SKU 90636 For technicial questions, please call 1-800-444-3353. Page 3

7. Maintaintools withcare. Keepclean. Donotuse adamagedtool. Tagdamaged

tools “Do not use”until repaired.

8. Tool service must be performed only by qualified repair personnel. Service or

maintenanceperformed byunqualifiedpersonnel could resultin a risk of injury.

9. Maintain labels and nameplates on this

tool.Thesecarryimportant information.

Ifunreadableormissing, contactHarbor

FreightTools for a replacement.

10. Always wear ANSI approved safety

impact eye goggles and heavy work

gloves when using this tool. Using

personal safety devices reduce the risk

for injury.Safetyimpacteyegogglesand

heavy work gloves are available from

Harbor FreightTools.

11. Maintain a safe working environment. Keep the work area well lit. Make sure

there is adequate surrounding workspace. Always keep the work area free of

obstructions, grease, oil, trash, and other debris. Do not use this tool in areas

near flammable chemicals, dusts, and vapors. Do not use this product in a

damp or wet location.

WARNING! People with pacemakers should consult their physician(s) before

using this product. Operation of electrical equipment in close proximity to a

heart pacemaker could cause interference or failure of the pacemaker.

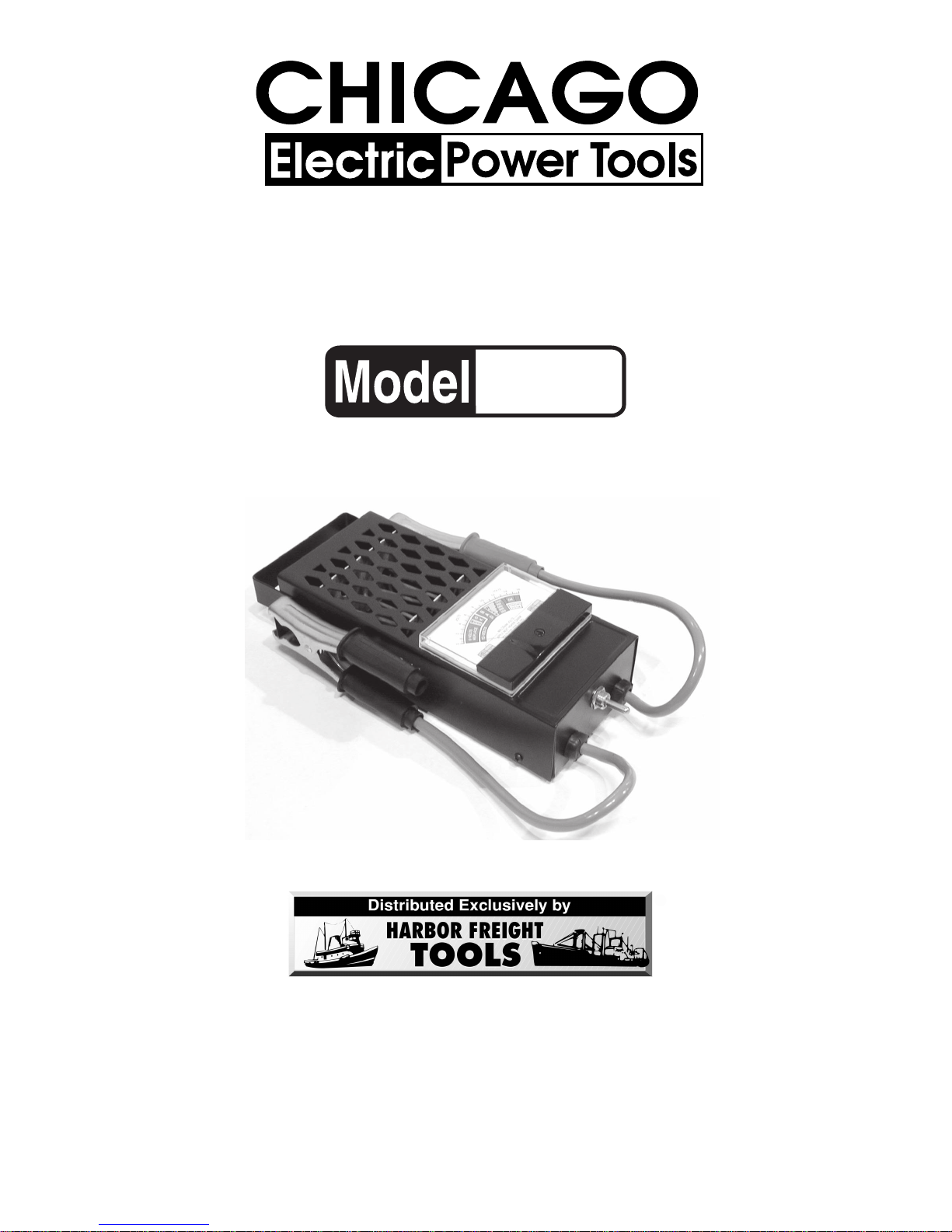

SPECIFIC SAFETY RULES FORTHE BATTERYTESTER

1. WhenconnectingtheBatteryCablestothebattery,avoidcreatingsparks(always

connect and disconnect clamps exactly as described in rule number 2, below,

and on page 4), especially when the battery is being charged.Explosive gases

are created during charging.Sparking could also damage the vehicle electrical

system.

2. Be certain of the test battery polarity before connecting the test Cable Clamps.

The red Cable Clamp (A) goes to the positive terminal of the battery.The black

Cable Clamp (B) goes to the negative terminal of the battery.

3. Whenplacing theBatteryTesterin thevehicle(on the frame,engine,orfender),

take special care that the metal housing of the BatteryTester does not come in

contact with either terminal of the battery or other electrical connections.

4. Do not drop the Battery Tester as it may affect proper operation.

5. Do not smoke or have open flames near the battery.

CAUTION!

Battery acid may cause severe

injury to eyes; always wear ANSI

approved safety goggles. Avoid

touching eyes while working with or

nearabattery. In caseof accidental

contact, rinse eyes with clean

water for at least 5 minutes and

see a doctor immediately.