StepperOnline ISD02 User manual

User’s Ma

nu

a

l

For

ISD02/04/08

Integrated Stepper Motor

Dr

i

ver

#7 Zhongke Road, Jiangning, Nanjing, China

Tel: 0086-2587156578

Web site: www. omc-stepperonline. com

E-Mail: sales@stepperonline. com

Designed by STEPPERONLINE®

©2019 All Rights Reserved

Attention: Please read this manual carefully before using the driver.

Table of

Contents

1. Introductions and Features................................................................................................................................... 1

1.1 Introductions..................................................................................................................................................1

1.2 Features.........................................................................................................................................................1

2. Specifications.......................................................................................................................................................... 1

2.1 Electrical Specifications (Tj = 25℃/77℉).................................................................................................1

2.2 Operating Environment and other Specifications....................................................................................1

2.3 Mechanical Specifications.......................................................................................................................... 2

3. Pin Assignment and Description..........................................................................................................................2

3.1 Connector P1 Configurations..................................................................................................................... 3

3.2 Connector P2 Configurations..................................................................................................................... 3

4. Typical application..................................................................................................................................................3

5. Interface................................................................................................................................................................... 4

5.1 Adjust Output Current..................................................................................................................................4

5.2 Microstep Resolution................................................................................................................................... 5

5.3 Power Supply Selection.............................................................................................................................. 5

6. Installation................................................................................................................................................................6

6.1 NEMA 17 Stepper Installation (without adapting flange)....................................................................... 6

6.2 NEMA 23 and Larger Stepper Installation (with adapting flange)........................................................ 6

Integrated Stepper Motor Driver ISD02/04/08

1

1. Introductions and Features

1.1 Introductions

The ISD02/04/08 is a parallel port control series of miniature high performance stepper motor drivers. Its

biggest feature is its small size and strong driving ability. Its thickness is less than 14 mm. They can be

directly mounted onto NEMA 8/11/14/17/23/24/34 series stepper motors with the corresponding flange.

ISD02 can provide 0-2A adjustable peak current;ISD04 can provide 1. 5-4A adjustable peak current; ISD08

can provide 3-8A adjustable peak current. Its high-speed current compensation function can compensate for

the effects of back electromotive force when the motor rotates at high speed. The ISD02 uses 10-28V DC

power supply, and the ISD04 and the ISD08 use 10-40V DC power supply.

1.2 Features

Miniature size 42. 3mm*42. 3mm*16. 5mm

Integrated with the motor, can also work separately

All-aluminum precision cast housing, sturdy and durable, good heat dissipation

0 - 2A / 1. 5 - 4A / 3 - 8A adjustable output current(ISD02/ISD04/ISD08)

5 selectable microstep solutions including 200, 400, 800, 1600, 3200

H-bridge bipolar constant current, online controllable offline / enable

Optical-isolated inputs

Automatic Current Reduction

Maximum frequency of whole step 12KHz; Maximum frequency of 3200 microstep 200KHz

2. Specifications

2.1 Electrical Specifications (Tj = 25℃/77℉)

Supply Power

10-40VDC(10-28VDC for ISD02)

Motor Output Current

Max 2A/4A/8A per phase (Adjustable through on-board

trimmer)

Driving Mode

PWM constant current

Microstep Resolution

200, 400, 800, 1600, 3200 set through on-board DIP switch 1

and switch 2

Insulation Resistance

>100MΩ

Dielectric Strength

0. 5KV in one minute

2.2 Operating Environment and other Specifications

Cooling

Free air

Working Environment

Avoid dust, oil fog and corrosive gases

Working

-40℃- 85℃

Humidity

<80%RH,no condensation, no frosting

Vibration

3G Max

Storage temperature

-50℃- 150℃

Weight

0. 1kg

Integrated Stepper Motor Driver ISD02/04/08

2

Tel: 0086-2587156578 Web: www. omc-stepperonline. com

Email:sales@stepperonline. com

2.3 Mechanical Specifications (Unit: mm)

Figure 1: Mechanical specifications

3. Pin Assignment and Description

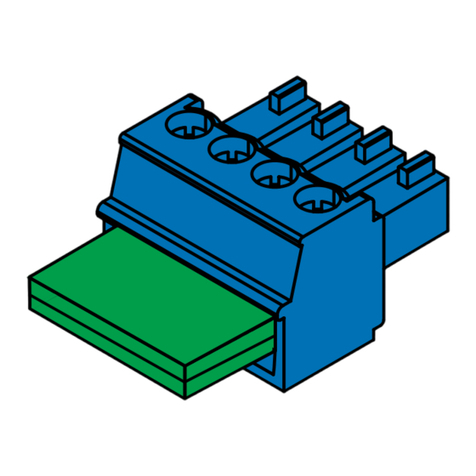

The ISD02/04/08 has two connectors P1&P2, P1 is for control signals connections, and P2 is for motor

connections. The following tables are brief descriptions of the two connectors.

