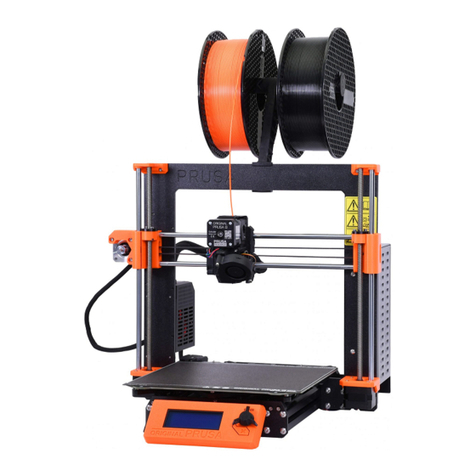

Stef's Engineering Prusa I3 MK3 Manual

Custom lighting kit for the Prusa I3 MK3

Build instructions

2

Introduction

Thank you for downloading my design! The content of this manual shows the main steps of the build

of this lighting kit I designed for the Prusa I3 MK3 printer. This is my first manual and my goal is to

give global instructions for the build together with a couple of build/purchase suggestions based on

my experiences building the lights myself.

There are a couple steps in the build that are shown in more detail in the video published on

YouTube, I recommend using the combination of this manual and the video during the build. If you

have any questions please feel free to comment below the video.

3

Before we start

There are a couple of important choices to make before you start printing the parts. And ordering the

hardware and electronics. These are things I also needed to consider during the design and they are

important for the success of the build.

Materials

I’ve printed these lights in both PLA and PETG. At first I expected PLA to be sufficient but with the

build finished I did notice that the led’s get rather hot, even with the heatsinks. I recommend that

you use a material that is capable of handling a bit higher temperatures than PLA. I used PETG in the

final design and haven’t had issues yet.

Electronics

I use a meanwell LPV-35-12 powersupply, it works well and can easily handle both leds. It does

however require you to work on wiring that connects to the mains electricity in your home. If you are

unclear how this should be done, or have no experience handling these circuits I strongly recommend

not to use this or a similar powersupply but instead use a wall adapter that is capable of supplying

the leds.

The LEDs cannot be powered from the printer’s own powersupply. It is already at the upper limit of

it’s capabilities and can not safely handle the additional load from the LED panels.

There are really cheap LED dimmers available, they work but it’s better to use one that is build a bit

better when you plan to use them as additional lighting for filming. The cheap dimmers are likely to

introduce flickering in the video.

Hardware

I made the design for Metric fasteners (DIN 912) . It may be possible though to use Imperial fasteners

that are very similar in dimensions, you can try this but I cannot guarantee that it will work. If it

doesn’t you can use the CAD files that I published to change the design to fit your needs.

I understand that theaded bushings are not as easily obtainable as normal bolts and nuts. Because of

that I Added a slightly modified version of the main body STL file that has a recess to fit a common

nut (DIN 934)

4

Parts overview

For this build you will need to buy and make a couple of parts, I’ve listed them below:

Shopping list:

2x - COB LED panel (120x35mm 12V 10W) sold by many suppliers on Ebay

4x - Aluminium heatsink (150x20mm) sold by many suppliers on Ebay

1x –Powersupply 12V 3A (check chapter [][] for tips and alternatives before purchasing)

2x –LED dimmer (check chapter [][] for tips before purchasing)

1x –Power switch

1x –Length of thermal tape (to cover both LED panels) or a syringe of thermalpaste

2x - M4 Threaded Brass bushing

2x - M4 washer

2x - M4*12

4x - M4*6 (can be longer but will stick out of the base frame)

Print list:

2x –Main Body

2x –Base Frame

4x –Extrusion Clips

2x –Heatsink wedge (optional for when needed)

5

Preparation Step 1 : Print Parts

For this project you will need to print the following parts:

2x –Main Body

2x –Base Frame

4x –Extrusion Clips

2x –Heatsink wedge (optional for when needed)

Suggested basic print settings:

0.3mm layer height

2 or 3 perimiters

2 or 3 bottom solid layers

2 or 3 top solid layers

When all the parts are finished you will need to clean up the edges to ensure a correct fit. You can

check if you need the heatsink wedges by testfitting one of the aluminium heatsinks in the main

body. If it’s not a tight fit you will need to print these two to fix the led and heatsinks in place.

