen Info ................................................................................................................. 37

Main-menu ............................................................................................................................... 37

Auto-freezedry-start ................................................................................................................ 38

Auto-freezedry-setting ............................................................................................................. 39

Auto-freezedry-freezing ........................................................................................................... 41

Auto-freezedry-maindry ........................................................................................................... 43

Auto-freezedry-finaldry ............................................................................................................ 43

Auto-freezedry-finaldry-pause ................................................................................................. 44

Auto-freezedry-complete ......................................................................................................... 44

Preset-curve-drying .................................................................................................................. 45

Function-test ............................................................................................................................ 47

Defrosting-setting .................................................................................................................... 47

Defrosting ................................................................................................................................. 48

Defrosting-complete ................................................................................................................ 48

Settings ..................................................................................................................................... 49

Cable-connection-warning ....................................................................................................... 50

Vacuum-leak-warning .............................................................................................................. 50

Vacuum-pressure-abnormal .................................................................................................... 51

Vacuum-not-reached-warning ................................................................................................. 51

stayfreshfreezedry.com

4

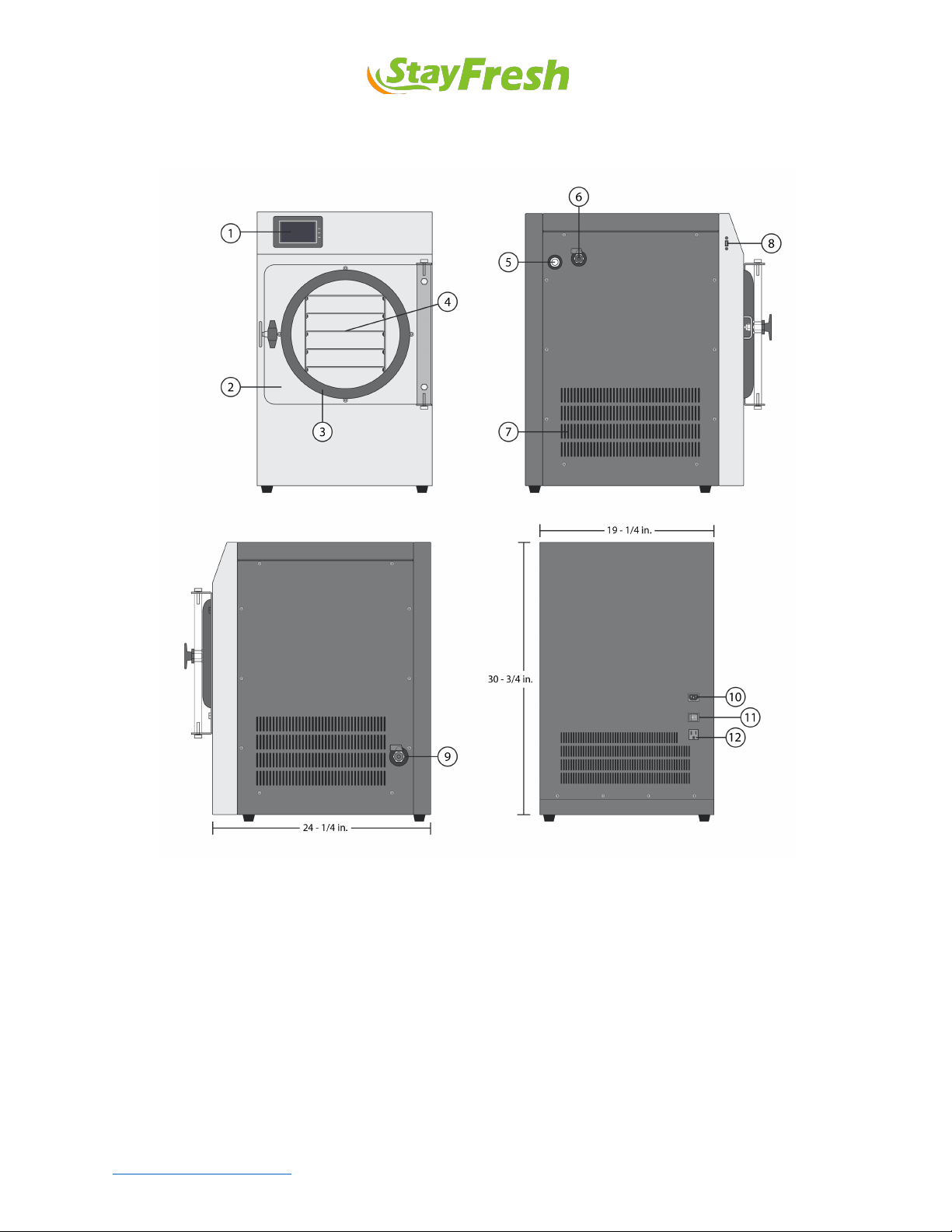

1.

