STEPCRAFT 10046 Assembly instructions

1

IMPORTANT: Read before using

Operating/Safety

Instructions

Call for consumer information

Customers from outside the U.S.

STEPCRAFT GmbH & Co. KG

An der Beile 2

58708 Menden

Germany

Phone: 0049-2373-179 11 60

Customers from the U.S. / Canada

STEPCRAFT Inc.

59 Field Street, Rear Building

Torrington, CT, 06790

United States

Phone: 001-203-5561856

Translation of the original Operating and

Safety Instructions

Date of: 11-14-2018

Heating Bed for

STEPCRAFT CNC Systems

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of

STEPCRAFT GmbH & Co. KG. For up-to date product literature, visit www.stepcraft.us for customers from North

America and Mexico or www.stepcraft-systems.com for customers from the rest of the world and click on the ser-

vice & support tab for this product.

Read the ENTIRE instruction manual in order to become familiar with the features of the product and

how to operate them. Failure to operate the product correctly can result in damage to the product,

personal property and cause serious injury, electric shock and/or fire.

Age Recommendation: For advanced handcrafters ages 14 and above. This is not a toy.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

Should you encounter any doubts or require any further information, please do not hesitate to contact us

before commissioning of the Heating Bed. Our contact details can be found on the front page of this man-

ual.

The term “power tool” in the warnings refers to your mains-operated (tethered) power supply and the Heating

Bed.

General Safety Warnings for the use of Power Tools

Work Area Safety

NOTICE

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate the power tool in explosive atmospheres, such as in the presence of flamma-

ble liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Electrical Safety

Do not expose power tools to moisture. The power tool is only suitable for indoor use. Water en-

tering a power tool will increase the risk of electric shocks.

Never spray any kind of liquids, especially inflammable liquids, onto this product.

Personal Safety

Use personal protective equipment. Always wear gloves. Protective equipment reduces the risk

of injuries and burns.

Power Tool Use and Care

Do not alter or misuse the tool. Any alteration or modification is a misuse and may result in serious

personal injury.

NOTICE

Maintain the tool. Check for misalignment or binding of moving parts, breakage of parts and

any other conditions that may affect the power tool's operation. If damaged, have the power

tool repaired before use. Many accidents are caused by poorly maintained power tools.

Always ensure a sufficient distance to the heated parts (heating bed surface) and never touch

them. This could result in severe burns.

This is not a handheld tool. The 3D Print Head is designed to be system-guided and must be

operated in STEPCRAFT CNC system or a comparable CNC router. The operation of the power

tool handheld may result in serious personal injury.

Never touch the workpiece (to measure or process it etc.) while the STEPCRAFT CNC System

or your CNC router is operating. There is a high risk of personal injury.

