SteelMax OSC 8 User manual

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

2. SAFETY PRECAUTIONS.................................................................................................. 6

3. STARTUP AND OPERATION........................................................................................... 7

3.1. Assembling................................................................................................................ 7

3.2. Connecting................................................................................................................. 8

3.2.1. To the welding circuit....................................................................................... 8

3.2.1. To the power supply........................................................................................ 9

3.2.2. To the Rail Runner 2 welding carriage............................................................10

3.3. Operating..................................................................................................................12

4. ACCESSORIES...............................................................................................................14

4.1. Freestanding support................................................................................................14

4.2. Power supply............................................................................................................15

5. EXPLODED VIEWS AND PARTS LIST............................................................................16

6. WIRING DIAGRAM..........................................................................................................19

7. DECLARATION OF CONFORMITY.................................................................................20

8. WARRANTY CARD..........................................................................................................21

OSC 8

OSC 8 Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The OSC 8 pendulum oscillator is designed to oscillate MIG/MAG torches with the

diameter of 16–22 mm (5/8–7/8″). The oscillator is installed onto a 22 mm (7/8″)

diameter rod and powered from the welding equipment. Can be controlled manually

or by using an external START-STOP switch.

Using an optional freestanding support allows you to weld pipes that rotate and

plates that move. Using an optional power supply allows you to connect the oscillator

to a 115 V or 230 Vpower source.

The oscillator can also be used on the Rail Runner 2 welding carriage to allow

work with or without seam tracking.

1.2. Technical data

Voltage

14–24 V DC

Power

50 W

Torch type

MIG/MAG

Torch diameter

16–22 mm (5/8–7/8″)

Oscillation type

Pendulum

Oscillation width at r=150 mm (6″)

1–30 mm (1–100%)

1/32–1-3/16″

Oscillation speed at oscillation width of 10 mm (3/8″) and

zero dwell time on ends

12–115 cycles/min (1–100%)

Oscillation dwell time on ends

0–3 s

Maximum torque

8 N·m (5.7 lb·ft)

Protection level

IP 21

Protection class

I

Required ambient temperature

0–50°C (32–122°F)

Weight

2 kg (4 lbs)

