1. DESCRIPTION

1.1. FUNCTION

The HYDAC charging and testing unit

FPU-1 is used to charge accumulators with

nitrogen or to check or to change the

existing pre-charge pressure in

accumulators.

For this purpose the charging and testing

unit is screwed onto the gas valve of the

hydraulic accumulator and connected via a

hose to a commercial nitrogen bottle.

If the nitrogen pressure is only to be

checked or reduced, the charging hose

does not need to be connected. The unit

has a screw-type tting with a built-in

gauge, check valve and a spindle for

opening the accumulator gas valve to

control the pressure.

HYDAC piston and diaphragm

accumulators can be charged and checked

without the need for adapters. Bladder

accumulators, however, require an A3

adapter.

Please read the Operating Manual!

No. 3.501.CE

Universal Charging

and Testing Unit FPU-1

for Bladder, Piston and Diaphragm

Accumulators

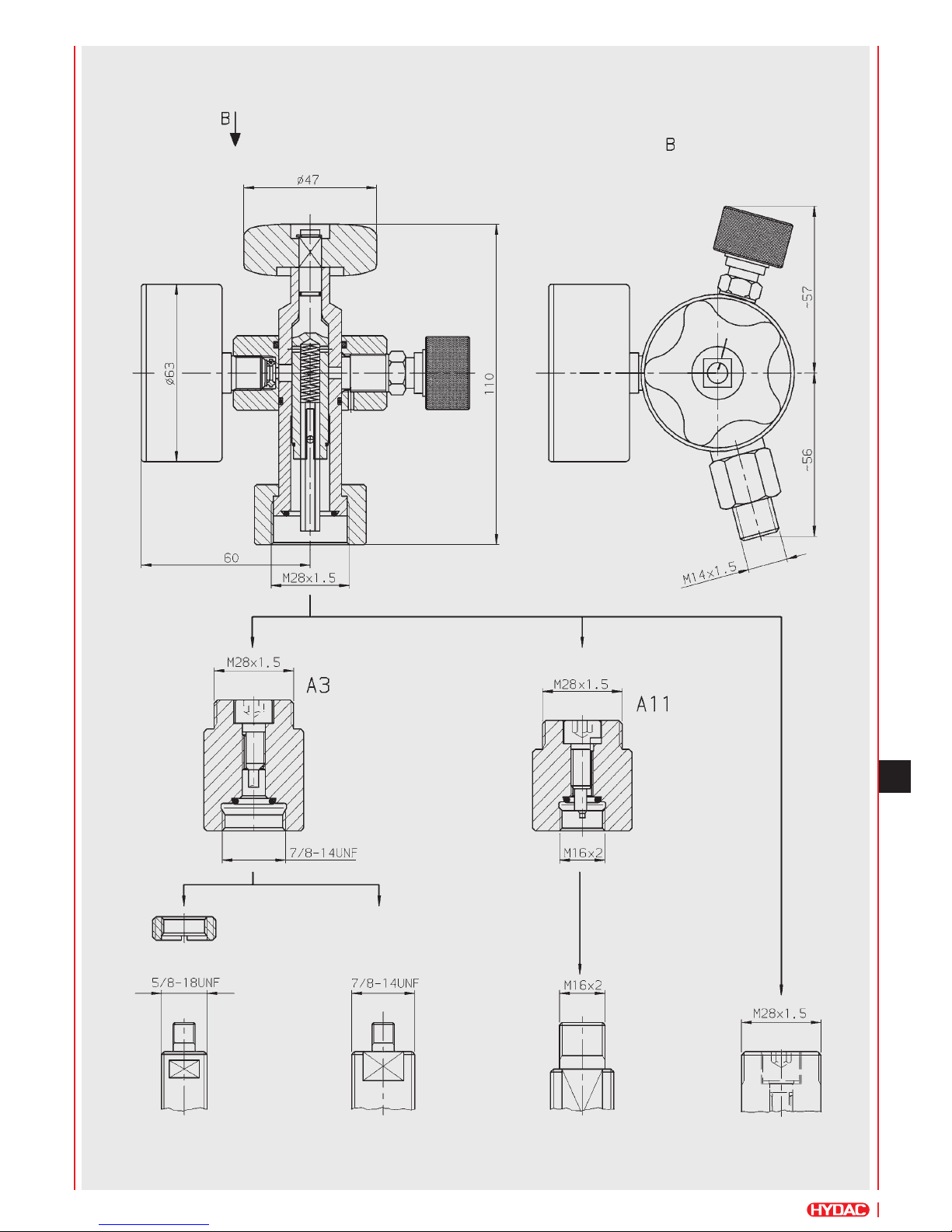