3

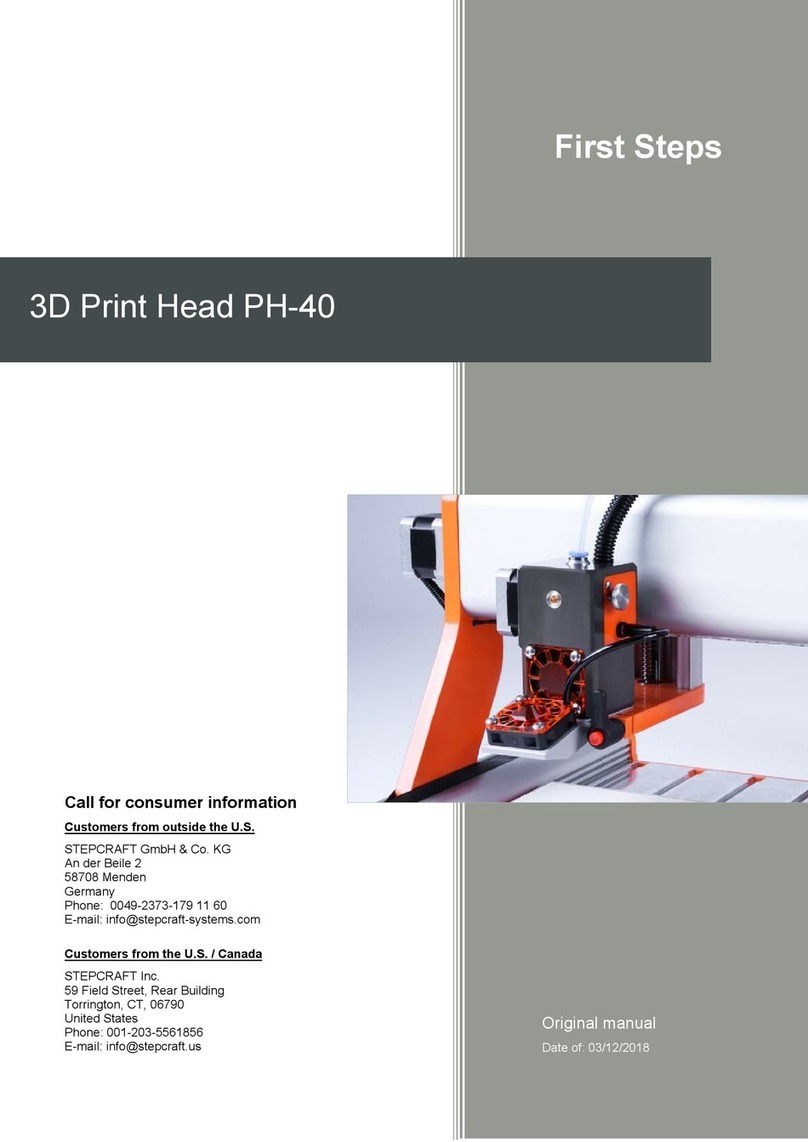

1 DESCRIPTION OF THE HEATING BED

1.1 FUNCTION DESCRIPTION

The STEPCRAFT Heating Bed consists of a flat sheet metal casing with a heatable glass table is in-

stalled which is adjustable in three points. The glass table can be levelled in height with two adjustment

wheels for it to be perfectly parallel with the print level. The Heating Bed can be connected directly to

the power supply with a wall power supply or via an adapter cable to the 3D Print Head PH-40.

The Heating Bed makes 3D printing much easier and more exact. This way, the difference in tempera-

ture between filament and bed is minimized and provides better adhesion. Additionally, warping (lifting

up of the workpiece`s periphery) is effectively prevented.

