Ouring 3DTALK-Knight User manual

Knight Installation Instructions

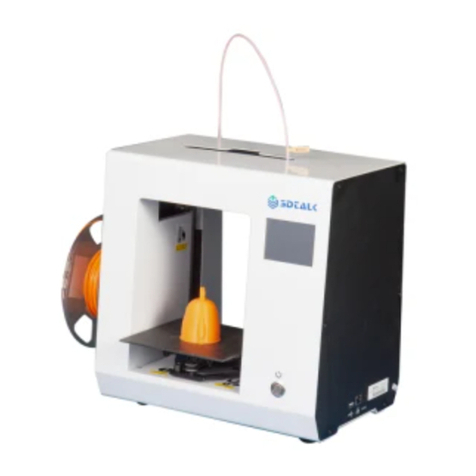

3DTALK Knight

Jiangsu Ouring 3D Technology Co.,Ltd

2

Contents

1.Product Introduction................................................................................................3

1.1Product Description......................................................................................................3

1.2 Notice... .......................................................................................................................3

2.Product profile.........................................................................................................4

2.1 Product Appearance....................................................................................................4

2.2 Product data...............................................................................................................15

3.Installing................................................................................................................17

3.1 Feeding filament.......................................................................................................18

3.2Adjusting ...................................................................................................................21

3.2.1.Adjusting of the extruder......................................................................................21

3.2.2 Adjusting of printing plate....................................................................................22

3.3 feeding water into the pump...................................................................................24

4、Instructions of printing material.........................................................................26

Jiangsu Ouring 3D Technology Co.,Ltd

3

1.Introduction of product

1.1 Production Description

3DTALK-Knight is the high technology digital 3d printer produced by Ouring.It

transports the consumables through the feeding pipe, through the wire feeder to the

nozzle, and then the nozzle heats to melt the material, and the melted material is

extruded through the nozzle in the form of thin wires. The movement of the nozzle is in

the coordinate system of the printing plate, after each layer is stacked. The print plate is

lowered layer by layer until a complete model is built. The printer provides you with a

variety of different color materials, and you can use the printer to print instantly, free

to show your creativity.Please read the product introduction carefully before using this

product out of the box. All rights reserved. All rights reserved. This document is subject

to change without prior notice.

1.2 Notice (please read the following tips carefully)

Please do use the designated power adapter included in the machine.

In the printing process, slight odor may be generated due to high temperature, but it

will not make users feel uncomfortable.You are recommended to use the machine in a

well ventilated environment.

The machine shall be repaired only by the authorized repairing technician. Before

replacement of any component, turn off the printer and cut off the power supply.

Removable components are dangerous. Please keep your fingers and body away from

them.

Hot surface danger: When setting and working, do not touch the extruder. At this time,

the temperature of the extruder is very high.

Be careful of electric shock: Due to electric shock risks, please do not touch any internal

electronic component.

Jiangsu Ouring 3D Technology Co.,Ltd

4

(1)(2)(3)

(6)

(5)

(4)

(7)

2.Product Profile

2.1 Product appearance

①Front

(1)USB

connector

(2)Touch

screen

(3)Power

button

(4)Right

magazine

(5)Front

door

(6)cover

(7)Left

magazine

Jiangsu Ouring 3D Technology Co.,Ltd

5

(1)

(2)

(3)

(4)

②Side

③Back

(1)cover

(2)front

door

(3)

magazine

(4)

casing

(1)back

panel

(2)fan

(3)

(DC220V/50Hz)

Power port

(4)Net port

(1)

(2)

(3)

(4)

Jiangsu Ouring 3D Technology Co.,Ltd

6

(1)

(2)

(4)(3)

④Inner Structure

⑤Inner sight

(1)extruder (2)right

magazine

(3)printing

plate

(4)left

magazine

water tank for cooling (2)heating part

(1)

(2)

Jiangsu Ouring 3D Technology Co.,Ltd

7

⑥extruder sketch

(1)right

feeding tube

(2)cooling fan

(3)cooling air

flue

(4)right

extruder

(5)left

extruder

(6)adjusting

part

(7)left

feeding tube

(6)

(5)

(4)

(3)

(2)

(1)

)

(7)

Jiangsu Ouring 3D Technology Co.,Ltd

8

⑦coordinates sketch

X

Z

Y

Jiangsu Ouring 3D Technology Co.,Ltd

9

⑧function introduction

red temperature number

left extruder real time

temperature

white temperature

The target left extruder

temperature set by the software

red temperature

right extruder real time

temperature

white temperature

The target right extruder

temperature set by the software

red temperature

printing plate real time

temperature

white temperature

Target printing plate temperature

set by the software

red temperature

heating room real time

temperature

white temperature

Target heating room temperature

set by the software

Name of the document

The name of the model which is under printing

volume

The volume data of the model

time

The printing time of the model

proceed

The process of this model

Auto power off

Touch this button when printing,when this button turns red,it

will auto power off after printing

Jiangsu Ouring 3D Technology Co.,Ltd

10

(the interface of printing )

