SteelMax S14 User manual

1

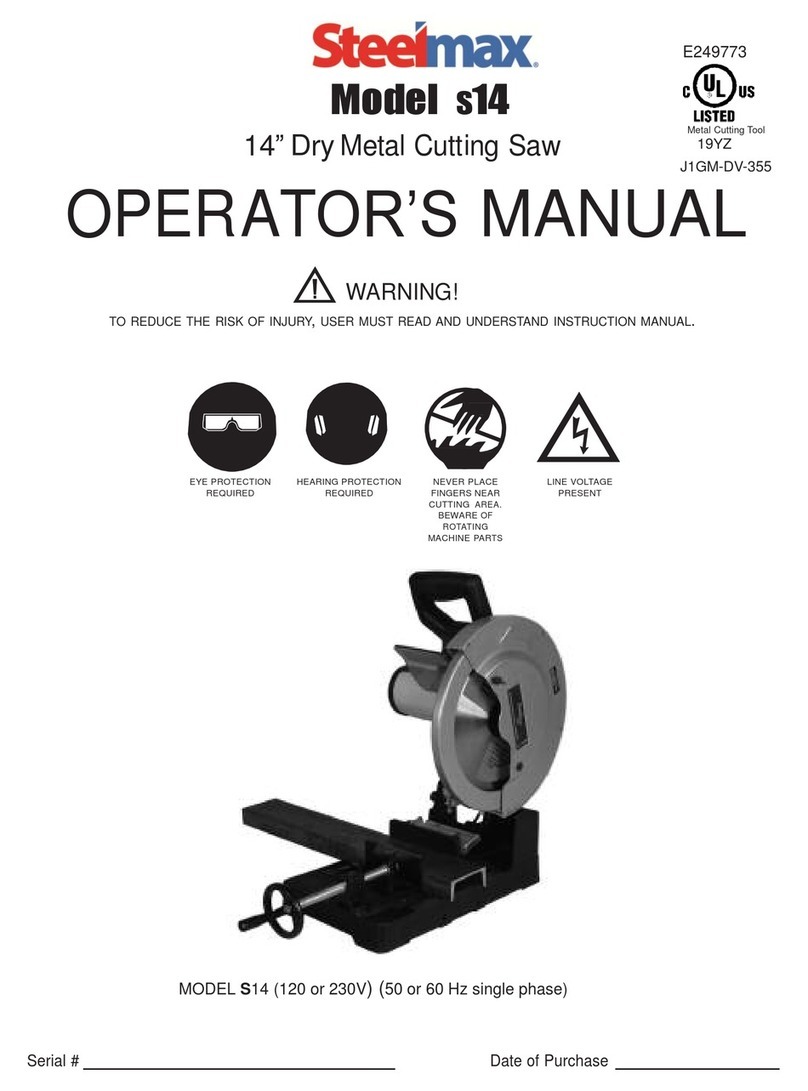

Model S14

350mm Dry Metal Cutting Saw

OPERATOR’S MANUAL

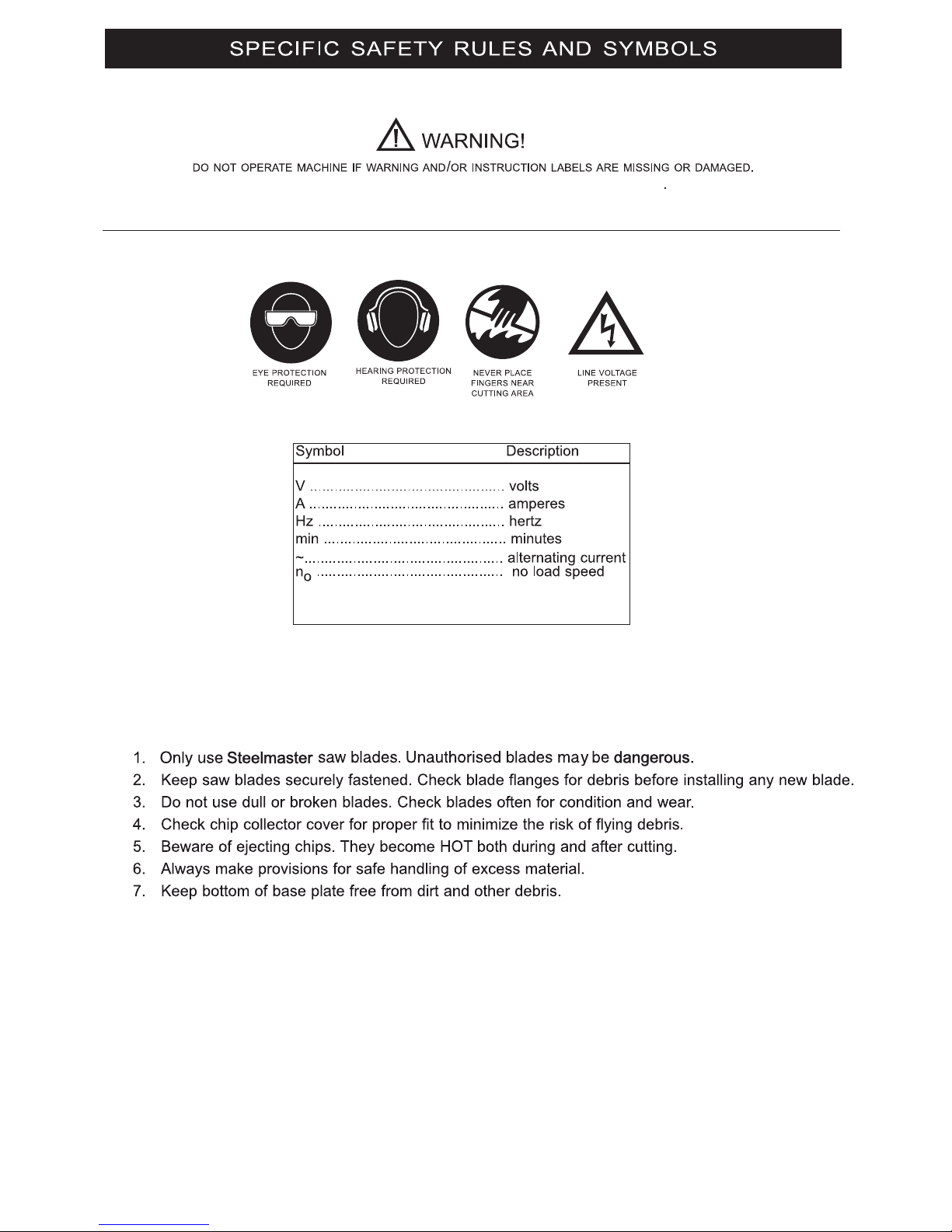

EYE PROTECTION

REQUIRED

HEARING PROTECTION

REQUIRED

Serial # Date of Purachse

WARNING!

