14

Notes on the operating instructions

- The operating instructions are in-

tended for specialist workers and

trained personnel.

- Before each stage of work, read the

relevant notes and warnings care-

fully, and keep to the sequence as

stated.

- Pay particular attention to the sec-

tion on ”General safety warnings”.

If you have any problems or questions,

please contact your supplier or

consult KELLER directly.

1. Description of the device

General description

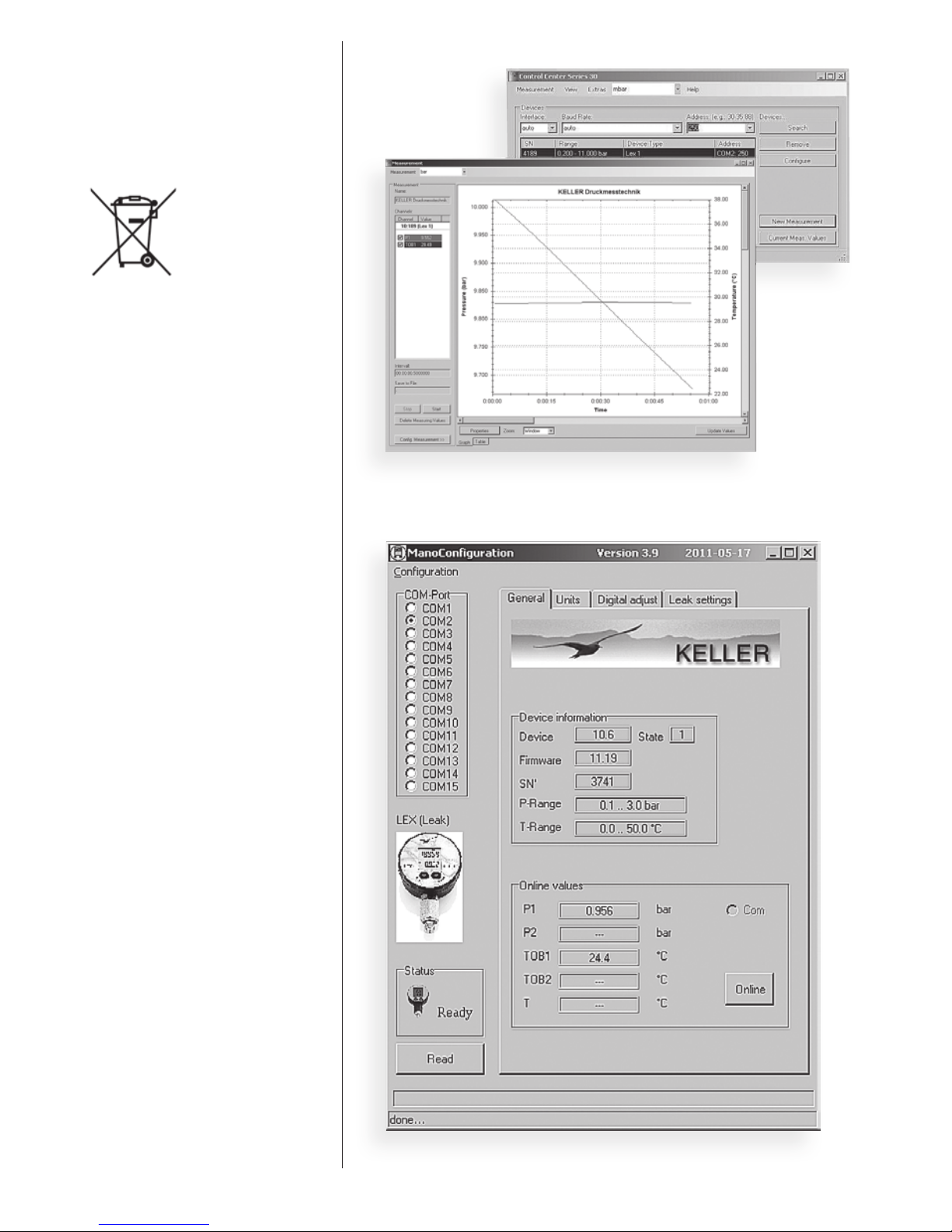

The high pressure calibrator enables

pressure to be generated by means of

the integrated pressure pump, up to

700 bar relative.

The measurement technology incor-

porated into this device allows ac-

curate measurement and documen-

tation of the characteristic of a test

object that is connected to it. The

measured pressure progression can

be displayed, evaluated and saved

with a computer monitoring program

(CCS30).