Specifications

○

1 Touch screen controller

○

7 Ventilation grille

○

2 Acrylic door

○

8 USB port

○

3 Door gasket

○

9 Drain valve

○

4 Tray shelf

○

10 Main power inlet

○

5 Vacuum port

○

11 Main power switch

○

6 Vacuum valve

○

12 Vacuum pump power outlet

stayfreshfreezedry.com

5

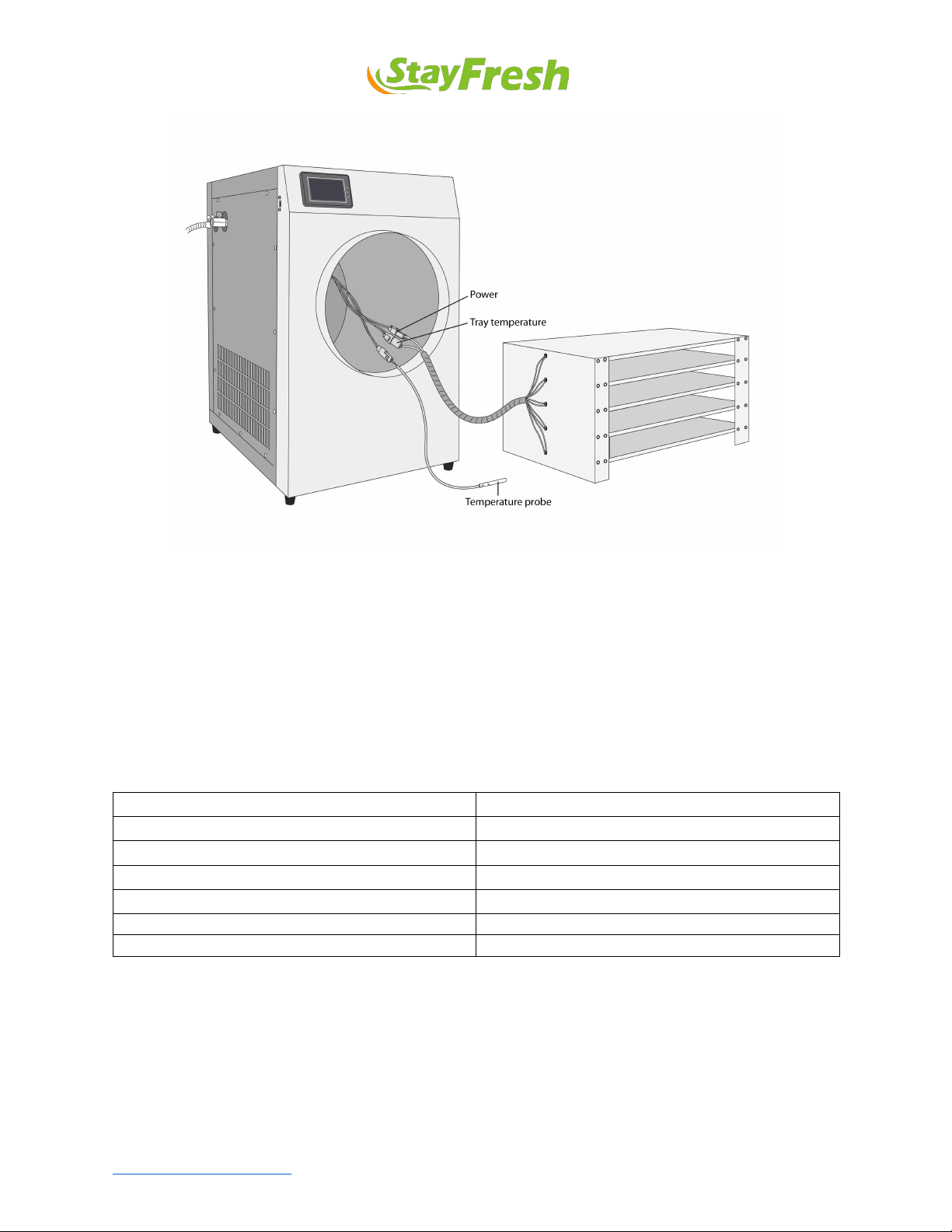

Inside the chamber, there are three cables: one for power, one for shelf temperature, and one

for the temperature probe. The temperature sensors are linked by a three-pin connector, while

the power is connected using a two-pin connector. The cables for power and tray temperature

are bundled together for convenience.

Avoid unplugging the power and sensor cables unless necessary to prevent damage.

Table 1 Technical specifications

Number of trays

4

Tray size

W 8 in. x D 20 in. x H 0.75 in.

