Stephill SSDP30-70 Series Owner's manual

Issue 3 June 2020

SSDP30-70 Range - DSE 6110 MK3 Control Module

User & Fault Finding Guide

User Guide Contents Issue 3

Description of the DSE 6110 Mk2 control module lay-out

General Operation

● How to Start the Generator

● How to Stop the Generator

Button Description

Generator Locked Out

Status Display

Typical No-Load Values - Status

How to Check the Generator AC Voltage is Correct

How to Check the Current Applied is Balanced

How to Check the Load Applied is Balanced and the Total Load

How to Check the Generator Frequency

How to Check the Engine Instruments

● Engine Speed

● Engine Oil Pressure

● Engine Coolant Temperature

● Engine Battery Voltage

● Engine Run Time

● Engine Fuel Level

● Maintenance Alarm

How to Check the Fuel Level (Generator Not Running)

How to Re-set the "Maintenance Alarm"

How to Check which Alarms Have Been Triggered

How to Check the Control Module "Event Log"

IDMT Alarm

Fault Finding Guide

12

4

Description

Page No.

3

3

3

9

5

5

5/6

6

7

7/8

8

11

9

9

11

9

9

10

10

10

11

10

JD/08/18

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

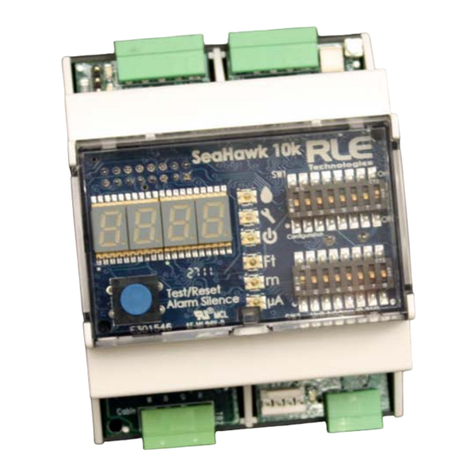

Below is a description of the front panel on the DSE 6110 MK3 module.

Status

Fig.1

How to Start the Generator

Press the button once then the button to start the generator.

How to Stop the Generator

Press the button to stop the generator

This user guide has been assembled to aid with the basic aspects of the DSE6110 MK3 module as configured

on Stephill Generators and to gain access to the information available. It has been produced as a "How to"

guide.

Once the 12V supply has been connected to the module (battery isolator key switched on), the LCD screen

will illuminate. The module will then load up with the Status screen if no alarms are present Fig.1. This is the

"home page" that is displayed when no other page has been selected.

Menu

Navigation

Module Display

Stop/Reset

Manual Auto Mode

Alarm Mute

Start

0 V

Generator at Rest

L - N

0 A

0 kW

- - - - pf

L - L

0 V

0.0 Hz

JD/08/18 3

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

Stop/Reset Mode

Manual Mode

Start

Menu Navigation

Used for navigating the instrumentation and configuration screens.

Example

Status Engine Generator

(page) (page) (page)

…And so on until the desired page is reached.

Auto Mode

Alarm Mute / Lamp Test

This button silences the audible alarm in the controller and illuminates all of the LED's

on the module's facia as a lamp test function.

Pressing the Start button in Manual Mode will begin the generator starting process

and run the generator in Manual Mode .

If an alarm becomes active while viewing the status page, the display shows the

Alarms page to draw the operators attention to the alarm.

This button places the module into it's Auto Mode . This mode allows the module to

control the function of the generator automatically. The module monitors the Remote

Start Input and once a start request is made, the set is automatically started. Upon

removal of the start signal the generator will stop.

It is possible to scroll to display the different pages of information

by repeatedly operating the Next and Previous page buttons.

Once selected, the page remains on the LCD display until the user selects a different

page, or after an extended period of inactivity (LCD Page Timer), the module reverts to

the status display.

If no buttons are pressed upon entering an instrumentation page, the instruments

displayed are automatically subject to the setting of the LCD Scroll Timer .

Alternatively, to scroll manually through all instruments on the

currently selected page, press the Instrumentation Scroll buttons.

This button places the module into its Manual Mode . Once in Manual Mode the

module will then respond to the Start button to start the generator and run it off load.