Figure 2:wiring terminal

Integrated Stepper Motor Driver ISD02/04/08

3

3.1 Connector P1 Configurations

Pin Function

Description

V+

Supply voltage. ISD02:10-28VDC, ISD04 And ISD08:10-40VDC.

GND

Supply voltage ground

VCC

Opto-coupler common anode

DIR

Direction input(1)

STP

Stepping pulse input(2)

ENA

Enable the controller(3)

Note:

(1) Input is considered high level if this terminal is not connected.

(2) Low-level pulse duration should > 4μs.

(3) An active low-level input shuts down power supply to the motor. High-level input or left open

makes the controller fully working. When awaken from shutdown mode, wait 1 millisecond

before sending pulse.

3.2 Connector P2 Configurations

Pin Function

Description

A+/A-

Connect to the stepper motor phase A.

B-/B+

Connect to the stepper motor phase B.

Warning: Incorrect connection of phase winds will permanently damage the driver.

Resistance between leads of different phases is usually > 100KΩ. Resistance between

leads of the same phase is usually < 100Ω.

Warning: In addition to the port of power supply and motor, the voltage of rest port

must be in the range of -0. 3V ~ 5. 3V, otherwise it will permanently damage the

controller.

4. Typical application

ISD02/04/08 driver’s wiring is very straightforward as shown in following Figure. Terminal 6 (EN) can be left

open if offline is not needed.

Integrated Stepper Motor Driver ISD02/04/08

4

Tel: 0086-2587156578 Web: www. omc-stepperonline. com

Email:sales@stepperonline. com

Figure 3:Typical application

5. Interface

ISD02/04/08 driver’s logic control inputs are all optically isolated. All opto-isolators share one common

anode (VCC) as shown in above schematic diagram. Typically, VCC is 5V. However, 3. 3V or voltages

higher than 5V are also acceptable, so long as the current through the opto-isolator’s emitter is between

5~20mA.

Should a voltage higher than 5V be applied to VCC, an additional resistor is needed for every terminal to

ensure that the current through each emitter does not exceed 20mA.

Figure 4:Optically Isolated Input Interface

Please note: in most situations, VCC can also be used as common cathode connection. This is because

the opto-isolators used in ISD02/04/08 are bidirectional (AC&DC) type.

5.1 Adjust Output Current

ISD02/04/08 is capable of providing maximum2A / 4A / 8A per phase output current respectively. In

specific application, the peak output current needs to be adjusted to meet the rated motor current. A

trimmer (potentiometer) is provided to serve this purpose at the bottom of the controller, as shown in the

following figure. Measuring the mapped voltage (Va) when tuning the trimmer provides a easy way to set

Integrated Stepper Motor Driver ISD02/04/08

5

the output current.

For ISD02, a mapped voltage “Va” of 0 - 2V proportionally represents 0 - 2A.

For ISD04, a mapped voltage “Va” of 1. 5 - 4V proportionally represents 1. 5 - 4A.

For ISD08, a mapped voltage “Va” of 1. 5 - 4V proportionally represents 3 - 8A.

Note:

The driver needs to be powered before mapped voltage “Va” can be measured. (Motor is not required to

be connected at this time. )

DIP1 (on the bottom side DIP switch 2) needs to be turned off to shut down the ACR Function.

After adjustment, user can choose to turn on the DIP1 to enable the automatic current reduction.

Current Adjustment

Trimmer

Before measuring Va:

1) Apply Power

2) Turn off DIP

Voltmeter

Mapped Voltage Va

Bottom Side

12 ~ 40VDC

Figure 5: Adjusting the Output Current

5.2 Microstep Resolution

The microstep resolution is set by both DIP switch 1 and DIP switch 2 located at top and bottom side of

the driver as shown in following figure. ISD02/04/08 driver can provide microstep control at 200, 400, 800,

1600, 3200 step resolutions.

Figure 6: Microstep settings

5.3 Power Supply Selection

ISD02/04/08 drivers accept a wide range input voltage from 12 to 40VDC. (ISD02 takes 10 - 28 VDC) In

general, higher supply voltage improves motor performance under high speed situation, but also increases

the power loss and temperature raise.