Local

documen

t

The model document installed in the machine : the document printed in this

machine will be stored in the local

Document

U disk

documen

t

Inset the U disk into this machine : the document stored in this U disk

start printing

start printing after pressing this button

Jiangsu Ouring 3D Technology Co.,Ltd

11

pause

Press this button when printing to pause.Press it again to continuing printing

Stop

Stop the printing

(interface )

Set the language adjusting the plate

Jiangsu Ouring 3D Technology Co.,Ltd

12

Changing the filaments changing the connection

initialize settings Update of software and hardware

Basic information of machine APP

(high class interface )

Jiangsu Ouring 3D Technology Co.,Ltd

13

Extruder Adjusting

Adjust the distance of the

extruder and the plate

heating room

Check out if the room can be

heated normally.It can be heated

before printing

Controlling

Control the XY axis and

plate moving manually

fan

Control the switch of fan manually

Heating Plate

Check out if the plate can

be heated normally.It can

be heated before printing

Electrical machinery power off

It can push and lift the extruder or

the plate easily if they can not

move automatically

⑨Accessories

X 1

Plug

COMBO(1kg)X 2

U DISK 1(8G)

Wrench X 1

hexagonal wrench

X 1

Shovel X 1

Net line X 1

PC Dull polish X 2

Printing plate X 1

Jiangsu Ouring 3D Technology Co.,Ltd

14

Bottle of Feeding water X 1

Glue stick X 1

Notice :

Please refer to the actual accessories for the accessories in the list of random accessories.

Jiangsu Ouring 3D Technology Co.,Ltd

15

2.2 DATA

①Specific

3DTALK - Knight

Building

Volume

254 X 254 X 210mm Thickness

accuracy

Position

resolution

Z(2.5μm)XY(11μm)Nozzle

diameter

Quantity of

nozzles

2 Nozzle

material

High strength hard

alloy

Printing speed 60mm/s - 200mm/s Nozzle

working

temperature

Nozzle flow

24ml/h

Support

Resistant of

edge warping

Homothermal

room+heating plate

Max

temperature

of room

cooling

Fan cooling+water cooling Intelligent

controlling APP,remote controlling

High class

function

Reminder of filaments

out,resuming printing after

power off

Machine size

620 X 590 X 600mm

Weight 45kg Machine

material

Hard metal

body+plastic mould

LCD

4.3 inches full color

touching screen

connection

U disk,WIFi,Ethernet

Document STL、OBJ、gcode Operation Windows / MAC iOS

Founded

automatically,easy to

remove

0.2mm-0.8mm

0.05mm - 0.5mm

245/280℃(pro)

60℃

Jiangsu Ouring 3D Technology Co.,Ltd

16

system

Software

Browser+ touch screen

AC

220V

Power

1000W

Power

connection

International plug

Knight material

ABS、PLA、Wood、PETG、Bronze、DuPont Hytrel 4100

Environmental requirements

Ambient temperature 15 °C ~ 30 °C ;

Relative humidity 20% to 50%;

Avoid moving the machine and strong vibration during printing work;

The power supply voltage is stable and fluctuates within ±10%.

