Owner's Manual

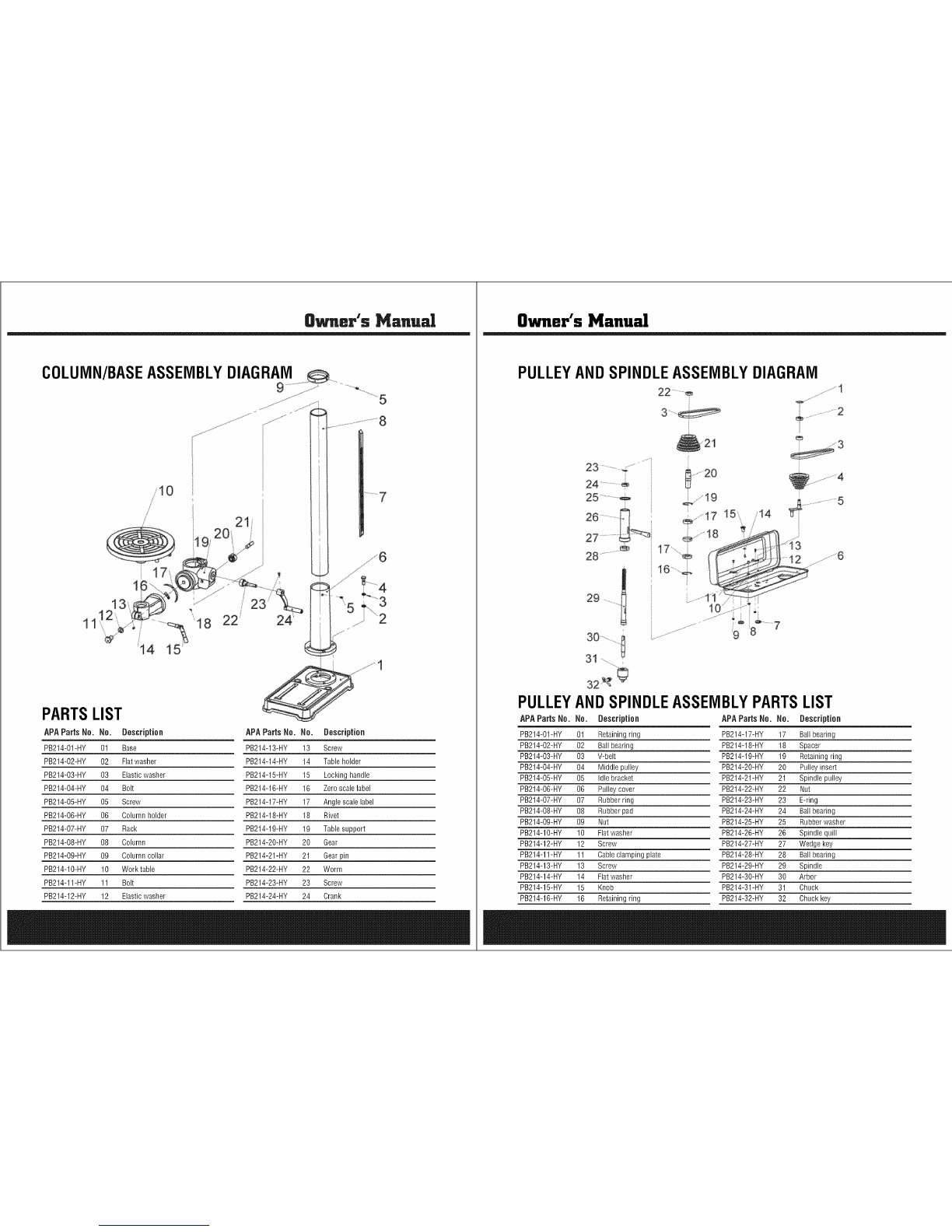

ASSEMBLY

SETTINGSANDADJUSTMENTS

Table

Thetable maybe raised,loweredor swivelledaboutthe column, by looseningthetable support locking

handle(Fig.8). Adjust accordinglyusing the table crank,and re-tighten the locking handle. If the table

assembly movesstiffly when beingswivelledabout the column, loosen the uppercollar allen screw

(atthe rack)to allowthe collarto moveveryslightly, therebyproviding alittle more clearancebetween

rackand collar. Tightenthe allen screwwhen satisfied.Thetable may alsobeturned on its axis by

looseningthe pinch bolt at its' mountingshaft.

SpindleDepth

Locatedaroundthe spindle feedshaft isa DepthStop Collar,printedwith a graduatedscale.Thecollar

is capableof turning about the shaft and maybe lockedin placeby the lockingscrew. Thescale is

printed in both inchesand metric.To set adrilling depth: 1. With the powerOFF,lowerthe drill bit so

that it contactsthe work, and hold in that position. 2. Loosenthe lockingscrew andturn the collar so

that the measurementfor the depth of hole required is in line with the pointer (C). Lockthe collar in

this position usingthe locking screw. Thedrill is now setto drill holesto your predetermineddepth,

from that particular start point.

ChangingDrill Speed

Beforechanging the speed,makesure the machineisswitched OFF,and unplugged.Undothe Belt

TensionLocking Screwson either side ofthe headandturn leverclockwise to relieveany tension on

the belts. Referto the chartinsidethe belt coverinstallthe beltsin the positions correspondingto the

spindle speedrequired.Levelthe motor, on its bracket,awayfrom the head,by turning levercounter

clockwiseso that tension is appliedto the belts.