TO REDUCE THE RISK OF INJURY,USER MUST READ AND UNDERSTAND INSTRUCTION MANUAL.

NEVER PLACE

FINGERS NEAR

CUTTING AREA.

BEWARE OF

ROTATING

MACHINE PARTS

LINE VOLTAGE

PRESENT

MODEL S14 (240V)

2

350mm Dry Metal Cutting Saw

Congratulations on your purchase of your SteelMaster brand Dry Metal Cutting Saw.

TABLE OF CONTENTS

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Safety Rules and Specific Instructions . . . . . . . .3- 4

Specific Safety Rules and Symbols . . . . . . . . . . . . . . . .5 -7

Functional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Assembly View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Emptying the Chip Chamber . . . . . . . . . . . . . . . . . . . . . .13

M a i n t e n a n c e / C h a n g i n g S a w B l a d e s . . . . . . . . . . . . . . 14

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . .15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2

LIMITED WARRANTY

Industrial Tool & Machinery Sales (hereinafter refered to as ITMS) will, within twelve (12) months from the original

date of purchase, repair or replace any goods found to be defective in materials or workmanship.

This warranty is void if the item has been damaged by accident, neglect, overload of tool, improper use,

improper service or other causes not arising out of defects in materials or workmanship.

This warranty does not apply to machines and/or components which have been altered, changed, or modified in any way,

or subjected to use beyond recommended capacities and specifications.

Electrical components are subject to respective manufacturers’ warranties. All goods returned defective

shall be returned prepaid freight to ITMS or agreed repair agent, which shall be the buyer’s sole and exclusive

remedy for defective goods. ITMS accepts no additional liability pursuant to this guarantee for the costs of travelling

or transportation of the product or parts to and from ITMS or the service agent or dealer, such costs are not included

THE MANUFACTURER RESERVES THE RIGHT TO MAKE

IMPROVEMENTS AND MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

350mm Dry Metal Cutting Saw

Congratulations on your purchase of your SteelMaster brand Dry Metal Cutting Saw.

TABLE OF CONTENTS

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Safety Rules and Specific Instructions . . . . . . . .3- 4

Specific Safety Rules and Symbols . . . . . . . . . . . . . . . .5 -7

Functional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Assembly View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Emptying the Chip Chamber . . . . . . . . . . . . . . . . . . . . . .13

M a i n t e n a n c e / C h a n g i n g S a w B l a d e s . . . . . . . . . . . . . . 14

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . .15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2

LIMITED WARRANTY

Industrial Tool & Machinery Sales (hereinafter refered to as ITMS) will, within twelve (12) months from the original

date of purchase, repair or replace any goods found to be defective in materials or workmanship.

This warranty is void if the item has been damaged by accident, neglect, overload of tool, improper use,

improper service or other causes not arising out of defects in materials or workmanship.

This warranty does not apply to machines and/or components which have been altered, changed, or modified in any way,

or subjected to use beyond recommended capacities and specifications.

Electrical components are subject to respective manufacturers’ warranties. All goods returned defective

shall be returned prepaid freight to ITMS or agreed repair agent, which shall be the buyer’s sole and exclusive

remedy for defective goods. ITMS accepts no additional liability pursuant to this guarantee for the costs of travelling

or transportation of the product or parts to and from ITMS or the service agent or dealer, such costs are not included

THE MANUFACTURER RESERVES THE RIGHT TO MAKE

IMPROVEMENTS AND MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

SteelMax

Our goods come with guarantees which cannot be excluded under the Australian Consumer Law.

You are entitled to replacement or refund for a major failure and to compensation for other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount to a major failure.

.

3

15 amp extension cord not exceeding 15 Metres.

only .

4

5

6

- DANGER! — Keep hands and body away from and to the side of the blade. Contact with blade will result in

serious injury.

- WARNING! — To reduce the risk of injury, check lower guard. It must close instantly! Keep free hand away

from blade at all times during operation. Support and clamp work. Wear eye and hearing protection.

Additional Specific Safety Rules:

DANGER! Keep hands away from cutting area and blade. Keep your second hand on auxiliary handle, or motor

housing. If both hands are holding the saw, they cannot be cut by the blade.

•Keep your body positioned to either side of the saw blade, but not in line with the saw blade. KICKBACK could

cause the material to jump backwards. (See "Causes and Operator Prevention of Kickback.")

•Do not reach underneath the work. The guard can not protect you from the blade below the work.

•Check lower guard for proper closing before each use. Do not operate saw if lower guard does not move freely

and close instantly. Never clamp or tie the lower guard into the open position. If saw is accidentally dropped,

lower guard may be bent. Raise the lower guard and make sure it moves freely and does not touch the blade or

any other part, at all angles and depths of cut.

•Check the operation and condition of the lower guard spring. If the guard and the spring are not operating

properly, they must be serviced before use. Lower guard may operate sluggishly due to damaged parts, gummy

deposits, or a buildup of debris.

•An unprotected, coasting blade will cause the saw to cut whatever is in its path. Be aware of the time it takes

for the blade to stop after switch is released.

•NEVER hold piece being cut in your hands. It is important to support the work properly to minimize body

exposure, blade binding, or loss of control.

•Contact with a "live" wire will also make exposed metal parts of the tool "live" and shock the operator.

•Always use blades with correct size and shape arbor holes. Blades that do not match the mounting hardware of

the saw will run eccentrically, causing loss of control.