OSC 8

OSC 8 Operator’s Manual

4

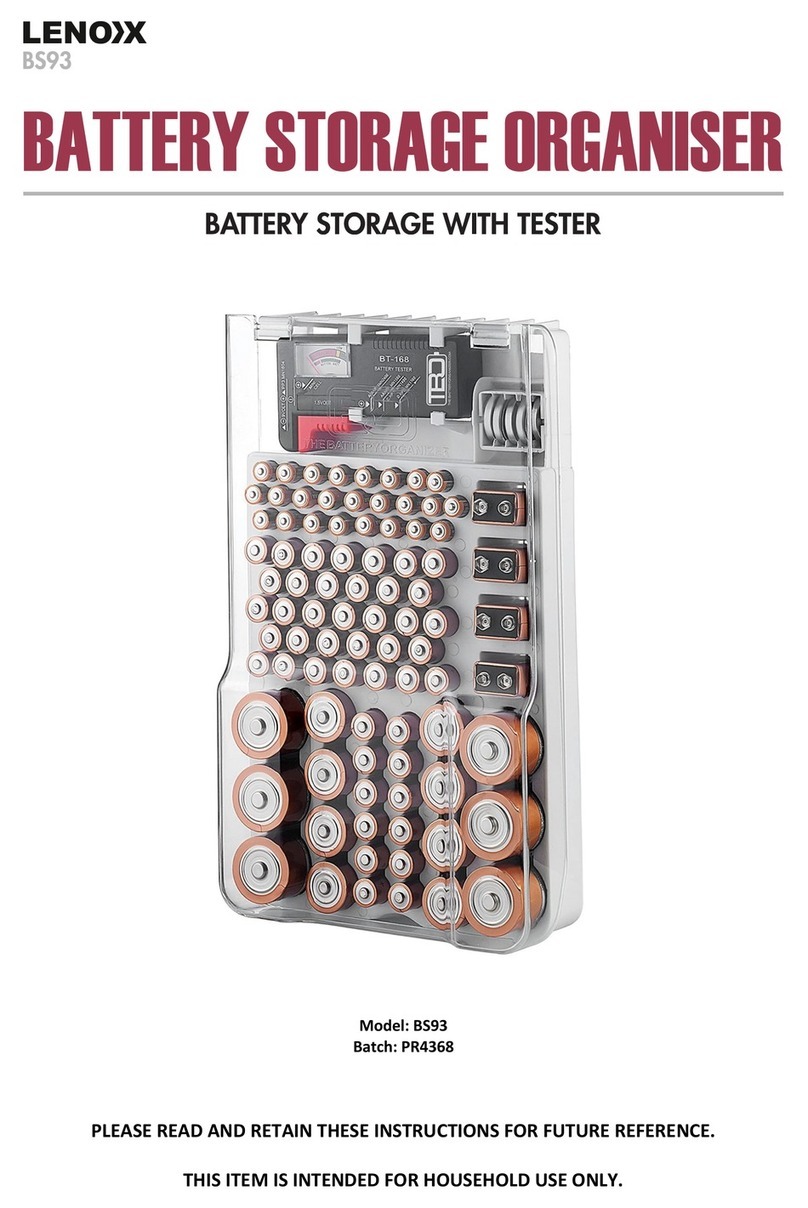

1.3. Equipment included

1

Oscillator

1 unit

2

2 m (6.5 ft) power cord

1 unit

3

Low rod torch holder with clip

1 unit

4

Arm

1 unit

5

Clamping block

1 unit

6

M6x40 screw

2 units

7

80 mm (3″) rod

1 unit

8

5 mm hex wrench

1 unit

–

Operator’s Manual

1 unit

1

2

3

4

5

7

6

8

OSC 8

OSC 8 Operator’s Manual

5

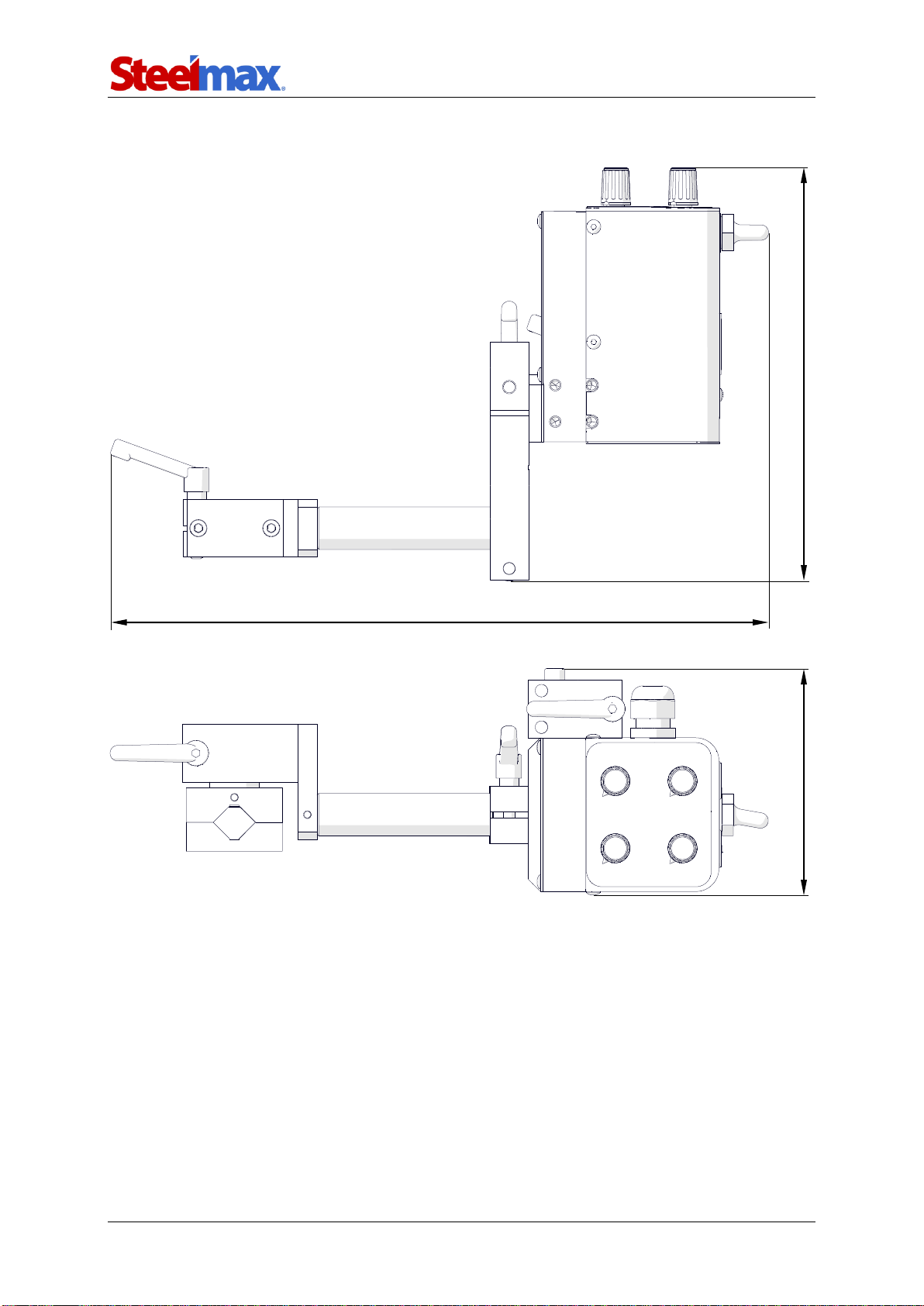

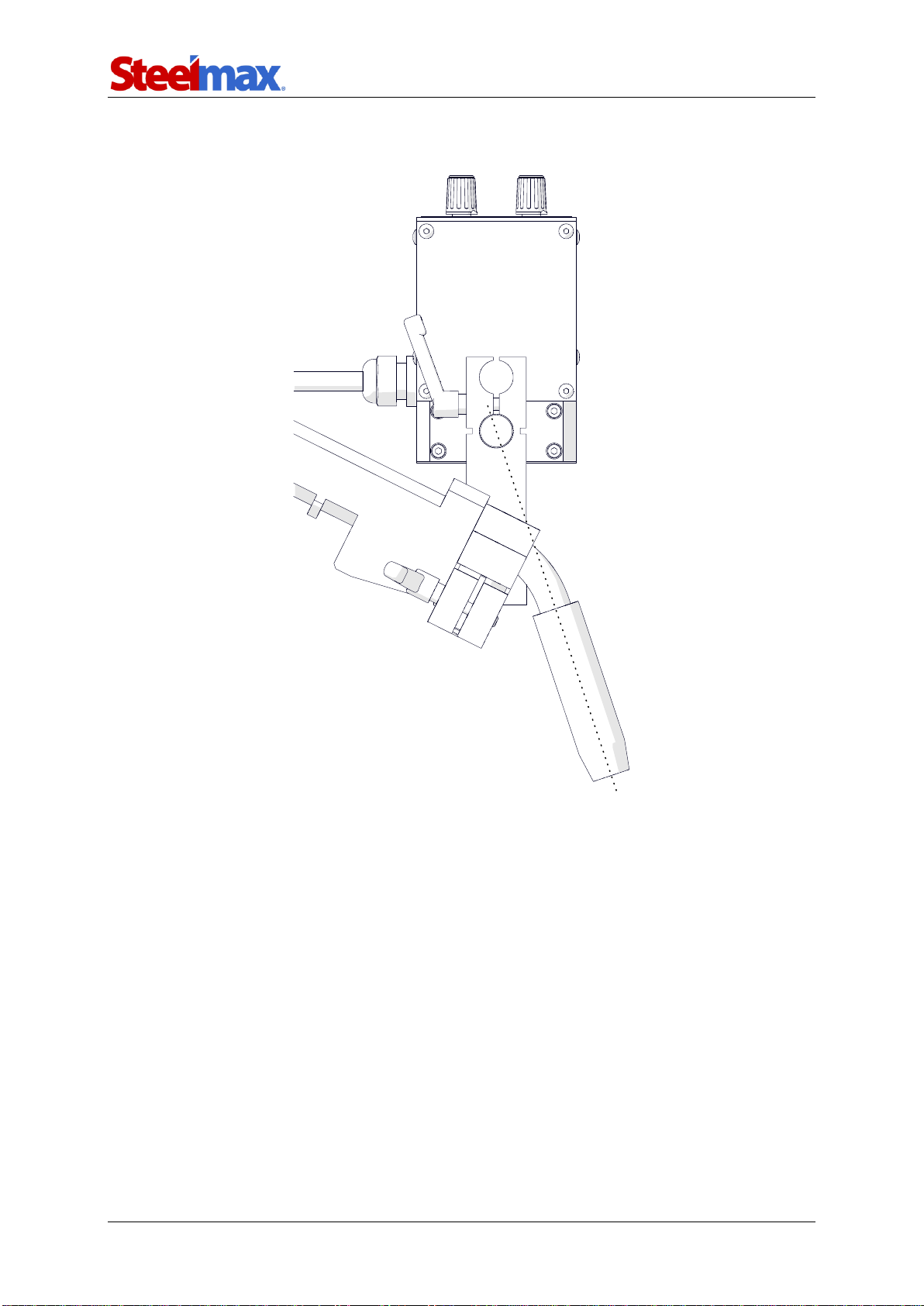

1.4. Dimensions

117 mm (4-5/8″)

215 mm (8-7/16″)

343 mm (13-1/2″)

OSC 8

OSC 8 Operator’s Manual

6

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete a training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the oscillator has all parts and they are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those

specified on the rating plate.

