SafetySafety

32

■Damage to hearing if effective hearing protection is not

worn.

INTENDED USE

This machine is designed to rip and cross cut wood

exclusively up to maximum thickness of 80 mm.

For correct operation it must be xed and operated as

explained in this manual.

MAINTENANCE

Do not make any adjustments while the motor is in motion.

Always make sure the machines plug has been removed

from the mains power source before changing brushes,

lubricating or when doing any works or maintenance

on the machine. After each use, check your machine

for damage or broken parts and keep it in top working

condition by repairing or replacing parts immediately. Clean

out accumulated dust. To assure safety and reliability, all

repairs with the exception of externally accessible brushes

should be performed by an authorised service centre.

Faults in the machine, including guards or saw blades,

should be reported as soon as they are discovered.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing

of as waste. The machine, accessories

and packaging should be sorted for

environmental-friendly recycling.

SYMBOL

Safety alert

V Volts

Hz Hertz

Alternating current

WWatts

noNo-load speed

min-1Revolutions or reciprocations per minute

CE conformity

Double insulation

Please read the instructions carefully before

starting the machine.

Wear ear protection

Wear eye protection

Danger! Sharp blade.

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

ICONS IN THIS MANUAL

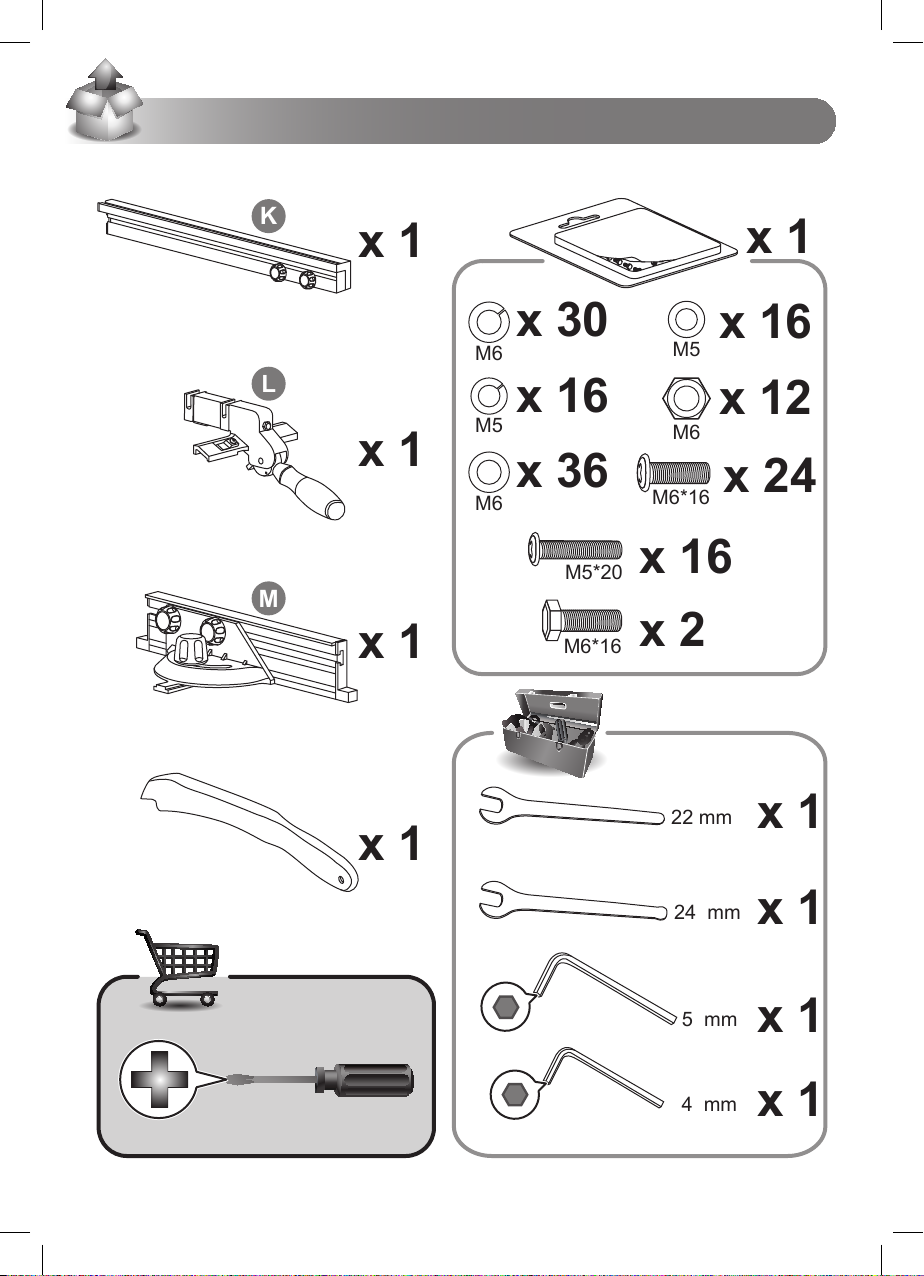

Unpacking

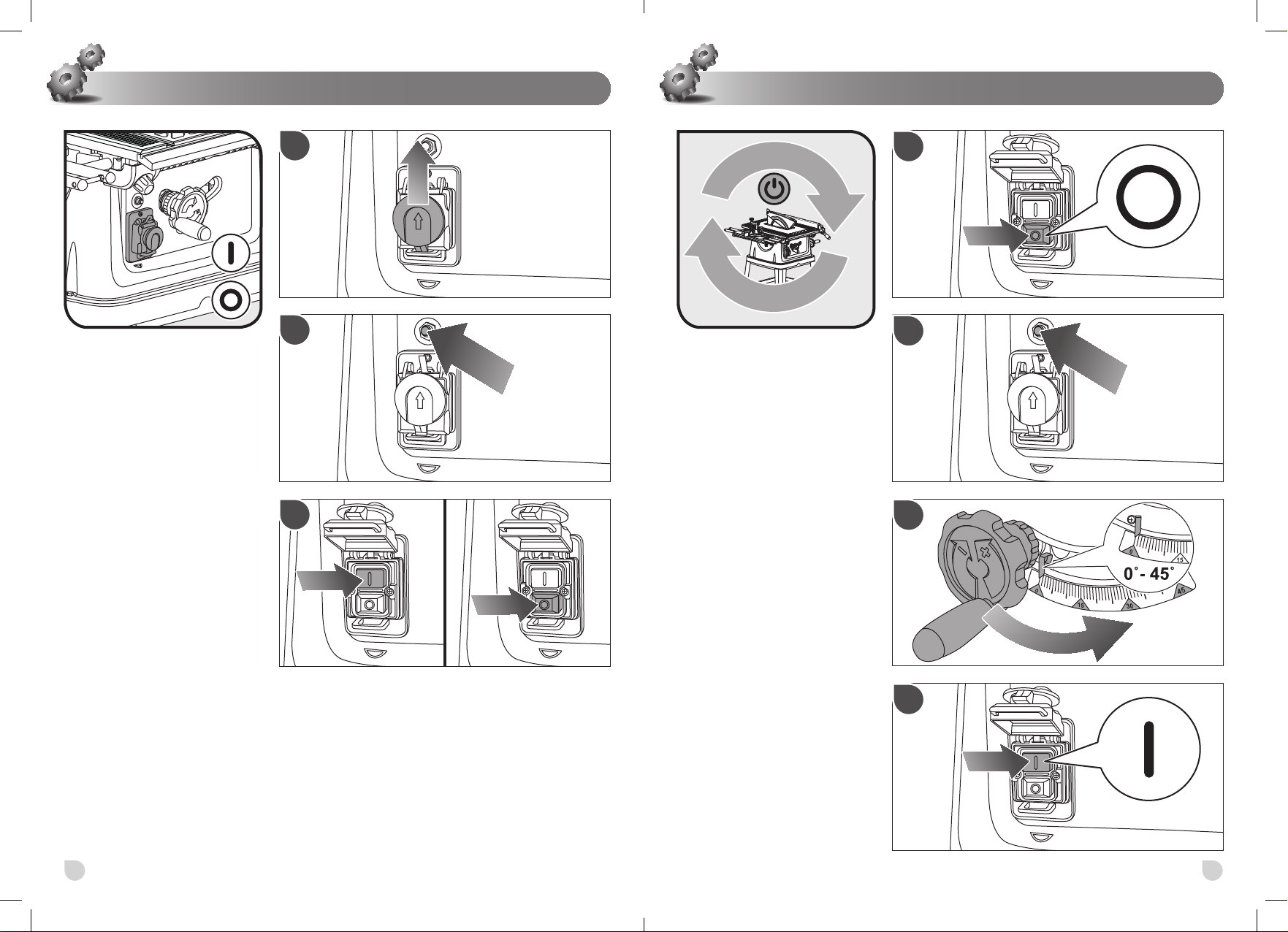

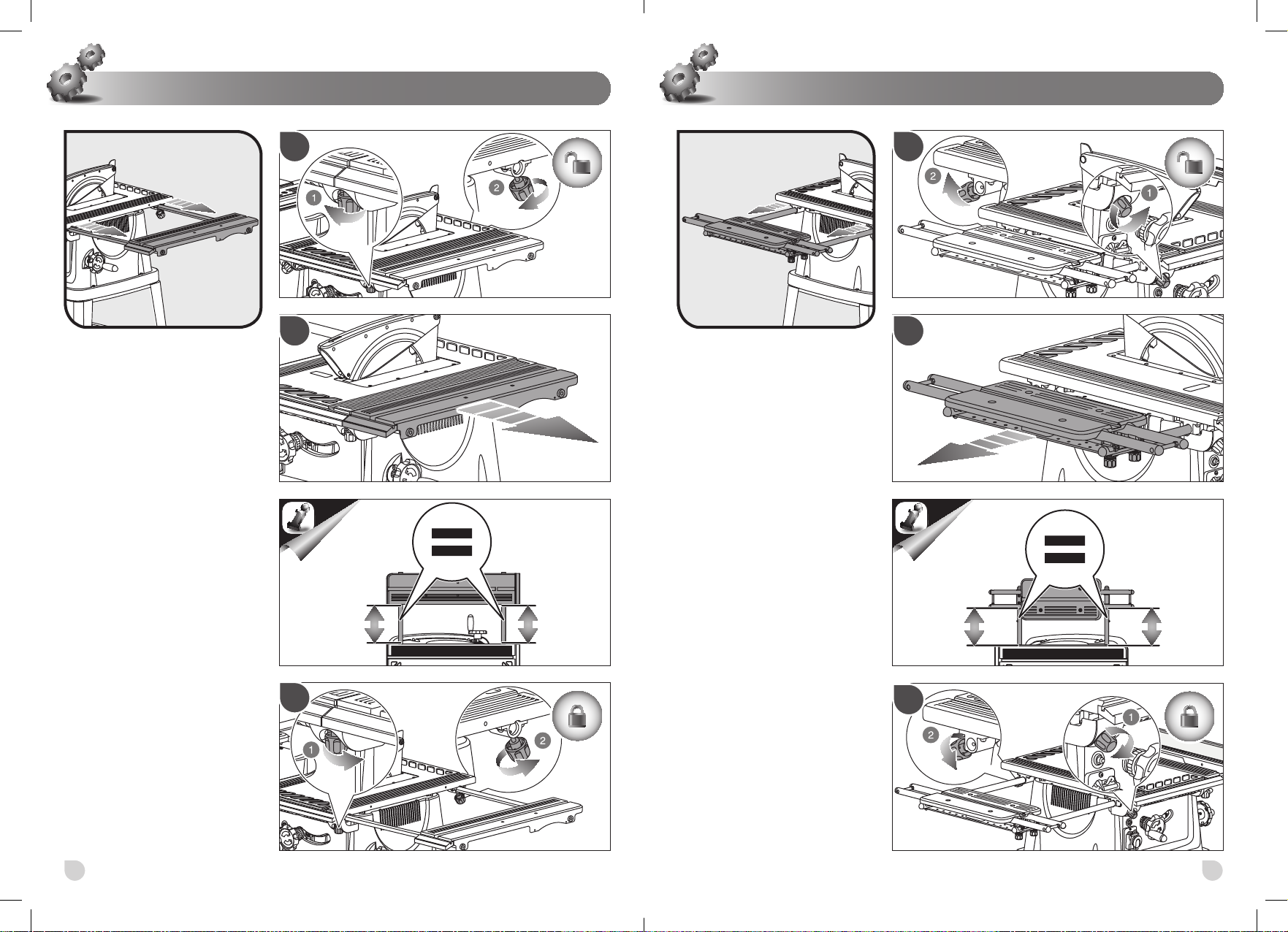

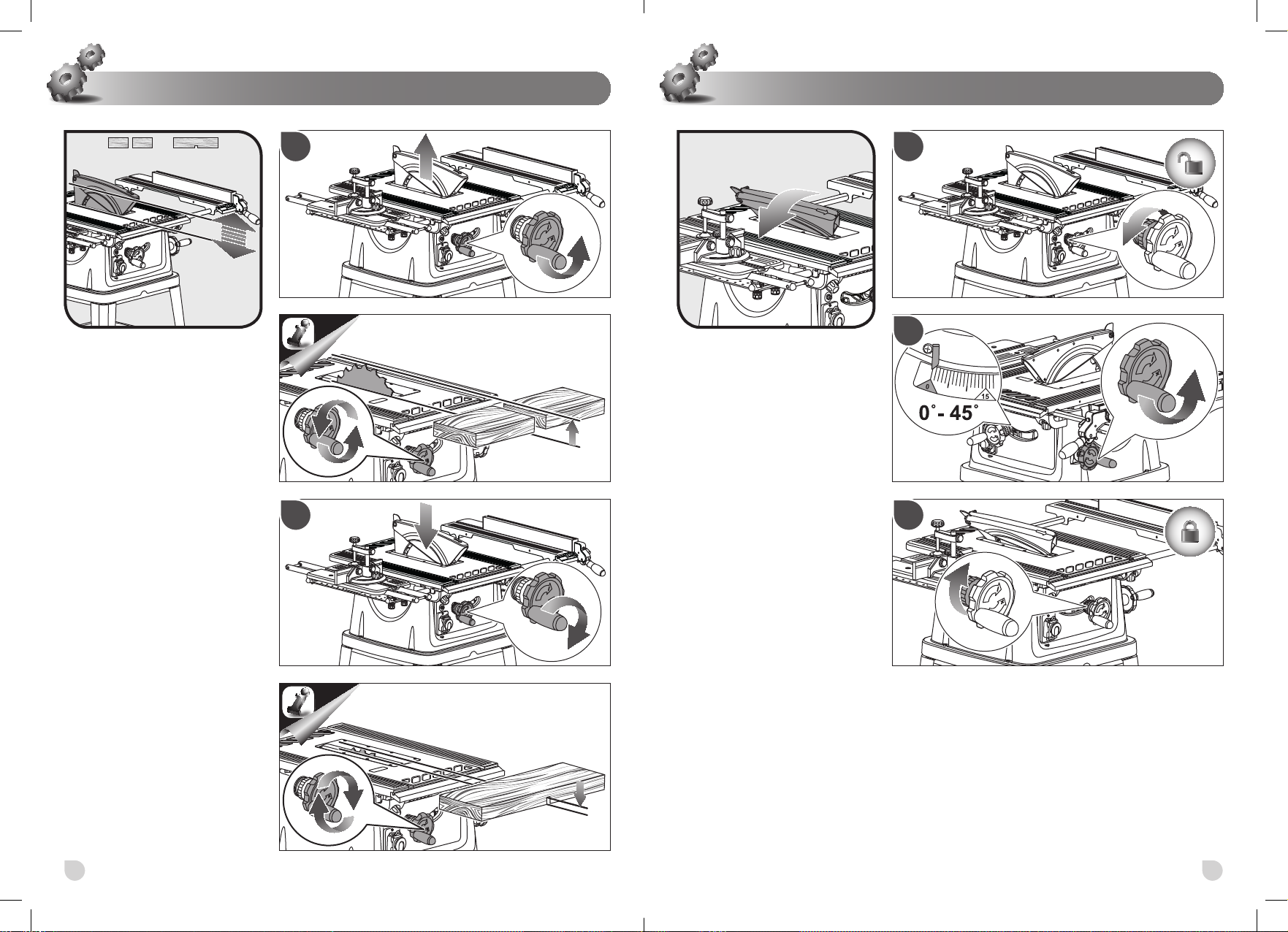

Getting started

Tools needed

Procedure search

Go to page #

Safety

Operation

Safety alert

Unplug

Information

Lock

Unlock

Waiting time

Wear safety hand gloves

changing the saw blade, make sure that the width of

the cut is wider than the body of the blade, which in turn

should not be wider than the thickness of the riving knife.