Icon

Description

This button places the module into its Stop/Reset Mode. This clears any alarm

conditions for which have triggered and criteria have been removed. If the engine is

running and the module is put into Stop mode, the fuel supply de-energises and the

engine comes to a standstill.

Button Description

JD/08/18 4

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

Generator Locked Out

to scroll to the alarms page to investigate.

Status Display

①

③

②

Fig.3

Typical No-Load Values

Fig.3 above is showing the typical no-load (nothing connected to the generator outputs) values.

②= L-L is showing the average AC voltage between phases, L1 to L2, L2 to L3 and L3 to L1 - 400V

③ = Showing the alternator frequency - Hz - This should be between 52.0 to 53.0 at no-load.

Typical Load Values

When you apply load the generator the Status screen will then show the following - Fig.4

①

② ③

Fig.4

① = Is showing the average amps between all three phases (Live).

②= Is showing the total load in kW that the generator is under.

③ = Is showing the alternator power factor - pf cosφ.

If Generator Locked Out is displayed on the screen - Fig.2 then this indicates that the generator cannot be

started due to an active Shutdown on the module.

Once you have issued a start request and the generator has started and running, the DSE 6110 MK3 module

will then begin checking that the engine instruments and the AC generator output are correct and are within

the pre-set parameters. After the "Saftey on Delay " of 10 seconds has elapsed and all is operating correctly,

the Status screen will typically look like the following Fig.3.

① = L-N is showing the average AC voltage between (Phase or Live) L1 to Neutral, L2 to Neutral and L3 to

Neutral - 230V

Press the Next and Previous page button

Press the Stop/Reset Mode button to clear the alarm, if

the alarm does not clear the fault is still active.

400V

Generator Available

L - N

0 A

0 kW

- - - - pf

L - L

230V

52.6 Hz

Status

12:34

Generator Locked Out

Fig.2

400V

Generator Available

L - N

17 A

12 kW

1.00 pf

L - L

230V

51.9 Hz

JD/08/18 5

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

How to Check the Generator AC Voltage is Correct

Note

Fig.6 below shows the typical no-load voltage between Phase and Phase L1-L2, L2-L3 and L3-L1.

How to Check If the Applied Current is Balanced

An unbalanced current can cause the generator voltages to become unstable and possibly shutdown the set.

Fig.7

Important Note

To check the current applied to the generator use the Next or Previous buttons until across the top of the

screen it reads Generator . Then press one of the Instrument Scroll buttons until Generator Current is

displayed at the top of the screen Fig.7

Ensuring the current on each phase is as even (balanced) as possible will eliminate nuisance Over Current or

Over/Under Voltage shutdown alarms.

If the page automatically scrolls to another, press either of the Instrument Scroll buttons

until you reach the desired page

Fig.6

Fig.5

The first page will show the AC voltage between each phase (L1,L2 and L3) and Neutral (when generator

running) Fig.5

To check the AC voltage output from the generator is correct, firstly you must isolate the

load from the generator (remove any AC plugs connected to the generator outputs). Either

before you start the generator or while the generator is running, use the Next or Previous

page button until across the top of the screen it reads Generator .

Generator Voltage

L1 - N

231V

L2 - N

L3 - N

231V

230V

Generator Voltage

L1 - L2

401V

L2 - L3

L3 - L1

400V

400V

Generator Current

L1

17 A

L2

L3

19 A

15 A

Next and Previous

Instrument Scroll

JD/08/18 6

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

How to Check the Total and Applied Load is Balanced

Example

②

①

Fig.8

① = Prime kW This is the rated load of the generator, up to this load the generator will run continuously.

Load Per Phase

Fig.9

Important Note

Total Load

Fig.10 shows the next Generator Load screen, this shows the combined average total kW load applied.

Ensuring the load on each phase is as even (balanced) as possible will eliminate nuisance Over Current or

Over/Under Voltage shutdown alarms.

Fig.10

To check the load applied to the generator use the Next or Previous buttons until across the top of the

screen it reads Generator . Then press one of the Instrument Scroll buttons until Generator Load is displayed

at the top of the screen Fig.9

② = Standby kW Is the maximum load the generator will take for 1 hour in 12. The generator can take this

load for one hour before shutting down. If the total kW load rises above this value the generator will

shutdown immediately.

