3

TABLE OF CONTENTS

1. T YPICAL INSTALLATIONS ......................................................................................................................... 4-5

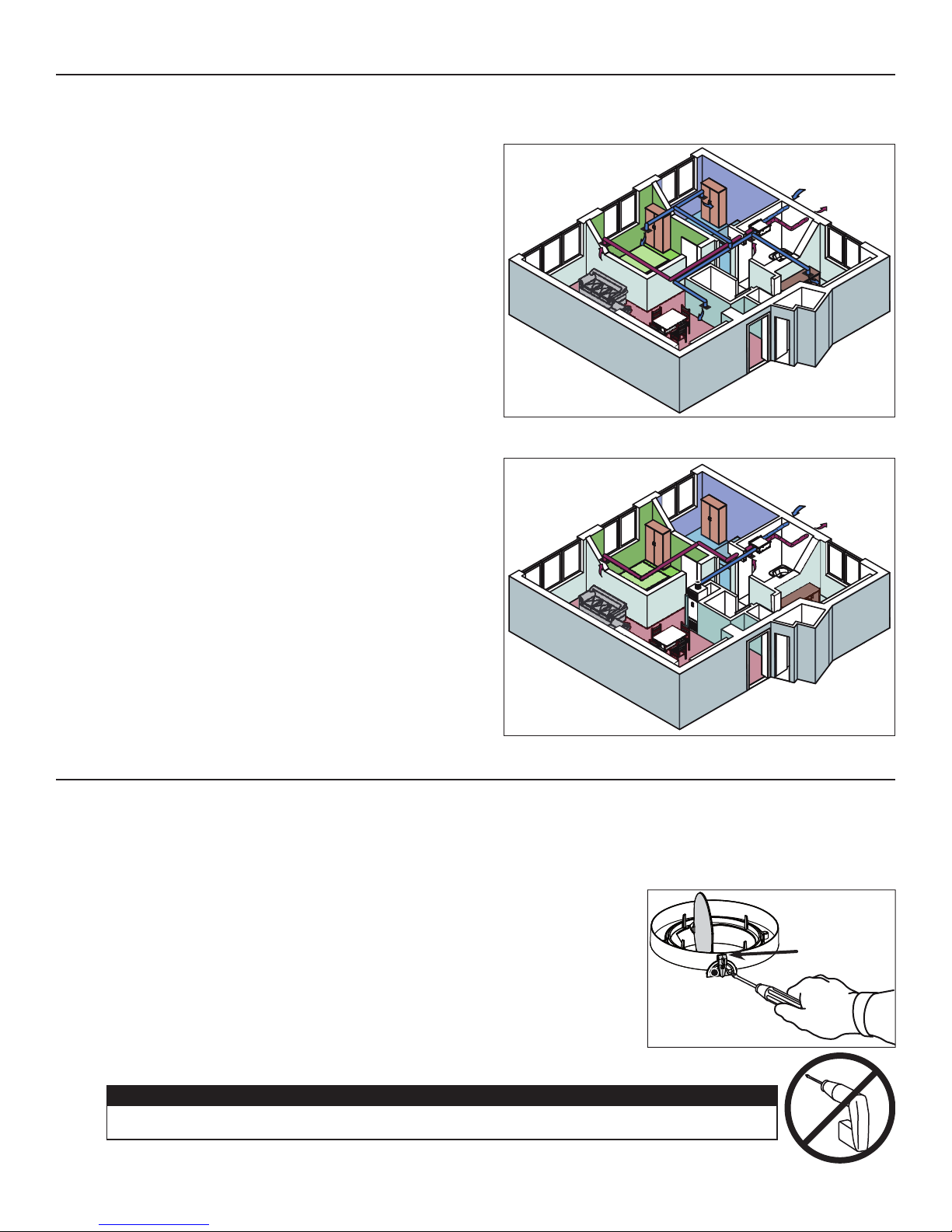

1.1 FOR HOUSE .................................................................................................................................................. 4

1.1.1 FULLY DUCTED SYSTEM............................................................................................................................................4

1.1.2 CENTRAL DRAW POINT.............................................................................................................................................4

1.1.3 SIMPLIFIED INSTALLATION...........................................................................................................................................4

1.2 FOR HIGH-RISE DWELLING .............................................................................................................................. 5

1.2.1 FULLY DUCTED SYSTEM ...........................................................................................................................................5

1.2.2 CENTRAL DRAW POINT ............................................................................................................................................5

2.INSTALLATION..................................................................................................................................... 5-12

2.1 INSPECT THE CONTENT OF THE BOX .................................................................................................................. 5