•Never use damaged or incorrect blade washer or bolts. The blade washer and bolt were specially designed

for your saw, for optimum performance and safety of operation.

•Always clamp workpiece in vise and check security of vise bolts and position often. Vise can loosen due to

vibration.

SPECIFIC SAFETY RULES (continued)

6

7

Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an uncontrolled

workpiece to lift up and out of the saw toward the operator. When the blade is pinched or bound

tightly by the kerf (saw cut) closing down, the blade stalls and the motor reaction drives the workpiece

rapidly backward. If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of

the blade can dig into the top surface of the material causing the material to climb out of the blade

and jump back toward operator. Kickback is the result of tool misuse and/or incorrect operating pro-

cedures or conditions and can be avoided by taking proper precautions as given below:

Maintain a firm grip with both hands on the saw. KICKBACK forces can be controlled by the operator,

if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the

saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the

workpiece from the saw or pull the material backward while the blade is in motion or KICKBACK may

occur. Investigate and take corrective actions to eliminate the cause of blade binding.

When restarting a saw in the workpiece, center the saw blade in the kerf and check that saw teeth

are not engaged into the material. If saw blade is binding, it may walk up or KICKBACK from the

workpiece as the saw is restarted.

Support large panels to minimize the risk of blade pinching and KICKBACK. Large panels tend to sag

under their own weight. Supports must be placed under the panel on both sides, near the line of cut

and near the edge of the panel.

Do not use dull or damaged blade. Dull or improperly set blades produce narrow kerf causing

excessive friction, blade binding and KICKBACK.

Blade depth and miter adjusting locking levers must be tight and secure before making a cut. If blade

adjustment shifts while cutting, it may cause binding and KICKBACK.

SPECIFIC SAFETY RULES (continued)

7

CAUSES AND OPERATOR PREVENTION OF KICKBACK

8

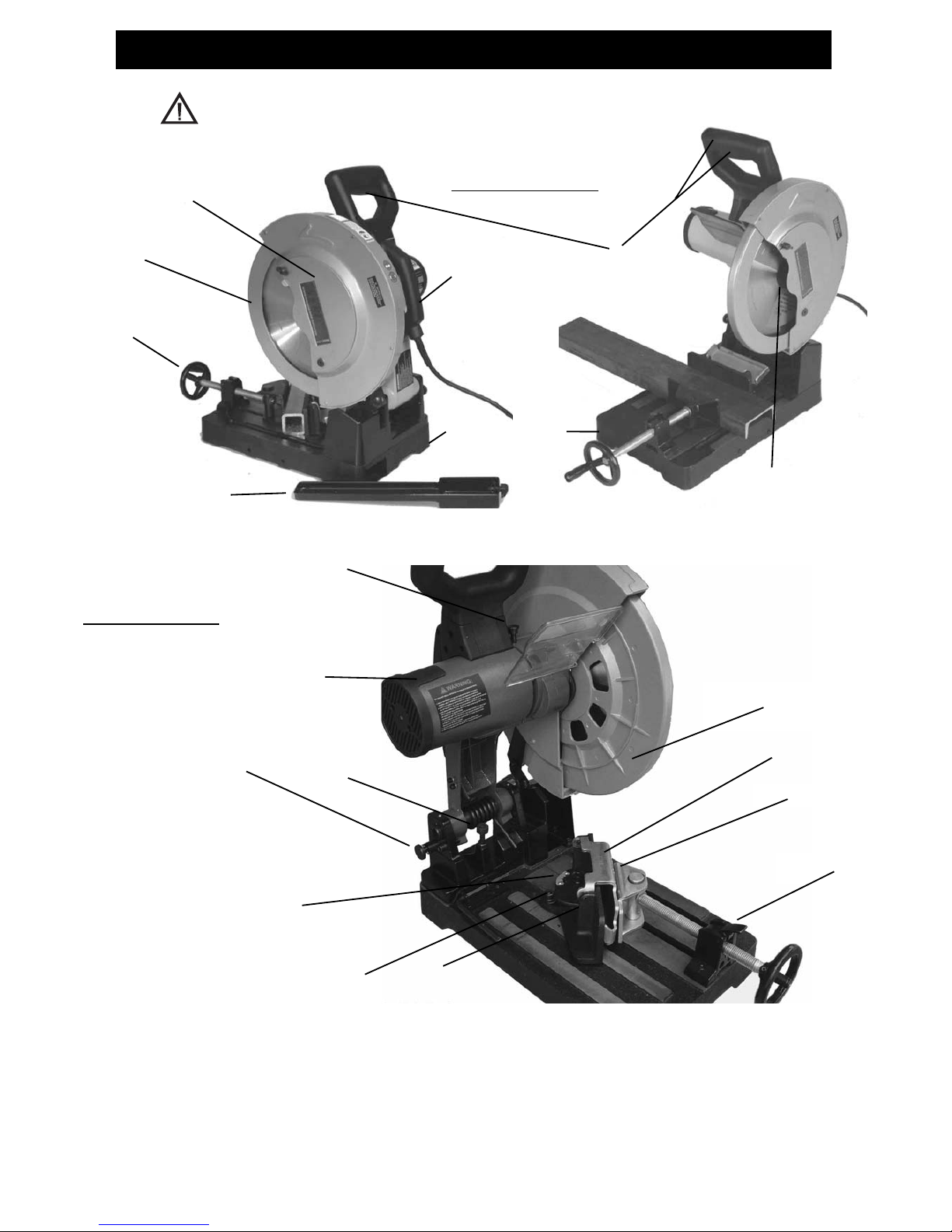

FUNCTIONAL DRAWINGS

8

Metal Cutting Saw

Blade

Chip Collector Tray

Miter Lock Bolts

Vise Jaw

Blade Depth

Adjustment Bolt

Vise Wheel

Handle

Blade Lock

Carbon Brushes

(Inside Cover)

Vise Clamp

Blade Guard

L

EFT

S

IDE

V

IEW

Auxiliary

Handle

R

IGHT

S

IDE

V

IEW

Trigger Switch and

Lock

Pipe Swivel

Vise

Blade Drive

Mounting Bolt

Swivel Guard

Miter Scale

Transport Lock

Vise Plate

Cast Iron Base

Caution! Always unplug saw before changing blades, servicing or adjusting saw.