Cold trap temperature

-40F

Rated current

15A

Power

115v/60Hz

Weight

165 lbs.

Dimension

W 20 in. x D 26 in. x H 31 in.

stayfreshfreezedry.com

6

2.

Installation Guide

The freeze dryer is designed for indoor use only and performs best in a temperature-controlled

room with temperatures ranging from 60F to 75F. Avoid using the freeze dryer in rooms where

the temperature exceeds 80F. Proper ventilation is necessary when operating the freeze dryer.

To ensure proper operation and safety, keep at least three inches of clearance between the

back of the freeze dryer and the wall, and at least six inches of clearance between the freeze

dryer and the walls on the left and right sides.

The freeze dryer requires a dedicated circuit and a 110V 15-amp outlet that must be within five

feet of the machine. Please ensure that the outlet is in good working condition and meets

electrical requirements before connecting the freeze dryer.

Installation steps:

Step 1.

Unpack the delivery box and ensure that all items on the packing list are present. Position the

freeze dryer in the appropriate location as described in the manual.

Step 2.

Remove the oil cap and use the funnel to fill the vacuum pump with oil until the oil level in the

sight glass reaches the middle line. Take note that the oil level will not immediately change

when pouring in the oil, but it will rise quickly once it starts to rise. After filling, replace the oil

cap and position the vacuum pump to the left side of the freeze dryer.

stayfreshfreezedry.com

7

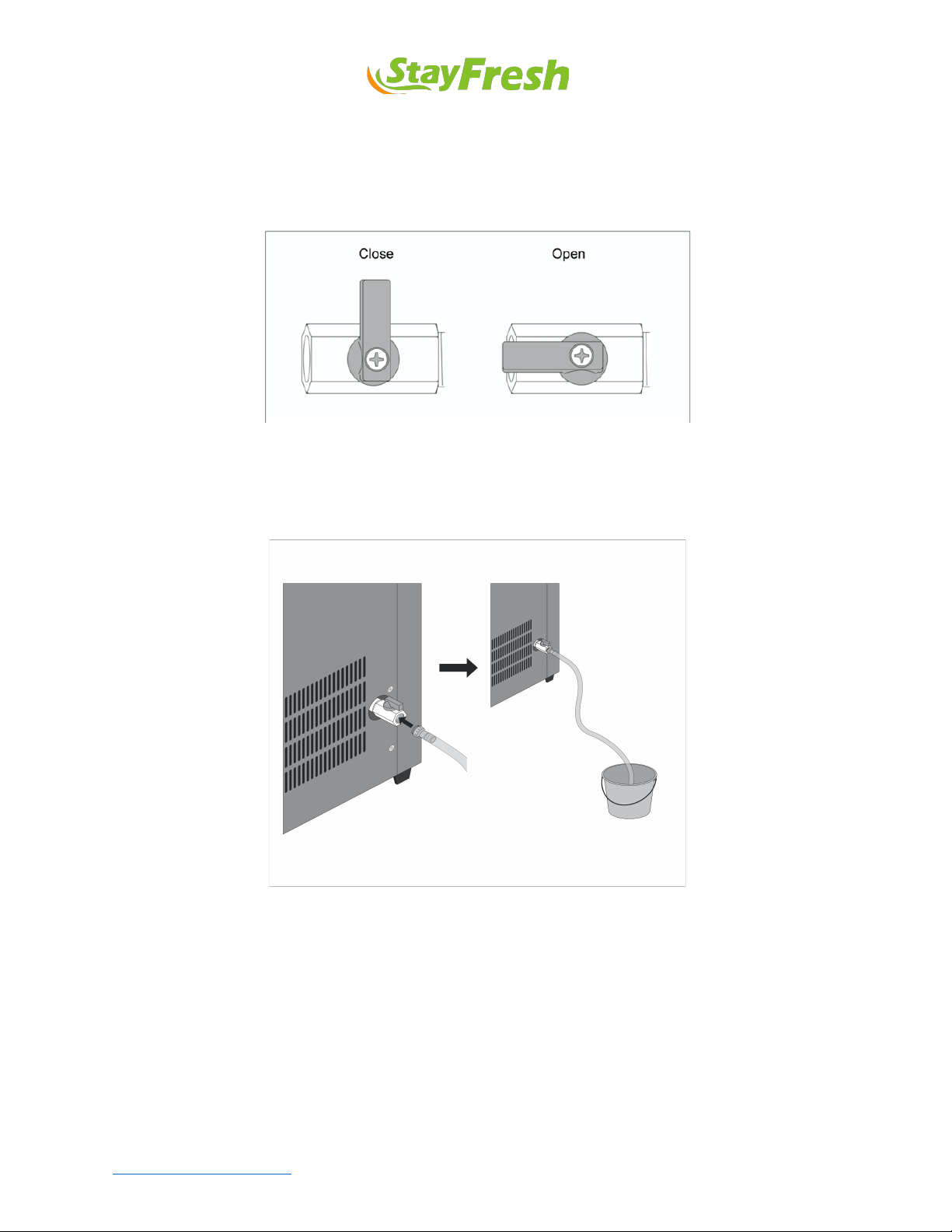

Step 3.

