Table of Contents

INTRODUCTION............................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

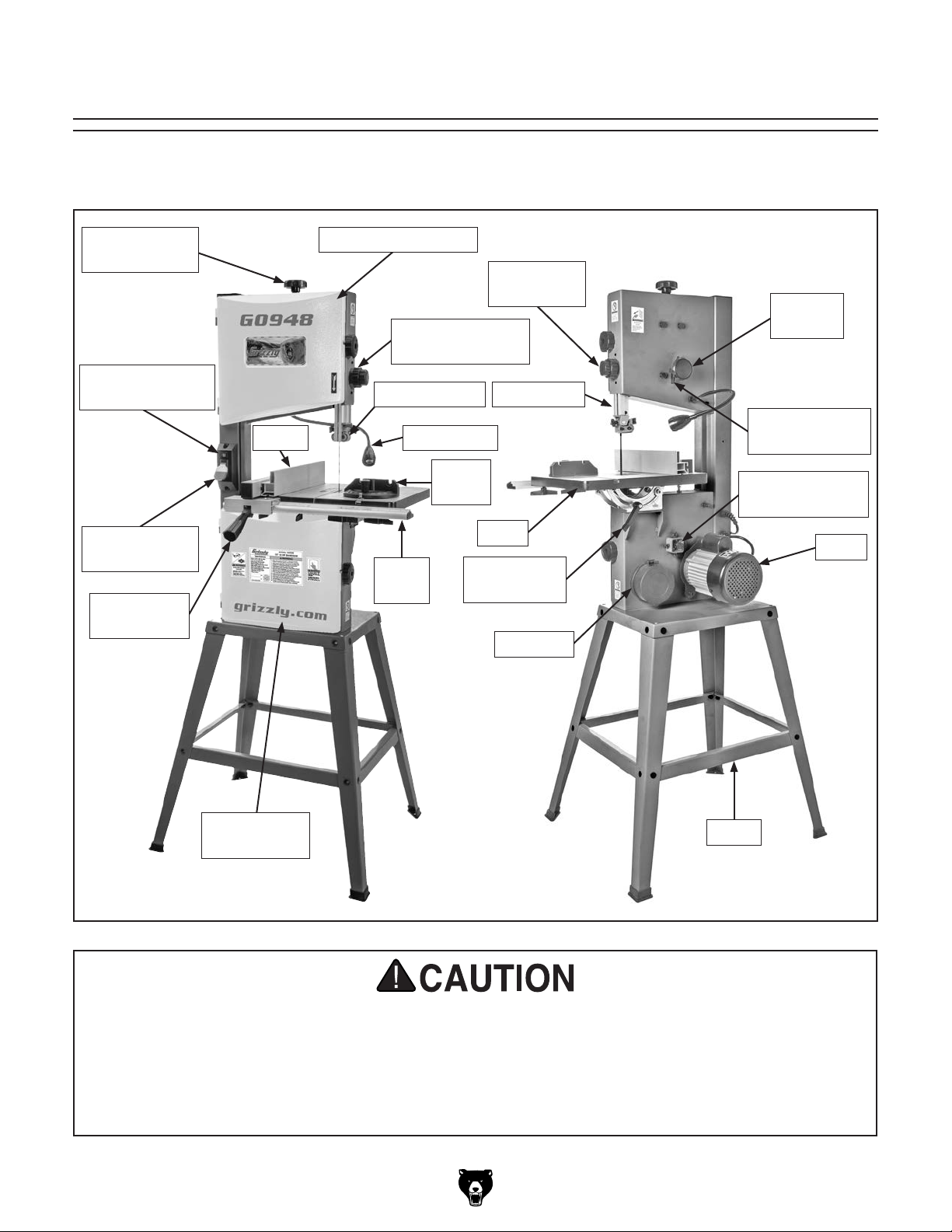

Identification ................................................... 3

Controls & Components ................................. 4

Machine Data Sheet ...................................... 6

SECTION 1: SAFETY....................................... 8

Safety Instructions for Machinery .................. 8

Additional Safety for Bandsaws ................... 10

SECTION 2: POWER SUPPLY ...................... 11

SECTION 3: SETUP ....................................... 13

Unpacking .................................................... 13

