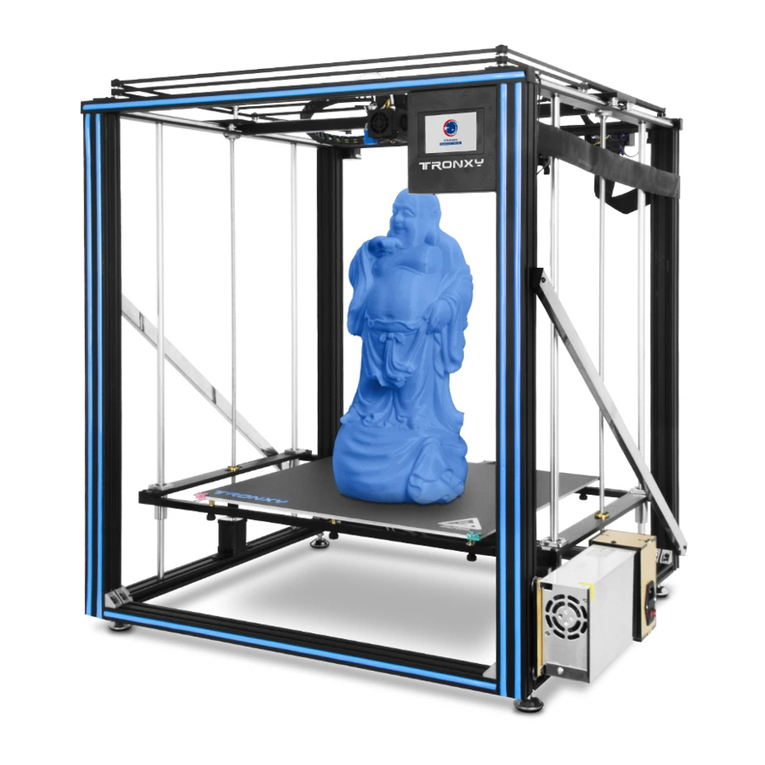

TRONXY XY-3 User manual

Instructions

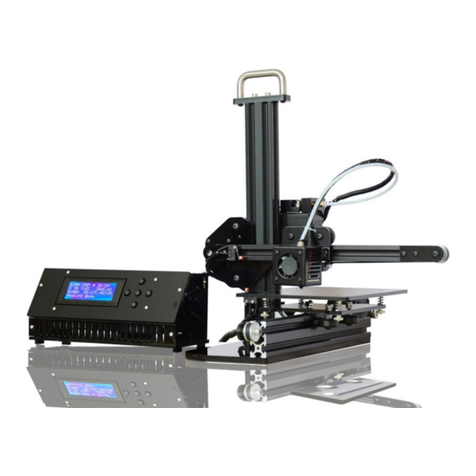

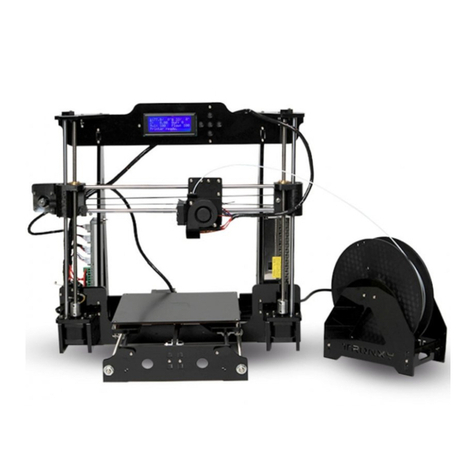

Model name:XY-3

SHENZHEN TRONXY TECHNOLOGE CO.,LTD

Notice

Before using this machine, please carefully read this notice and

the following notes:

1. Children should stay away from the machine when using the

machine. Children are forbidden to touch the machine in use.

2. Please put the machine on a stable surface before using the

machine.

3. Please keep this notice for future reference.

4. The open hole of the housing is strictly prohibited to be

covered for ventilation and heat dissipation of the machine to

avoid overheating.

5. Please pay attention to the notice and warning posted on the

machine to avoid danger or injury.

6. It is strictly forbidden to use the machine in the environment

of inflammable and explosive substances.

7. It is strictly prohibited to pour any liquid or dust into the

machine, or it will damage the machine or even cause a

dangerous accident.

8. Please do not disassemble and repair the machine without

permission. In addition to normal quick assembly steps and

common problems, please ask a professional to deal with them.