Connect the power cord to the wall outlet and the other end to the back of the freeze dryer (○

10

main power inlet on page 4). Plug the vacuum pump cord to the back of the freeze dryer (○

12

vacuum pump power outlet on page 4). Turn on the vacuum pump switch on the back of the

vacuum pump. Refer to the following for the generic schematic of ON/OFF statuses for the

switch.

Step 4.

Connect one end of the PVC vacuum hose to the freeze dryer (○

5vacuum port on page 4) and

the other end to the vacuum pump. Tighten the connection using the hose clamps.

stayfreshfreezedry.com

8

Step 5.

Close the vacuum valve (○

6vacuum valve on page 4) and the drain valve (drain valve on page 4).

Refer to the following for the Open/Close statuses for the valve.

Step 6.

Connect the drain hose to the drain valve (○

9drain valve on page 4). Place the other end of the

hose in a water bucket (not provided).

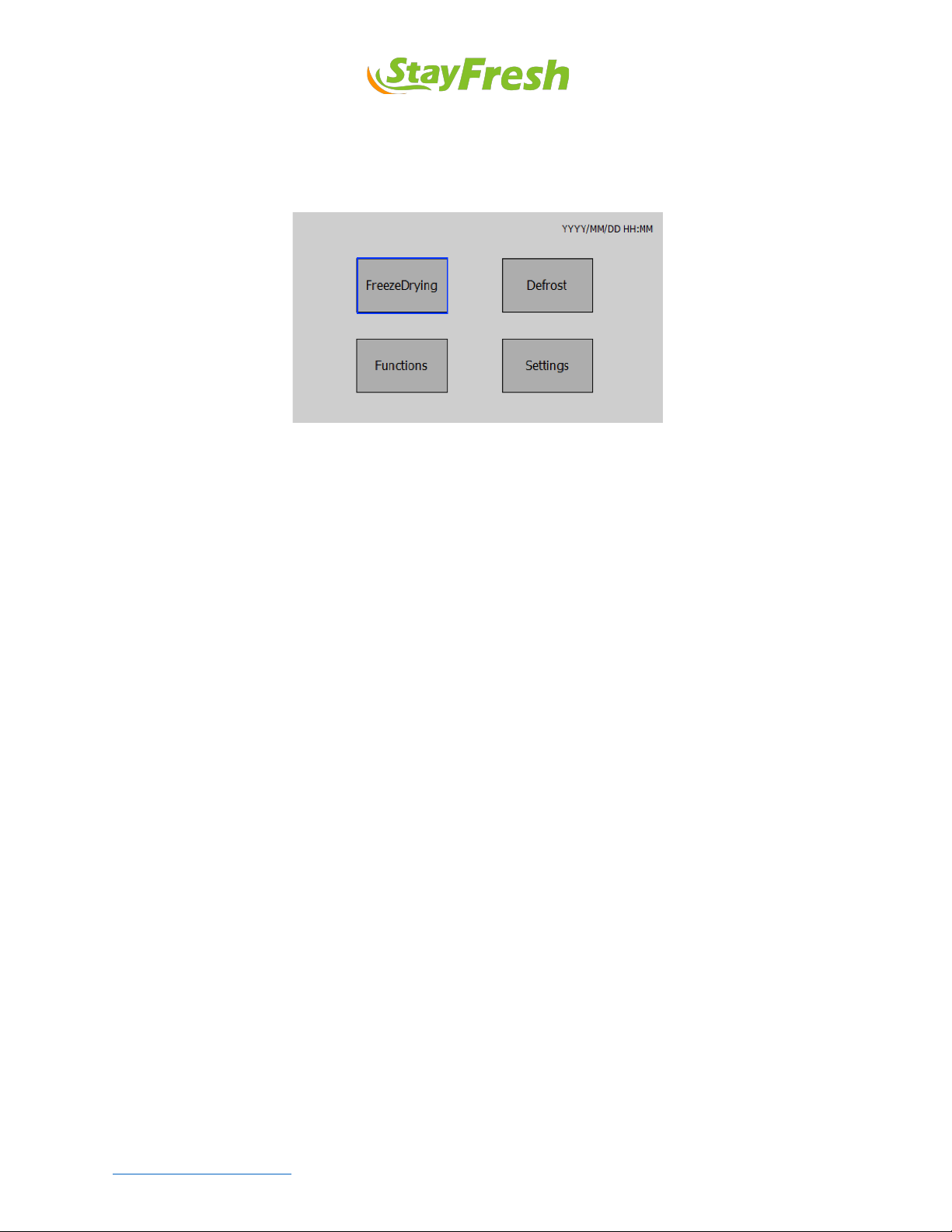

Step 7.