Needed for Setup ......................................... 13

Inventory ...................................................... 14

Hardware Recognition Chart ....................... 15

Site Considerations ...................................... 16

Assembly ..................................................... 16

Dust Collection ............................................. 19

Adjustment Overview ................................... 19

Initial Blade Tracking ................................... 20

Test Run ...................................................... 21

Tensioning Blade ......................................... 22

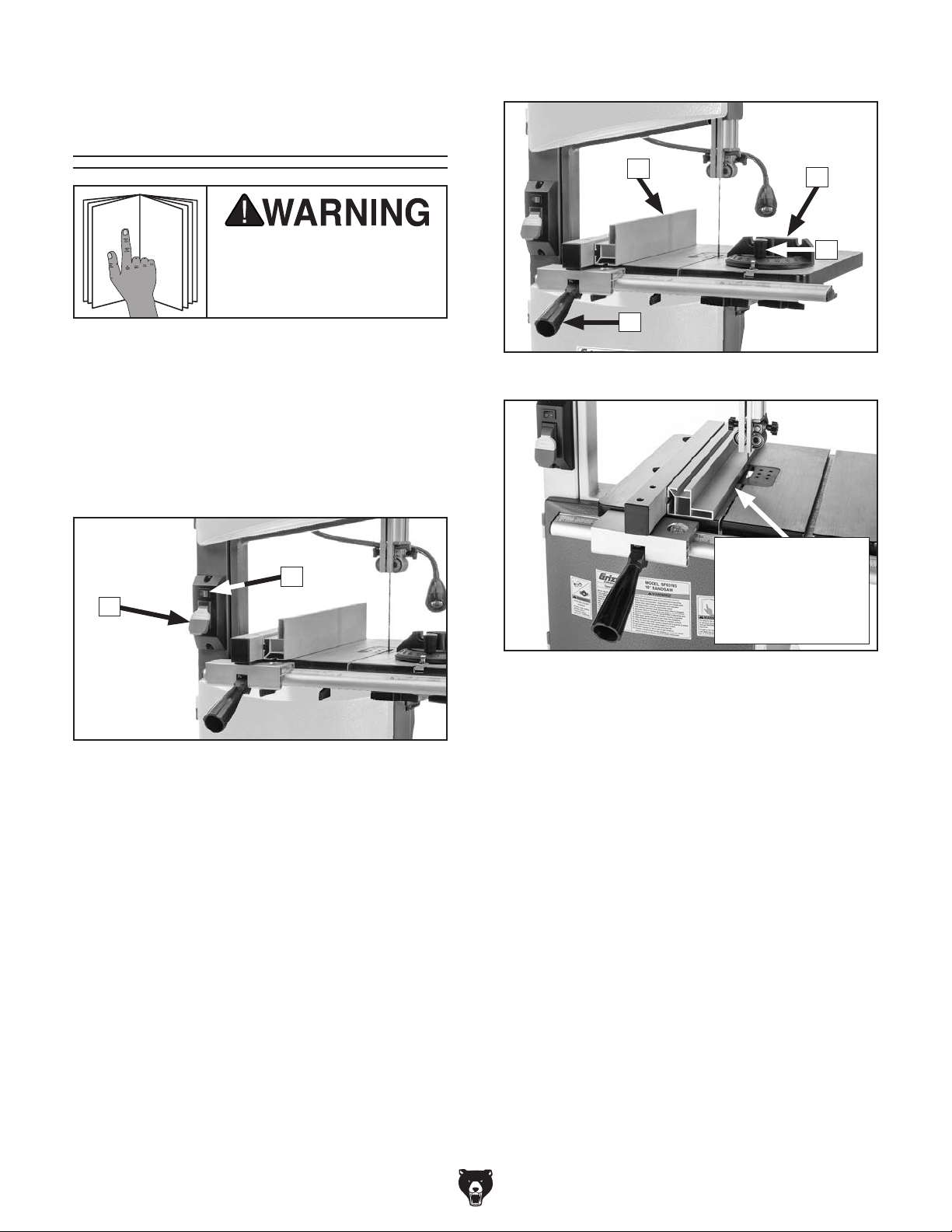