Using the generator serial plate on the generator control panel door as a reference, you can check the

maximum kW load that can be applied to the model type of Stephill Generator. Fig.8 below is an example of a

standard SSDP70A, highlighted are the two values to be most aware of.

Generator Load

L1

12 kW

L2

L3

13 kW

10 kW

Generator Load

Total

12 kW

Next and Previous

Instrument Scroll

JD/08/18 7

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

How to Check Generator Frequency - Hz

Fig.11

Important Note

How to Check the Engine Instruments

Below are typical examples of each engine instrument screen - Fig.12 to Fig.17.

Engine Speed

Fig.12

Engine Oil Pressure

Fig.13

Engine Coolant Temperature

Fig.14

Cont.

The generator frequency can be found on two pages, on the Status page, as shown in Fig.3 Status display.

Also the frequency has it's own instrument screen in the Generator page(s).

To access the frequency in the Generator pages, use the Next or Previous buttons until across the top of the

screen it reads Generator . Then press one of the Instrument Scroll buttons until Generator Frequency is

displayed at the top of the screen page Fig.11

The typical no-load frequency should be between 52.0 and 53.0 Hz. If at no-load the frequency is as low as

51.5 Hz then it would be advisable to check the condition of the fuel filters, air filters and oil. Ensure the

engine is serviced regularly to safeguard the healthy running of the generator.

Most of the engine instruments will only be active once the engine is running. To check the engine

instruments press either the Next or Previous buttons until across the top of the screen it reads Engine .

Then press one of the Instrument Scroll buttons to scroll through all the engine instruments.

Generator Frequency

52.6 Hz

Engine Speed

1575 RPM

Engine Oil Pressure

4.88bar

70psi

488 kPa

Engine Coolant Temp.

82⁰C

180 ⁰F

Engine Battery Voltage

Next and Previous

Instrument Scroll

Next and Previous

Instrument Scroll

JD/08/18 8

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

Engine Battery Voltage

Fig.15

Engine Run Time

Fig.16

Engine Fuel Level

Fig.17

Service Hours

How to Check the Generator Fuel Level

Fig.19

Viewing the Fuel Level Without Starting the Generator

Fig.20

The Engine Fuel Level screen will then show the

percentage of fuel remaining in the fuel tank. Also you

can see the quantity of fuel remaining, this is shown in

litres.

To be able to view the fuel level page use the "How to Check the Engine Instruments" section elsewhere in

this guide. Depending on the engine state, running or at standstill, you will see one of two screens showing

the current fuel level.

Fig.18

Fig.19 shows no registered fuel level, this is the fuel

level screen when the generator is at standstill (not

running). At this state the fuel level sensor is not

energised.

To view the fuel level you must first navigate to the Engine Fuel Level screen - as above. Then using the Tick

Button , press and hold. After a few seconds the fuel level screen should then register a fuel level. You must

continue to hold the Tick Button down to continue to view the fuel level - Fig.20.

Engine Battery Voltage

14 . 4 V

14 . 5 V

Battery

Charge Alt

Engine Run Time

28 Start(s)

196h 12m

Engine Fuel Level

++++ %

Engine Fuel Level

28%

98 Litre

Service Hours

303h 48m

Engine Fuel Level

28%

98 Litre

Tick Button

JD/08/18 9

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

How to Reset the "Service Hours Alarm " Warning

Before Resetting the Service Hours

Resetting the Service Hours

Fig.21

a) Ensure the Service Hours screen is visable.

b) Press and hold the button. The timer should then reset to the pre-set hours (usaully 500h).

Important Note

The Service Hours timer can only be reset if the Service Hours Warning has been activated (reached 0h 0m).

How to Check Which Alarms Have Been Triggered

When an alarm is active, the Internal Audible Alarm sounds.

The audible alarm is silenced by pressing the Alarm Mute / Lamp Test button.

Fig.22

① = Number of active alarms. This is alarm 1 of a total of 2 active alarms.

② = The cause of the alarm.

③ = The type of alarm, e.g. Shutdown.