Turn on the power switch at the back of the freeze dryer (○

11 main power switch on page 4). The

touch screen should light up and display the main menu. Assign a name to your freeze dryer by

pressing the top left corner of the touch screen.

Allow the freeze dryer to settle for 24 hours before using it for the first time. Refer to Section 5

of the manual for instructions on how to run the automated freeze-drying process.

stayfreshfreezedry.com

9

3.

Freeze-Drying Process

The freeze-drying process is divided into three stages: freezing, main drying, and final drying.

Freezing

The freezing stage duration varies depending on the food's type, weight, and thickness, taking

anywhere from 6-15 hours for unfrozen food and 2-4 hours for frozen food. During this stage,

the cold trap temperature drops gradually to around -40F, and only the compressor runs. Frost

may be visible on the interior chamber surface, and condensation may form on the acrylic door

and gasket.

Main drying

The main drying stage begins automatically when the preset freezing time, shelf temperature,

or food temperature is reached, as explained in the Auto-freeze-dry-setting in Section 10.

Alternatively, you can start the drying process by pressing the 'Drying' button. The vacuum

pump operates for a set duration at the beginning of this stage, and the chamber pressure

drops to or below 550mTorr. The heater is then turned on to maintain the pressure at the initial

target pressure, and the patented freeze-drying algorithm is initiated.

During the constant-pressure phase, the pressure remains constant, while the shelf

temperature gradually increases. Once the target shelf temperature is reached, the algorithm

enters the constant-temperature phase, during which the shelf temperature is maintained at a

constant level, and the vacuum pressure gradually decreases. This cycle repeats until the

maximum shelf temperature is reached.

The compressor, vacuum pump, and heater are all running continuously during the main drying

stage, and ice rings may appear on the chamber's interior surface.

Final drying

The final drying stage begins when the maximum temperature is reached or when a preset food

temperature measured by the temperature probe is reached (if the probe is in use). These

indicators suggest that most of the moisture has been extracted from the food. The default

final dry duration is seven hours. The drying algorithm adjusts the final dry time automatically

when the temperature probe is in use. Extra final dry hours can be added manually if necessary.

During the final drying stage, the compressor, vacuum pump, and heater operate similarly to

the main drying stage. When the drying is complete, the heater and vacuum pump are turned

off, and the compressor continues running to keep the chamber cool.

stayfreshfreezedry.com

10

4.

Food Preparation

To prepare food for freeze-drying:

1. Wash the food thoroughly to remove any dirt or debris. Freeze drying won’t kill bacteria

in the food.

2. Cut the food into small pieces if possible, for better drying results. For solid foods, cut

them into pieces that are less than half an inch thick.

3. For liquid or semi-liquid foods, pour them evenly onto the trays.

4. Ensure that foods of similar type and thickness are on each tray for even drying.

5. Avoid mixing frozen and unfrozen foods in the same batch.

6. Foods with high moisture levels should be in one batch for efficiency reasons, as the

drying time will depend on the moisture level of the foods in the same batch.

7. Note that oily foods may not be suitable for freeze-drying, as the process only removes

water from the food and the oil may go rancid after packaging in a mylar bag.

stayfreshfreezedry.com

11

5.

Automated Freeze-Drying

Press the ‘FreezeDrying’ button on the main menu to enter the automated freeze-drying mode.

The automated freeze-drying process may vary slightly depending on whether the food is pre-

frozen or if you're using the temperature probe.

For a more detailed description of the automated freeze-drying process, refer to the following

sections. Each section includes steps that require your action and information enclosed in

boxes. Touch screen names may be underscored in each step, and you can find further details

in Section 10. Touch Screen Info.

stayfreshfreezedry.com

12

Freeze-drying unfrozen food without the temperature probe

Step 1.

Inspect and make sure there is no sign of ice or water in the bottom of the chamber and in the

groove of the door gasket.

Step 2.

Load trays with unfrozen food, insert the trays onto the shelves, and close the acrylic door.

Step 3.

Close the vacuum valve. Remove any residual water in the drain pipe, using the brush (refer to

Section 6 for more details) and close the drain valve.

Step 4.

Press the ‘FreezeDrying’ button on the touch screen to go to the Auto-freezedry-start

screen. Then press the ‘Settings’ button to go to the Auto-freezedry-setting screen. Adjust

trigger conditions that automatically triggers drying to begin. Use the default setting for

beginners. Press the ‘Back’ button to return to the Auto-freezedry-start screen.

