2 PennEngineering • www.pemnet.com

• Readtheinstructionscarefullybeforeusingthetool.

• Forallmaintenanceand/orrepairspleasecontactPennEngineeringanduseonlyoriginalspareparts.

PennEngineeringmaynotbeheldliablefordamagesfromdefectivepartscausedbyfailuretouse

orginalspareparts.

• Thetoolmustbeusedonlybyexpertworkers.

• Aprotectivevisorandglovesmustbeputonwhenusingthetool.

• Useequipmentrecommendedinthemaintenancechaptertodoanymaintenanceand/orregulationof

thetool.

• Fortoppingofftheoil,wesuggestusingonlyuidsinaccordancewiththefeaturesspeciedinthis

workingbook.

• Ifanydropofoiltouchesyourskin,youmustwashwithwaterandalkalinesoap.

• Thetoolcanbecarriedandwesuggestputtingitintoitsboxafterusing.

• Thetoolneedsathoroughsix-monthlyoverhaul.

• Repairingandcleaningoperationsmustbedonewhenthetoolisnotfed.

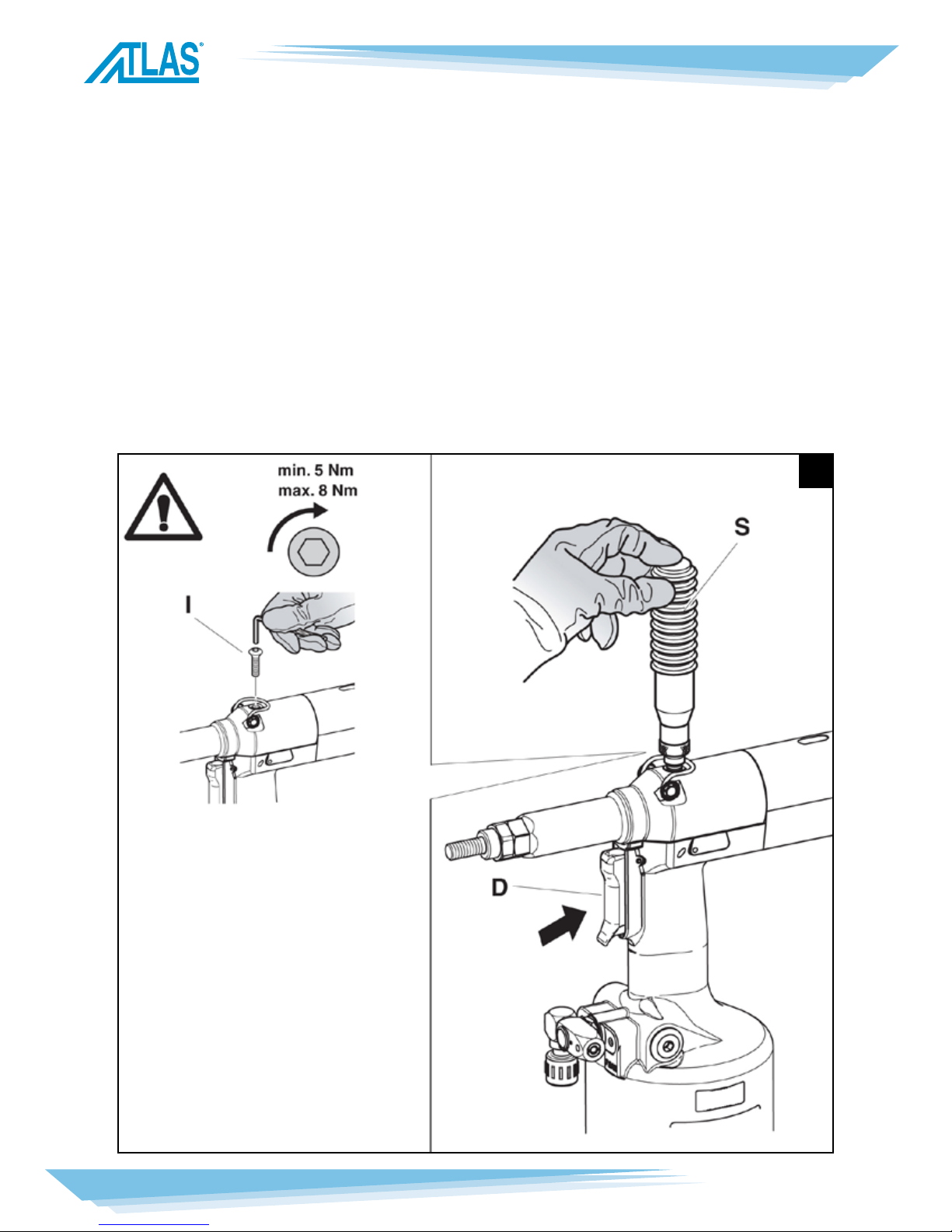

• Ifitispossible,wesuggestasafetybalancer.

• ThetoolismadesothatacousticpressurelevelcontinuousequivalentweightedAisnotmorethan75

dB(A)wherepeopleworks.

• Ifthenoiselevelismorethan85dB(A),youmustusesomehearingprotections(anti-noiseheadset,

etc.).

• Theworkbenchandtheworksurfacemustbealwayscleanandtidy.

• Donotallowunauthorizedpersonstousetheworkingtools.

• Makeyousurethatthecompressedairfeedinghoseshavethecorrectsizetobeused.

• Donotcarrytheconnectedtoolbypullingthehose.Theholemustbefarfromanyheatingsourcesor

fromcuttingparts.

• Keepthetoolsingoodconditions;donotremoveeithersafetypartsorsilencers.

• Afterrepairingand/oradjusting,makesureyouhavealreadyremovedtheadjustingspanners.

• Beforedisconnectingthecompressedairhosefromthetoolmakesurethatthereisnopressureinthe

hose.

• Theseinstructionsmustbecarefullyfollowed.

GENERAL NOTES AND USE

ThetoolcanbeemployedonlyforthreadedinsertswiththreadofM4toM12diameter.TheAE45oil

pneumaticsystemassuresmorepowerthanthepneumaticsystemusedforothermodels.Thatmeansa

reductionintheproblemsduetothewearandtearofthecomponents,therefore,therewillbeanincrease

inreliability.Thetechnicaisolutionsadoptedreducethedimensionsandtheweightofthetoolwhich,for

thesereasons,makeitveryhandy.Thepossibilitiesofleakagefromtheoil-dynamicsystem,areeliminated

bysomesealedgaskets,whichsolvethisproblem.

SAFETY MEASURES AND REQUIREMENTS