9. Do not use the machine under high temperature (above 85 °C)

environment, otherwise may damage to the machine.

10. It is recommended not to run the printer when unattended.

11. The machine is not covered by warranty as follows:

A. Product damage caused by abnormal external force (such as falling, extrusion,

knock, collision);

B. product damage caused by violation of product operation manual;

C. Product damage caused by use of materials that are not compatible with or

have not been recognized by relevant national standards;

D. beyond use under the conditions of use (such as the mainboard working

environment for 5 to 40 ℃, customers in the above 40 ℃or below 5 ℃when used

under the condition of damage).

E. damage caused by privately modifying firmware and appearance structure.

F. Damage caused by improper storage (such as dampness, mildew, etc.).

G. Damage caused by irresistible external factors.

H. Use parts normally, such as printing baseplate, nozzle and other accessories.

I. pure artificial condition damage.

J. If the warranty period is exceeded or the valid documents for the warranty

period are not available.

Catalogue

1、Introduction to basic parameters………… 4

2、Packing list ………………………… 5

3、Introduction to machine structure …… 6

4、Installation instructions……………… 7

5、Connection ………………………… 8

6、Product debugging …………………… 9

7、Print operation………………………… 10

8、Fault cause analysis………………………21

Print size

310*310*330mm

Power inpout

110V/220V AC,50/60Hz

Positioning

accuracy

X/Y0.0125mm,Z0.02mm

Power output

DC 12V 30A

Print speed

20-100mm/s(advs 60mm/s)

Connection

USB interface.SD card

Nozzel size

0.4mm optional

Hotbed

temperature

Support

print color

single color

Nozzle

temperature

≤260°C

Materials

support

PLA.ABS.HIPS.WOOD.PC.PVC

environmental

temperature

8-40°C

print thickness

0.1mm-0.4mm optional

Environmental

humidity

20-80%

Machine

materials

Aluminium and sheet metal

Slicing software

TRONXY exclusive slice software

Machine weight

9.5kg

File format

STL.OBJ.DAE.AMF.G-Code

Packing weight

≈ 11kg

Operate

software

Repetier-Host.Cura

Packing size

630*552*195mm

Operate system

WinXP/Win7/MacOS

Machine size

588*544*529mm

Power failure

resume print

Support

Display

3.5 inches full color touch screen

Certificates

CE FCC

filament runout

detector

optional

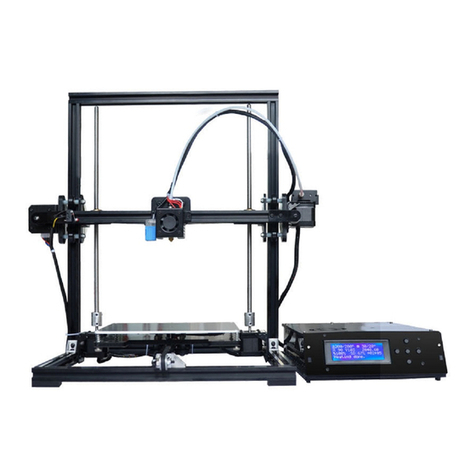

1、Machine parameter

Upper rack Base Power

supply

Power lines

Reader

(incl SD

card)