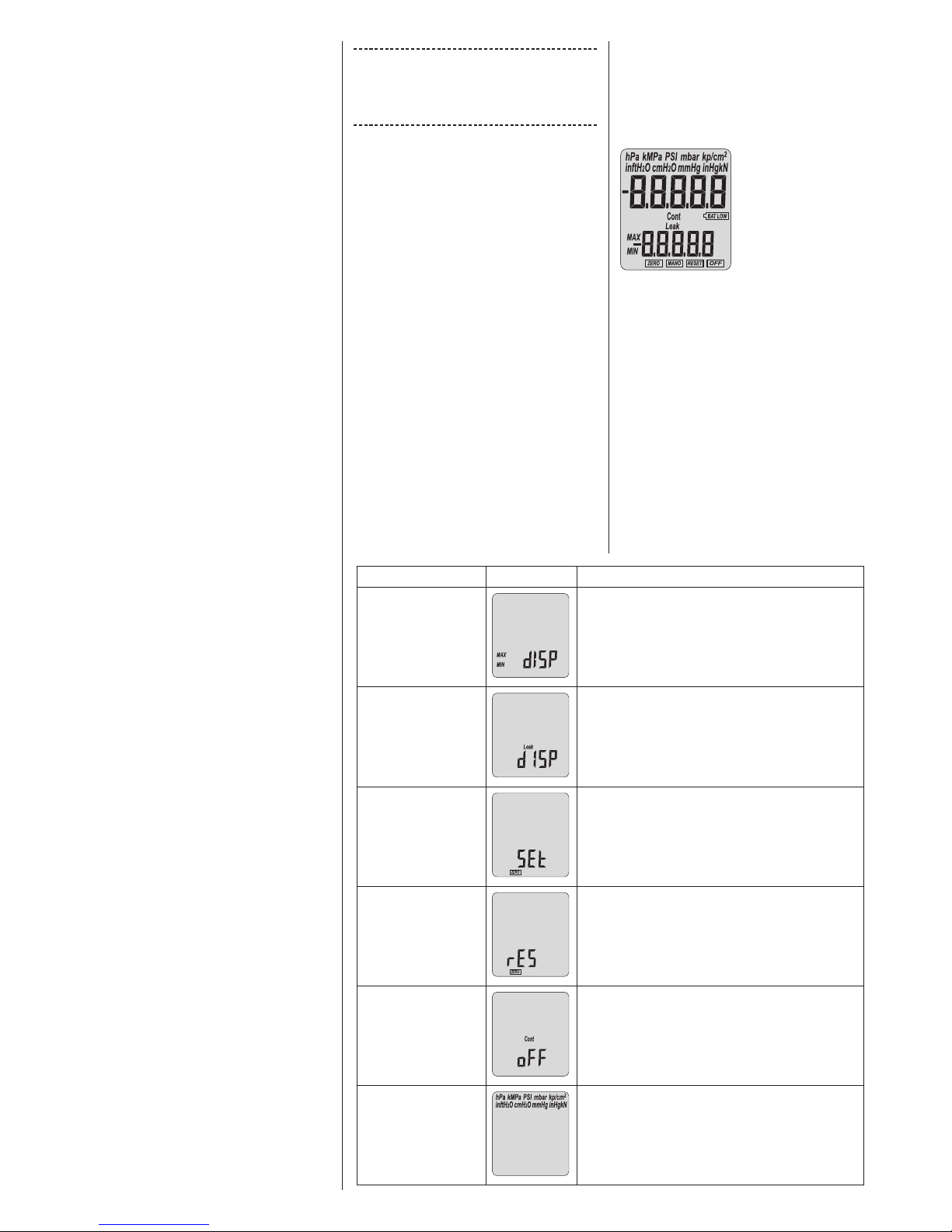

The calibrator is operated with the

two function buttons SELECT and

ENTER, located directly below

the display. The calibrator itself is

powered by a 3,0 V battery, but power

can also be supplied externally via the

K-114A interface converter. Test ob-

jects (transmitters or pressure switch-

es) must be supplied from an external

source.

Pressure range for the display

High pressure calibrators are them-

selves calibrated with the ambient air

pressure as the zero point reference.

The Zero function allows any desired

pressure value to be set as the new

zero point reference.

To take relative measurements,

the high pressure calibrator is

zeroed at ambient pressure (Set

Zero). To reset the pressure zero

point to the factory setting, use the

RES Zero function (reset zero).

Commissioning

A pressure-resistant connection for

the test object is required in order to

use the high pressure calibrator. The

pressure connection for the test object

is already screwed to the pressure

distributor of the high pressure calibra-

tor so that it is pressure resistant when

it leaves the factory, and it must not be

dismantled.