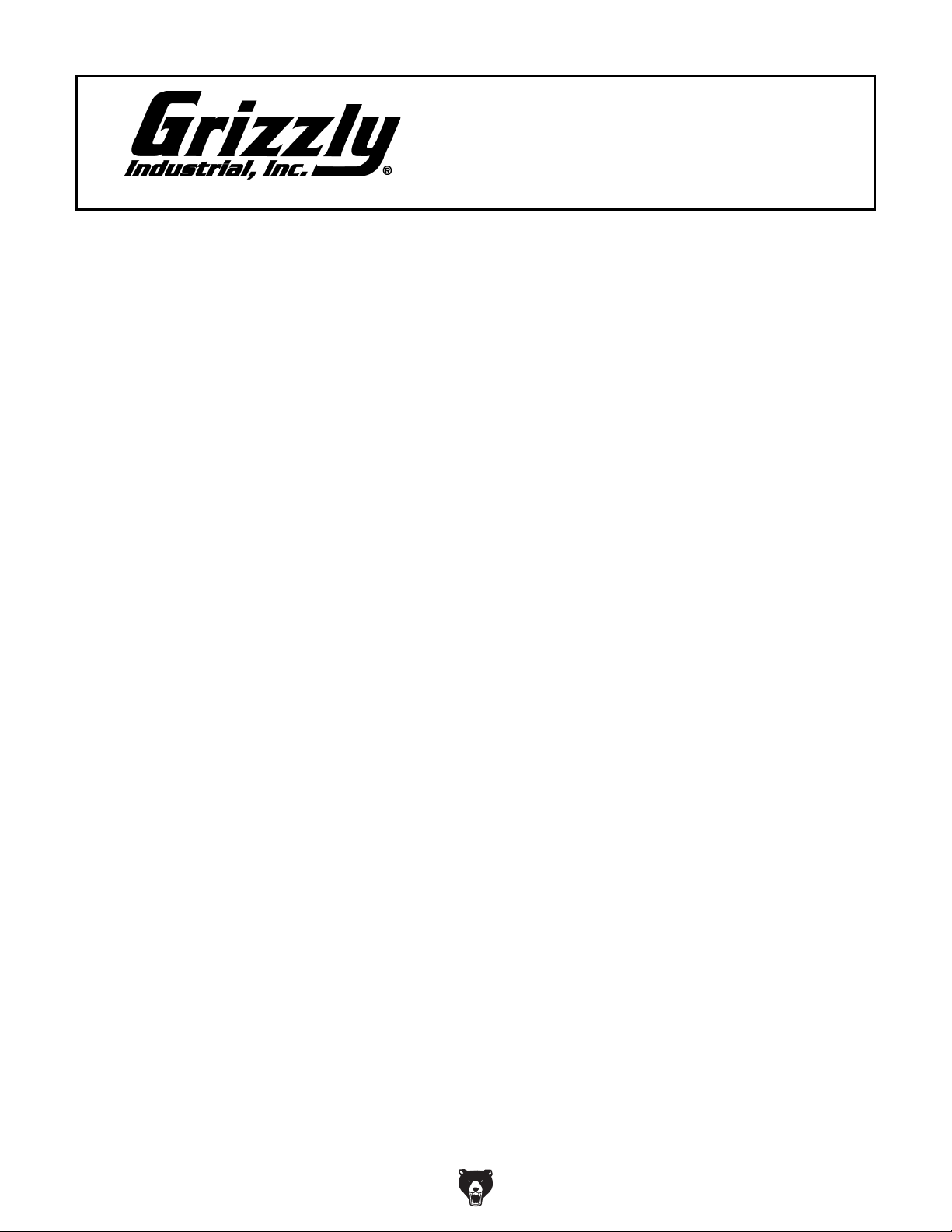

Adjusting Blade Support Bearings ............... 24

Adjusting Blade Guide Bearings .................. 25

Aligning Table .............................................. 27

Aligning Fence ............................................. 28

Calibrating Miter Gauge ............................... 29

SECTION 4: OPERATIONS ........................... 30

Operation Overview ..................................... 30

Basic Functions of a Bandsaw .................... 31

Workpiece Inspection................................... 31

Setting Upper Blade Guide Height .............. 32

Tilting Table ................................................. 32