printer head

XY-3

Control box

ilament rack

HM5*25

4PCS PM4*25

2PCS

quick coupling

M6

Filament

USB cable Hotbed

sticker Tie

screwdriver

Scrabble

knife

Hexagonal

wrench

Specification

reinforced p

late

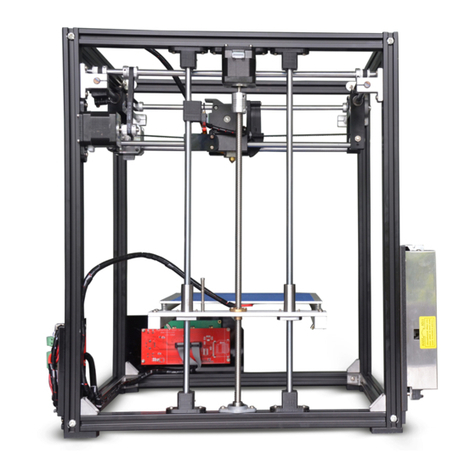

2、Packing list

2

17 18

22 23

Serial

number

Name

Serial

number

Name

Serial

number

Name

Serial

number

Name

1 Upper rack 8

right slider

assembly

15 feeding motor 22

power

interface

2

Left slider

assembly

9 print head parts 16 Z moto 23

voltage

change-over

3 extruder 10 leveling nuts 17 USB interface 24

4Z-Endstop 11 Y axis wheel 18

SD card

interface

25

5 control box 12 hotbed 19 Y axis motor 26

6

bottom

frame

13 lead screw 20 Z-Endstop 27

7 teflon tube 14 X axis moto 21 Power switch 28

1

3

4

5

6

7

8

9

10

11

12

13

15

14

16

19

20

21

3、Introduction to machine structure

4、Installation instructions

1

Run 2PCS M4*25 screws through the

front z-axis profile and lock the power

on the back of the profile.

Take out the material rack, lock

the boat nut with the screw knife,

and fix the material rack on the

upper beam.

Put the four holes on the base, and lock the four

holes on the base with four PM5*25 screws.

Take left and right reinforced plate, Install on the pr

inter as shown

3

4

Power

supply

Control box

Tighten the boat nuts with a

screwdriver,Fix the control box on

the aluminum of the base.

Pay attention: The control box must be fixed

on the beam, otherwise its easy to hit the

print head.

2

M4*25

Filament rack

left right

Y-motor

Y-Endstop Heat-bed

Power

Z-motor X-motor

Extr-motor

X-motor

Y-motor

Z-motor

E-motor

Endstop

Heat-bed

Power

Connection

AC:110V-220V

Z-Endstop

X-Endstop

Thermal line

Thermal line

Fault detectionr

Fault detectionr

2PS M3*10

screws

Z-Endstop 2PS M4*8

screws

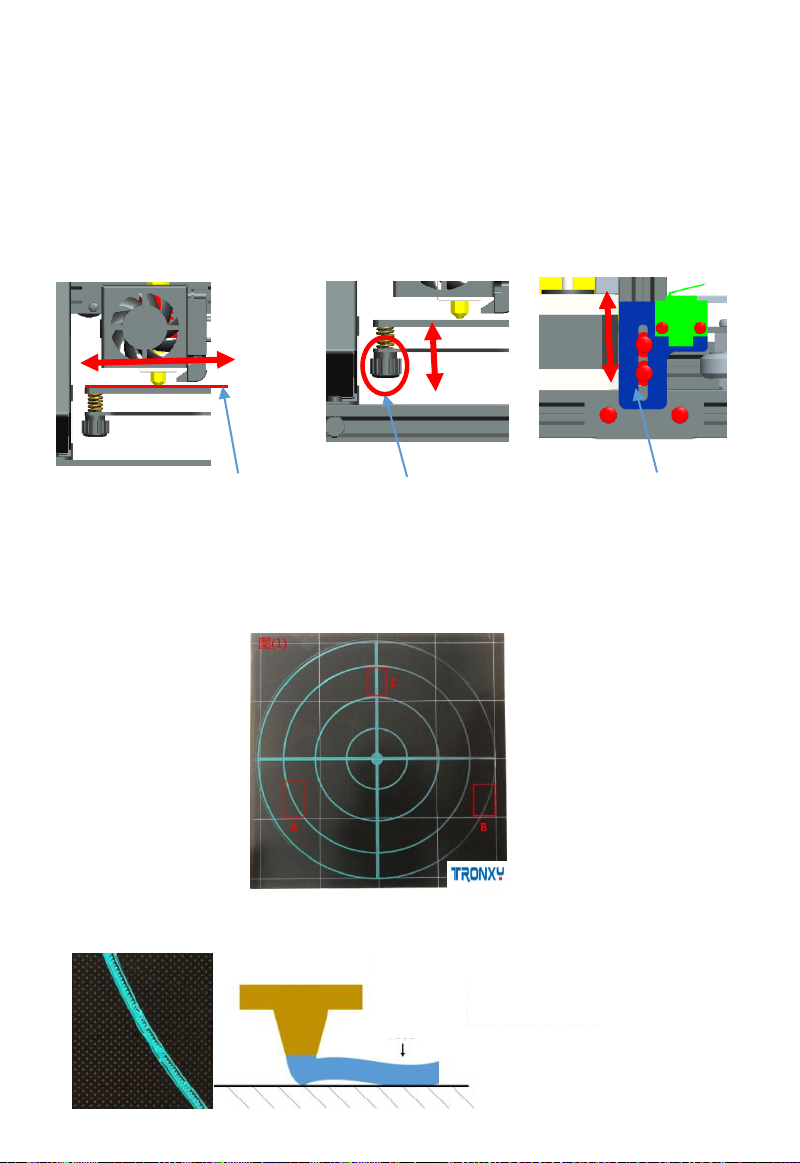

Due to transportation reasons, the Z axis wire rod may not move smoothly or get stuck, the belt is

loose, and so on. The following steps can be used to fine-tune the product.