Preparation Step 2 : Electronics

Testfit if the led dimmer you purchased fit’s through the cable channel in the main body. If it doesn’t

you will have to solder the wires from the Dimmer to the LED panel already fed through this channel.

Solder the wires from the dimmer on each of the LED panels

Measure the length from the preferred position of the LED panel up to where you want to position

the powersupply and cut or extend the wires as needed. If you use one powersupply (As I do) I

recommend joining the wires behind the printer for a cleaner look.

Degrease the back of the led and apply the thermal tape (when used) or degrease in preparation of

the application of the thermal paste. Do not apply the thermal paste though until just before you are

ready to install the heatsinks to the back of the LED panel.

6

Assembly Step 1: Insert clips in frame

Assembly Step 2: Rotate clips

You should be able to insert the clips by hand without excessive force. If this not possible smooth the

surface that mates with the extrusion profile with some sandpaper, check the fit frequently.

7

Assembly Step 3: Push baseframe on lower frame printer

Assembly Step 4: Fasten M4 screws

8

Assembly Step 5: LED placement

Guide the wires from the dimmer through the cable channel and place led in it’s recess.

Assembly Step 6: Heatsink placement

Remove the backing from the thermal tape, or apply the thermal paste to the back of the LED panel.

Ensure that it is positioned straight in the recess and gently place the heatsinks one at the time. Press

them firmly against the led to ensure a good contact with the tape or paste. When your heatsinks fit

loosely in the recess, you can now fix them in place with the wedges.

9

Assembly Step 7: Fasten your lights

Guide the wires through the base frame and screw the main body in place. Connect the wires and

the build is finished!

Enjoy!

10

Disclaimer

The content of this document is furnished for informational use only, is subject to change without notice, and should not be

construed as a commitment by Stefs Engineering. Stefs Engineering assumes no responsibility or liability for any errors or

inaccuracies that may appear in the content of this guide.

The material and information contained in this document are for general information purposes only. You should not rely

upon the material or information in this document as a basis for making any business, legal or any other decisions. Whilst

we endeavour to keep the information up to date and correct, Stefs Engineering makes no representations or warranties of

any kind, express or implied about the completeness, accuracy, reliability, suitability or availability with respect to the

document or other information. Any reliance you place on such material is therefore strictly at your own risk.

Table of contents

Popular 3D Printer manuals by other brands

Felix Storch

Felix Storch Pro 3 L quick start guide

TENLOG

TENLOG TL-D5 instruction manual

Mynt3d

Mynt3d Junior2 user manual

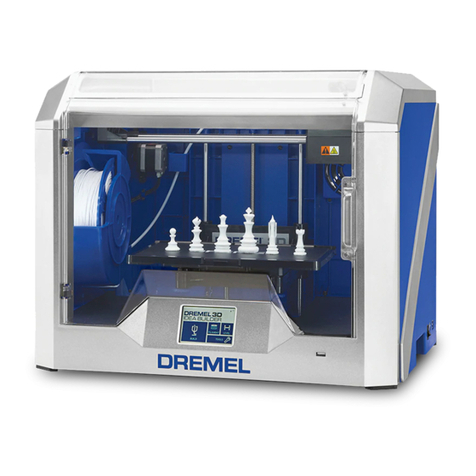

Dremel

Dremel 3D40 Idea Builder instructions

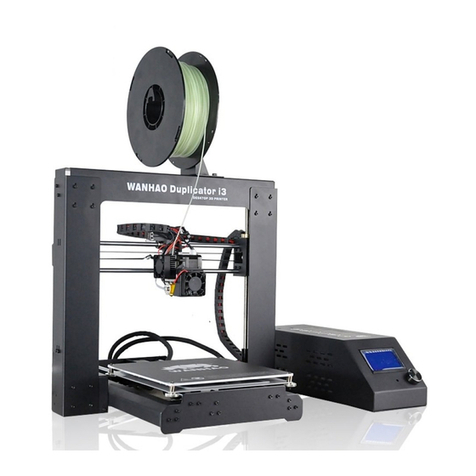

WANHAO

WANHAO Duplicator i3 Step by step installation instructions

Prusa Research

Prusa Research i3 MK2.5S Multi Material Upgrade 2S user manual