5. Do not carry the oscillator by the cord. This can cause damage.

6. Keep the oscillator dry. Do not expose it to rain, snow, or frost.

7. Do not use near flammable materials, or in explosive environments.

8. Connect the power cord only after you set the switch to the middle position.

9. Install only MIG/MAG torches with the diameter of 16–22 mm (5/8–7/8″).

10. Do not stop the oscillator by hand. To stop, set the switch to the middle position.

11. Repair only in a service center appointed by the seller.

OSC 8

OSC 8 Operator’s Manual

7

3. STARTUP AND OPERATION

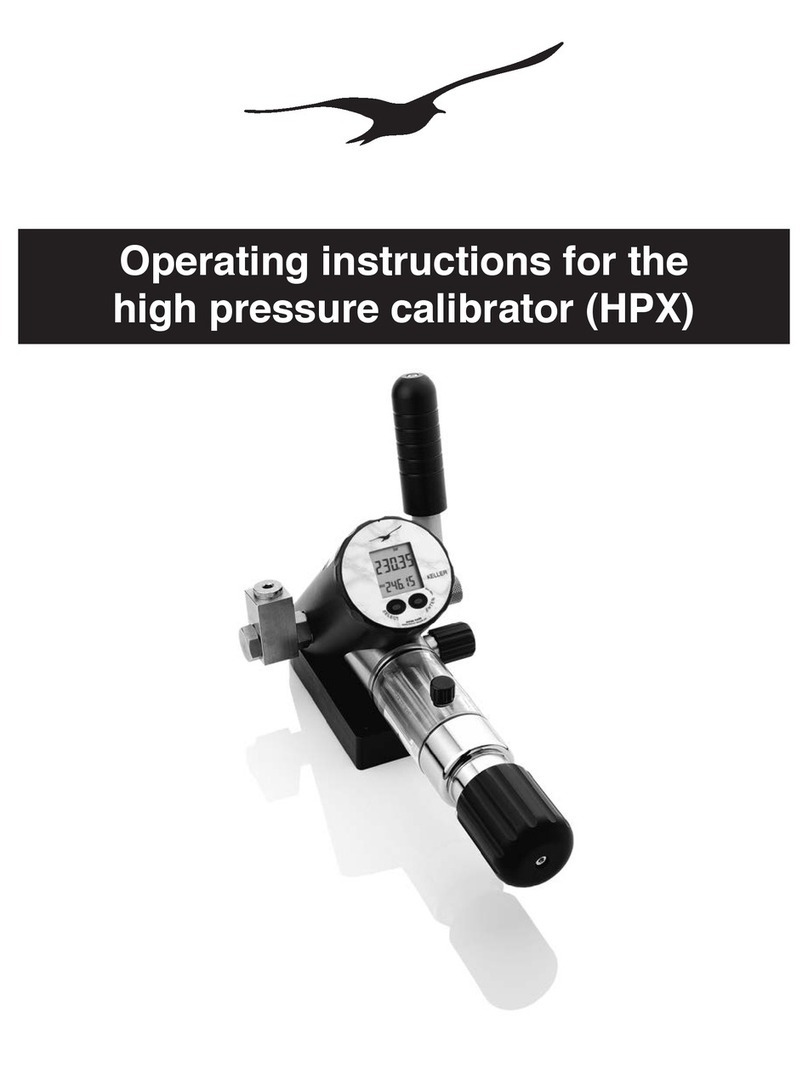

3.1. Assembling

Use the 5 mm hex wrench to install the clamping block in the chosen position. Point

the arm down, and then install the arm and the torch holder.

INCORRECT

CORRECT

OSC 8

OSC 8 Operator’s Manual

8

3.2. Connecting

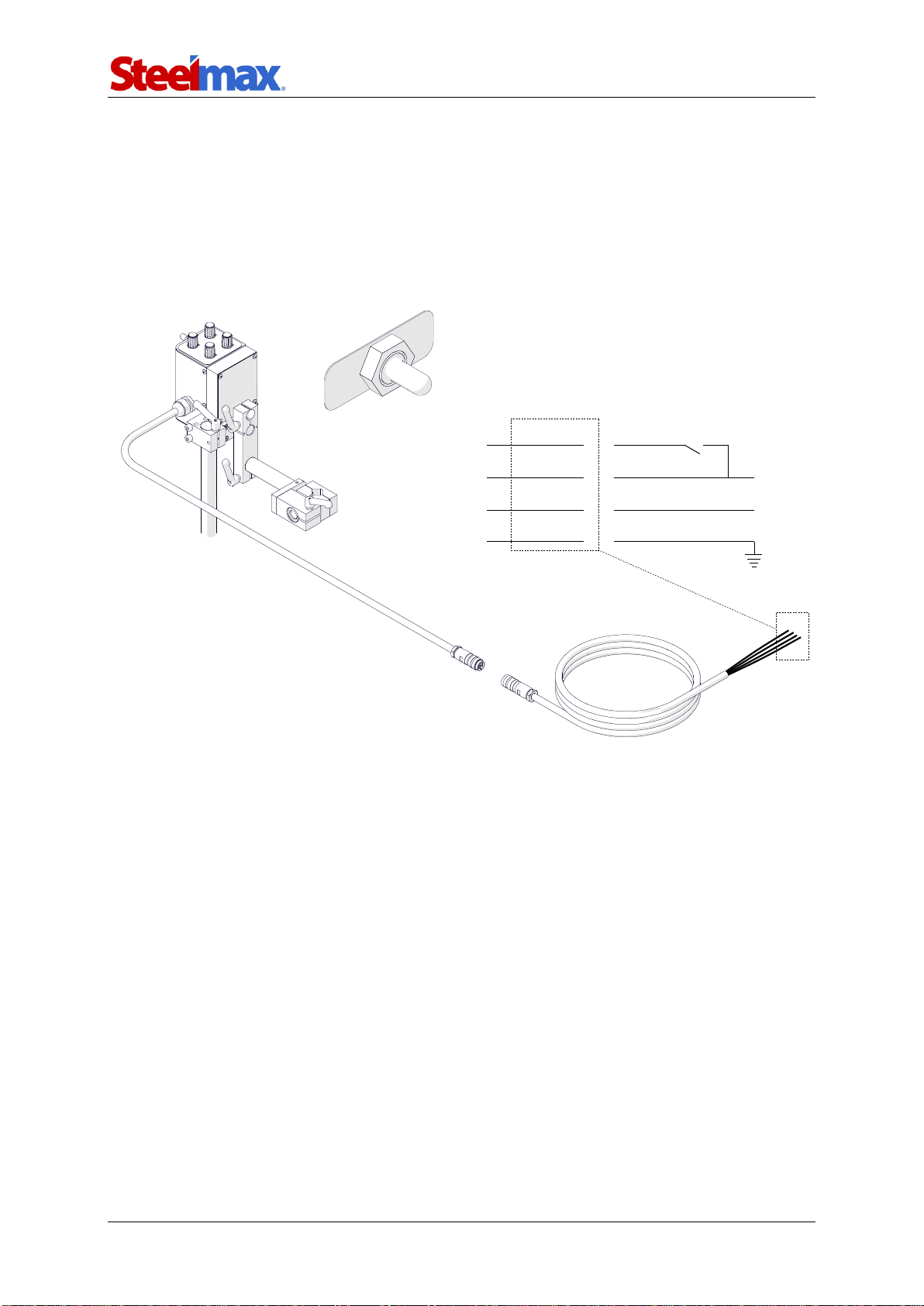

3.2.1. To the welding circuit

Put the oscillator onto a 22 mm (7/8″) diameter rod (1) and set the switch to the

middle position (2). Then, connect the power cord to the welding circuit (3). Next,

connect the power cord to the oscillator (4).