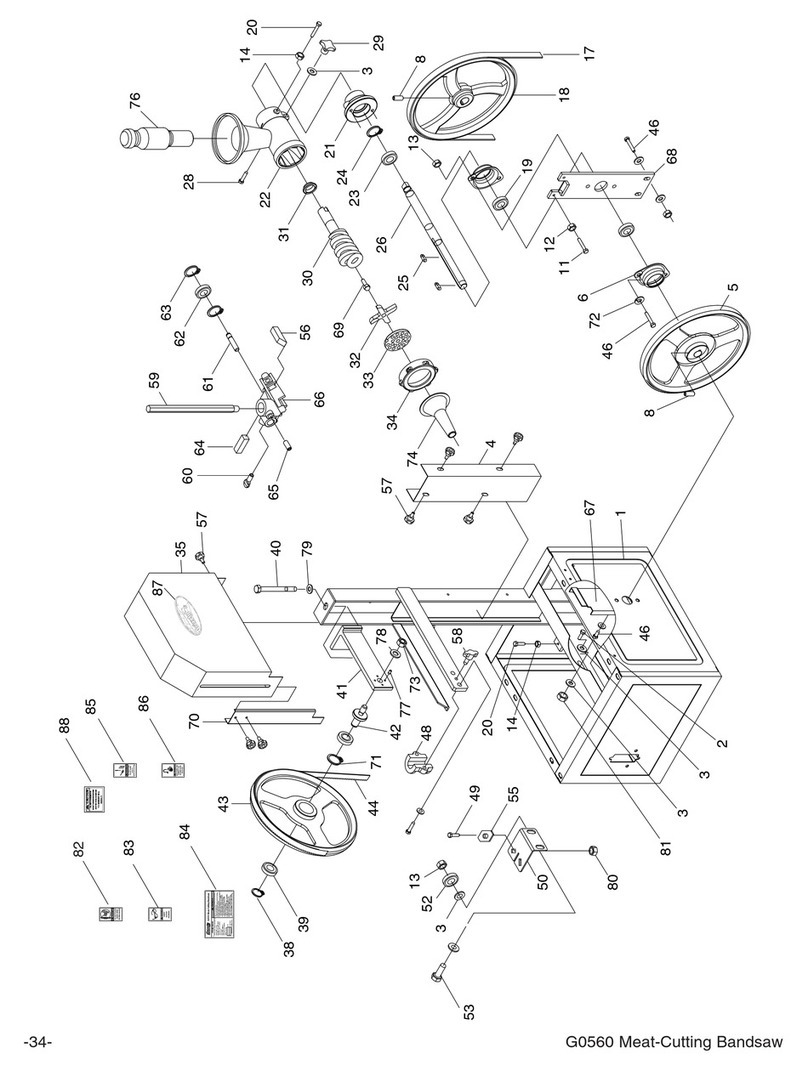

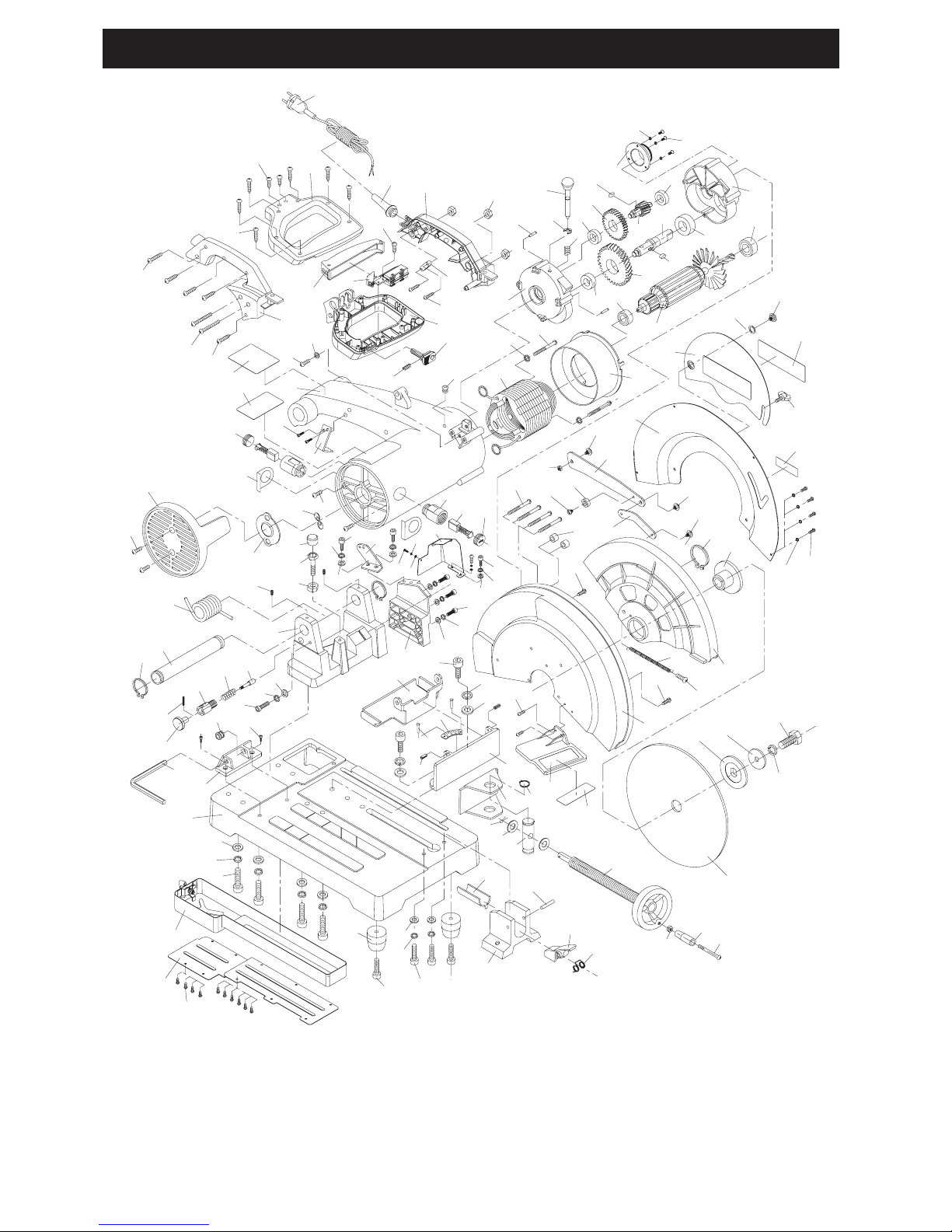

9

EXPLODED VIEW

9

42

92

151

149

148

13

115

112

54

1

2

6

7

32

3

33

4

5

60

61

62

56

31

117

110

38

40

35

37

44

58

137

136

139

138

65

66

8

9

10

12

11

34

36

41

39

43 45

46

47

48

50

51

52

53

55

57

49

59

63

67

68 69 70

76

79

77

80 105

106

107

108

109

113

114

116

118 119

120

122

124

125

126

129

130

131

133

134

135

140

141

142

143

146

147

150

144

127 128

145

81

82

83

72

71

73

74 75

104

102

100

99

98

96 97

103

101

21 20

22

25

28

19

26

30

14

15

18

16

17

23

24

29

27

88

89

90

91

111

64

78

121

132

123

152

85

87

86

93

94

95

154

155

166

153

160

161

162

156

157

158

165

159

163

164

167

0

30

45

15

10

.ytQ#traPnoitpircseDmetI

PARTS LIST

10

2SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

51X5MWERCS1

1REVOCDNE2

3 1PACGNIRAEB

201X5MWERCS4

2DAPREPAP5

1ETALPEMAN6

251X5MWERCSXEH7

1TIMILHTPED8

1GNISUOHROTOM9

1

2

3

4

5

6

7

8

9

1LEBALGNINRAW01

1REHSAWGNIRPS11

101X5MWERCS21

1GNIRPS31

1HCTIWSBMUHT41

1 1FLAHMOTTOB-ELDNAH5

121X2.4TSWERCS61

1HCTIWSNIAM71

1 1ELDDAPHCTIWS8

1FLAHTFEL-ELDNAHYRRAC91

2 152X2.4TSWERCS0

2 206X5MWERCS1

103X5MWERCS22

991X2.4TSWERCS32

2 1FLAHPOT-ELDNAH4

1DROCREWOP52

26 1TOOBDROC

1FLAHTHGIR-ELDNAHYRRAC72

28 251X2.4TSWERCS

29 CORD CLAMP 1

35MTUN03

1EVEELSREBBUR13

2REDLOHHSURB23

33 CARBON BRUSH 2

2PACHSURB43

35 S 1ROTAT

25REHSAWGNIRPS63

208X5MWERCS73

38 WIND BAFFLE 1

1GNIRAEB93

1ERUTAMRA04

41 BEARING 1

42 1TFEL-GNISUOHRAEG

281X4ANIP34

1GNIRPS44

18GNIRGNINIATER54

1KCOLELDNIPS64

47 BEARING (6000) 1

48 1RAEGRELLAMS

121X5YEK94

1TFAHSRAEG05

1)0026(GNIRAEB15

52 BEARING (6001) 1

53 BIGGER GEAR 1

54 KEY 6X12 1

1TFAHSTUPTUO55

1)4026(GNIRAEB65

1THGIR-GNISUOHRAEG75

1PACGNIRAEB85

321X4MWERCS95

60 RETAINING RING 14 2

1SIXAMRA16

62 1GNIRPSDAOL

63 PIVOTING ARM BASE 1

231X5MWERCS46

18MTUN56

105X8MTLOB66

26REHSAW76

26REHSAWGNIRPS86

69 HEX SCREW M6X20 2

1TAESLEVELGNITCARTER07

71 1KCOLTROPSNART

72 PIN 3X18 1

1TAESKCOL37

1GNIRPS47

1NIP57

1MM8HCNERWXEH67

1TAESHCNERW77

78 RETAINING RUBBER 1

251X5MWERCS97

1ESABWAS08

81 W 401REHSA

401REHSAWGNIRPS28

403X01MTLOBXEH38

01

11

21

31

41

15

61

71

18

91

20

21

22

32

24

52

26

72

28

29

03

13

23

33

43

35

63

73

38

93

04

41

42

34

44

54

64

47

48

94

05

15

52

53

54

55

65

75

85

95

60

16

62

63

46

56

66

76

86

69

07

71

72

37

47

57

67

77

78

97

08

81

28

38

84 0

1SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/0

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

SS350/

8REHSAWGNIRPS58

18REHSAW68

153X8MTLOBXEH78

1ESIVLEVIWS88

28X3TEVIR98

1ELACSRETIM09

241X6NIP19

1ETALPESIV29

201REHSAW39