Firstly you will need to access the Service Hours in the Engine pages, use the Next or Previous buttons until

across the top of the screen it reads Engine . Then press one of the Instrument Scroll buttons until Service

Hours is displayed at the top of the screen page Fig.21

The Service Hours Alarm screen is a count down timer, when the timer reaches zero hours a Warning Alarm

will be issued and displayed on the screen. The Warning Alarm will allow the user to operate the generator

as normal but the Warning Alarm will be present until a service reset has been performed.

Firstly, ensure an adequate service has been performed on the engine. Refer to the generator handbook or

check on the Service section found on;

The Service Hours should be showing 0h 0m, this idicates that the countdown timer from the last service has

been achieved. To reset this timer;

To check which alarm(s) have been triggered, use the Next or Previous buttons until across the top of the

screen it reads Alarms . Fig.20 shows the Alarms page. To see each individual alarm that is currently

activated, press one of the Instrument Scroll buttons to cycle through.

Emergency Stop

Shutdown

2/2

Alarms

www.stephill-generators.co.uk

Service Hours

0h 0m

Next and Previous

Instrument Scroll

③

①

②

Next and Previous

Instrument Scroll

JD/08/18 10

Stephill Generators SSDP30-70 - DSE 6110 Module User Guide Issue 2

How to Check the Control Module "Event Log"

Example

Fig.23

IDMT Alarm

If the IDMT Alarm is enabled, the controller begins following the IDMT ‘curve’ when the trip level is passed.

If the trip is surpassed for an excess amount of time (set at 1 hour) the IDMT Alarm triggers a shutdown.

High Current Shutdown is a latching alarm and stops the generator.

Remove the load then press the button to reset the module.

The higher the overload the faster the trip. The speed of the trip is dependent upon the fixed formula.

T = t / ((IA / IT) – 1) 2

Where: T is the tripping time in seconds.

IA is the actual current of the most highly loaded line (L1 or L2 or L3).

IT is the delayed over-current trip point.

Over 110% load would issue an immediate shutdown on the generator.

The module maintains a log of past alarms and selected status changes. Currently the module is capable of

storing the last 250 log events. This is always subject to change with module updates.

To view the Event Log , use the Next or Previous buttons until at the top of the screen it reads Event Log

Fig.23, press one of either the Instrument Scroll buttons to view the next or last event. The Event Log always

contains the most recent events, along with the engine hours.

With typical settings, this allows for overload of the set to the limits of the Typical Brushless Alternator

whereby up to 110% overload is permitted for 1 hour.

tis the time multiplier setting and also represents the tripping time in seconds at twice full load (when IA / IT

= 2).

This setting is to provide normal running of the generator up to 100% full load. If full load is surpassed, the

Immediate Warning alarm is triggered, the set continues to run.

The effect of an overload on the generator is that the alternator windings begin to overheat; the aim of the

IDMT Alarm is to prevent the windings being overload (heated) too much. The amount of time that the set

can be safely overloaded is governed by how high the overload condition is.

This is event 1

Engine hours

Coolant Temp High

Shutdown

1

Event Log

196h 21m

Next and Previous

Instrument Scroll

JD/08/18 11

Fault Finding Contents Issue 2

Before Starting the Generator

Generator Not Starting

● Use "Generator Not Starting" flow chart.

Generator Running

Generator Stops

● Fail to Start shutdown

● AC Voltage shutdown

● Frequency shutdown

Common Fault Conditions

● Emergency Stop shutdown

● Low Oil Pressure shutdown

● Oil Pressure Sender Sender Fault shutdown

● Fail To Stop

● High Engine Temperature shutdown

● Coolant Level shutdown

● Charge Alternator Failure

● Hardwire Door shutdown

● Engine runs but the generator will not take load.

Generator Not Starting Flow Chart

Description

Page No.

13

18

18

17

13

16

16

17

13

16

16

17

17

17

13

14

14

14/15

JD/08/18

Stephill Generators SSDP30-70 - DSE 6110 Fault Finding Guide Issue 3

1) Unplug all load connected to the generator outputs.

2) Check the engine oil level.

3) Check the water/coolant level -

4) Check the fuel level.

5) Check the battery voltage.

At standstill the battery voltage should be around 12.4 to 12.6V DC.

6) Check fuel pump operation - if applicable.

Generator Not Starting

Use the "Generator Not Starting" flow chart found in this guide.