Jiangsu Ouring 3D Technology Co.,Ltd

17

3.Installing and using

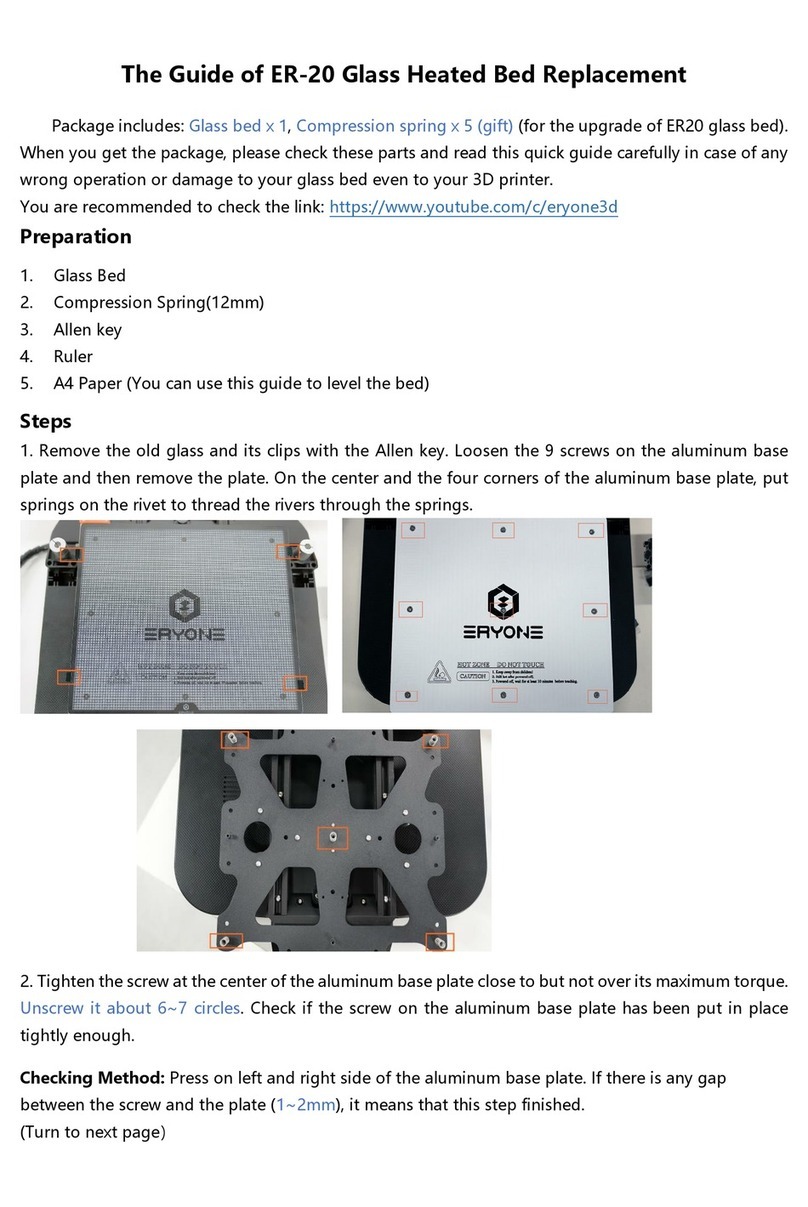

Installing steps 1 - 3

1.

After the equipment is taken out of the package, it is placed in a horizontal position, and

the fixed strip and the protective cotton inside the equipment are completely taken out;

2.

Remove the printing platform from the device packaging, attach the black platform

sandpaper that is randomly attached to the printing platform, and install the platform on

the platform bracket of the device;

1 Take out the printing platform, attach the random matte paper to the smoother

surface of the platform, and place the platform on the platform bracket of the

equipment, with the matte cardboard facing up;

Printing plate plate holder

2 After the printing platform is placed on the platform bracket, the printing platform is

stuck in the fixed module around the bracket. When the platform cannot move left, right

or rear on the bracket, please clamp the bezel module on the front side of the bracket to

the printing platform. And tighten the fixing knob of the module clockwise.

Plate fixation fixation button

3.

Remove the power cord from the starter kit and connect the device to the power source.

Jiangsu Ouring 3D Technology Co.,Ltd

18

3.1 Feeding materials

Feeding materials steps 1 - 8

1.

Separate the nozzle that needs to be fed from the corresponding tube; the specific

method is as follows:

Continue to press down on the blue gasket on the feed nozzle and pull out the

corresponding white tube (as shown below)

2.

After disconnecting the feed nozzle from the material tube, open the package of the

material wire to find the end of the material wire. If the hair is deformed or damaged at

the end of the material, please cut off the wire; By reducing the feed resistance during

the feed, the front end of the filament can be straightened.

Note: After the material yarn is used for material return, the end of the material wire will

usually be melted and deformed. Before re-feeding, please cut off the deformation part

to prevent the blockage phenomenon.

3.

5cm - 8cm。After the material wire is prepared, the hand-held material wire is

continuously pushed from the corresponding wire feeder opening until it is exposed 5 cm

- 8 cm from the nozzle tube.

Jiangsu Ouring 3D Technology Co.,Ltd

19

(Note: The feeding end of the left feeding box of the feeding box is the left nozzle; the

feeding end of the feeding port of the right box is the right nozzle.

4.

The material wire exposed by the nozzle end pipe is straightened, and the "wire feeder

handle" (see the following figure) of the feeding nozzle is continuously pressed, and the

material wire exposed by the material pipe is inserted into the blue hole, and the "send"

is released. The wire handle" allows the "wire feeder" inside the nozzle to clamp the

material wire and insert the tube into the blue hole.

(sketch of the handle of feeding tube)

5.

After the "wire feeder" inside the nozzle clamps the material wire, place the material

tray in the cartridge and cover the cartridge cover

Handle of right extruder

Handle of left

extruder

Jiangsu Ouring 3D Technology Co.,Ltd

20

6.

Turn on the power, press the "Power Switch" button at the device power jack, and click

the front panel "Switch button"

7.

After the system displays the main interface data is normal, click the “Settings” button

and select the “In/Return” function.

8.

In the "in/out" interface, select "L" and "R" to select the "in/out" nozzle ("L" means left

nozzle; "R" means right nozzle).

After selecting the nozzle, set the appropriate feed temperature (COMBO feed

temperature: 240 ° C) by clicking “ ” / “ ”, and click the "feed" button, when the

red temperature value of the interface reaches the white temperature value, the

material will be extruded from the corresponding nozzle, when When the material

filament extruded by the nozzle is even and smooth, click the “Stop” button and the

feeding work is completed.

Table of contents

Other Ouring 3D Printer manuals