NOTE:Theidlerpulleywill 'float' sothat tension isequallyappliedto both belts.Tensioniscorrect when

the beltsdeflectbyapprox.1/2"attheir centerwhenusing reasonablethumb pressure.Lockthe motor in

this position usingthe two lockingscrews. If the belt should slip while drilling, adjust the belttension.

OPERATION

J,_ CAUTION I

Wearsafety eyewear and dustfilters or respirators while using this tool.

Insertthe drill bit intothe jaws of the chuck by approximately1".Becertainthat the jaws do not touch

theflutes ofthe drill. Beforetighteningthe chuck,makesurethat the drillbit iscenteredwithin the jaws.

Makesurethe tableheightand position isset sothat drilltravel is sufficientfor the job in hand.

Makesurethe work issecurelyclamped, or held in a drill vise boltedto the table. Neverhold it with

barehands.Severepersonalinjury may.becausedif the workpieceisforced out ofthe operator's hand,

anddamageto the machineincurred if the work strikes the column. Ifthe pieceis of irregular shape

andcannotbe laidflat on thetable, it should besecurelyblocked andclamped.Anytilting, twisting or

shifting, resultsnot only ina rough hole, but alsoincreasesdrill bitbreakage.

Forsmall workpiecesthat cannot beclampedto the table, usea Drill PressVise.The vise must be

clampedor boltedto thetable. Whendrilling completelythrough wood,always positiona pieceof scrap

wood betweenthe workpieceandthe table to preventsplintering on the undersideofthe workpieceas

the drill breaksthrough. Thescrap pieceofwood must makecontactwith the leftsideof the column.

Inaddition,setthedepth of drill travelso that the drill cannotpossiblycome into contactwith the table,

or, alignthe table so that the center hole is directly in line withthe drill bit. Whencompletely satisfied

thatthe setup is sound, lowerthe ChuckGuard into place,and switch the machineON.

Owner's Manual

Insert KEYinto switch. Keyis madeof yellow plastic. A light isalso providedwhich is built into the

head.Thelight switch is locatedabovethe ON/OFFswitch.

REMOVINGTHECHUCK

To removethe chuck,pull the spindledownfully, usingthefeed handles.Theslot inthe sideofthe Quill

will becomevisible. Notethe position of the chuck,perhapsby placinga chalkmark, in linewith the

chuck, onthe column,then raisethe table sothat it is onlyan inch or so belowthe position marked.

Placeathick cloth,or similar material,onthetableto catchthe chuck,to preventdamagewhenit drops.

Pull down the spindleonce more, until the slot in the Quilltube is visible. Insertthe drift wedgeinto

the slot and giveit a sharp tap, preferablywith a copper hammer.This will breakthe sealbetweenthe

quill tubeand the arbor, allowingthe chuckto fall free,on to the cloth onthe table.To disconnectthe

chuckfrom the arbor, giveit a sharp rapwith a soft headmallet to breakthe taper seal.

NOTE:Morsetaper drills (MTS), mayalso beusedwith this machine,and areinserted intothe Quillto

replacethe arbor. Removalis the sameasthat for removingthe chuck.

[AWASNIN6 I

Disconnectthe powersupplybeforecleaning.Wearsafelyeyewearbeforecleaning.Usedcompressed

dry air to blow off dust and debris. Usea soft bristle brush if compressed air is notavailable.

Applying excessive force I CAUTION I

to the tool can overload the motor, decreasethe life and increase the

wear onthe too.

Some chemicals candamagethe I CAUTION I

product. De oatuse harshchemicals suchas gasoline, carbon

tetrach or de, pa at th ooer,etc. I CAUTIONI

Aqualifiedrepairtechnicianmostperiormanytoolserviceorrepair.Serviceor maintenanceperformed

by unquafifiedpersonnencoundresuntin injury'.Useonnyidenticalreplacementparts.Useof unauthorized

parts or fa ureto fo ow ma ntenance nstruct ons maycreatea rsk of e ectrc shock or nury.

I_WARNiNG I

Do not make contactwith agroooded so#ace while osing drill press.

Contactwith surfaceslike pipes,radiators or major appliancesincreaseyour risk ofelectric shock.

TheDrill Pressmust be properly maintainedfor maximum performance.Always inspectbeforeuse.

Anydamageshould be repaired,and faults rectified. Pleaserefer to the troubleshooting chart. If you

areunableto correctany problems, pleasecontactcustomer service.

Monthly(Whenin constant use)

1. Checktightness of mounting bolts,and headand column securing setscrews.

2. Checkbeltfor wear and replaceif frayed or damagedin anyway.

3. Blow out any dustthat may haveaccumulated inthe motor fan.

4.Apply athin coatof wax pasteor lightoil to the tableand columnfor lubricationandto help prevent

corrosion.

Lubrication

All bearingsare packedwith greaseatthe factory and requirenofurther lubrication.After use, remove

allswarffrom the machineandthoroughly,cleanallsurfaces.Componentsshouldbedry,with machined

surfaces lightlyoiled. Always removedoll bits, and store in a safe place.