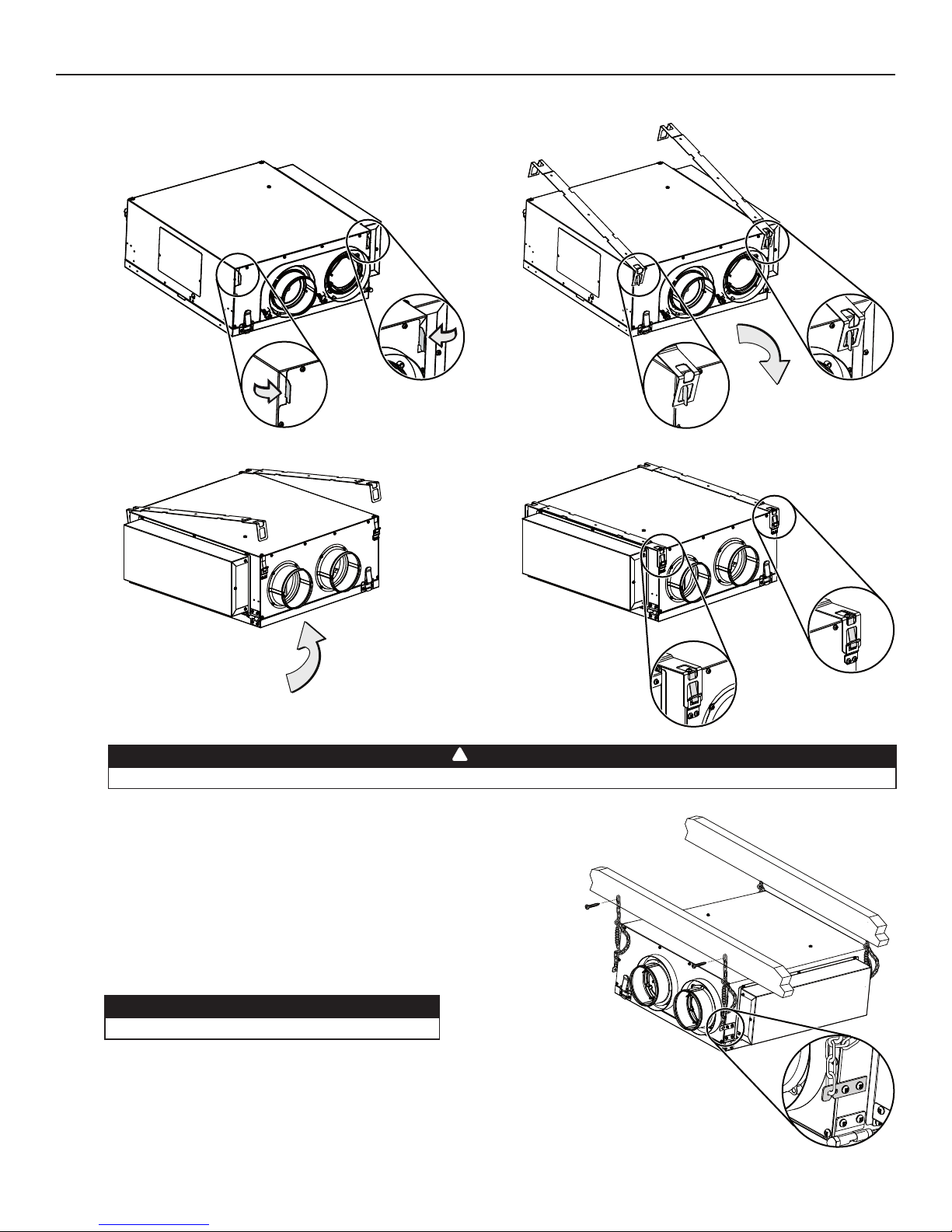

2.2 UNIT PREPARATION ......................................................................................................................................... 5

2.3 LOCATING THE UNIT ........................................................................................................................................ 6