Green

Brown

White

Yellow

Welding circuit

External START-STOP

14–24 V DC

GND

Shield

1

2

3

4

OSC 8

OSC 8 Operator’s Manual

9

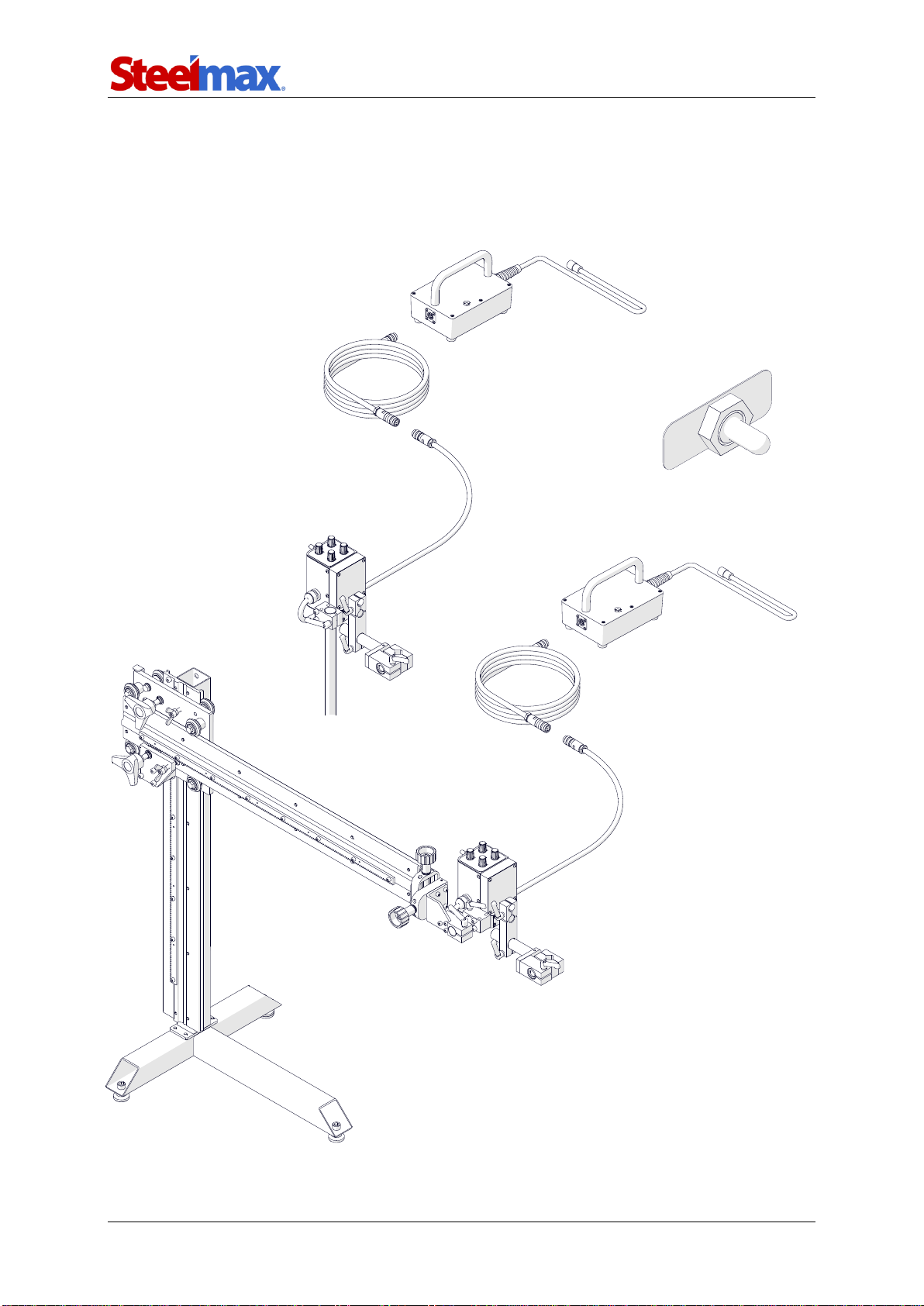

3.2.1. To the power supply

Put the oscillator onto a 22 mm (7/8″) diameter rod (1) or a freestanding support (2,

option). Next, set the switch to the middle position (3). Then, connect the oscillator to

the power supply (4, option).