Choosing Blades .......................................... 34

Blade Selection Chart .................................. 37

Blade Care & Break-In ................................. 38

Blade Breakage ........................................... 38

Removing/Installing Blade ........................... 39

Changing Blade Speed ................................ 40

Ripping ......................................................... 41

Crosscutting ................................................. 41

Resawing ..................................................... 42

Cutting Curves ............................................. 42

Stacked Cuts................................................ 43

SECTION 5: ACCESSORIES......................... 44

SECTION 6: MAINTENANCE......................... 47

Schedule ...................................................... 47

Cleaning & Lubricating ................................. 47

SECTION 7: SERVICE ................................... 48

Troubleshooting ........................................... 48

Checking/Adjusting Belt Tension ................. 51

Replacing Belt .............................................. 52

Aligning Wheels ........................................... 53

Blade Lead ................................................... 56

Adjusting Wheel Brush ................................ 57

SECTION 8: WIRING...................................... 58

Wiring Safety Instructions ............................ 58

Wiring Diagram ............................................ 59

Electrical Components ................................. 60

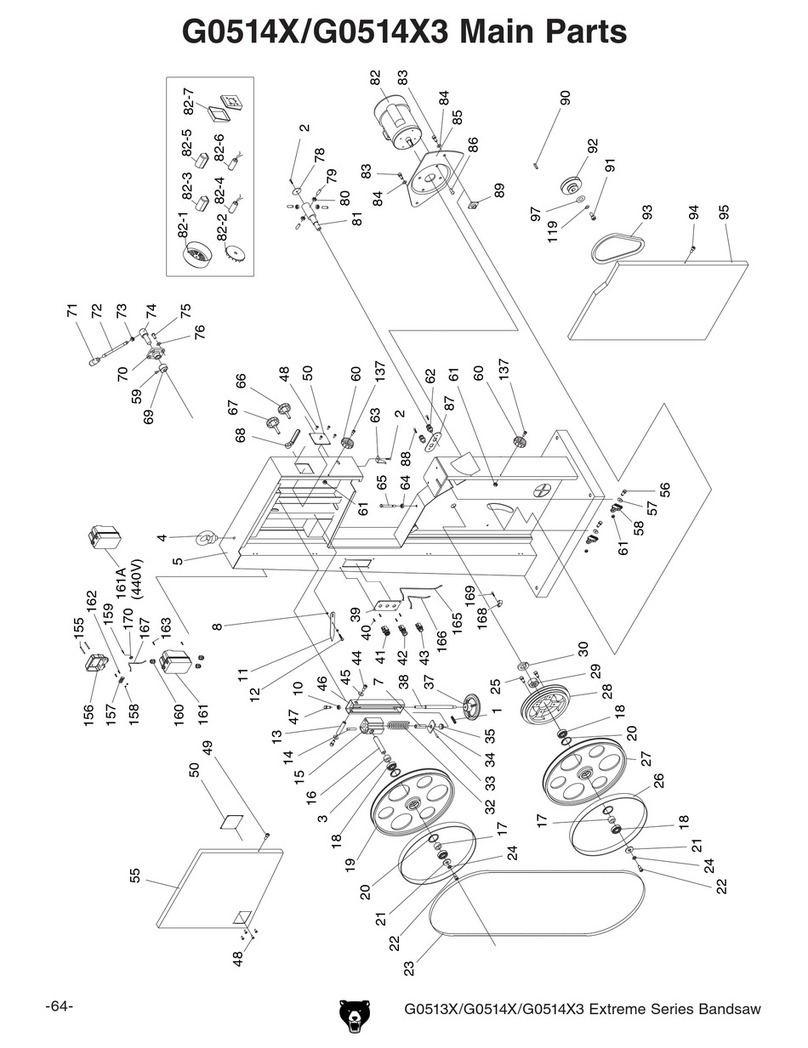

SECTION 9: PARTS....................................... 61

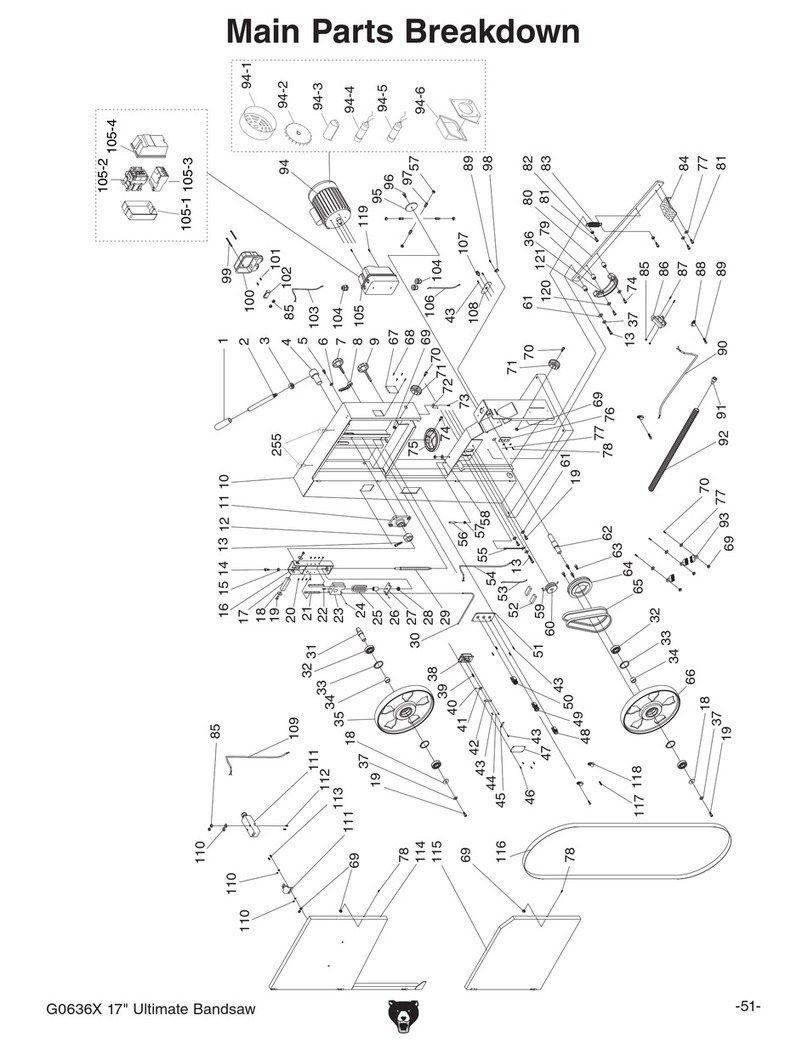

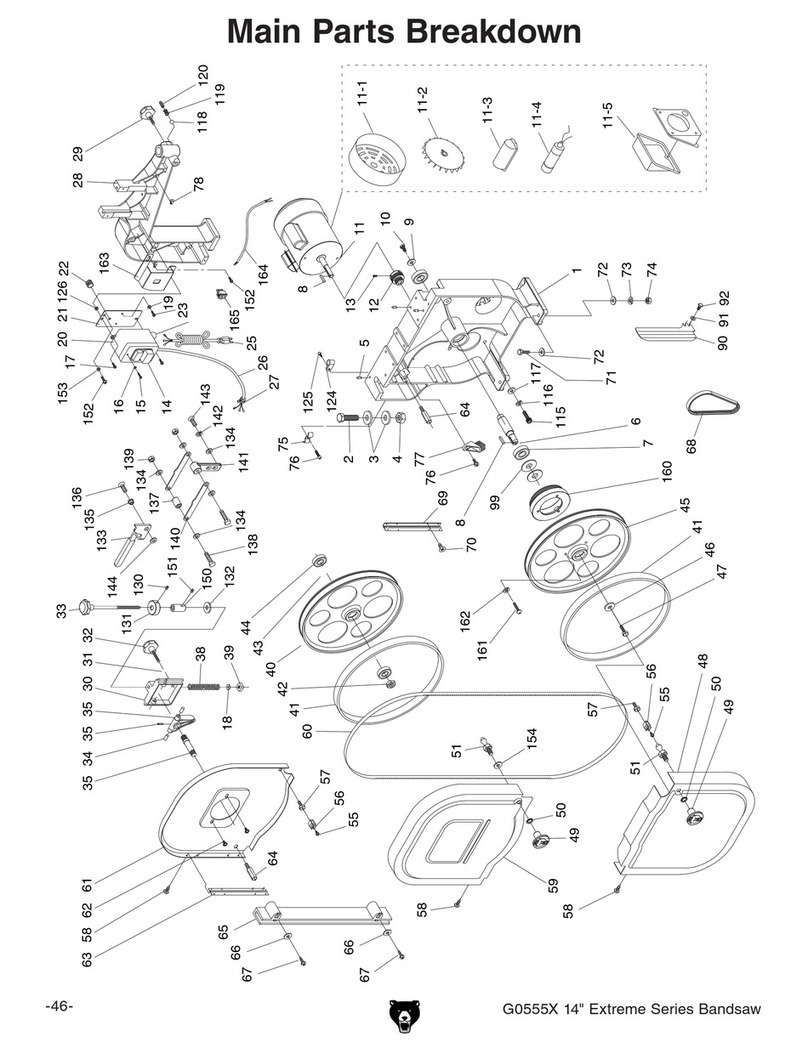

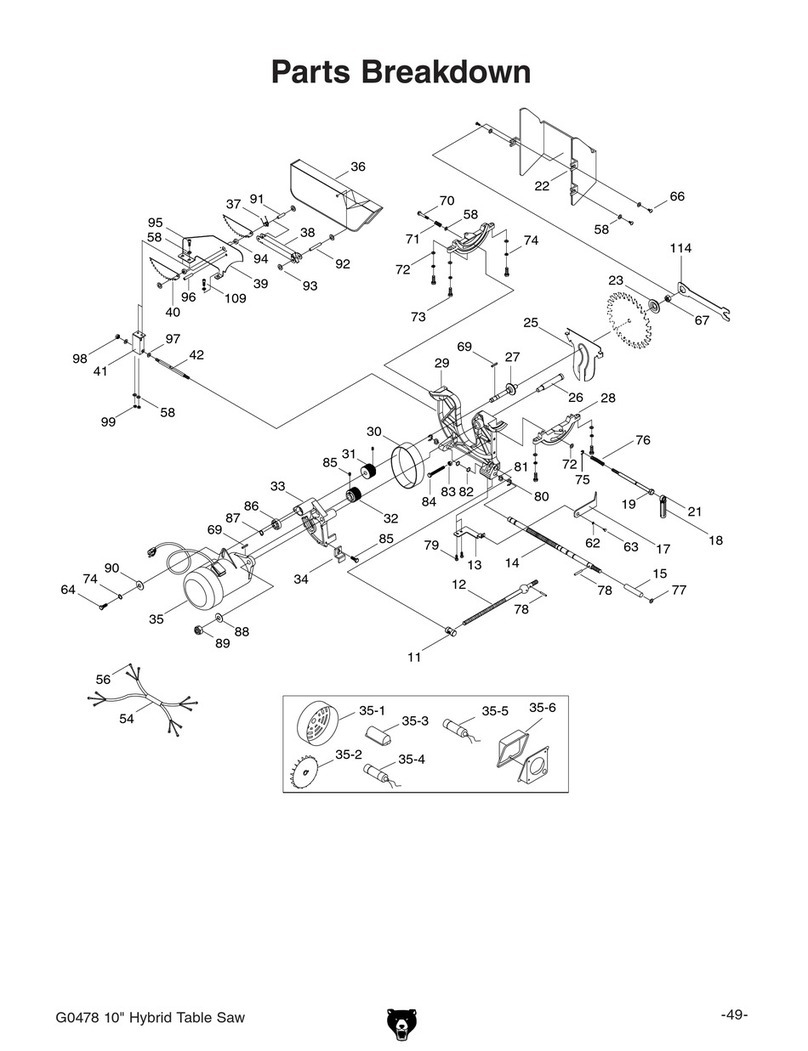

Main ............................................................. 61

Labels & Cosmetics ..................................... 64

WARRANTY & RETURNS ............................. 65