Step 5.

Press the ‘Start’ button to go to the Auto-freezedry-freezing screen and the compressor will be

turned on.

Note that the ‘Drying’ button will be disabled for one minute after pressing the ‘start’

button. You can still adjust freezing drying parameters using the ‘Settings’ button on the

right bottom during the freezing stage.

Once the default trigger conditions are met or the ‘Drying’ button is pressed, the freeze

dryer will automatically start the drying process and transition to the Auto-freezedry-

maindry screen.

Upon completion of the main drying stage, the freeze dryer will proceed to the final dry

stage and switch to the Auto-freezedry-finaldry screen. During this stage, you have the

option to increase or decrease the final dry hours. For beginners, it is recommended to

use the default setting.

Step 6.

After the final dry stage is finished, the vacuum pump will stop and the motorized ball

valve will close automatically. The screen will switch to the Auto-freezedry-complete

screen and beep for 30 seconds. In case you're not around when the drying process is

finished, the trays might get excessively cold since the compressor will still be running. If

needed, use the 'Warm Tray' button to heat up the trays.

stayfreshfreezedry.com

13

When the final dry stage is completed, open the vacuum valve to normalize the pressure, then

open the acrylic door. Check if the food is completely dry on each tray.

All pieces of food should be warm immediately after drying is complete if the default

maximum shelf temperature is used. Press the ‘Back to Final Dry’ button to go to the

Auto-freezedry-finaldry-pause screen if more final dry hours are needed. Use the up

arrow to add extra final dry hours to enable the ‘Final Dry’ button. Then press the ‘Final

Dry’ button to restart the drying process.

If the food is completely dry, press ’Exit’ to stop the compressor, seal the freeze-dried food in

the bags as soon as possible. Otherwise, read section ‘What to do after drying is complete’ and

follow the steps.

Step 7.

Remove ice in the chamber. Read Section 6 for defrosting.

Step 8.

Change/filter vacuum pump oil if needed. Check section 9 for details.

stayfreshfreezedry.com

14

Freeze-drying unfrozen food with temperature probe

Step 1.

Inspect and make sure there is no sign of ice or water in the bottom of the chamber and in the

groove of the door gasket.

Step 2.

Load trays with unfrozen food, insert the trays onto the shelves.

If the food consists of solid pieces, pick the largest piece on the second tray (from top to

bottom), and insert the temperature probe into the center of the piece. Place the piece back on

the tray. If the food is liquid/semi-liquid, immerse the temperature probe in the food.

Close the acrylic door.

Step 3.

Close the vacuum valve. Remove any residual water in the drain pipe using the brush (refer to

Section 6 for more details) and close the drain valve.

Step 4.

Press the ‘FreezeDrying’ button on the touch screen to go to the Auto-freezedry-start

screen. Then press the ‘Probe in use’ button.

Press the ‘Settings’ button to go to the Auto-freezedry-setting screen. Adjust the trigger

conditions that automatically triggers drying to begin. Use the default setting for beginners.

Press the ‘Back’ button to return to the Auto-freezedry-start screen.

Step 5.

Press the ‘Start’ button on the Auto-freezedry-start screen to enter the freezing stage.

Note that the ‘Drying’ button will be disabled for one minute after pressing the ‘start’

button. You can still adjust freezing drying parameters using the ‘Settings’ button on the

right bottom during the freezing stage.

Once the default trigger conditions are met or the ‘Drying’ button is pressed, the freeze

dryer will automatically start the drying process and transition to the Auto-freezedry-

maindry screen.

Upon completion of the main drying stage, the freeze dryer will proceed to the final dry

stage and switch to the Auto-freezedry-finaldry screen. During this stage, you have the

option to increase or decrease the final dry hours. For beginners, it is recommended to use

the default setting.

stayfreshfreezedry.com

15

Step 6.

After the final dry stage is finished, the vacuum pump will stop and the motorized ball

valve will close automatically. The screen will switch to the Auto-freezedry-complete

screen and beep for 30 seconds. In case you're not around when the drying process is

finished, the trays might get excessively cold since the compressor will still be running. If

needed, use the 'Warm Tray' button to heat up the trays.

When the final dry stage is completed, open the vacuum valve to normalize the pressure in the

chamber, then open the acrylic door. Check if the food is completely dry on each tray.

All pieces of food should be warm if the default maximum shelf temperature is used. Press

the ‘Back to Final Dry’ button to go to the Auto-freezedry-finaldry-pause screen if more

final dry hours are needed. Use the up arrow to add extra final dry hours to enable the

‘Final Dry’ button. Then press the ‘Final Dry’ button to restart the drying process.