1

2

3

4

4

OSC 8

OSC 8 Operator’s Manual

10

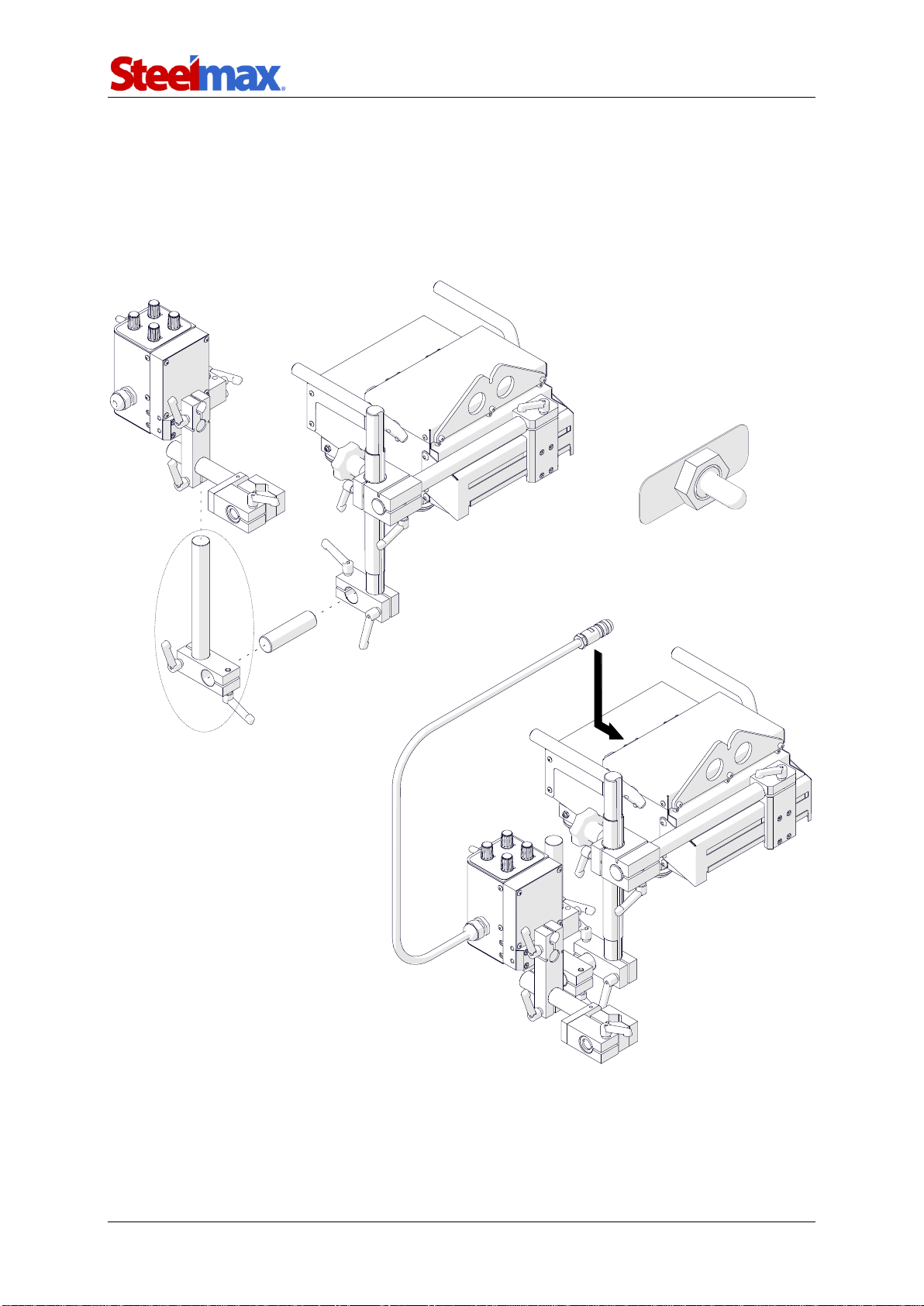

3.2.2. To the Rail Runner 2 welding carriage

To use the oscillator without seam tracking, assembly the oscillator with a 203 mm

(8″) rod and a clamping block (1, option). Then, use the 80 mm (3″) rod to put the

oscillator onto the carriage (2). Next, set the switch to the middle position (3) and

connect the oscillator to the carriage (4).

1

2

3

4

Part number:

KLM-0236-00-16-00-0

(203 mm rod)

KST-0525-11-00-00-0

(Clamping block)

OSC 8

OSC 8 Operator’s Manual

11

To use the oscillator with seam tracking, put the oscillator onto the carriage with the

installed seam tracking attachment (1). Next, set the switch to the middle position (2)

and connect the oscillator to the tracking sensor (3).

2

1

3

OSC 8

OSC 8 Operator’s Manual

12

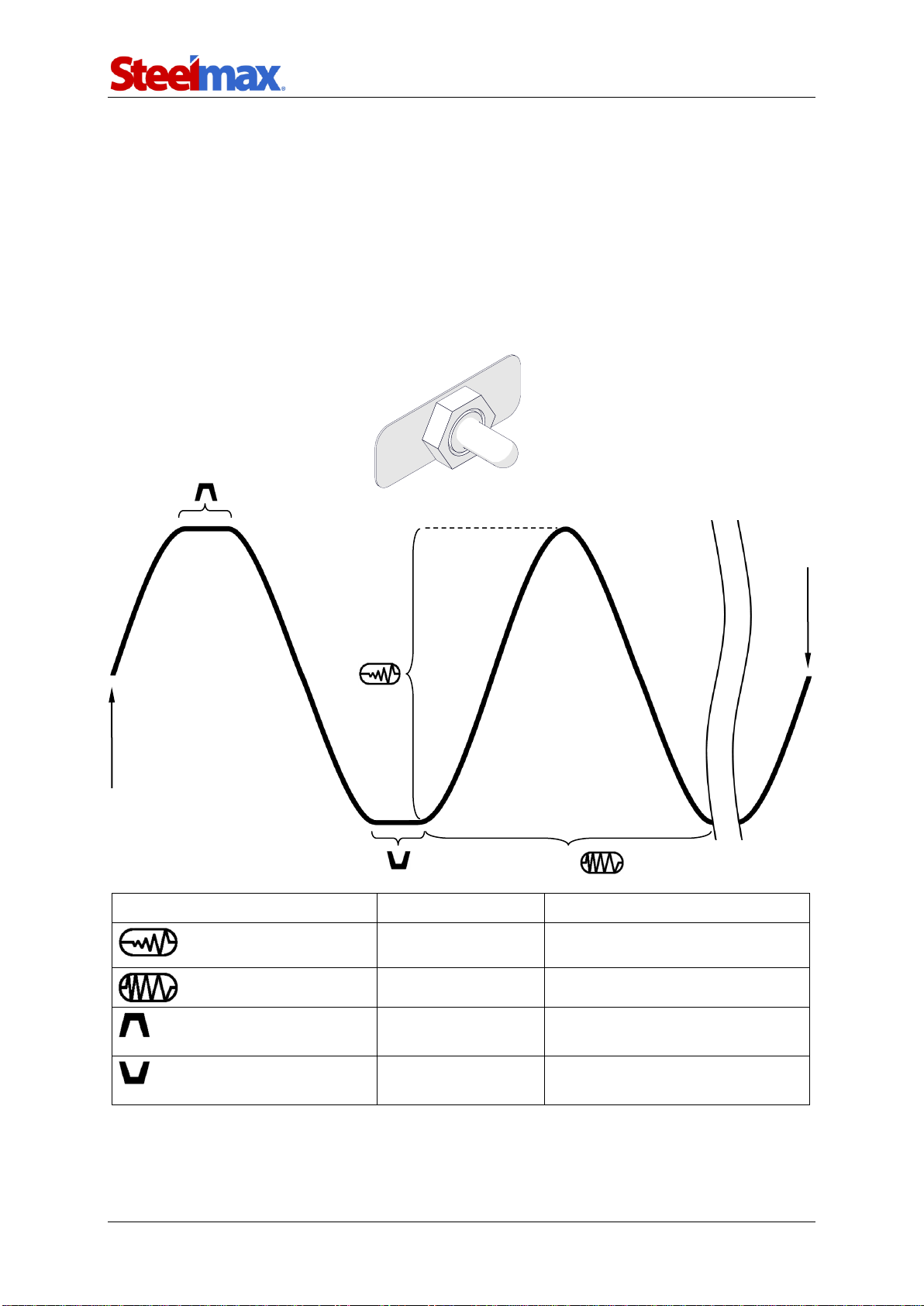

3.3. Operating

Use the knobs to set the required parameters from the table that follows. Then, set

the switch to MANUAL control to start oscillations. To stop oscillations, set the switch

to the middle position.