Recommended torque for the test

object pressure connection: 30 Nm

IMPORTANT!

Nothing must adhere to the surface of

the test object (no oil, grease, water,

etc). Impurities could pass through the

adapter to reach the high pressure

calibrator and damage it.

Overpressure

If the pressure exceeds the measuring

range by more than 20%, the measur-

ing cell or the mechanism of the high

pressure calibrator may be destroyed.

Recalibration

The recalibration cycle depends on

the conditions of use. Recommended

recalibration cycle: 1 year.

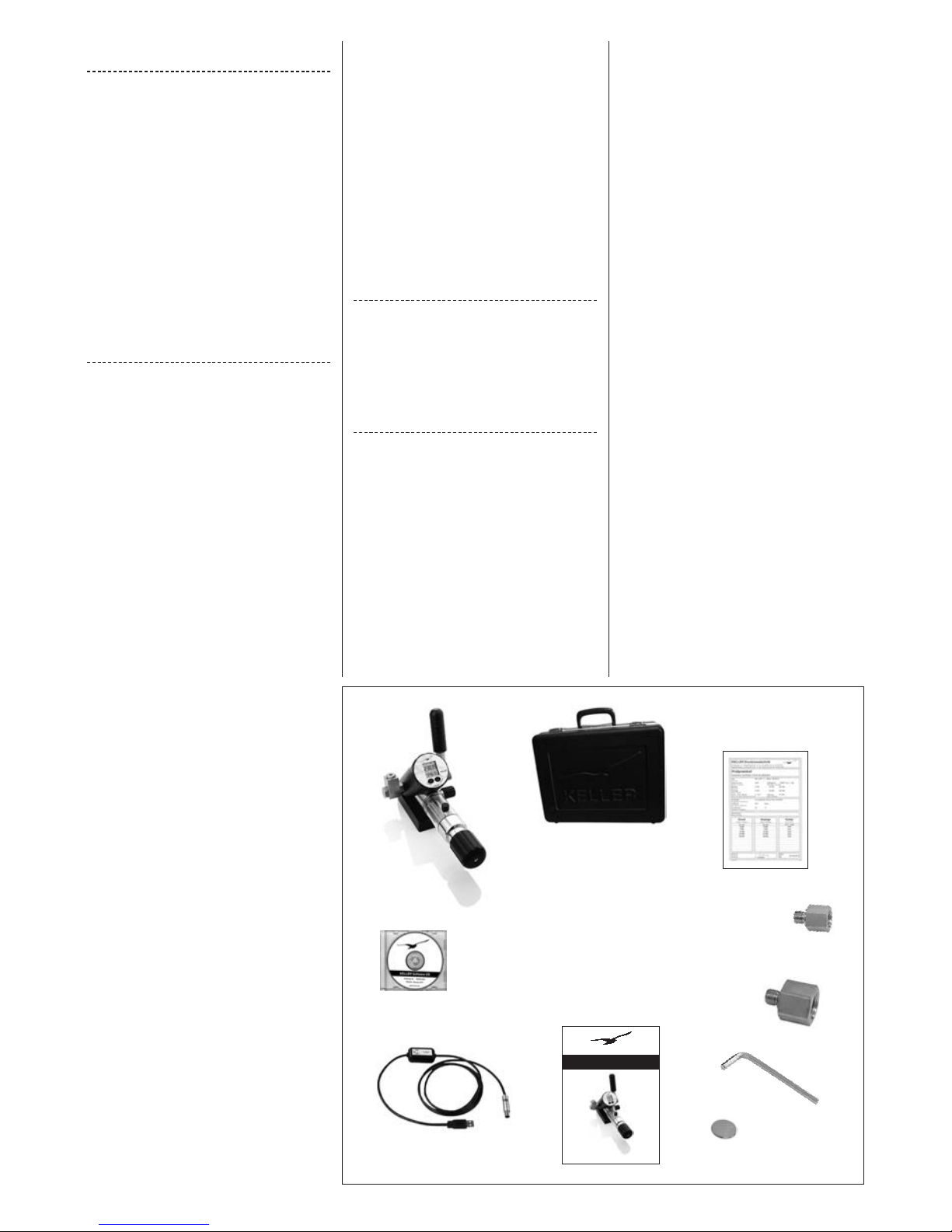

Scope of delivery

- 1calibrator(includingoillling)

- 1 carrying case

- 1 test record (5 points)

- 1testobjectadapterG1/4”–G1/8”

- 1testobjectadapterG1/4”–G1/2”

- 1 Allen key

-

1 spare battery, type CR2430 (3,0 V)

- 1 set of operating instructions

- 1 USB interface converter, K-114A

- 1 KELLER software CD

Intended use

The high pressure calibrator (HPX)

may only be used to generate pres-

sure with the type HLP 22 BP hydrau-

lic oil that is supplied with the product.