If the food is completely dry, press ’Exit’ to stop the compressor, seal the freeze-dried food in

the bags as soon as possible. Otherwise, read section ‘What to do after drying is complete’ and

follow the steps.

Step 7.

Remove ice in the chamber. Read Section 6 for defrosting.

Step 8.

Change/filter vacuum pump oil if needed. Check section 9 for details.

stayfreshfreezedry.com

16

Freeze-drying frozen food without temperature probe

Step 1.

Pre-freeze the food on the trays in a deep freezer for over 24 hours to make sure the food is

completely frozen.

Step 2.

Inspect and make sure there is no sign of ice or water in the bottom of the chamber and in the

groove of the door gasket.

Step 3.

Close the vacuum valve. Remove any residual water in the drain pipe using the brush (refer to

Section 6 for more details) and close the drain valve.

Step 4.

Press the ‘FreezeDrying’ button on the touch screen to go to the Auto-freezedry-start

screen. Then press the ‘Frozen Food’ button to let the control algorithm know the food is

frozen.

Press the ‘Settings’ button to go to the Auto-freezedry-setting screen. Adjust the trigger

conditions that automatically triggers drying to begin. Use the default setting for beginners.

Press the ‘Back’ button to return to the Auto-freezedry-start screen.

Step 5.

Press the ‘Start’ button on the Auto-freezedry-start screen to enter the freezing stage.

The screen will jump to Auto-freezedry-freezing and the compressor will be turned on.

Note that the ‘Drying’ button will be disabled for one minute. You can still adjust freezing

drying parameters using the ‘Settings’ button on the right bottom during the freezing stage.

Step 6.

After allowing the freeze dryer to run for 1-2 hours, check the shelf temperature. Once it

reaches below -5F, proceed to load the freeze dryer with trays containing frozen food. Close the

acrylic door and then press the ‘Food in Chamber’ button.

The freeze dryer will start the drying process and jump to the Auto-freezedry-maindry

screen when any of the default trigger conditions are met or the ‘Drying’ button is

pressed.

When the main drying stage is completed, the freeze dryer will enter the final dry stage

and the screen jumps to Auto-freezedry-finaldry. You can increase or decrease the final

dry hours during the final dry stage.

Step 7.

stayfreshfreezedry.com

17

After the final dry stage is finished, the vacuum pump will stop and the motorized ball

valve will close automatically. The screen will switch to the Auto-freezedry-complete

screen and beep for 30 seconds. In case you're not around when the drying process is

finished, the trays might get excessively cold since the compressor will still be running. If

needed, use the 'Warm Tray' button to heat up the trays.

When the final dry stage is completed, open the vacuum valve to normalize the pressure, then

open the acrylic door. Check if the food is completely dry on each tray.

All pieces of food should be warm if the default maximum shelf temperature is used. Press

the ‘Back to Final Dry’ button to go to the Auto-freezedry-finaldry-pause screen if more

final dry hours are needed. Use the up arrow to add extra final dry hours to enable the

‘Final Dry’ button. Then press the ‘Final Dry’ button to restart the drying process.

If the food is completely dry, press ’Exit’ to stop the compressor, seal the freeze-dried food in

the bags as soon as possible. Otherwise, read section ‘What to do after drying is complete’ and

follow the steps.

Step 8.

Remove ice in the chamber. Read Section 6 for defrosting.

Step 9.

Change/filter vacuum pump oil if needed. Check section 9 for details.

stayfreshfreezedry.com

18

Freeze-drying frozen food with temperature probe

Step 1.

Disconnect the temperature probe in the chamber.

If the food is of solid pieces, pick the largest piece and insert the temperature probe into the

center of the piece. Place the piece back on the tray. If the food is liquid/semi-liquid, immerse

the temperature probe in the food.

Pre-freeze the food on the trays with the temperature probe in a deep freezer for over 24 hours

to make sure the food is completely frozen.

Step 2.

Inspect and make sure there is no sign of ice or water in the bottom of the chamber and in the

groove of the door gasket.

Step 3.

Close the vacuum valve. Remove any residual water in the drain pipe using the brush (refer to

Section 6 for more details) and close the drain valve.

Step 4.

Press the ‘FreezeDrying’ button on the touch screen to go to the Auto-freezedry-start

screen. Then press the ‘Probe in Use’ button and the ‘Frozen Food’ button to let the controller

know the food is frozen and the temperature probe is being used.

Press the ‘Settings’ button to go to the Auto-freezedry-setting screen. Adjust the trigger

conditions that automatically triggers drying to begin. Use the default setting for beginners.

Press the ‘Back’ button to return to the Auto-freezedry-start screen.

Step 5.

Press the ‘Start’ button on the Auto-freezedry-start screen to enter the freezing stage.