If the switch is set to EXTERNAL control, oscillations start when a 14–24 V DC is

supplied to the green wire (refer to chapter 3.2.1 for the diagram). To stop oscillations,

use an external START-STOP switch to disconnect the green wire.

Parameter

Value

Description

0–100%

Oscillation width.

0–100%

Oscillation speed.

0–3 s

Oscillation dwell time in the

top position.

0–3 s

Oscillation dwell time in the

bottom position.

Weld

end

Weld

start

1 /

EXTERNAL

MANUAL

OSC 8

OSC 8 Operator’s Manual

13

To get the correct shape of oscillation, make sure that the axis of the torch

crosses with the axis of the oscillator’s output shaft.

OSC 8

OSC 8 Operator’s Manual

14

4. ACCESSORIES

4.1. Freestanding support

Allows welding with oscillation of pipes that rotate and plates that move.

Part number:

STJ-0629-24-00-00-0

OSC 8

OSC 8 Operator’s Manual

15

4.2. Power supply

Allows you to connect the oscillator to a 115 V or 230 Vpower source.

Part number:

ZSL-0497-16-00-01-0 (115 V US)

ZSL-0497-16-00-00-0 (230 V CEE)

OSC 8

OSC 8 Operator’s Manual

16

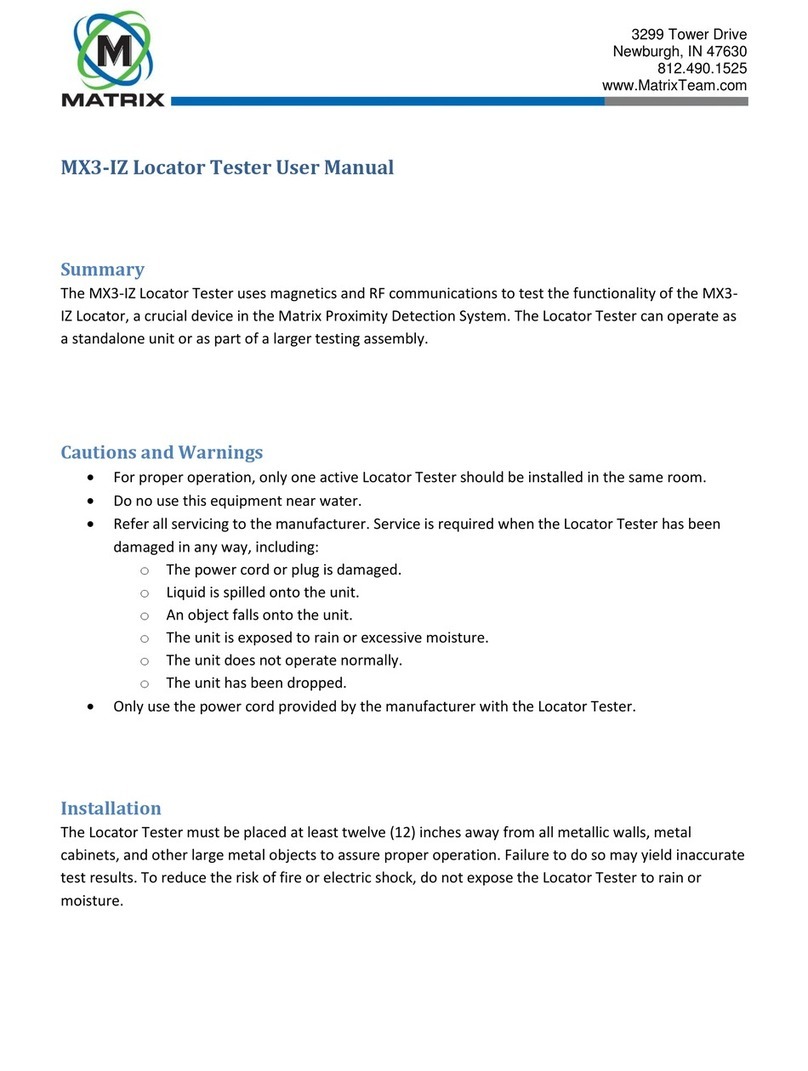

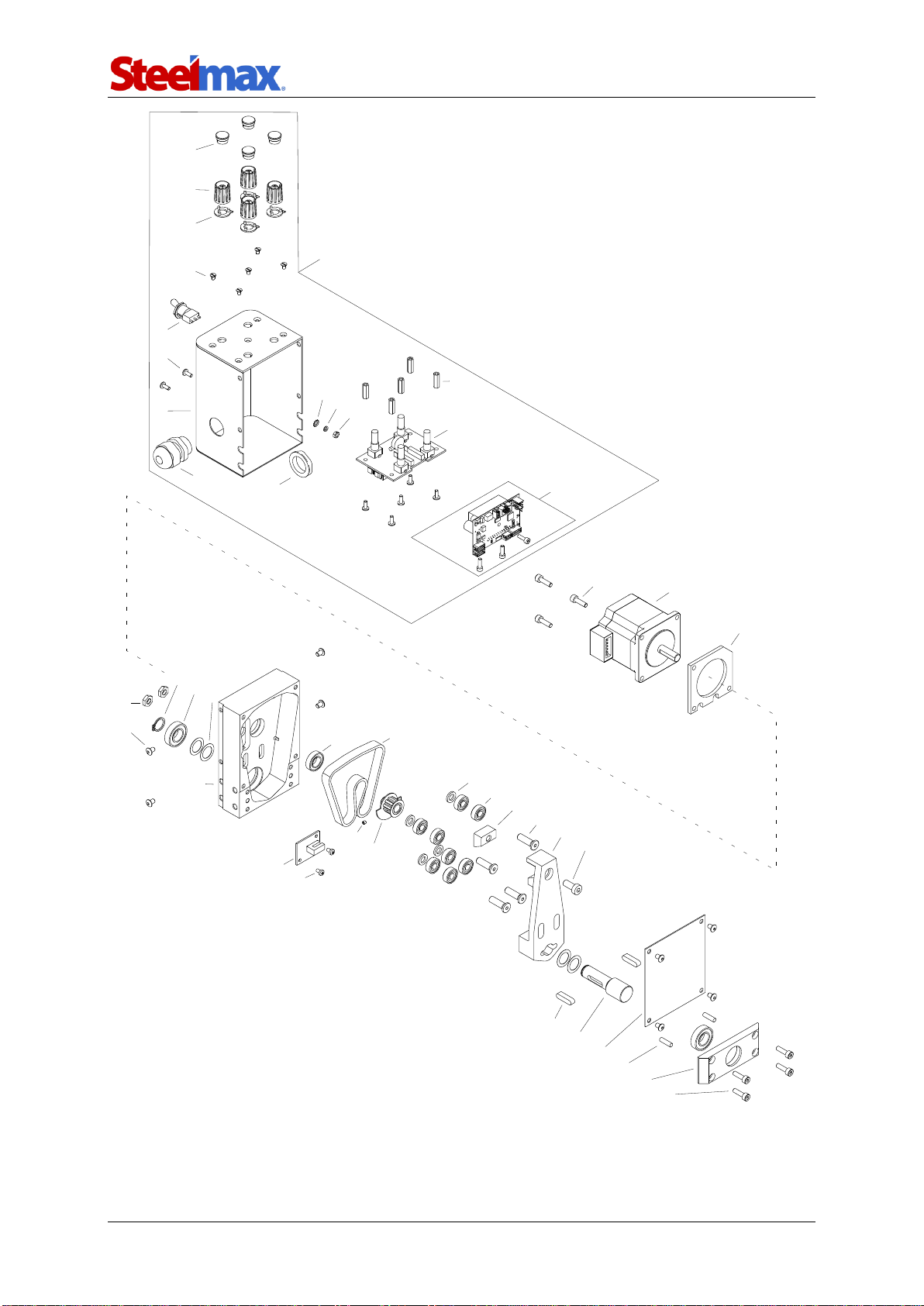

5. EXPLODED VIEWS AND PARTS LIST

6

8

4

5

2

1

3

9

7

ITEM

PART NUMBER

DESCRIPTION

Q-TY

1

RKJ-000043

HANDLEVER M6-25

1

2

UCW-0497-13-00-00-0

CLAMP

1

3

SRB-000124

HEX SOCKET HEAD CAP SCREW M6x40

2

4

KLC-000008

5 MM HEX WRENCH

1

5

RAM-0477-01-10-00-0

OSCILLATOR ARM ASSY

1

6

UCW-0476-06-00-00-0

TORCH HOLDER LOWER ROD CLAMP ASSY

1

7