1. Z-axis screw debugging:

When the machine is not moving smoothly in the direction of the Z axis or is stuck, please loosen 2

M3 fixing screws of the motor components of the right and left Z axis or 4 M3*8 fixing screws of

the screw nut. Manually rotate the X-axis assembly to the highest point, then lock the 4 M3*8

screws in the screw nut. Also, manually turn the X axis component to the minimum, and then lock

the power unit 2 M3*8 screws (4 M3*8 screws of proper screw rod screws can be unscrewed if

there is any problem. The power will not be switched until the X-axis component is returned

smoothly.

X axis assembly

2. Belt adjustment:

If the belt is too loose or too tight, loosen the M4*8 screw slightly, and then drag it back or move

it forward. The elastic degree of the belt can be adjusted, and the screw can be locked after

being adjusted

2PS M4*8

screws

4PS M4*8

acrews

X- axis belt

Y- axis belt

6、Production debugging

7、Print operation

1. Operation interface introduction:

Print files

information menu

System information

menu

Tools menu

(1)、System menu

1. State

Hot bed

current temperature

Nozzle current

temperature

Z axis speed

X axis speed Y axis speed

Return

2.Machine details Company

LOOG

Software version

ID code

Display style

Speaker

volume

3. Language selection

English/Chinese switch

4. Factory Settings

factory data reset screen test

5. Screen correction

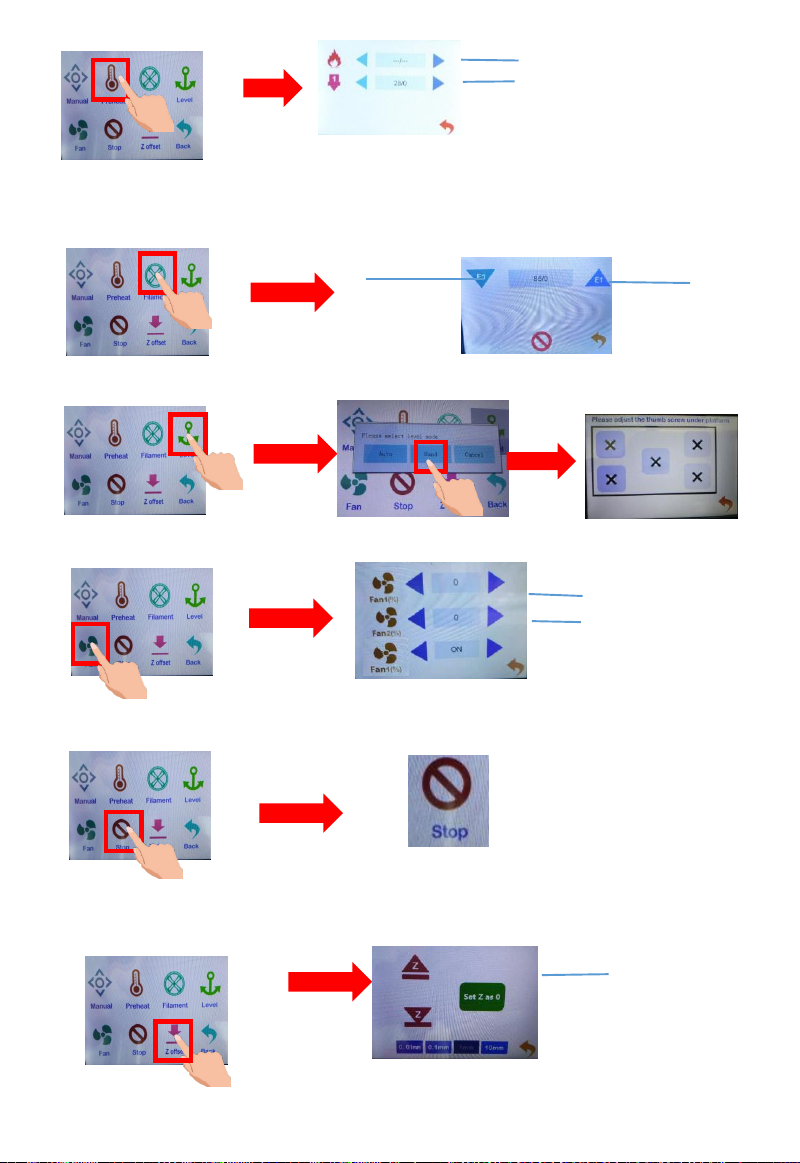

(2)、Tools menu

1. manual Z axis turn up

X axis turn right

Z axis turn down

displacement

distance

Y axis go forward

Y axis turn back

X axis turn left

The extrusion motor

sends out filaments

Zero place

Extrusion motor

delivering filaments

Return

Hot bed current temperature/target

temperature

Nozzle current temperature/target

temperature

27/45

27/200

2. preheating

4. Automatic leveling

6. Z axis set zero (this function

only automatically leveling before

it takes effect)

3.Unload

filaments Extrusion motor

delivering

filaments

Extrusion

motor sent out

filaments

5.Fan

Fan 1 switch

Fan 2 switch

6. Emergency stop

Emergency

stop task

Set Z to 0

3

(3)、print upturn

Turn down

return

folder

Print files

1.Print file

information menu

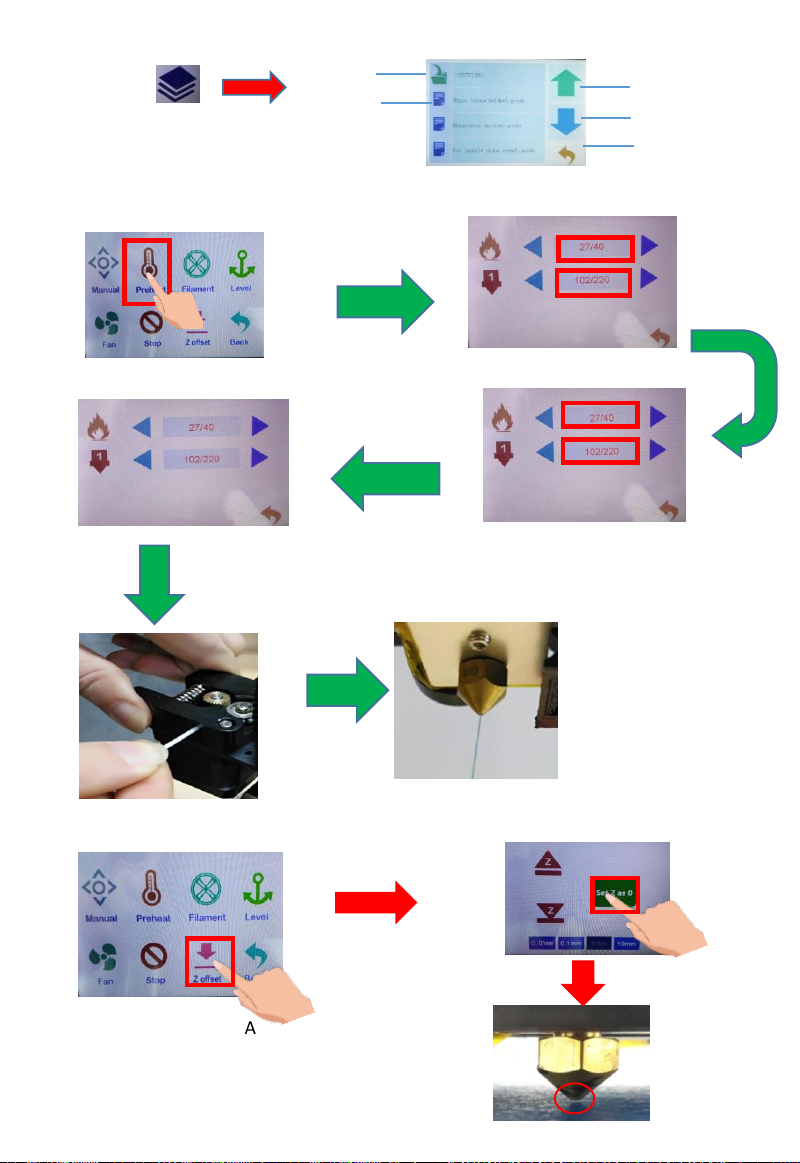

3.Unload filaments:

Click on the red

area to start

heating

The temperature

reaches the target

temperature

Click preheating

Straightening the front end

of the filaments, press the

extruder clip with your

hand, insert the filaments

into the hole of the

extruder until the nozzle is

in position. When the

filaments flow out of the

nozzle, the filaments have

been loaded

select “Z offset”. put one A4 paper between

the nozzle and platform, pulling the paper

backwards and forwards, if it happens to have

a little bit of resistance, that is well

spaced.Then click "Set Z to 0". (Observe distance)

4.Unload filaments:

Step 1: move the printing head to the nearest boundary point of the platform by

hand, as shown in FIG. (1). Then place an A4 paper between the nozzle and the

platform (2).Then move the printing head to another boundary point of the

platform, and repeat the above operation to adjust the leveling, until the four

points around the platform and the middle of the platform have been leveling

completed (if leveling nut adjustment fails to meet leveling, it can be adjusted via

upper and lower adjustment of z-axis adjusting block, and then fine-tuning with

leveling nut until the platform leveling).

(1)A4paper (2)leveling nuts (3)Z-Endstop

Attention!!!If the platform is uneven, the first layer of printing may be as follows :(1)

too high (partial/integral) (2) too low (partial/integral) (3) moderate ; As shown in the

following figure

AB

C

4. Verify platform flatness and print test:

too high

Filament

A phenomenon: the gap

between extruded

consumables is too large to

even touch the platform

Step 2: click "tool"→ "manual" →"return to zero”, then the three axis will automatically

return to the origin, and then click" emergency stop "to close the motor.

Finally, plug in the SD card and click “print”.(attention direction )The model has

been sliced and attached to the card. Choose one of them to print, such as "Cat (mobile

phone stand)“, After waiting for the temperature to reach the target temperature, it will

automatically start printing.

Filament

Filament

too low

moderate

B phenomenon:

inadequate extrusion

consumables, or even

scraping the platform

C phenomenon: extrusion

consumables uniform,

just to the platform

How to connect computer printing

1、Connection

2、Driver setup

1、The SD card has the installation program of USB driver 2, click

"Software" 3, and click "CH340G USB Drive" 4. According to the computer

system, select decompress 5 and get the installation driver after

decompress

1

23

45

13

2

1、Connect power2、Connect the USB cable to the computer3、

Connect the USB cable to the motherboard

There are 2 modes of 3D printing: offline printing

and online printing

Offline

printing

Insert the card into the

machine for printing Select model print

Online

printing

Computer connect

computer

After the drive is

installed, the printer is

controlled by computer

Print

mode

The on-line printing signal is transmitted by the computer through the data

line, and the unstable factors such as signal interference are very easy to

exist. Therefore, it is recommended that customers use offline printing as

much as possible

Install

67

Connect the computer with data cable, it is not possible to install the driver

automatically when you first connect to the computer, so to check

whether the driver is installed successfully, right-click on the computer and

select "my computer", click properties and select "equipment manager". If

the exclamation mark as shown in the figure below, you need to manually

install the printer driver to the computer

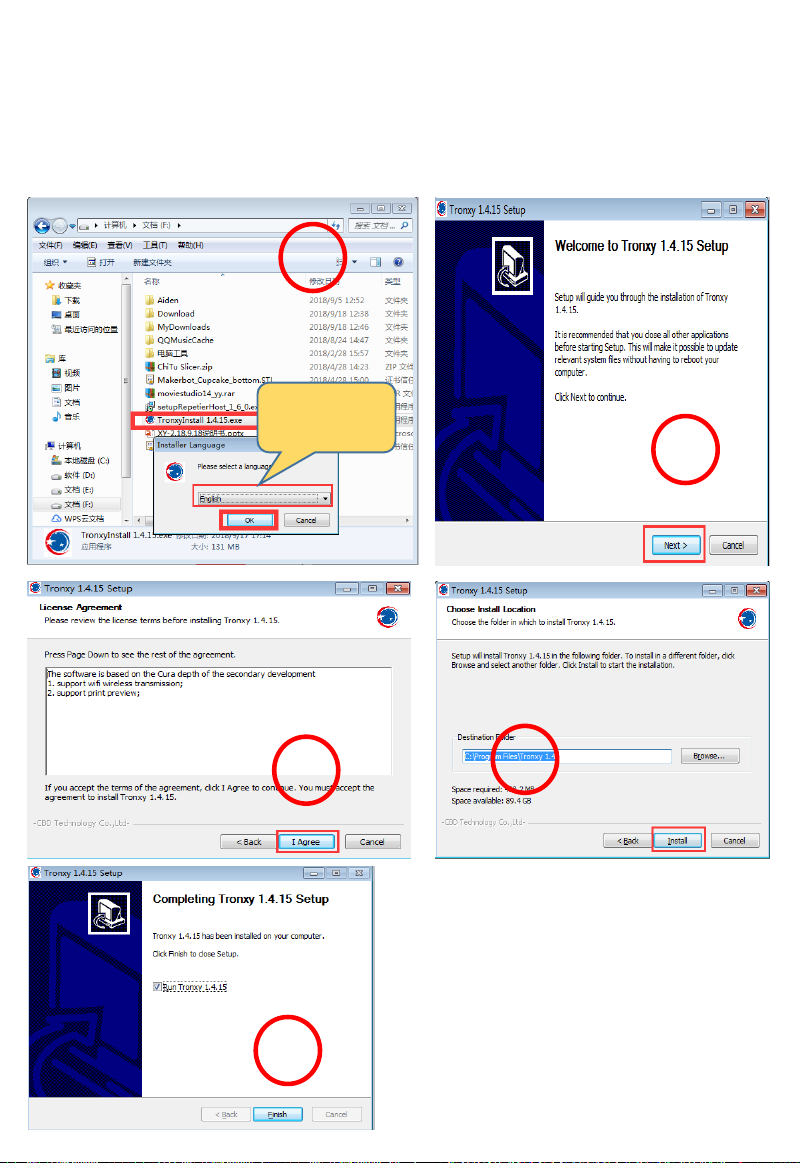

Slice software

1、Slice software

installation

1)install file → click “TRONXY” → choose langrage → OK → next → accept→ install

→ complete

3

1

1

2

3

2

4

5

Chinese and

English options

2. Use of slicing software

1. The user can double-click the slicing software of "TRONXY" installed on the desktop

to launch it to the following interface and conduct the module slicing.

Title bar

Menu bar

Open folder

Documents

sent

Parameter

setting

Model

preview

Observati

on Angle

of view

Move

model

Scaling

model

Rotate

model

Model

mirror

Estimated

usage time

speed

Model size

2. Model operation: file -- select model -- move/zoom/rotate/mirror.

1

2

After selecting

the model,

you can

move/scale/ro

tate/mirror

Other operations:

1) right click on the blank part of the model to rotate the model.

2) click the left mouse button on the blank part of the model to move the model.

3) scroll the scroll wheel in the middle of the mouse to zoom the perspective.

4) right click the blank of the model, and the dialog box can be operated accordingly.

3、Model parameter Settings: file - select

model.

1

3

Move your mouse

over here to

comment

2

Optional

recommendation

or customization

Parameter

setting

Thickness:Important parameters that determine the print quality, typically

0.4 nozzle is set to 0.2

Print temperature:PLA 200 ℃,ABS 240 ℃,Other filaments can be

consulted

Platform temperature:PLA:45 ℃; ABS:80 ℃,Other filaments can be

consulted

Adhere type:Increase the adhesion of the first layer of the platform model

and reduce the edge sticking or peeling when the model is printed

Filament diameter: filament diameter is 1.75mm

Nozzle size:The nozzle diameter is usually 0.4mm

Print speed:advs 60mm/s,Do not set too fast, too fast will affect printing

accuracy

Some parameters are set for reference

4、Menu bar Settings - preferences - printers - printer Settings

The first line of

code setting

(no changes are

required in general)

The last line of

code setting

(no changes are

required in general)

Filament and

nozzle diameter

Model size

setting

Print typesetting

Table of contents

Other TRONXY 3D Printer manuals

TRONXY

TRONXY D01 User manual

TRONXY

TRONXY X6D User manual

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY XY-3 PRO V2 User manual

TRONXY

TRONXY Ultrabot User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X5SA-500-2E User manual

TRONXY

TRONXY X5SA User manual

TRONXY

TRONXY X5SA-500 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X1 User manual

TRONXY

TRONXY P802M User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X6-2E User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY VEHO 600-2E User manual