Read and understand all instructions.

Safetyrulesfor laserlights

The laser guide used in the tool is Class I with a

maximum output of ? 1mw and a wavelength of

650nm. The laser guide does not normally present

an optical hazard, although staring at the beam may

cause flash blindness.

USER INFORMATION

CAUTION.The use of optical instruments with

this laser product will increase the chance of eye

damage.

•Do not stare into the laser beam.

•The laser shall be used and maintained in

accordance with the manufacturer’s instructions.

•Never aim the beam at any person or an object

other than the work piece.

•Always ensure the laser beam is aimed at a

sturdy work piece without a reflective surface,

i.e. wood or rough coated surfaces are

acceptable. Bright shiny reflective sheet or the

like is not suitable for laser use as the reflective

surface could direct the beam back at the

operator.

General safety instructions

WARNING.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal

injury.

Save these instructions.

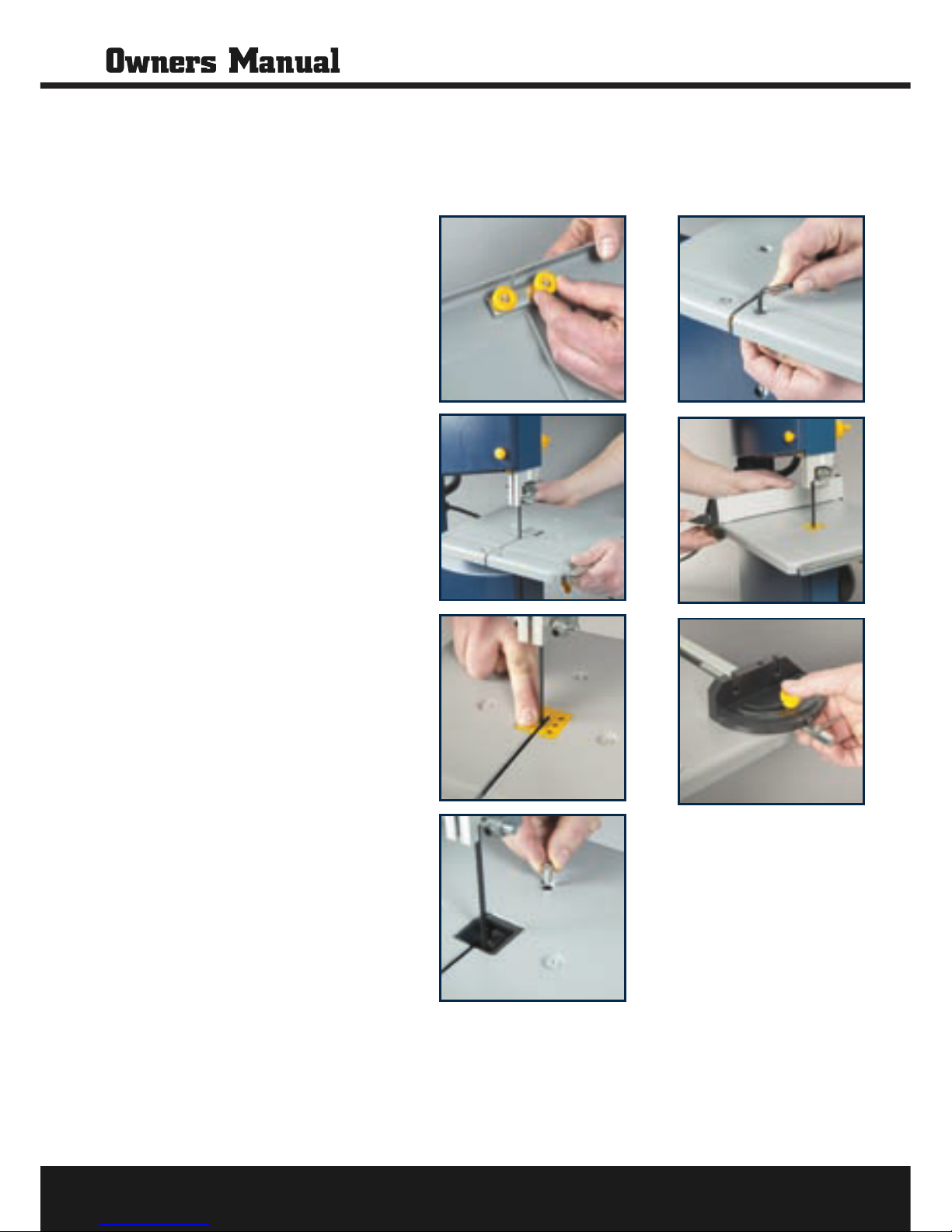

1. Keep guards in place and in working order.

2. Remove adjusting keys and wrenches.

3. Keep work area clean.Cluttered areas and benches

invite accidents.

4. Don’t use in dangerous environment. Don’t use

power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

5. Keep children away. All visitors should be kept

safe distance from work area.

6. Make the workshop kid proof with padlocks,

master switches, or by removing starter keys.

7. Don’t force the tool. It will do the job better and

safer at the rate for which it was designed.

8. Use the right tool. Don’t force tool or attachment

to do a job for which it was not designed.

9. Use the proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. The table on page 7 of this manual

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage

number, the heavier the cord.

10. Wear proper apparel. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair.

11. Always use safety glasses. Also use face or

dust mask if cutting operating is dusty.

Everyday eyeglasses only have impact

resistant lenses: they are not safety glasses.

12. Secure work. Use clamps or a vise to hold

work when practical. It’s safer than using your

hand and it frees both hands to operate the tool.

13. Don’t overreach. Keep proper footing and

balance at all times.

4