Generator Running

Fig.1

Generator Stops/Shuts down

Caution hot steam can burn!

This value should

be between 230 -

235V AC

This value should

be between 398 -

404V AC

If the generator stops/shuts down then this would usually because the DSE 6110 MK3 control module has

detected a fault condition and has issued a Shutdown Alarm to stop the generator. The DSE 6110 MK3 control

module will display an Alarm page to indicate an active alarm(s).

This basic fault finding guide has been complied to assist with the operation on Stephill Generators that use a DSE 6110

Mk3 control module.

STEPHILL GENERATORS LTD STRESS THAT THE ULTIMATE RESPONSIBILTY FOR THE SAFE USE OF THE GENERATOR

RESTS WITH THE USER.

Recommended Checks Before Attempting Any Fault Finding

Before starting the generator or attempting any fault finding, ensure the following aspects of the generator are checked.

Trying to start a generator with load applied, can result with a "Fail to Start" warning as well as draining the

battery and possible damage to the main alternator.

The frequency should be between 52.0 - 53.0Hz

The typical values shown in Fig.1 above would indicate that the engine and alternator are operating correctly

while no load is applied to the generator.

Fig.1 below is a typical Status screen while the generator is running with no-load.

Note that no Amps or kW will be displayed with no-load.

Press and hold the "Fuel Pump Prime" button on the control panel (refer to user handbook) listen for the fuel pump

operating inside the generator canopy.

Once you have carried out the checks above and the engine has started, generator is running, you can then check

the AC output values from the generator using the DSE 6110 MK3 module.

400V

Generator Available

L - N

0 A

0 kW

- - - - pf

L - L

230V

52.6 Hz

JD/03/20 13

Stephill Generators SSDP30-70 - DSE 6110 Fault Finding Guide Issue 3

Failed to Start - Shutdown

The module will display Failed to Start after 3 attempts to start.

This shutdown is issued if the AC frequency measured on the DSE 6110 MK3 hasn’t reached the desired level - Fig.2.

c) Check the connections on both sides of the fuse holders.

Gen Under Voltage - Shutdown

c) Check the connections on both sides of the fuse holders.

Important Note

If the above has not highlighted the fault condition, then a closer look at the main alternator would be the next step.

Gen Under Frequency/Hz - Shutdown

The module detected that the generator output voltage on one or more phases has fallen below

a pre-set level - Fig.3.

d) Remove the main alternator control box lid and check all connections on the main windings. Check for broken,

lose or burnt wiring.

b) Check the three fuses on the back of the control panel that have a Brown, Black and Grey wire terminated. A

spare fuse can be found in the fuse holder.

a) Check the AC plug in the back of the DSE 6110 control module is firmly inserted. This is the green plug with a

Brown. Black, Grey and Blue wires.

Navigate to the Generator Voltage screen on the DSE 6110 module (user guide - page 4). Start the generator and check

that all the voltages displayed are correct. If there is an large imbalance of voltages then check the following;

The module detected that the generator output frequency has fallen below a pre-set level -

Fig.4.

d) Remove the main alternator control box lid and check all connections on the main windings and AVR

(Automatic Voltage Regulator). Check for broken, lose or burnt wiring.

b) Check the three fuses on the back of the control panel that have a Brown, Black and Grey wire terminated. A

spare fuse can be found in the fuse holder.

a) Check the AC plug in the back of the DSE 6110 control module is firmly inserted. This is the green plug with a

Brown. Black, Grey and Blue wires.

Navigate to the Generator Voltage screen on the DSE 6110 module (user guide - page 4). Start the generator and check

that all the voltages displayed are correct. If there is an large imbalance of voltages or no voltage then check the following;

Generator Alarms DSE 6110 MK3

Using the Status screen or the Generator Frequency screen, start the generator and monitor the frequency on the display -

Hz. Typically the no-load frequency should be between 52.0 and 53.0Hz.

Continued

Failed to Start

Shutdown

1/1

Alarms

Fig.2

Gen Under Voltage

Shutdown

1/1 Alarms

Fig.3

Gen Under Frequency

Shutdown

1/1

Alarms

Fig.4

JD/03/20 14

Stephill Generators SSDP30-70 - DSE 6110 Fault Finding Guide Issue 3

No Frequency

If no frequency can be seen on the DSE 6110 display then follow the checks listed above on Gen Under Voltage .