201REHSAWGNIRPS49

252X01MTLOBXEH59

1WAJESIV69

122GNIRGNINIATER79

162X3NIP89

221REHSAW99

58

68

78

88

98

09

19

29

39

49

59

69

79

89

99

1 1SIXAWAJESIV00

1ELDNAHDAERHT101

16MTUN201

1ELDNAHLEEHW301

145X6MWERCS401

1LEBALGNINRAW501

1NOITCETORPEYE601

221X4MWERCS701

1REVOCYTEFAS801

409X5MWERCS901

2REPPOTSREBBUR011

121X5MWERCS111

101X4MWERCS211

113 LOAD SPRING 1

101X4MWERCS411

1DRAUGGNITCARTERREWOL511

116 RETAINING RING 42 1

1EGNALFRENNI711

12WERCS811

1RELLORGNITCARTERDRAUG911

11REVEL021

15MTUN121

122 SCREW 4 1

1WERCS321

124 12REVEL

125 SCREW 3 1

1REVOCLEETS621

127 SPRING WASHER 4 4

401X4MWERCS821

129 W 1LEBALGNINRA

130 SWIVEL GUARD 1

131 W 1REHSA

132 1WERCS

133 1LEBALOGOL

1TUNGNIW431

1SSBL350-MSEDALBWAS531

1EGNALFRETUO631

1REHSAW731

101REHSAWGNIRPS831

152X01MTLOBXEH931

140 CHIP BOX 1

141 CHIP BOX SEAT 1

0101X4MWERCS241

2TOOFREBBUR341

144 253X8MTLOBXEH

28REHSAW541

28REHSAWGNIRPS641

203X8MTLOBXEH741

1NIP841

149 CLAMP 1

150 SUPPORT 1

1DAP151

141PILCGNIRPSGNIRAEB251

153 251X2.4TSWERCS

1PACTLOB451

1ESABLLAMS551

303X6MTLOBXEH651

36REHSAW751

158 SPRING W 36REHSA

159 STEEL COVER 1

151X5MWERCS061

15REHSAW161

15REHSAWGNIRPS261

281X6MTLOBXEH361

26REHSAWGNIRPS461

26REHSAW561

1PMALCGNIRPSDAOL661

167

1 00

101

201

301

401

501

601

701

801

901

011

111

211

113

411

511

116

711

811

911

021

121

122

321

124

125

621

127

821

129

130

131

132

133

431

63

1

731

831

931

140

141

241

341

144

541

641

741

841

149

150

151

251

153

451

551

651

751

158

159

061

161

261

361

461

561

661

167 3REHSAWGNIRPS

.ytQ#traPnoitpircseDmetI

11

Your SteelMaster® brand saw is shipped complete and protected inside its shipping box. Remove all contents from the

box and inspect to ensure no damage was incurred during shipping. Your SS350 Metal Cutter package should also

include the following:

ASSEMBLY

D E S C R I P T I O N P A R T #Q T Y

OPERATOR’S MANUAL

1

1

1

)2(SGULPRAE

SAFETY GOGGLES

1HCNERWMM8

14” STEEL BLADE (OPTIONAL) SSBL350-MS 1

GETTING STARTED

CAUTION!

ALWAYS DISCONNECT THE SAW FROM POWER SOURCE BEFORE MAKING ADJUSTMENTS.

Refer to the "Functional Description" on page 8 and "Exploded View” drawing on page 9. If required, install an

authorized metal cutting saw blade by first loosening wingnut (item 134) and rotating the swivel guard (item 130)

up and out of the way. Then loosening the 8mm blade hex bolt and remove the outer blade flange and washer.

Verify the correct seat of blade onto the inner blade flange lip. Always check blade installation for proper direc-

tion of rotation. From the front of saw, blade travels downward. Improper mounting will cause blade wobble and

a possible hazardous condition. Reinstall blade bolt and flanges. Position Swivel guard and secure with thumb