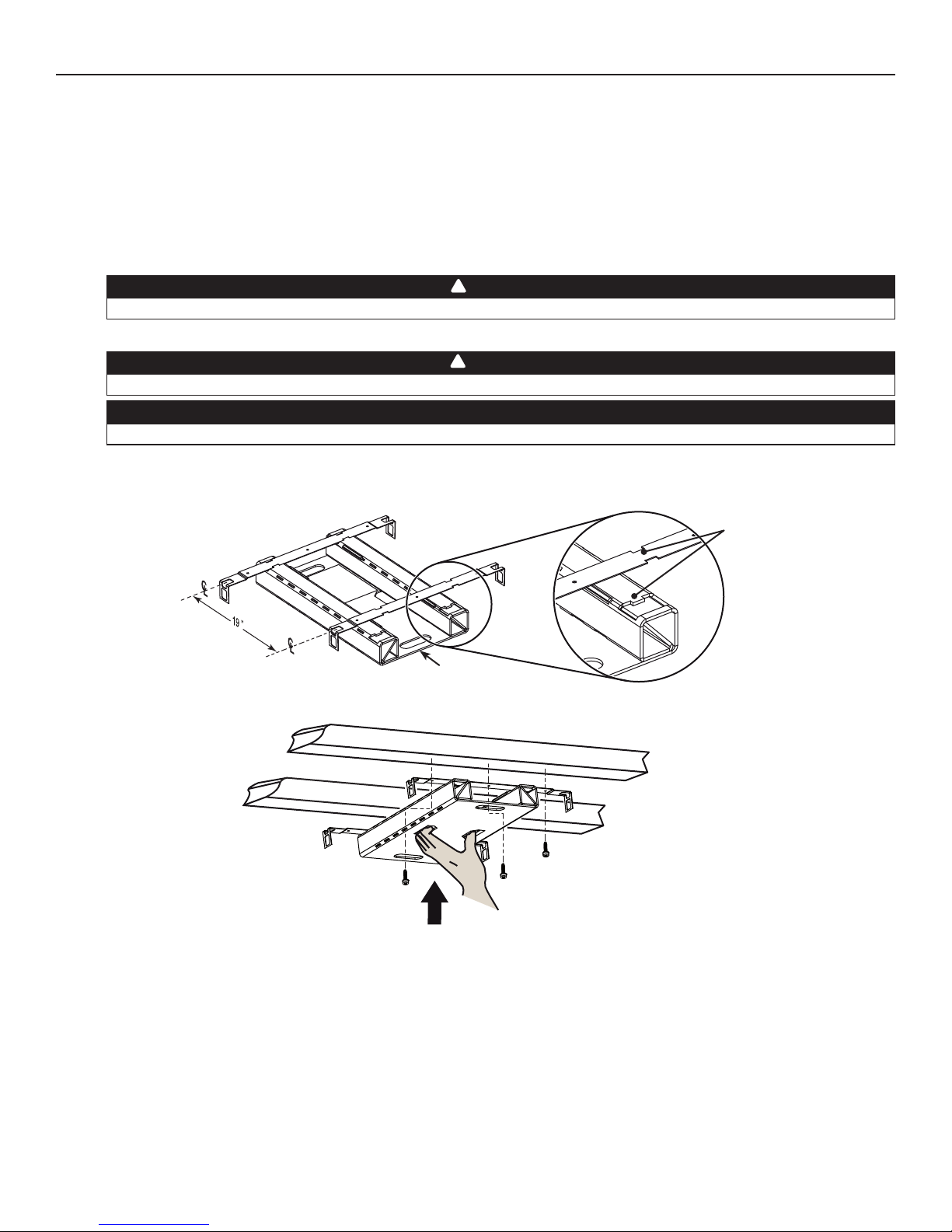

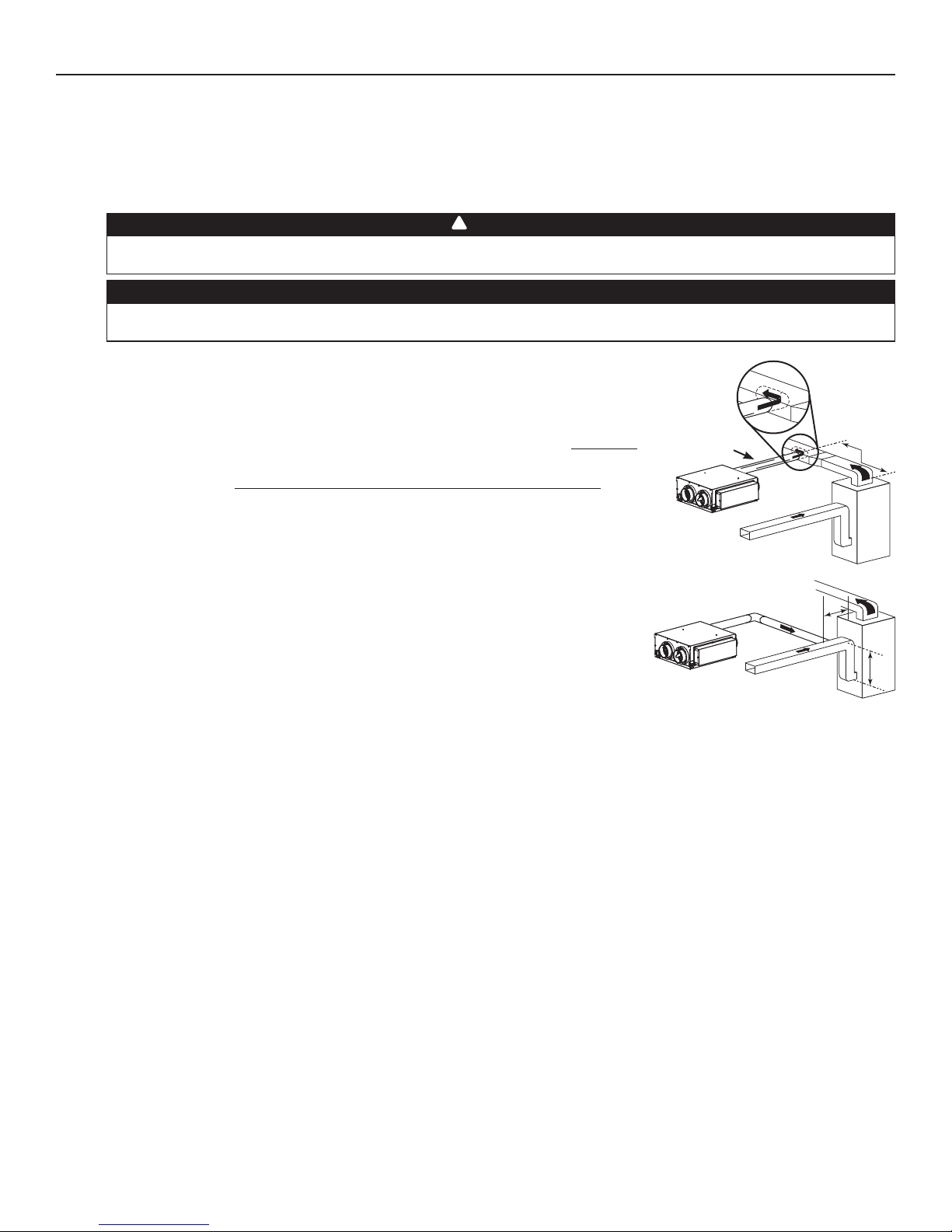

2.4 HOW TO HANG THE UNIT ..............................................................................................................................6-8

2.5 PLANNING OF THE DUCTWORK .......................................................................................................................... 8

2.6 INSTALLING THE DUCTWORK AND REGISTERS ................................................................................................. 8-10

2.6.1 FULLY DUCTED SYSTEM...........................................................................................................................................8

2.6.2 CENTRAL DRAW POINT............................................................................................................................................9

2.6.3 SIMPLIFIED INSTALLATION........................................................................................................................................ 10

2.7 CONNECTING THE DUCTS TO THE UNIT..............................................................................................................11

2.8 INSTALLING 2 EXTERIOR HOODS...................................................................................................................... 12

2.9 INSTALLING TANDEM®TRANSITION KIT .............................................................................................................. 12

3.CONTROLS...................................................................................................................................... 13-16

3.1 BOOTING SEQUENCE ..................................................................................................................................... 13

3.1.1 ERV100SP UNIT BOOTING SEQUENCE ................................................................................................................... 13

3.1.2 ERV100S UNIT BOOTING SEQUENCE ..................................................................................................................... 13

3.2 ERV100SP UNIT INTEGRATED DEFROST CONTROL........................................................................................... 14

3.3 ERV100S UNIT INTEGRATED CONTROL........................................................................................................... 14