Low Frequency

a) Check the 6-way diverter valve is in the correct position for the application - local or remote fuel tank.

b) Check the condition of the fuel system -

Fuel Hoses - are the fuel hoses in good condition - also check when generator is running.

Hose Clips - are not loose from any previous services or are broken/damaged.

Leaks - check for any fuel leaks.

External Fuel Tank - check all external connections and fuel hoses for leaks and/or damage.

d) Check the condition of the fuel. Try a new fuel source if possible.

c) Is the engine due a service - replace the fuel filters and change/replace the water trap filter. It maybe also

worth checking the air filter(s) are in good condition - replace is necessary.

If the above fails to raise or rectify the issue it may be worth checking the engine for possible malfunctions or faults - e.g.

injectors, fuel injector pump etc. Refer to engine handbook or engine specialist.

The frequency, in most cases, is dependant directly by the rotational speed of the engine. The slower the engine runs, the

lower the frequency.

The Gen Under Frequency shutdown will occur if the engine speed has slowed below a pre-set level. On most cases

frequency shutdown will occur for a low frequency.

DO NOT ADJUST THE ENGINE SPEED

The most common issues with a Gen Under Frequency shutdown are associated with a low frequency measured on the DSE

6110. This is usually associated with the fuel system. In order to have the engine run efficiently and at the correct speed the

fuel system needs to operating at its full potential. Below are some checks on the fuel system.

JD/03/20 15

Stephill Generators SSDP30-70 - DSE 6110 Fault Finding Guide Issue 3

• Check E-stop has not been pressed in.

• Check E-stop switch wires are not loose.

• Check oil level and fill to the correct level if necessary.

• Oil switch fault - see below.

• Oil sender fault - see below.

• Check for continuity between the oil switch body to the engine earth.

• Replace oil sender.

• Check connections at the oil sender

• Check continuity between wire No.16 on the DSE 6110 to the oil sender.

• Check continuity between wire No.15 on the DSE 6110 to engine earth.

• Check continuity between wire No.1 on the oil sender to engine earth.

• Replace oil sender.

• Check for loose wires on the oil switch.

• Check continuity between wire No.43 from the DSE 6110 to the oil switch.

• Replace oil switch.

Oil Pressure Low

Switch

Fail to stop could indicate a faulty oil pressure switch!

• Check oil pressure switch and pipework - remove & clean - Oil & filter change would be

advisable.

Continued

Oil Pressure Shutdown

Fault operates after the

engine has fired.

Oil Pressure Low Sender

(####)

Fault Condition

Fail to Stop

Alarm after 1 to 2

minutes when engine is at

rest.

Emergency Stop

Shutdown

Common Fault Conditions

Below is a general guide for the most common fault conditions on a Stephill Generator using a DSE 6110 Mk3 control

module.

Checks & Tests

• Check wiring is not open circuit - check for continuity between each side of the switch on the

back of the E-stop.

• Check that both wires on the E-stop have continuity to the corresponding positions on the

back of the DSE 6110 - wire No.2 & 3.

• Check that 12V is present across between position 3 and 1 on the back of the DSE 6110

module.

• Check engine oil pressure when running. On the DSE 6110 Engine page. (2 to 5 bar is normal)

• Check oil pressure sender and switch assembly including pipework - remove & clean - Oil &

filter change would be advisable.

• Check continuity between wire No. 43 on the oil switch to the DSE 6110 module (remove from

oil switch to test).

• To test the oil pressure switch first remove wire No.43 and link this wire to a clean earth point

on the engine. Start the generator, as soon as the engine starts to run remove the wire No.43

from the earth point. If the generator continues to run then this would indicate that the wiring is

good and the fault could possibly be the oil pressure switch.

• Check oil pressure sender and pipework - remove & clean - Oil & filter change would be

advisable.

JD/03/20 16

Stephill Generators SSDP30-70 - DSE 6110 Fault Finding Guide Issue 3

• Check water/antifreeze level in the radiator.

Caution hot steam can burn!

• Check the inside face of the radiator is not obstructed with oil/dirt or debris.

• Check the condition of the fan belt, damaged, broken or loose.