screw (item# 134).

11

Quick release

pipe vise

ADJUSTING THE VISE

The vise has two positions for optimal cutting and a

quick release swivel vise (item 88) for use with pipe, tub-

ing and round profiles. Always use the vise in the most

forward position that will completely cut through the

material. Smaller profiles can lift out of the vise more

easily when the vise is in the rear most position. Larger

material requires the vise be moved to the rear position.

To move the vise, proceed as follows:

Loosen the vise hex bolts and using the supplied 8mm

hex wrench. Move the vise to the desired position and

reinstall.

The thread vise wheel handle and movable vise jaw

should be positioned to tightly grip material to be cut. Vise Plate

Vise Jaw

SteelMax

S14

12

WHAT YOU SHOULD KNOW BEFORE SAWING

12

1. Select the correct saw blade appropriate to the material being cut. (mild steel, stainless steel or aluminum)

2. The material surface should be clean and level, free from rust, dirt, scale, and other debris.

3. Material may become heat treated if flame cut. Always avoid cutting near these areas whenever possible.

4. Adjust the vise plate to the desired miter angle by loosening the left and right Miter Lock bolts

(item# 95). Refer to “Exploded View”.

5. When cutting smaller profiles, vise plate may be moved forward to aid in cutting quality and to minimize pull-out

from the vise. Miter can be set by observing index marks printed on vise bracket.

6. Connect machine to power source.

7. Firmly grasp guide handle and trigger handle switch (item# 14, 15 and 24).

8. Position material in the saw vise and align cutting line with blade. Adjust the front and rear vise plates as

necessary to firmly hold material in the desired position.

9. When ready, start saw motor by activating trigger switch (item# 17).

10. Slowly approach material edge and gently apply pressure until saw blade has established a cutting groove in the

material.

11. Apply smooth, constant pressure without over-loading saw motor.

WARNING!

IF SAW MOTOR SHOULD STALL OR STOP BEFORE A COMPLETE CUT IS MADE ALWAYS REMOVE BLADE FROM

MATERIAL BEFORE ATTEMPTING TO RESTART MOTOR.FAILURE TO DO SO COULD RESULT IN PERSONAL INJURY.

OPERATION

WARNING!

NEVER START THE SAW WITH CUTTING EDGE OF SAW BLADE CONTACTING WORK SURFACE.

DO NOT RETRACT BLADE GUARD (ITEM# 115)MANUALLY.GUARD RETRACTS AUTOMATICALLY.

WHAT YOU SHOULD KNOW WHILE SAWING

ALWAYS CHECK BLADE DOWN-STOP BOLT,LOCK NUT AND BOLT CAP (ITEM #65,66, 154)FOR CORRECT

POSITIONING AND WEAR BEFORE FIRST USE AND AFTER EACH BLADE CHANGE.FAILURE TO DO SO COULD

RESULT IN PERSONAL INJURY DUE TO BLADE CONTACT WITH SAW BASE OR CHIP BOX.

1. After installation of saw blade or before first use, adjust down-stop bolt so that blade does not contact chip

tray bottom when blade is in the full down position.