Integrated Stepper Motor Driver ISD02/04/08

6

Tel: 0086-2587156578 Web: www. omc-stepperonline. com

Email:sales@stepperonline. com

6. Installation

6.1 NEMA 17 Stepper Installation (without adapting flange)

1. Screw mount ISD controller / driver onto the motor

2. Wire the motor leads.

6.2 NEMA 23 and Larger Stepper Installation (with adapting flange)

1. Screw mount the adapting flange onto the motor

2. Screw mount ISD controller / driver onto the adapting flange

3. Wire the motor leads.

This manual suits for next models

2

Table of contents

Other StepperOnline Control Unit manuals

StepperOnline

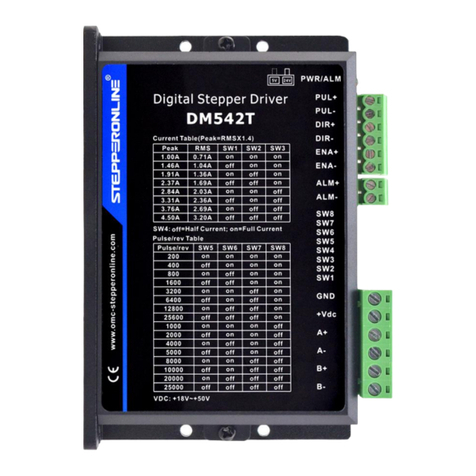

StepperOnline DM542T User manual

StepperOnline

StepperOnline DM456AI User manual

StepperOnline

StepperOnline DM480AI User manual

StepperOnline

StepperOnline CL57T User manual

StepperOnline

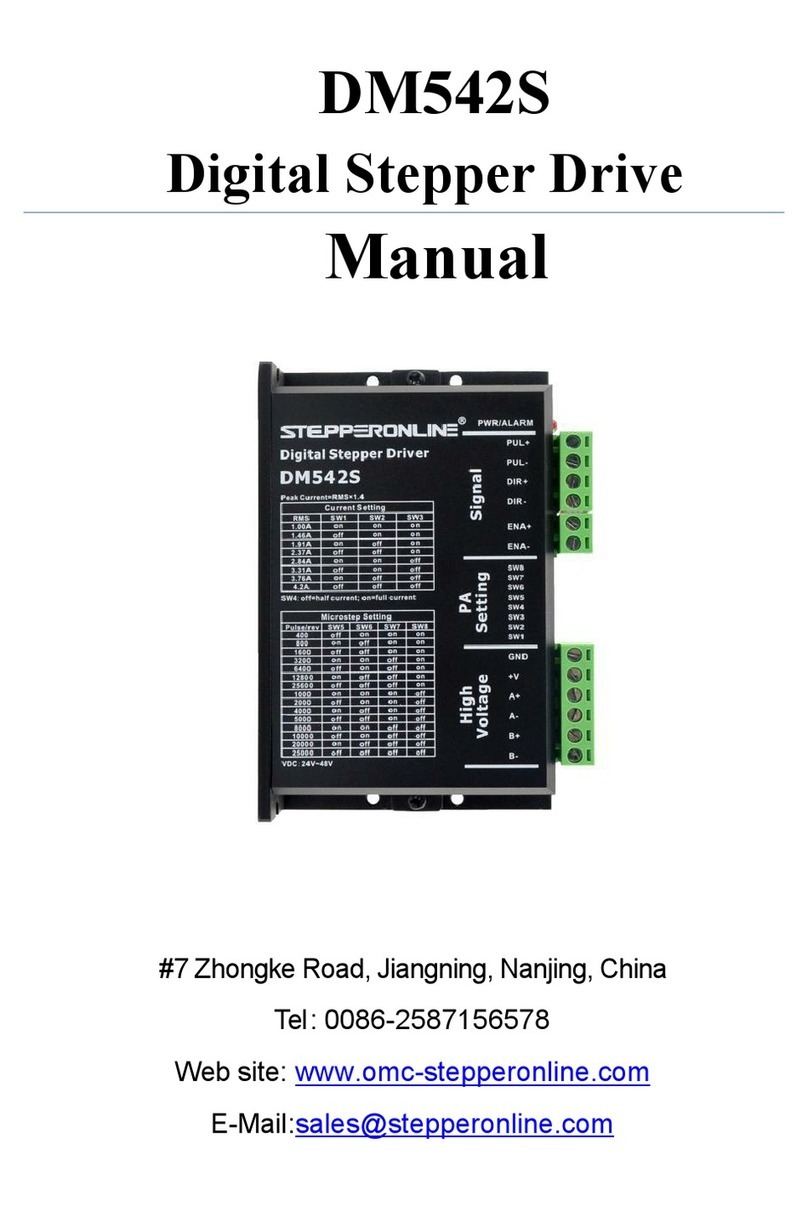

StepperOnline DM542S User manual

StepperOnline

StepperOnline MA860H User manual

StepperOnline

StepperOnline Y Series Instruction Manual

StepperOnline

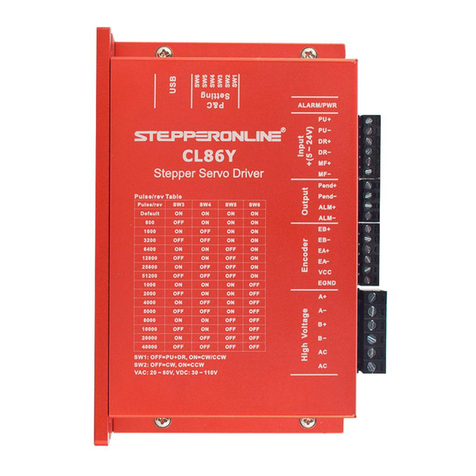

StepperOnline CL86T User manual

StepperOnline

StepperOnline DM542T User manual

StepperOnline

StepperOnline CL86T User manual