3.4 SETTING EXTENDED DEFROST FOR ERV100S UNIT.......................................................................................... 14

3.5 ELECTRICAL CONNECTION TO WALL CONTROLS ............................................................................................ 15-16

3.5.1 ELECTRICAL CONNECTION TO VT8W MAIN WALL CONTROL ........................................................................................16

3.5.2 ELECTRICAL CONNECTION TO VT7W MAIN WALL CONTROL ........................................................................................16

3.5.3 ELECTRICAL CONNECTION TO VT4W MAIN WALL CONTROL ........................................................................................16

3.5.4 ELECTRICAL CONNECTION TO VT6W MAIN WALL CONTROL ........................................................................................16

3.5.5 ELECTRICAL CONNECTION TO OPTIONAL AUXILIARY WALL CONTROLS ............................................................................16

4.ELECTRICAL CONNECTION TO THE FURNACE ...............................................................................................17

5.SPEED SELECTION .................................................................................................................................17

6.WIRING DIAGRAM ..................................................................................................................................18

7. B ALANCING THE UNIT ..............................................................................................................................19

7.1 WHAT YOU NEED TO BALANCE THE UNIT .......................................................................................................... 19

7.2 PRELIMINARY STAGES TO BALANCE THE UNIT .................................................................................................... 19

7.3 BALANCING PROCEDURE ................................................................................................................................ 19

8.SERVICE PARTS............................................................................................................................... 20-21

9.TROUBLESHOOTING .......................................................................................................................... 22-24