RKJ-000036

HANDLEVER M6-32

1

8

TLJ-0419-04-02-03-0

INSULATION TUBE

1

9

WSP-0497-17-00-00-0

SUPPORT

1

10*

WZK-0497-14-00-00-0

POWER SUPPLY WIRE SET

1

* not shown in the drawing

OSC 8

OSC 8 Operator’s Manual

17

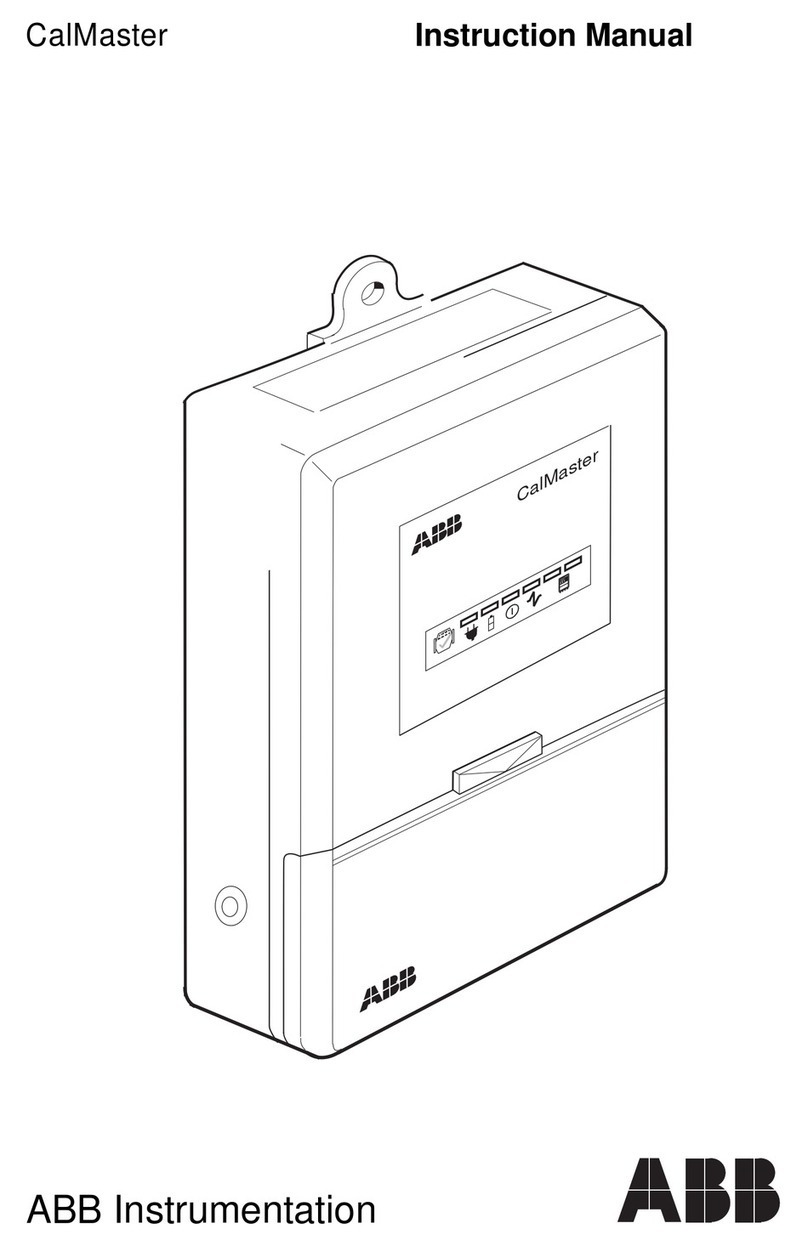

8

7

9

10 17

1

11

6

12 13 14

4

3

16

25

15

2

18 19

23 24

21

20

26

27 28

22

32

31

33 34

29

30

35 36 37

40

39

38

42 43

41

44

OSC 8

OSC 8 Operator’s Manual

18

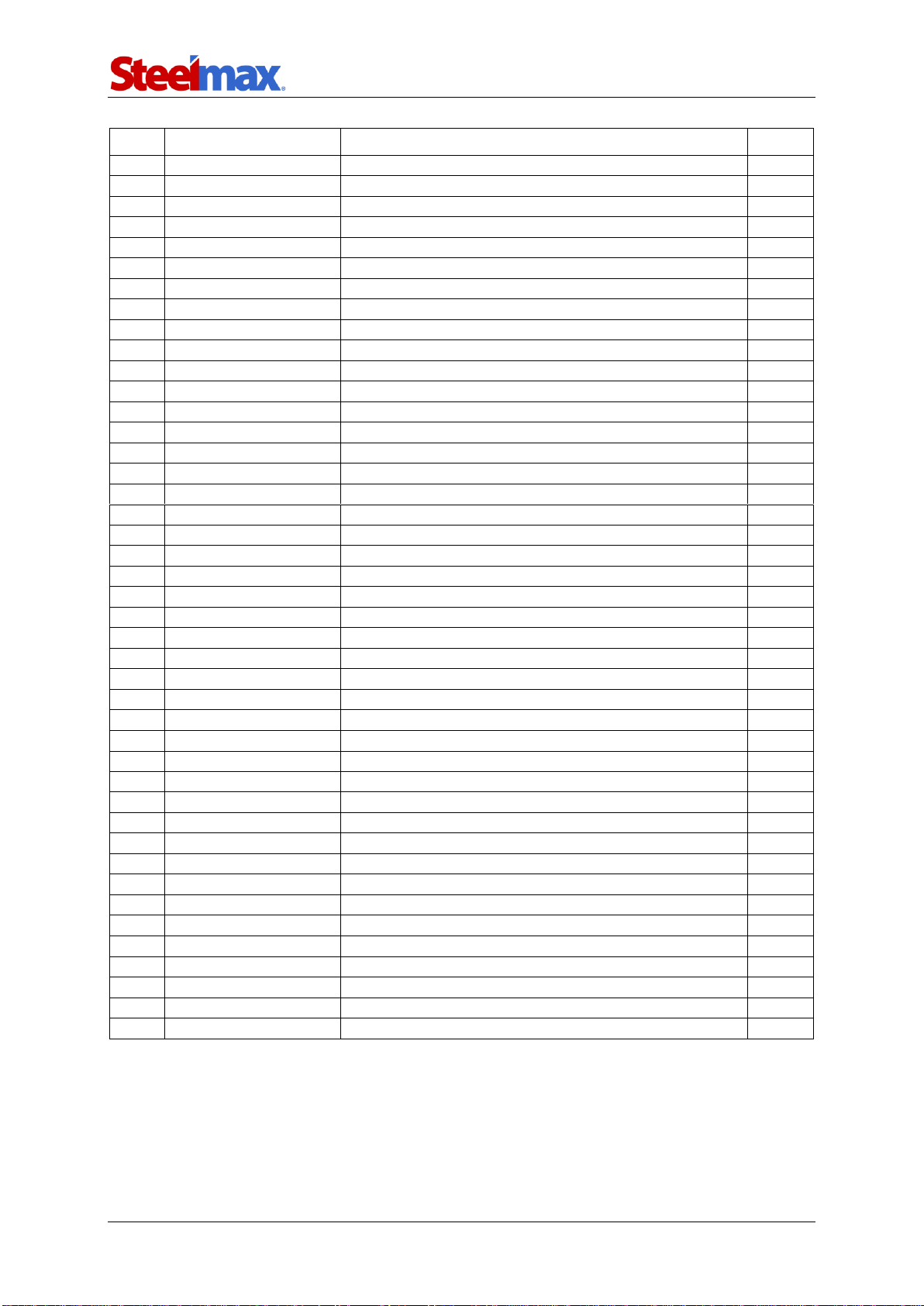

ITEM

PART NUMBER

DESCRIPTION

Q-TY

1

OBD-0497-09-00-00-0

HOUSING ASSY

1

2

ZLP-000020

CAP

4

3

PKT-000027

KNOB

4

4

WSK-000008

KNOB INDICATOR

4

6

WKR-000372

COUNTERSUNK HEAD SCREW M3x5

5

7

WZK-0497-09-02-00-0

TRAVEL DIRECTION SWITCH WIRE SET ASSY

1

8

WKR-000313

HEX SOCKET BUTTON HEAD SCREW M3x8

7

9

OBD-0497-09-01-00-0

HOUSING

1

10

WZK-0497-09-03-00-0

POWER CORD WIRE SET

1

11

NKR-000040

STRAIN RELIEF NUT

1

12

PDK-000058

EXTERNAL TOOTH LOCK WASHER 3.2

1

13

PDK-000041

SPRING WASHER 3.1

1

14

NKR-000009

HEX NUT M3

1

15

TLJ-000122

DISTANCE SLEEVE

5

16

MDL-0497-09-07-00-0

MODULE

1

17

MDL-0497-09-06-00-0

OSCILLATOR MODULE ASSY

1

18

SRB-000063

HEX SOCKET HEAD CAP SCREW M4x14

3

19

SLN-0497-10-00-00-0

MOTOR

1

20

DYS-0497-04-00-00-0

MOTOR PLATE

1

21

NKR-000139

LOW HEX NUT M6

2

22

WKR-000292

HEX SOCKET BUTTON HEAD SCREW M4x6

8

23

PRS-000003

EXTERNAL RETAINING RING 12z

1

24

LOZ-000085

BALL BEARING 12x24x6

2

25

PDK-000178

WASHER 12x18x0.2

4