■It is necessary to select a saw blade which is suitable

for the material being cut.

■Wear suitable personal protective equipment when

necessary, this could include hearing protection to

reduce the risk of induced hearing loss, respiratory

protection to reduce the risk of inhaling harmful dust,

gloves when handling saw blades and rough material.

■Saw blades should be carried in a holder whenever

practicable.

■The dust produced when using this tool may be harmful

to health. Do not inhale the dust. Use a dust absorption

system and wear a suitable dust protection mask. Remove

deposited dust thoroughly, e.g., with a vacuum cleaner.

■Do not use saw blades made of high-speed steel.

■Use the push stick when required. Always use a push

stick for ripping narrow timber. The push stick should

always be stored with the machine when not in use.

■Always use the saw blade guard and riving knife for

every operation, including through sawing. Through

sawing operations are those in which the blade cuts

completely through the work piece when ripping or

cross-cutting.

■Cutting rebates or grooves is only permitted with a

suitable protective device fitted, e.g., a protective tunnel

over the saw table.

■Do not use circular saws for cutting slots (grooves in

work piece).

■Use only saw blades in which the maximum possible

speed is not less than the maximum spindle speed of

the tool and the material to be cut.

■When transporting the machine, use only transportation

devices and never use guards for handling or transportation.

■During transportation, the upper part of the saw blade

should be covered, for example, by the guard.

■Secure work. Use clamps or a vise to hold work when

practical. It is safer than using your hand and frees both

hands to operate the tool.

■Dust developing during operation can be harmful to

your health, inflammable or explosive. Never cut metals

or materials which may create hazardous dust.

■Always use in a well-ventilated area. Remove sawdust

frequently. Clean out sawdust from the interior of the

saw to prevent potential fire hazard.

■Keep the floor area free of loose material, e.g., chips

and cut-offs.

■Never leave tool running unattended. Turn power off.

Do not leave the tool until it comes to a complete stop.

■Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

■Appliances used at many different locations including

open air should be connected via a residual current

device (RCD).

■Ground all tools. If the tool is equipped with three-prong

plug, it should be plugged into a three-hole electrical

receptacle.

■Never stand on tool. Serious injury could occur if the tool

is tipped or if the cutting tool is unintentionally contacted.

■Always keep the blade guard and riving knife in place

and in working order.

■Only use the saw with guards in good working order

and properly maintained, and in position.

■Always keep hands away from the path of the saw blade.

■Never reach into the danger area of the plane when it

is running.

■Feed the work piece into the blade or cutter against the

direction of rotation only.

■Remove adjusting keys and wrenches. Form the habit

of checking to see that keys and adjusting wrenches

are removed from the tool before turning it on.

■Always saw one work piece at a time. Sawing more

than one work piece at a time may jam the saw blade or

cause slipping of work pieces.

■Always use either the fence or the mitre gauge to

position and guide.

■When blade is running or when interrupting a cut, release

the trigger and hold the saw motionless until the blade

comes to a complete stop. Never attempt to remove the

saw from the work piece or pull the saw backward while

the blade is in motion or kickback may occur.

■Do not touch the saw blade immediately after sawing.

The saw blade gets hot during sawing.

■Do not use with any covers/guards removed.

■Use only saw blades recommended by the manufacturer.

■Always use the correct adjustment of the blade guard

and riving knife.

■Make sure the distance between the saw and the riving

knife is less than 5mm.

■The noise load is determined by the material to be

sawed as well as the saw blade type.

■Troubles in the machine, including the protective equipment

and the saw blade, are to be reported to the person

responsible for the safety once they are discovered.

RESIDUAL RISKS

Even when the machine is used as prescribed, it is still

impossible to completely eliminate certain residual risk

factors. The following hazards may arise in connection with

the machine’s construction and design:

■Contact with the saw blade in the uncovered saw zone.

■Reaching into the running saw blade (cut injuries).

■Kick-back of workpieces and parts of workpieces due to

improper handling.

■Saw blade fracturing.

■Catapulting of faulty carbide tips from the saw blade.

■Damage to lungs if effective dust mask is not worn.