1. After the cut, release trigger switch to the “OFF” position.

2. When saw motor completely stops, clear both drop piece and material from vise.

AFTER COMPLETING THE CUT

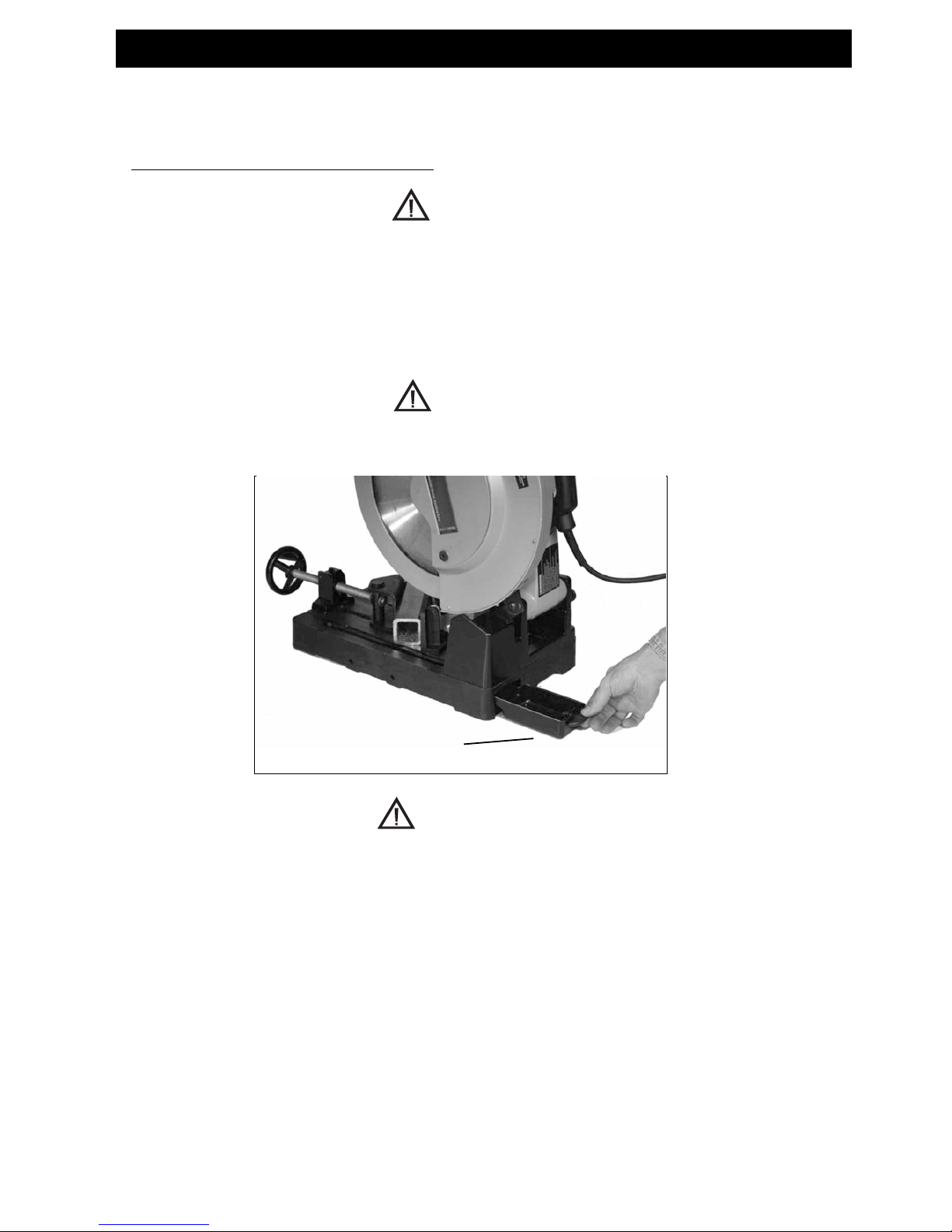

EMPTYING THE CHIP COLLECTOR BOX

WARNING!

ALWAYS DISCONNECT THE SAW FROM POWER SOURCE BEFORE CHANGING BLADES,CLEARING CHIPS OR MAKING ADJUSTMENTS.

1. Turn the Chip Collector Box retaining thumbscrew (see below).

2. Remove chip collector box from the back of saw.

3. Empty chip collector completely. Clean all debris from saw body.

4. Install chip collector box in saw and fasten securely by tightening thumbscrews.

OPERATION (continued)

13

WARNING!

FAILURE TO INSTALL COLLECTOR BOX TOTALLY AND SECURE MAY RESULT IN UNCONTROLLED DISCHARGE OF CHIPS AND OPERATOR

INJURY

.ALWAYS VERIFY PROPER INSTALLATION OF CHIP BOX AND CHECK FREQUENTLY.

FOR BEST PERFORMANCE, EMPTY THE CHIP COLLECTOR BOX OFTEN.

WARNING!

MOTOR DOWN-STOP BOLT AFFECTS HOW FAR BLADE TRAVELS INTO THE CHIP COLLECTOR BOX.AN IMPROPERLY ADJUSTED DOWN-

STOP CAN HIT THE BOTTOM OF BOX,CAUSING AN EJECTION HAZARD.ALWAYS CHECK DOWN-STOP ADJUSTMENT AFTER REPLACING

SAW BLADES OR SERVICING MACHINE.

Chip Tray

13

EMPTYING THE CHIP COLLECTOR BOX

WARNING!

ALWAYS DISCONNECT THE SAW FROM POWER SOURCE BEFORE CHANGING BLADES,CLEARING CHIPS OR MAKING ADJUSTMENTS.

1. Turn the Chip Collector Box retaining thumbscrew (see below).

2. Remove chip collector box from the back of saw.

3. Empty chip collector completely. Clean all debris from saw body.

4. Install chip collector box in saw and fasten securely by tightening thumbscrews.

OPERATION (continued)

13

WARNING!

FAILURE TO INSTALL COLLECTOR BOX TOTALLY AND SECURE MAY RESULT IN UNCONTROLLED DISCHARGE OF CHIPS AND OPERATOR

INJURY

.ALWAYS VERIFY PROPER INSTALLATION OF CHIP BOX AND CHECK FREQUENTLY.

FOR BEST PERFORMANCE, EMPTY THE CHIP COLLECTOR BOX OFTEN.

WARNING!