Note You may experience low battery charge DC if the fan belt is loose.

• Check that the generator air inlets and outlets are not obstructed.

• Check temp switch and sensor wiring.

• Check wires 13 and 40 in the DSE 6110.

• Check the operation of the engine thermostat.

• Radiator may be blocked - replace.

• Possible faulty water pump.

• Check water/antifreeze level in the radiator.

Caution hot steam can burn!

• Check wiring into the coolant switch.

• Check the condition of the fan belt and tightness.

Note you may experience low charge if fan belt is loose.

• Check for loose wires on the charge alternator.

• Check battery DC voltage while generator running, should be 13.0-15.0V.

• Check for continuity of wire No.52 from the charge alternator to the starter motor.

• Check for continuity of wire No.6 from the charge alternator to the DSE 6110.

• Check the condition of the battery and change if necessary.

• Check/replace the charge alternator.

• Check the hardwire door is fitted securely

• Check the magnetic connection behind the hardwire door and control box.

• Check wiring from the switch to the DSE 6110 wire No.46.

• Check switch operation. (Open from ground to fault).

• Check all MCCB/MCB’s are in the ON (up) position.

• Check wiring on the sockets, switches and circuit breakers.

• Check engine temperature display on the DSE 6110 - Engine page. High engine temperature

shutdown is set at 110 °C.

Engine runs but generator

will not take load.

Hardwire Door

Shutdown

High Engine Temperature

Charge Alternator Failure

Battery not changing

Coolant Level Low

Shutdown

• If the symptoms persist check that the radiator has had the correct antifreeze utilised when

serviced?

• Ensure the exciter wire (No.6) at the charge alternator is around 12V DC, but only when the

generator is running.

• Ensure the exciter wire (No.6) at the DSE 6110, is around 12V DC, but only when the generator

is running - no DC volts measured could indicate a faulty DSE 6110 control module.

• Check the Earth Leakage Relay hasn't tripped (Ref. Generator handbook)- Bypass or adjust if

necessary.

If all the above has not solved the high engine temperature issue then the following may

apply;

• Check for continuity from the above wires at the DSE 6110 to the temperature switch and

sender.

• Flush the radiator out and replace the water/antifreeze mix 50/50. Use the correct antifreeze

as indicated near the filler.

• If the generator runs with the plug removed from the coolant sensor, replace the sensor.

JD/03/20 17

Issue 2

Fuel solenoid is operational

check - remove and check the

plunger moves when the prime

button is pressed

Generator battery

voltage is 12.4V or

more at standstill

"Jump" or change 12V battery

Generator battery

voltage falls below

9.5V when cranking

Emergency Stop is

displayed when cranking

3-way valve/6-way

diverter is in the correct

position

Starter motor cranking

12v DC between wire 50

on the starter motor and

battery negative while

cranking

Check/replace fuses, relays and

DSE 6110 module connections

behind the control panel.

Check the DC engine loom plug

and socket connections.

12V DC between wire 5 & 1 on

the DSE 6110 & start relay

when cranking

Replace DSE 6110 module

Check/replace

starter motor

Yes

No

No

Enough fuel in the fuel

tank

Fuel pump operational -

press and hold the prime

button - if applicable

12V present between

wires 51 & 1 on the

fuel pump plug when

the prime button is

pressed.

Replace 12V fuel lift

pump

Yes

Disconnect the injector return

pipe near the fuel pump - fuel

runs free when the prime

button is pressed

Check/replace fuses, relays and

DSE 6110 module connections

behind the control panel.

12V DC between wire 4 & 1 on the DSE

6110 & fuel relay when cranking.

No

Check the DC engine loom plug

and socket connections.

No

Yes

No

Try different fuel - fuel source

could be contaminated

12V DC present between wires

51 & 1 on the fuel solenoid

when the prime button is

pressed or engine starting

Check/replace fuel filters & clean

replace water trap filter

Yes

Yes

Yes

Yes

Yes

No

Possible engine issue - injectors etc.

Replace fuel solenoid

Yes

No

No

Yes

Yes

No

No

No

No

No

No

No

No

Start

Yes

By-pass emergency

stop switch

JD/08/18 30-70kVA Generator Not Starting Flow Chart 2019

This manual suits for next models

1

Table of contents