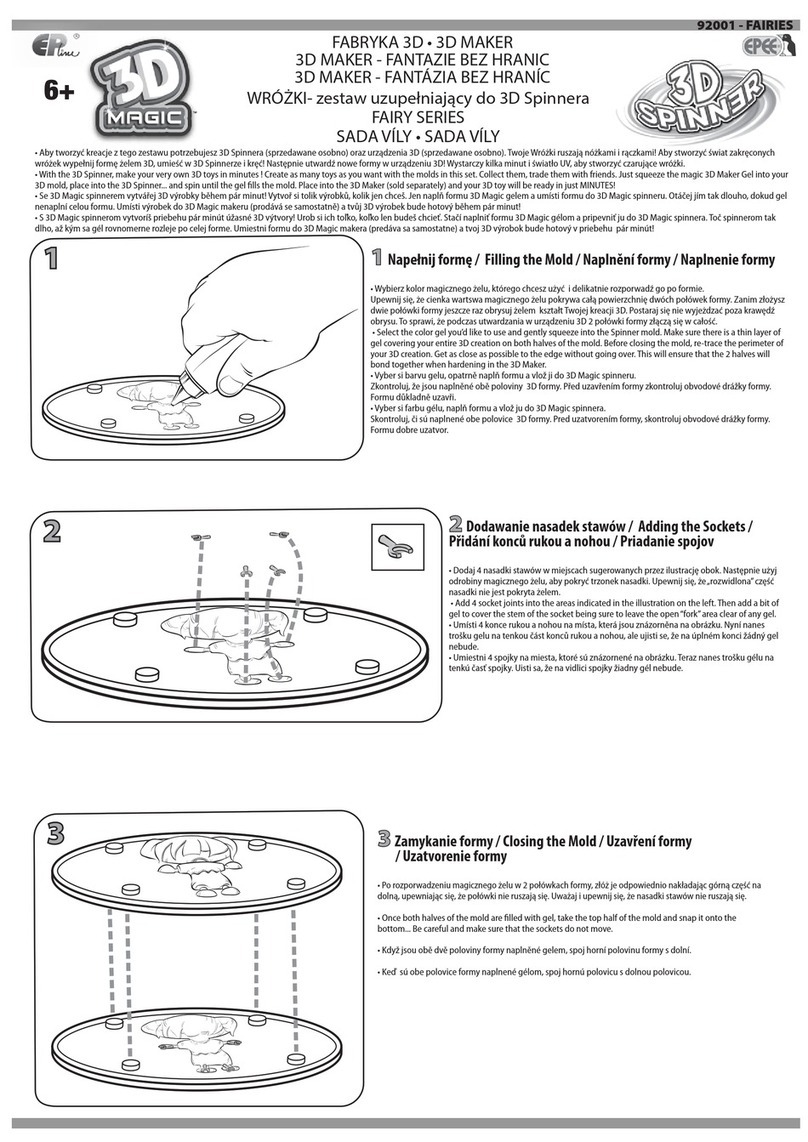

1.2 DESCRIPTION OF THE COMPONENTS

1 = Glass print table (heated)

2 = Right and left adjustment wheel

3 = Print table casing and fastening clips

4 = Current input

1.3 INTENDED USE

The STEPCRAFT Heating Bed is only to be used as 3D print base. The system has been especially de-

signed for the assembly and the connection to a STEPCRAFT CNC system.

2 COMMISSIONING /LEVELING

2.1 MOUNTING THE HEATING BED

The Heating Bed can either be fixed on the machine table using the machine`s clamping system or

screwed onto the T-slot table of your STEPCRAFT CNC system with the help of four M6x8 screws.

2.2 ELECTRICAL CONNECTION

The Heating Bed can either be connected to the mains with a power supply (19 V, 3 A) or directly to the

3D Print Head PH-40 using the Heating Bed connection cable. The latter has the advantage of a three-

step heating as well as of the automatic on/off switching of the Heating Bed.

2.3 LEVELING THE PRINT TABLE

1. Move the Print Head all the way down using the right and left adjustment wheel (counterclock-

wise).

2. Move the print nozzle to the center back of the Print Table (see picture, point 1). Place a piece

of paper in the area of point 1 and move the Z-axis slowly, step-by-step downwards until the

print nozzle touches the paper. You can easily test this by slightly moving the paper to and fro.

4

3. Drive the print nozzle to the front left to point 2 by moving X and Y. Place the paper in this area

and slowly turn the left adjustment wheel clockwise until the print nozzle touches the paper.

4. Repeat the procedure on the front right with point 3. The print table should now be even with the

print level.

Tip: Screw both adjustment wheels a quarter turn downwards and repeat step 2-4 for an even more

accurate result.

3 TECHNICAL SPECIFICATIONS

Total dimensions: 216 mm x 213 mm

Dimension table: 210 mm x 210 mm

Height: 18 mm

Weight: 0,5 kg

Heating performance: 40 Watt

Heating Bed Temperature:

19 V operation: approx. 70°C –80°C

Operated via PH-40: Level 1: approx. 45°C;

Level 2: approx. 70°C;

Level 3: approx. 90°C

4 TRANSPORT /STORAGE

Please make sure that the Heating Bed is not exposed to heavy shocks during transport. This can lead

to unwanted vibrations. If necessary, transport the device in suitable containers.

5 MAINTENANCE /SERVICE

To ensure continued enjoyment of your STEPCRAFT Heating Bed, handle it carefully.

Regular maintenance positively affects the life expectancy of the device.

Scrap filament rests from the glass table with a flat blade.

The print table has to be free of grease to provide an optimal filament adhesion. It is best to clean the

print surface with glass cleaner or spirit.

Copyright © STEPCRAFT®

Table of contents

Other STEPCRAFT 3D Printer manuals