MOTOR DOWN-STOP BOLT AFFECTS HOW FAR BLADE TRAVELS INTO THE CHIP COLLECTOR BOX.AN IMPROPERLY ADJUSTED DOWN-

STOP CAN HIT THE BOTTOM OF BOX,CAUSING AN EJECTION HAZARD.ALWAYS CHECK DOWN-STOP ADJUSTMENT AFTER REPLACING

SAW BLADES OR SERVICING MACHINE.

Chip Tray

14

WARNING!

ALWAYS DISCONNECT THE SAW FROM POWER SOURCE BEFORE CHANGING BLADES,CLEARING CHIPS OR MAKING ADJUSTMENTS.

CHANGING SAW BLADES

Refer to the diagram to the right.

1. Place saw on a level, secure surface.

2. Move the swivel guard (item #130) by

loosening the thumb screw (item #134)

and rotating it to expose the blade

retaining bolt.

3. Engage spindle lock (item# 46).

4. Using supplied hex wrench, loosen and

remove the blade drive mounting bolt,

washer and outer blade drive flange

(items# 136-139).

5. Move the blade guard up and out of the

way (item # 115).

6. Remove saw blade. (item 135)

7. Thoroughly clean inner and outer blade

drive flanges and blade mounting

surface before installing new blade.

8. Verify that blade rotation is correct.

9. Reverse process to install new blade.

MAINTENANCE

14

Swivel Guard

Thumb Screw

Blade Flange

and Bolt

Metal Cutting

Saw Blade

Blade Guard

15

1. Machine will not turn on

•Inspect power cord for damage. Check & replace if needed.*

•Inspect brushes for excessive wear. Replace if needed. (2)*

•Do not exceed 30 minutes run time without cool down of saw.

•Check trigger switch for operation. Replace if needed.*

2. Losing Power

•Inspect brushes and replace if needed. (2)*

•Extension cord too long. Limit cord length to 15M or less.

•Extension cord too thin. Use 15AMP or larger.

3. Blade Guard Sticks

•Remove guard and remove any foreign material.

Guard must move freely. Use light grease on mating contact surfaces to aid in movement.

•Check guard return spring for sufficient tension. Replace if spring is weak.

•Check guard for distortion. Replace if distorted or damaged.

4. Blade Spins on Spindle

•Check for proper tightness and installation. Inspect inner blade flange and outer blade

flange for wear or damage. Replace if wear is excessive.

•Check flange mating surfaces for flatness. Replace if excessive distortion exists.

•Check to ensure flat washer is present between bolt head and outer blade drive flange.

5. Low Blade Life/Teeth Chipping

•Wrong blade for the type of material.

SSBL350-MS for mild steel up to 25.4mm solid.

SSBL350-AL for aluminum up to 25.4mm solid.

SSBL350-SS for stainless steel up to 13mm solid.

SSBL350-TS for thin steel up to 6mm solid.

•Aggressive contact with blade into material. The blade must be allowed to do the work.

•Too much vibration due to insufficient clamping, worn or bent blade, or worn parts (see "Saw Vibrates"

below).

6. Saw Vibrates

•Check blade for tightness.

•Inspect inner blade flange and outer blade drive flange for wear or damage. Replace if needed.

•Check to ensure work is properly clamped. Both primary and cut-off piece can cause vibration.

•Check miter lock for tightness.

•Check blade teeth for missing carbide, bends or cracks.

350mm METAL CUTTING SAW

15

TROUBLESHOOTING CHECKLIST

CAUTION!

ALWAYS DISCONNECT THE SAW FROM POWER SOURCE BEFORE TROUBLESHOOTING

SERVICE WORK SHOULD ONLY BE PERFORMED BY A SERVICE TECHNICIAN QUALIFIED & COMPETANT TO PERFORM SUCH TASKS

* NOTE: ELECTRICAL SERVICE WORK MUST ONLY BE CARRIED OUT BY A LICENCED ELECTRICIAN

.

16

ACCESSORIES

Saw Blades

#traPnoitacilppA

For cutting mild steel to 25.4mm SSBL350-MS

For cutting thin steel to 6mm SSBL350-TS

For cutting aluminum to 25.4mm SSBL350-AL

For cutting stainless steel to 13mm SSBL350-SS

YOUR STEELMASTER DISTRIBUTOR

©1/08

DIMENSIONS AND SPECIFICATIONS

)"71(mm134thgieH

)"4.31(mm043htdiW

)"12(mm335htgneL

31kgthgieW

2200W240V -rotoM

50 Hz / 1500 RPM

)"0.1(mm4.52robrAedalB

)"0.41(mm553retemaiDedalB

Depth of Cut/Pipe or Angle (maximum) 120mm (4.75")

Depth of Cut/Plate or Bar Solid (maximum) 25.4mm Mild Steel (1")

25.4mm Aluminum (1")

13mm Stainless Steel (1/2")

SPECIFICATIONS

Model SS350

16

Industrial Tool & Machinery Sales

email: [email protected] / web www.industrialtool.com.au

DISTRIBUTOR

S14

ACCESSORIES

Saw Blades

#traPnoitacilppA

For cutting mild steel to 25.4mm SSBL350-MS

For cutting thin steel to 6mm SSBL350-TS

For cutting aluminum to 25.4mm SSBL350-AL

For cutting stainless steel to 13mm SSBL350-SS

YOUR STEELMASTER DISTRIBUTOR

©1/08

DIMENSIONS AND SPECIFICATIONS

)"71(mm134thgieH

)"4.31(mm043htdiW

)"12(mm335htgneL

31kgthgieW

2200W240V -rotoM

50 Hz / 1500 RPM

)"0.1(mm4.52robrAedalB

)"0.41(mm553retemaiDedalB

Depth of Cut/Pipe or Angle (maximum) 120mm (4.75")

Depth of Cut/Plate or Bar Solid (maximum) 25.4mm Mild Steel (1")

25.4mm Aluminum (1")

13mm Stainless Steel (1/2")

SPECIFICATIONS

Model SS350

16

Industrial Tool & Machinery Sales

Other manuals for S14

2

Other SteelMax Saw manuals