26

KRP-0497-01-00-00-0

BODY

1

27

LOZ-000123

BALL BEARING 10x19x5

1

28

PAS-000013

TOOTHED BELT 130XL037

1

29

WZK-0497-11-00-00-0

TRANSOPTOR WIRE SET

1

30

WKR-000180

CROSS RECESSED PAN HEAD SCREW M3x5

2

31

WKR-000484

HEX SOCKET SET SCREW WITH FLAT POINT M3x3

1

32

KOL-0497-02-00-00-0

MOTOR GEAR ASSY

1

33

PDK-000155

SMALL ROUND WASHER 6.4

4

34

LOZ-000110

BALL BEARING 6x15x5

8

35

DCS-0497-07-00-00-0

BELT HOLDER

1

36

SRB-000386

HEX SOCKET ULTRA LOW HEAD CAP SCREW M6x20

4

37

WDZ-0497-03-00-00-0

CROSSHEAD

1

38

SRB-000301

LOW HEAD HEX SOCKET CAP SCREW M6x14

1

39

WPS-000033

PARALLEL KEY 5x5x20

2

40

WLK-0497-05-00-00-0

SHAFT

1

41

OSL-0497-08-00-00-0

FRONT COVER

1

42

KLK-000034

DOWEL PIN 4n6x14

2

43

OPR-0497-06-00-00-0

BEARING MOUNTING

1

44

SRB-000063

HEX SOCKET HEAD CAP SCREW M4x14

4

OSC 8

OSC 8 Operator’s Manual

19

6. WIRING DIAGRAM

OSC 8

OSC 8 Operator’s Manual

20

7. DECLARATION OF CONFORMITY

Declaration of Conformity

PROMOTECH sp. z o.o.

ul. Elewatorska 23/1

15-620 Białystok

Poland

We declare with full responsibility that:

OSC 8 Pendulum Oscillator

is manufactured in accordance with the following standards:

•EN 12100

•EN 60204-1

•EN 60974-10

and satisfies regulations of the guidelines: 2004/108/EC, 2006/95/EC, 2006/42/EC.

Person authorized to compile the technical file:

Marek Siergiej, ul. Elewatorska 23/1, 15-620 Białystok, Poland

Białystok, 5 September 2016 ___________________________

Marek Siergiej

CEO

Table of contents