The screen will jump to Auto-freezedry-freezing and the compressor will be turned on.

Note that the ‘Drying’ button will be disabled for one minute. You can still adjust freeze-

drying parameters using the ‘Settings’ button on the right bottom during the freezing stage.

Step 6.

After allowing the freeze dryer to run for 1-2 hours, check the shelf temperature. Once it

reaches below -5F, proceed to load the freeze dryer with trays containing frozen food.

Reconnect the temperature probe in the chamber, ensuring that the female and male

connectors are clean and dry before connecting. Place the piece with the temperature probe on

the second tray from the top.

Close the acrylic door and then press the ‘Food in Chamber’ button.

stayfreshfreezedry.com

19

The freeze dryer will start the drying process and jump to the Auto-freezedry-maindry

screen when any of the default trigger conditions are met or the ‘Drying’ button is

pressed.

When the main drying stage is completed, the freeze dryer will enter the final dry stage

and the screen jumps to Auto-freezedry-finaldry. You can increase or decrease the final

dry hours during the final dry stage.

Step 7.

After the final dry stage is finished, the vacuum pump will stop and the motorized ball

valve will close automatically. The screen will switch to the Auto-freezedry-complete

screen and beep for 30 seconds. In case you're not around when the drying process is

finished, the trays might get excessively cold since the compressor will still be running. If

needed, use the 'Warm Tray' button to heat up the trays.

When the final dry stage is completed, open the vacuum valve to normalize the pressure in the

chamber, then open the acrylic door. Check if the food is completely dry on each tray.

All pieces of food should be warm if the default maximum shelf temperature is used. Press

the ‘Back to Final Dry’ button to go to the Auto-freezedry-finaldry-pause screen if more

final dry hours are needed. Use the up arrow to add extra final dry hours to enable the

‘Final Dry’ button. Then press the ‘Final Dry’ button to restart the drying process.

If the food is completely dry, press ’Exit’ to stop the compressor, seal the freeze-dried food in

the bags as soon as possible. Otherwise, read section ‘What to do after drying is complete’ and

follow the steps.

Step 8.

Remove ice in the chamber. Read Section 6 for defrosting.

Step 9.

Change/filter vacuum pump oil if needed. Check section 9 for details.

stayfreshfreezedry.com

20

Freeze-drying candies

Step 1.

Inspect and make sure there is no sign of ice or water in the chamber, shelving unit, and in the

groove of the door gasket.

Step 2.

Load trays with candies, insert the trays onto the shelves, and close the acrylic door.

Step 3.

Close the vacuum valve. Remove any residual water in the drain pipe, using the brush (refer to

Section 6 for more details) and close the drain valve.

Step 4.

Press the ‘FreezeDrying’ button on the touch screen to go to the Auto-freezedry-start

screen. Then press the ‘Candy’ button go to the setting screen. Adjust max shelf temperature

and final dry hours if necessary.

Step 5.

Press the ‘Start’ button to go to the Auto-freezedry-freezing screen and the compressor will be

turned on.

By default, the pump will start after 15 mins of compressor running, and the heater will

be activated after 15 mins of pump running. Note that the ‘Drying’ button will be disabled

for one minute after pressing the ‘start’ button.

Upon completion of the main drying stage, the freeze dryer will proceed to the final dry

stage and switch to the Auto-freezedry-finaldry screen. During this stage, you have the

option to increase or decrease the final dry hours. For beginners, it is recommended to

use the default setting.

Step 6.

After the final dry stage is finished, the vacuum pump will stop and the motorized ball

valve will close automatically. The screen will switch to the Auto-freezedry-complete

screen and beep for 30 seconds. In case you're not around when the drying process is

finished, the trays might get excessively cold since the compressor will still be running. If

needed, use the 'Warm Tray' button to heat up the trays.

When the final dry stage is completed, open the vacuum valve to normalize the pressure, then

open the acrylic door. Press the ‘Back to Final Dry’ button to go to the Auto-freezedry-finaldry-

pause screen if you want more final dry hours or if you want back-to-back batch runs. Use the

up arrow to add extra final dry hours to enable the ‘Final Dry’ button. Then press the ‘Final Dry’

button to restart the drying process.

Other manuals for 4H11560US

1

Table of contents

Other StayFresh Dryer manuals

Popular Dryer manuals by other brands

ffuuss

ffuuss eos user manual

KitchenAid

KitchenAid 53-3498 installation instructions

Schulthess

Schulthess Spirit topLine TW 8340 operating instructions

Whirlpool

Whirlpool LGR4624BW0 parts list

World Dryer

World Dryer AirMax D M5-972A manual

Alliance Laundry Systems

Alliance Laundry Systems ADEE9BSS user guide