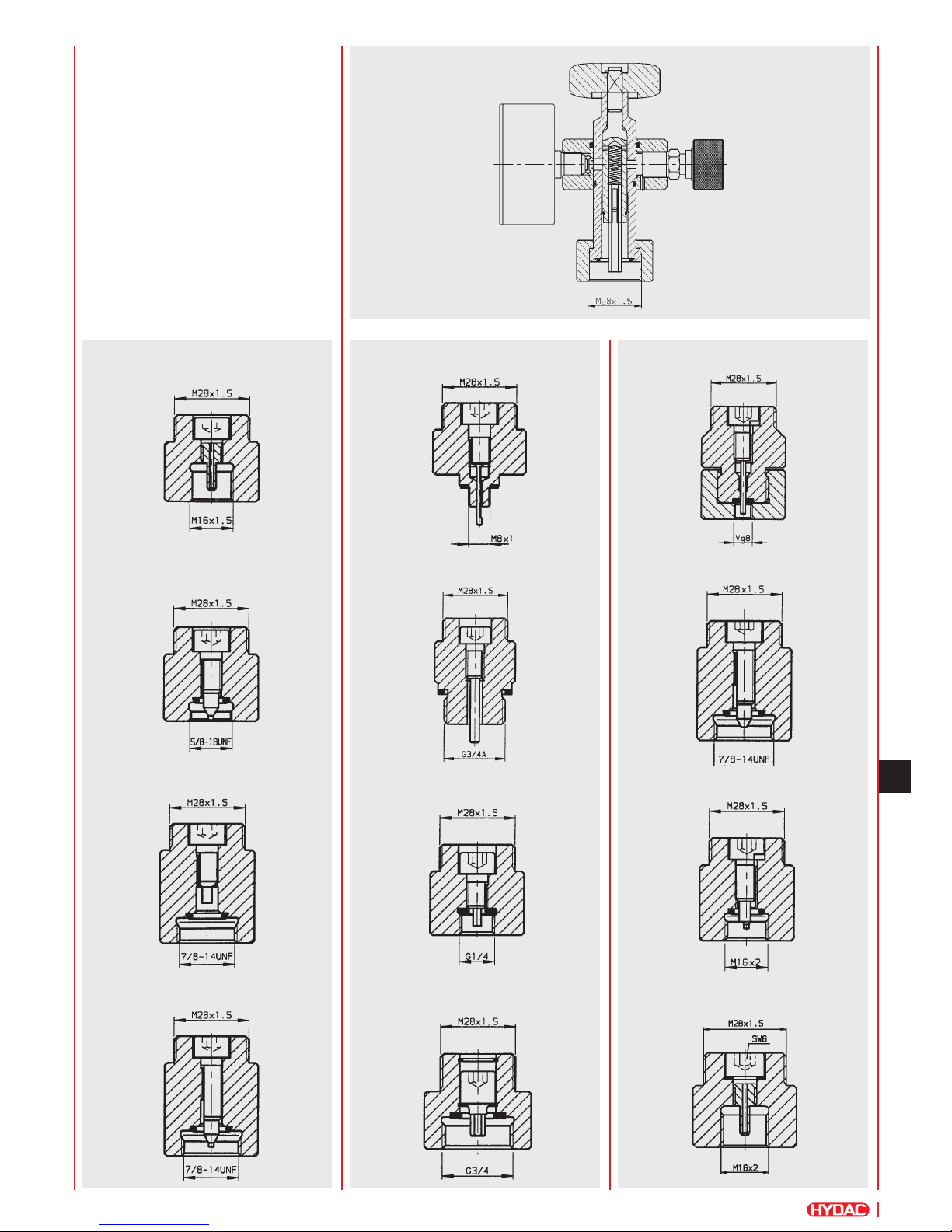

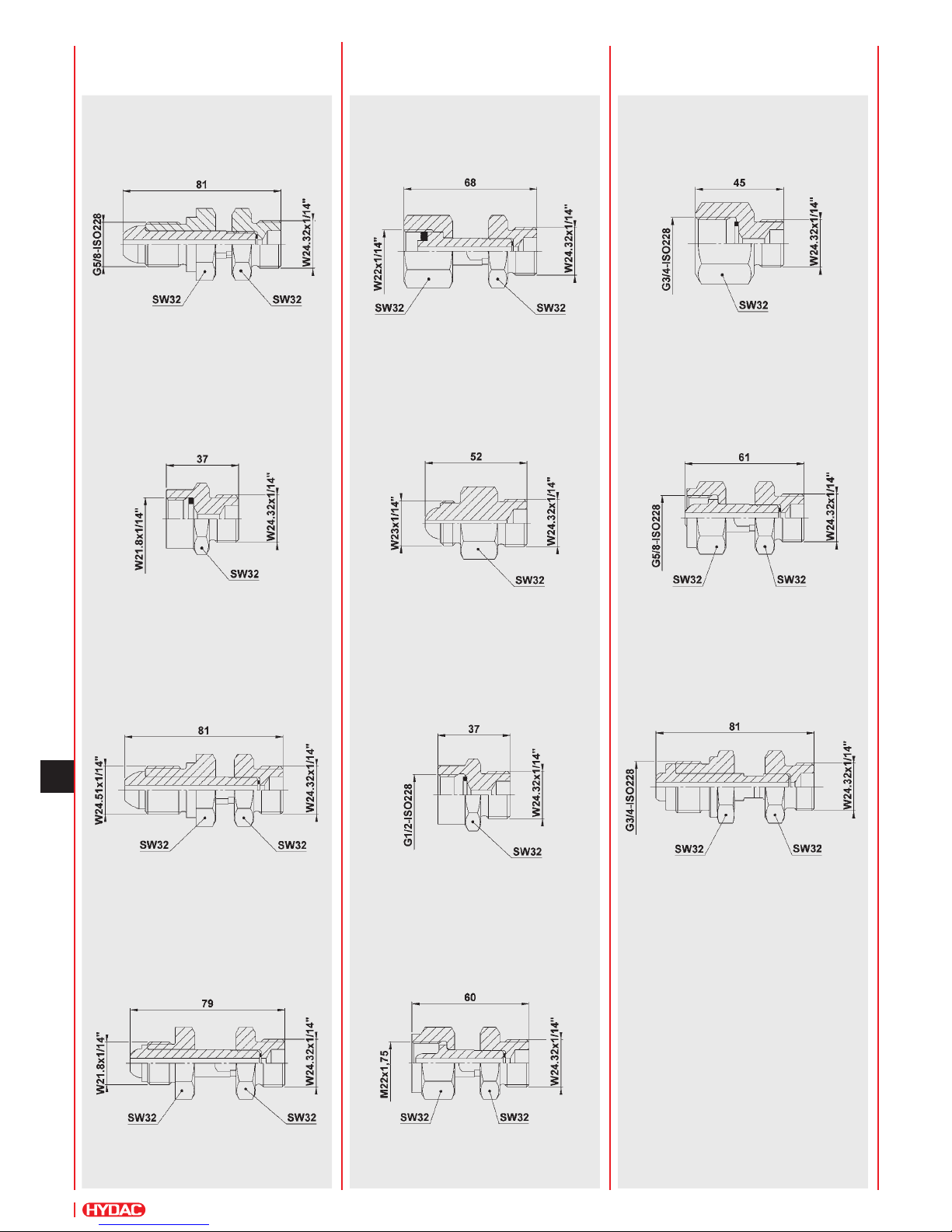

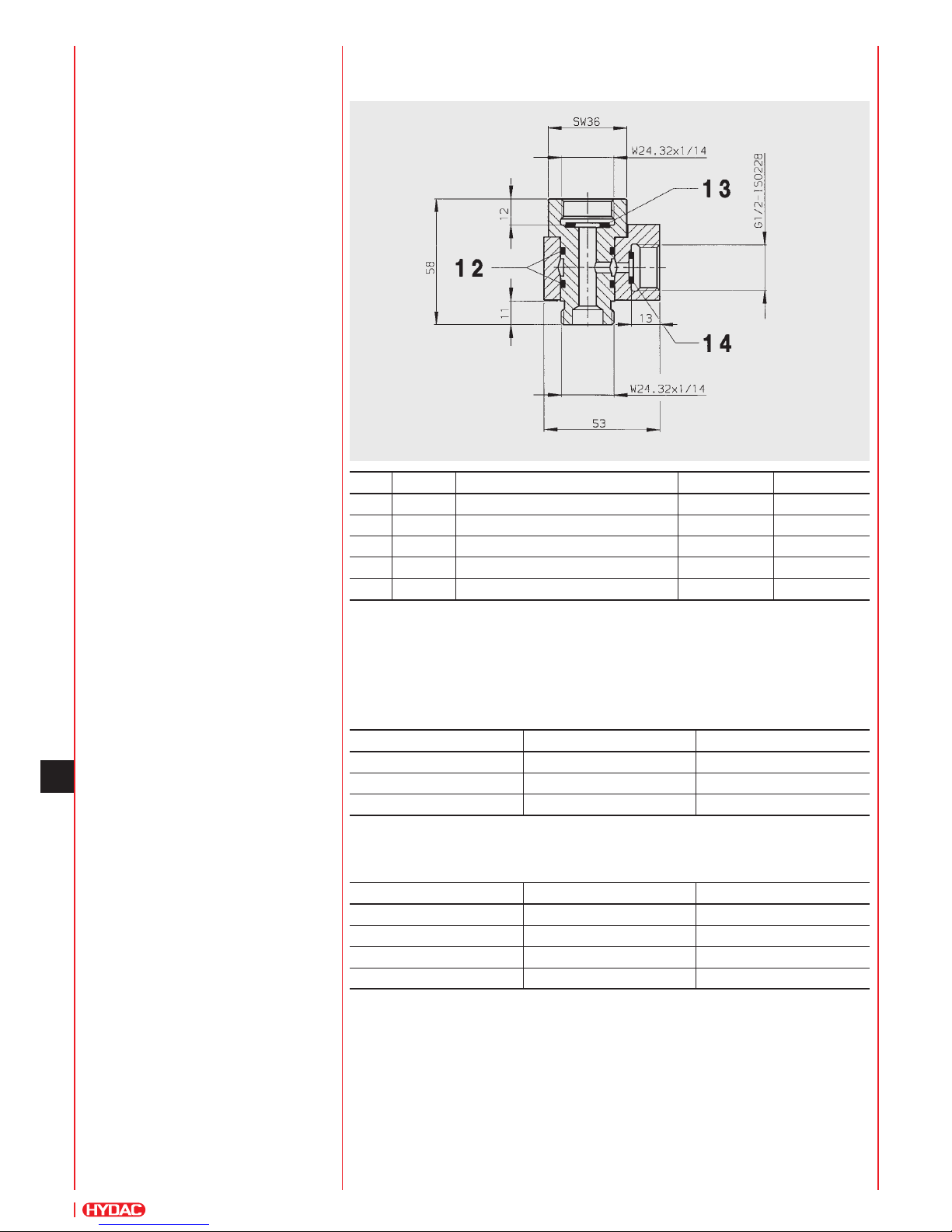

1.3. SPECIAL MODELS1.2. DESIGN

The HYDAC charging and testing unit

for bladder, piston and diaphragm

accumulators consists of:

zValve body

zSpindle

zCheck valve

zRelease valve

zPressure gauge

zCharging hose

zA3 adapter for bladder accumulators

Release valve

Spindle

Check valve

Pressure gauge

For higher pressures, the following special

models are available:

zFPS 600

for bladder accumulators up to 600 bar

max. pre-charge pressure (see technical

information 293715).

zFPK 600

for piston, diaphragm and

SB800-1.5 accumulators up to 600 bar

max. pre-charge pressure (see

technical information 297248).

zFPH 800

for high pressure bladder accumulators

up to 800 bar max. pre-charge pressure

(see technical information 242948).

The photo top left shows a possible order

option, including accessories.