Use of the calibrator with other media

will damage it. The operational safety

of the device supplied is guaranteed

only if it is used as intended. The limit

values as stated (see page 19: ”Tech-

nical data”) must never be exceeded.

Before installing the high pressure

calibrator, check that it is suitable for

your applications.

2. General safety warnings

The current national regulations on

accident prevention and workplace

Operating instructions for the

high-pressure calibrator (HPX)

October 2012

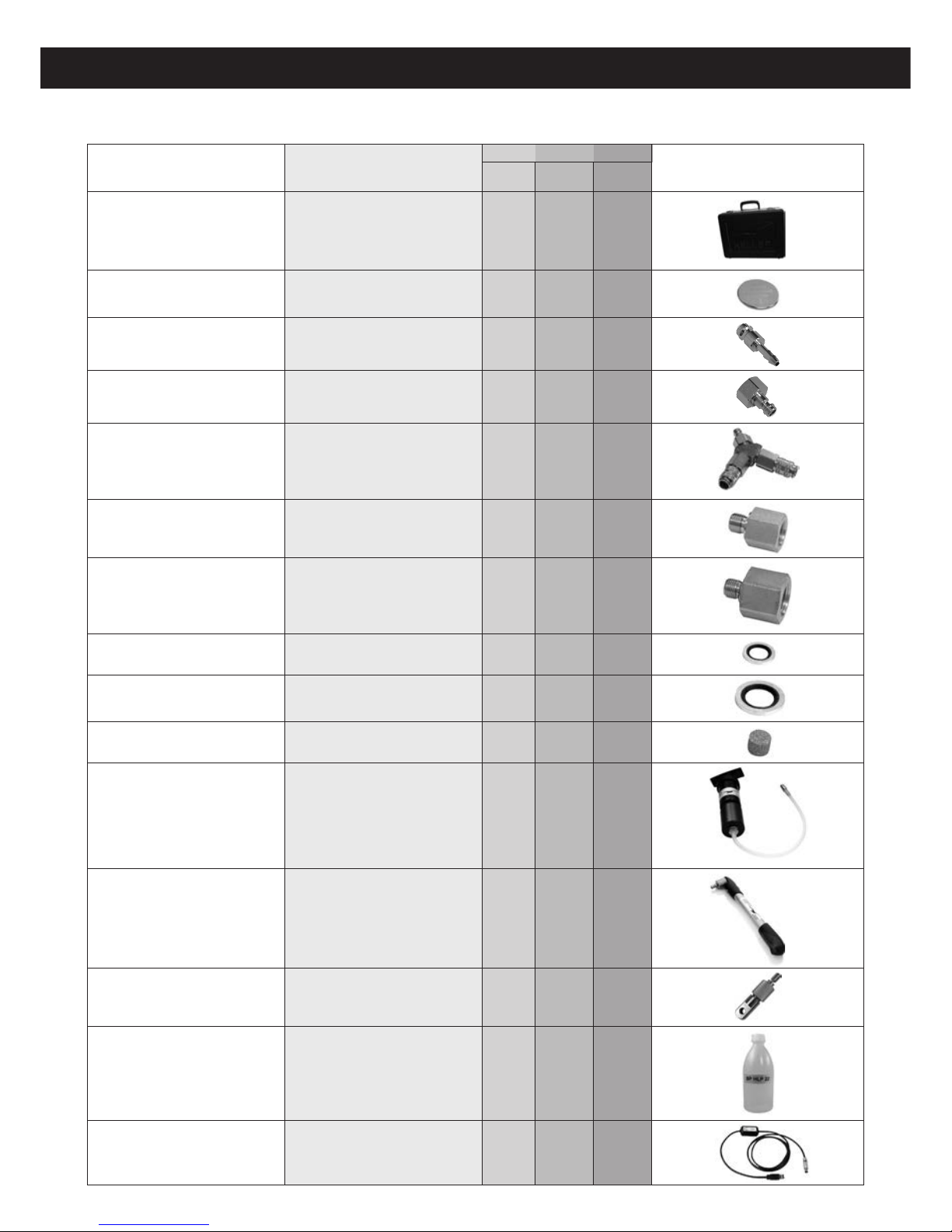

Scope of delivery

High pressure calibrator